Processing method for malodorous gas of chemical area sewage plant

A technology for malodorous gas and sewage treatment plants, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., and can solve the problems of secondary pollutants and high operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

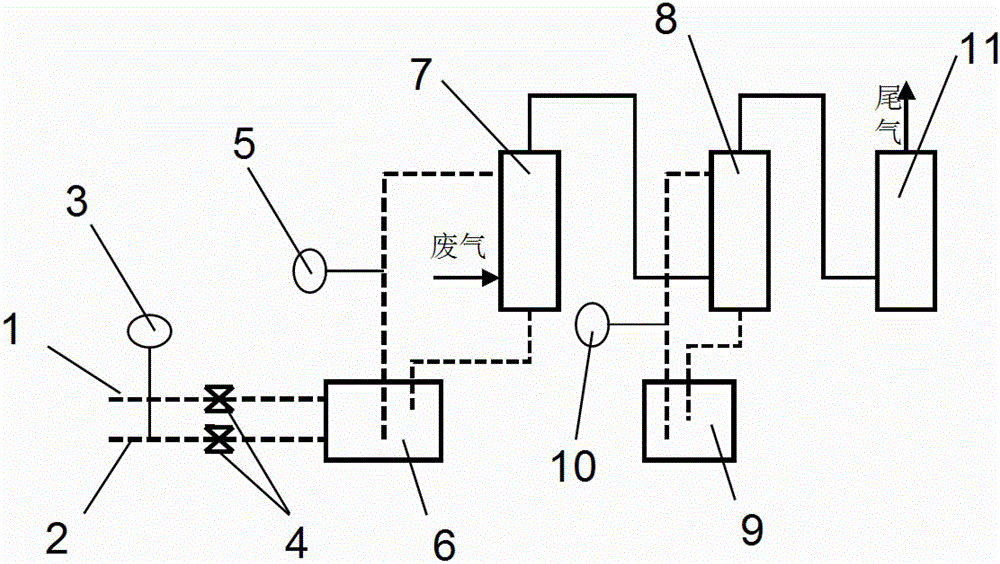

[0016] this invention figure 1 The reference signs in are as follows: 1—NaOH concentrated liquid; 2—NaClO concentrated liquid; 3—distributed control system; 4—control valve; 5—pH and sulfide detector; 6—NaOH and NaClO Solution storage tank; 7—Washing tower; 8—Biological filter tower; 9—Nutrient solution storage tank; 10—Solenoid valve; 11—Absorptive device. The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] see figure 1 As shown, the method for treating malodorous gas from sewage plants in chemical industry areas of the present invention mainly includes chemical absorption, biological oxidation, and adsorption steps, all of which are carried out at normal pressure and at a temperature of 0-40°C.

[0018] The chemical absorption step includes entering the malodorous gas from the sewage plant in the chemical area into the chemical scrubber, and contacting the scrubbing liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com