Spinning apparatus, apparatus and process for manufacturing nonwoven fabric, and nonwoven fabric

a technology of nonwoven fabric and spinning liquid, which is applied in the direction of weaving, manufacturing tools, melting spinning methods, etc., can solve the problems of poor productivity of electropinning, difficult fibrous form of spinning liquid, and high cost so as to achieve stable spinning, increase the amount of spinning liquid extrusion, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(Preparation of Spinning Liquid)

[0077]Polyacrylonitrile (manufactured by Aldrich) was dissolved in N,N-dimethylformamide so as to become a concentration of 10 mass % to prepare a spinning liquid (viscosity (temperature: 25° C.): 970 mPa·s).

(Preparation of Apparatus for Manufacturing Nonwoven Fabric)

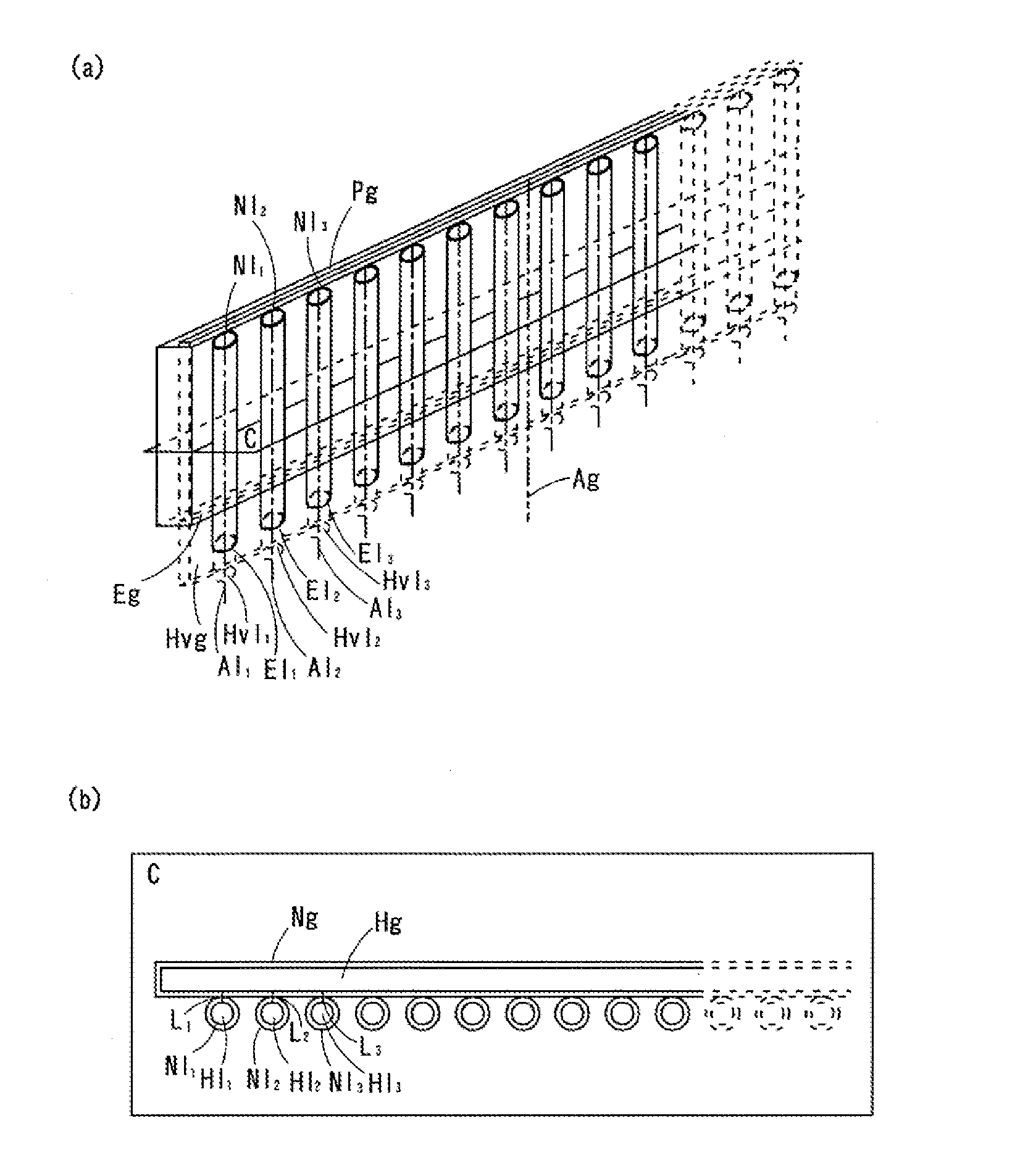

[0078]A manufacturing apparatus as shown in FIG. 1 comprising the following parts was prepared.

(1) Supply equipment for spinning liquid: syringe

(2) Gas supply equipment: compressor

(3) Nozzles for extruding liquid (Nl1 to Nl19): metal nozzle

(3)-1 Exits for extruding liquid (El1 to El19): circular, 0.3 mm in diameter (cross-sectional area: 0.07 mm2)

(3)-2 Columnar hollows for liquid (Hl1 to Hl19): cylindrical, 0.3 mm in diameter

(3)-3 Outer diameter of nozzles: 0.55 mm each

(3)-4 Number of nozzles: 19

(4) Plate for ejecting gas (Pg): metal plate

(4)-1 Exit for ejecting gas (Eg): rectangular, 0.5 mm in width and 50 mm in length

(4)-2 Columnar hollow for gas (Hg): rectangular parallelepiped, 0.5 mm...

example 2

[0083]As a resin, a polypropylene resin [(MI=1500), Shear rate at a temperature of 200° C.: 3145 s−1, viscosity: 5000 mPa·s] was prepared.

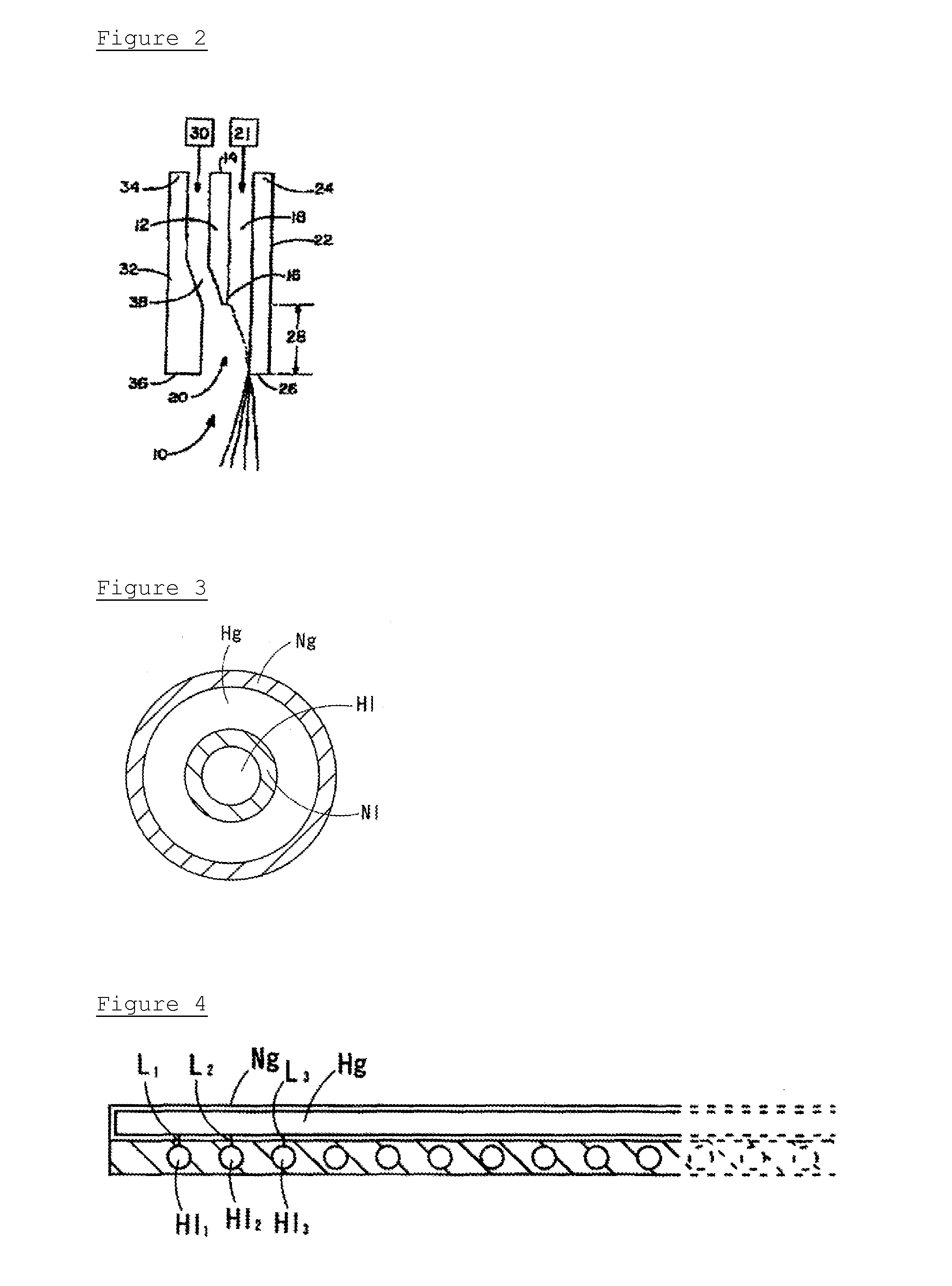

[0084]A spinning apparatus comprising a plate for ejecting gas (Pg), which contained a columnar hollow for gas (Hg), and a plate for extruding liquid, in which columnar hollows for liquid (Hl1 to Hl67) were bored, with the cross-section as shown in FIG. 4 when the columnar hollows are cross-sectioned with a plane perpendicular to the central axis of the columnar hollow for gas (Hg), was prepared. More particularly, this spinning apparatus contained the following members.

(1) Resin supply equipment: extruder

(2) Heated gas supply equipment: compressor (compressed air was heated by a heater)

(3) Plate for extruding liquid: a set of metal plates having a wall thickness of 1 mm

(4) Exits for extruding resin liquid (El1 to El67): 67 circular exits (El1 to El67) having a diameter of 0.15 mm were arranged in a single and straight line at intervals of 5 mm, a...

example 3

[0086]A nonwoven fabric was produced under the same conditions described in Example 2, except that the amount of resin extruded was 10 g / hour / nozzle. The produced nonwoven fabric had a mass per unit area of 5 g / m2, a thickness of 150 μm, an average fiber diameter of 1100 nm, and a CV value of 0.3. The fibers which formed the nonwoven fabric were thick, but the unevenness of fiber diameters was very small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com