Methane biodesulfurization method

A technology for biological desulfurization and biogas, applied in the field of biogas biological desulfurization, can solve the problems of high operating cost, difficult to control operating conditions, low desulfurization efficiency, etc., and achieve the effects of simple equipment, stable operation and reduced impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

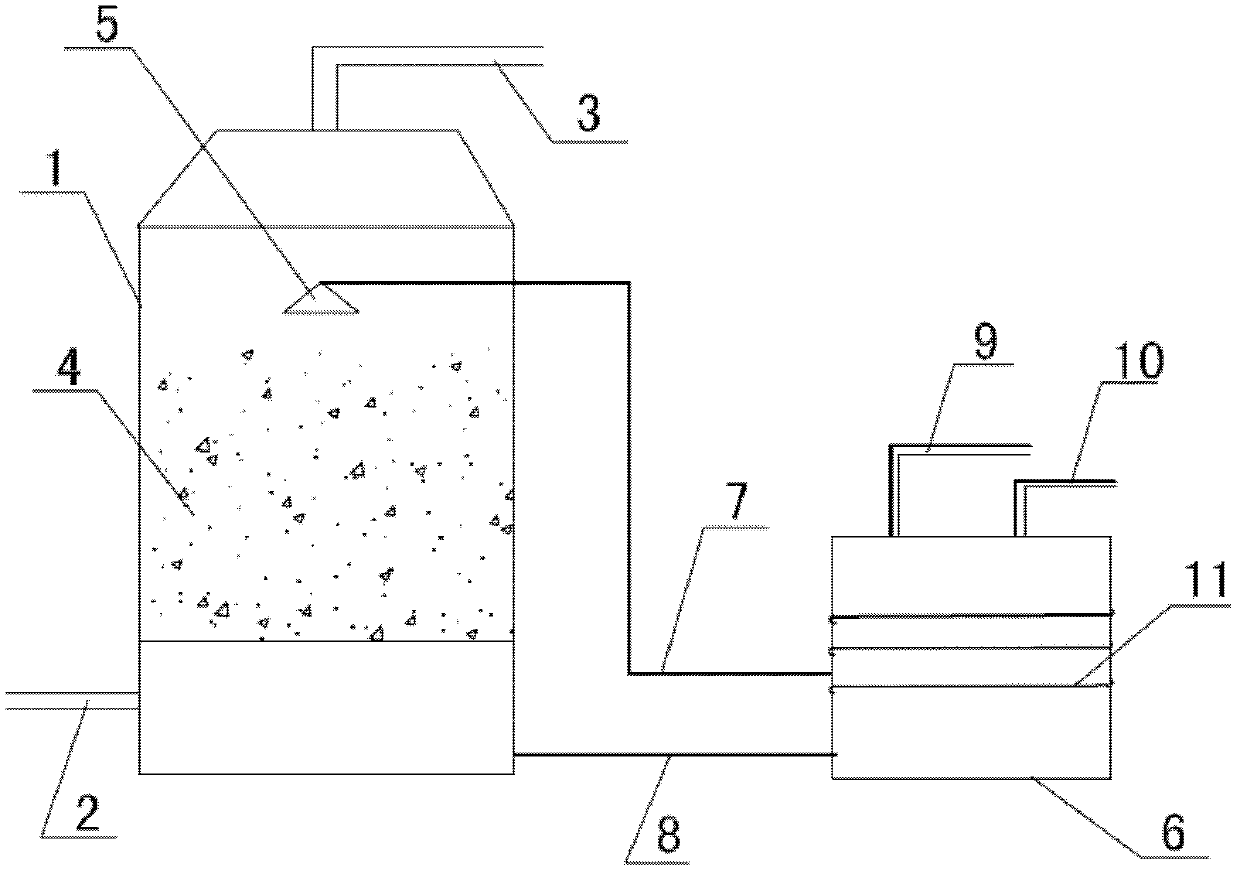

[0027] The desulfurization device includes a desulfurization tower 1, the bottom and top of the desulfurization tower 1 are respectively provided with an inlet pipe 2 and an outlet pipe 3, the tower is filled with elastic packing 4, and a spray head 5 is arranged above the elastic packing 4, and one side of the desulfurization tower 1 A circulating water tank 6 is provided, and the circulating water tank 6 is provided with a circulating fluid outlet pipe 7 and a circulating fluid inlet pipe 8, wherein the circulating fluid outlet pipe 7 is connected to the spray head 5, and the circulating fluid inlet pipe 8 is connected to the bottom of the desulfurization tower 1, The top of the circulating water tank 6 is provided with a water supply pipeline 9 and a nutrient solution adding pipeline 10, and the 6 sets of circulating water tanks are connected with a heating pipeline 11.

[0028] The spray head 5 in the desulfurization tower 1 sprays the circulating fluid from the circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com