Method for removing acidic gases through biological technology

A technology of acid gas and biological method, which is applied in the field of acid gas purification, can solve problems such as pollution, low desulfurization efficiency, and poor stability of desulfurization efficiency, and achieve the goals of avoiding blockage, low investment cost, good fluidization state and oxygen mass transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

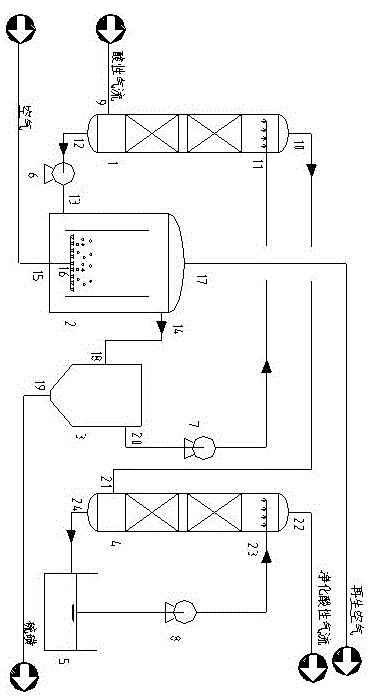

Image

Examples

Embodiment 1

[0039] Example 1: Immobilization process of Thiobacillus alkalophilus

[0040] Take Na 2 S 2 o 3 8 g / L, KNO 3 5 g / L, NaHCO 3 2g / L, KH 2 PO 4 Cultivate 0.1g / L medium at 30ºC for 2 days, and at the same time moderately aerate every 4 hours to expand the cultivation of the basophilic thiobacillus group, and then put 0.5% biological ceramsite as the carrier to make the basophilic thiobacillus group attached and fixed The above-mentioned culture was continued for 5-8 days, so that a large number of alkalophilic thiobacilli were attached to the carrier, and the attached biomass was weighed to be 1.536 mg / g, and the immobilization process was completed.

Embodiment 2

[0041] Embodiment 2: Biotrickling filter tower hanging membrane process

[0042] Mix organosulfurophage solution with K 2 HPO 4 5 g / L, NaH 2 PO 4 2g / L, MgCl 2 0.2 g / L, NH 4 The culture solution of Cl 2 g / L and glycerol 2 g / L was inoculated at a ratio of 1:20, with 0.5 mmol / L mercaptan as the sulfur source, and the nutrient solution containing organosulfurophilic bacteria was sprayed onto the filler from top to bottom, Organosulfur-phagocytic bacteria are fixed on the filler, and the film-forming efficiency is accelerated through the synchronous acclimation of the dominant bacteria on a regular basis, and gradually grow and fix to form a stable, uniform and dense biofilm, completing the biological film-forming process of the biological trickling filter tower.

Embodiment 3

[0043] Example 3 Acid gas removal process

[0044] The exhaust gas to be treated is the stripping exhaust gas of sulfur-containing wastewater in the petrochemical industry, and its main composition is: 20% CO 2 , 4%H 2 S, COS / CH 3 CH / CS 2 2000 ppmv, 75.8%N 2 . Exhaust gas pressure: 0.1MPa.

[0045] to 100 Nm 3 / h acid gas enters the chemical absorption tower, the pH value of the lye is 8.0, and the circulation volume is 0.5 Nm 3 / h Through gas-liquid countercurrent contact, the chemical absorption of acid gas is realized. Rich CO 2 、H 2 The lye of S enters the biological regeneration tower, CO 2 As a carbon source for microbial growth, HS - In air aeration rate 4m 3 / h, ORP value is maintained in the range of -340mV~-360mV / / The conductivity is stable at about 32 mS / cm, and the HS - Biological oxidation to sulfur. The elemental sulfur was separated by centrifugation, weighing 6kg / h, and the sulfur recovery rate was 98.8%. Rich in COS, CS 2 and CH 3 The acid-poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com