Processing method of wastewater in coal chemistry industry

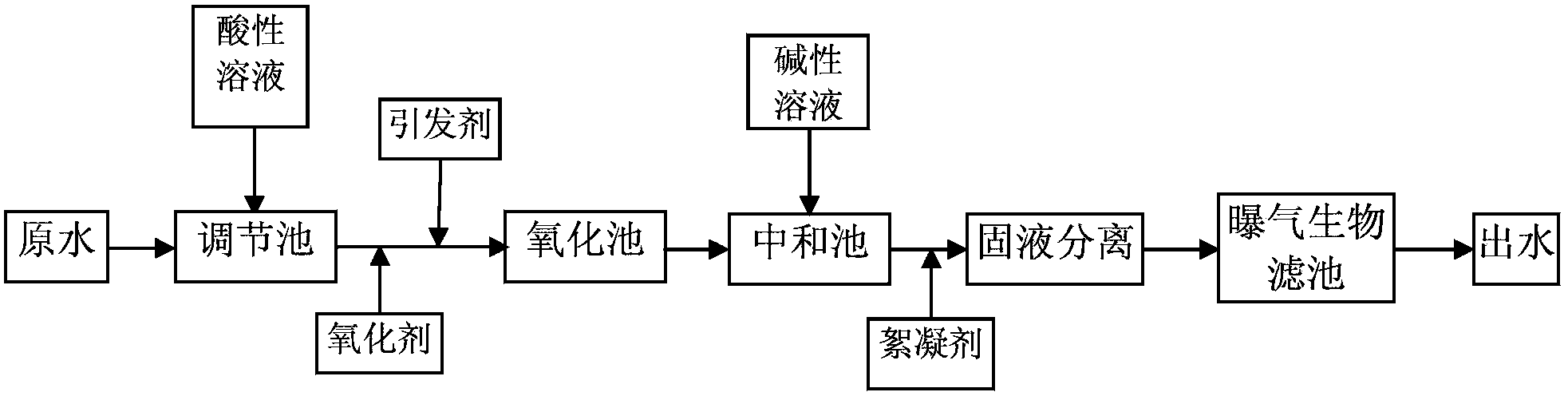

A technology for coal chemical wastewater and treatment method, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The problem of poor biodegradability, etc., can achieve the effect of good wastewater purification effect, strong controllability of effluent quality, and easy control of operating process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

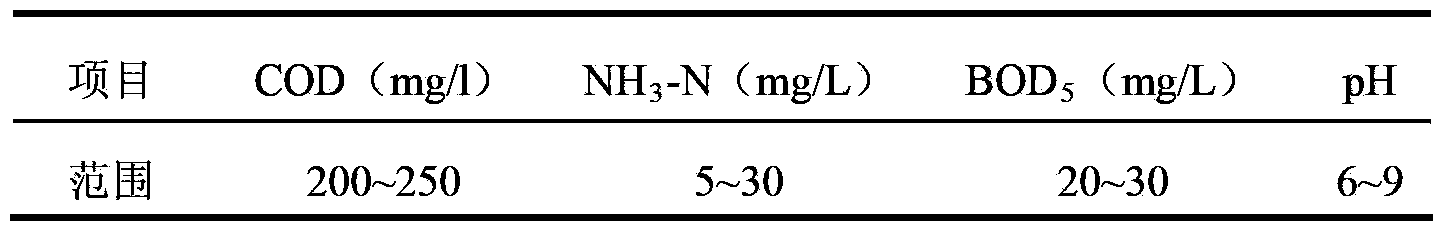

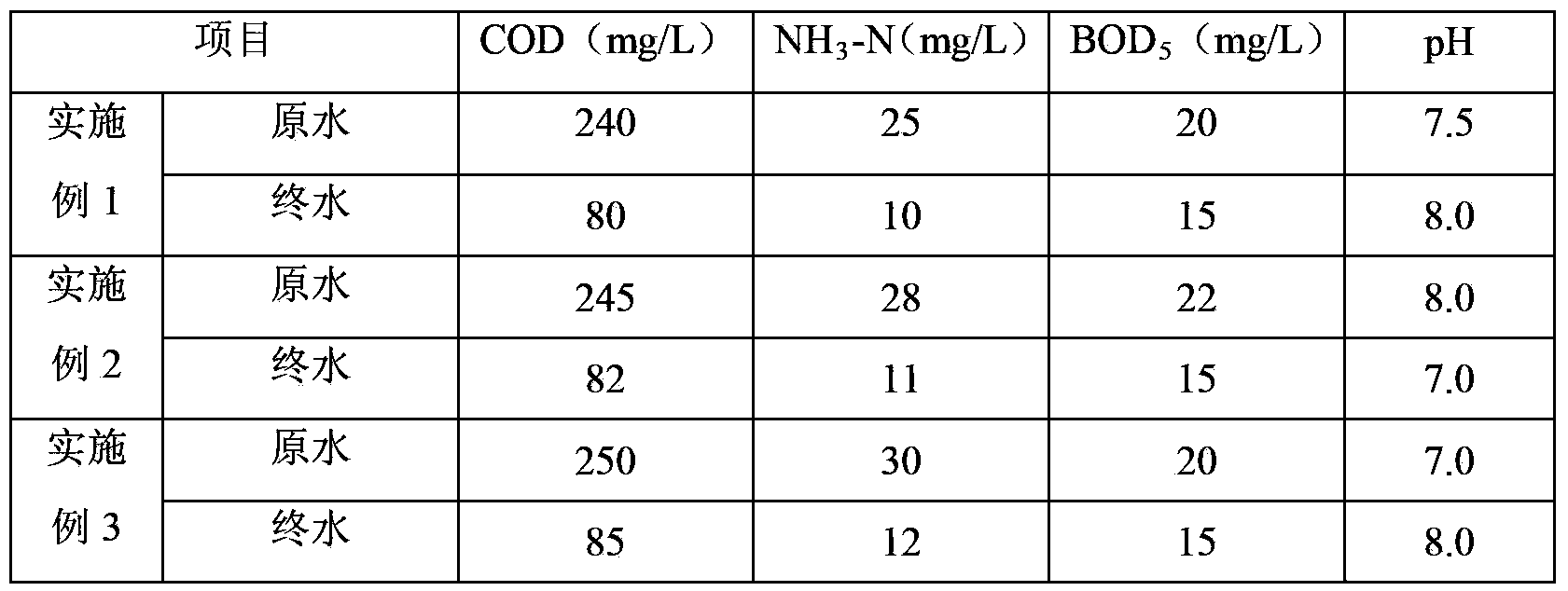

Embodiment 1

[0076] 1. Acidification treatment

[0077] The secondary biochemical oxidation effluent treated by the coal chemical wastewater treatment station is passed into the water quality adjustment tank, industrial sulfuric acid is added to the wastewater, and the wastewater is stirred with compressed air, mixed evenly, and the pH value of the wastewater is adjusted to 5.0. The water quality adjustment tank The hydraulic retention time is 30min.

[0078] In addition to sulfuric acid, the acidic solution added to the waste water in the acidification treatment stage of the present invention can also be selected from hydrochloric acid, nitric acid or steel pickling waste liquid, wherein, the steel pickling waste liquid is produced in the hot rolling process of steel Acidic waste liquid produced, in which H + The concentration of Fe is 0.05~5g / L, Fe 2+ The concentration is 60~250g / L. Selecting the iron and steel pickling waste liquid can introduce the initiator Fe into the waste water ...

Embodiment 2

[0095] 1. Acidification treatment

[0096] Pass the secondary biochemical oxidation effluent treated by the coal chemical wastewater treatment station into the water quality adjustment tank, add hydrochloric acid to the wastewater, use a mixer to stir the wastewater, mix it evenly, adjust the pH value of the wastewater to 4.5, and control the wastewater in the water quality adjustment The hydraulic retention time in the pool is 20min.

[0097] 2. Chemical oxidation treatment

[0098] 2-1) Use a pump to send the effluent from the regulating tank to the flat-flow partition oxidation tank through two pipeline mixers in series, add the oxidant potassium persulfate solution with a metering pump before the first mixer, and add the oxidant potassium persulfate solution to the second mixer Add the initiator ferrous chloride solution with a metering pump before, so that the mass concentration of potassium persulfate in the wastewater is 343mg / L (molar concentration is 1.27mmol / L), and...

Embodiment 3

[0106] 1. Acidification treatment

[0107] Pass the secondary biochemical oxidation effluent treated by the coal chemical wastewater treatment station into the water quality adjustment tank, add nitric acid to the wastewater, stir the wastewater with compressed air or a mixer, and mix it evenly, adjust the pH value of the wastewater to 4.75, and control the wastewater The hydraulic retention time in the water quality regulating tank is 25min.

[0108] 2. Chemical oxidation treatment

[0109] 2-1) Use a pump to send the effluent from the regulating tank to the backflow partition oxidation tank through two pipeline mixers connected in series, and add the oxidant potassium monopersulfate solution in front of the first mixer with a metering pump. Add the initiator sodium sulfite solution with a metering pump before the mixer, so that the mass concentration of potassium monopersulfate in the wastewater is 375mg / L (molar concentration is 2.46mmol / L), and the mass concentration of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com