Method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green

A technology for the production of wastewater and chromium oxide green, which is applied in the direction of chromium oxide/hydrate, chemical instruments and methods, water/sewage multi-stage treatment, etc., which can solve the problems of high treatment costs, water pollution, and inability to meet the requirements of direct discharge of industrial wastewater, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

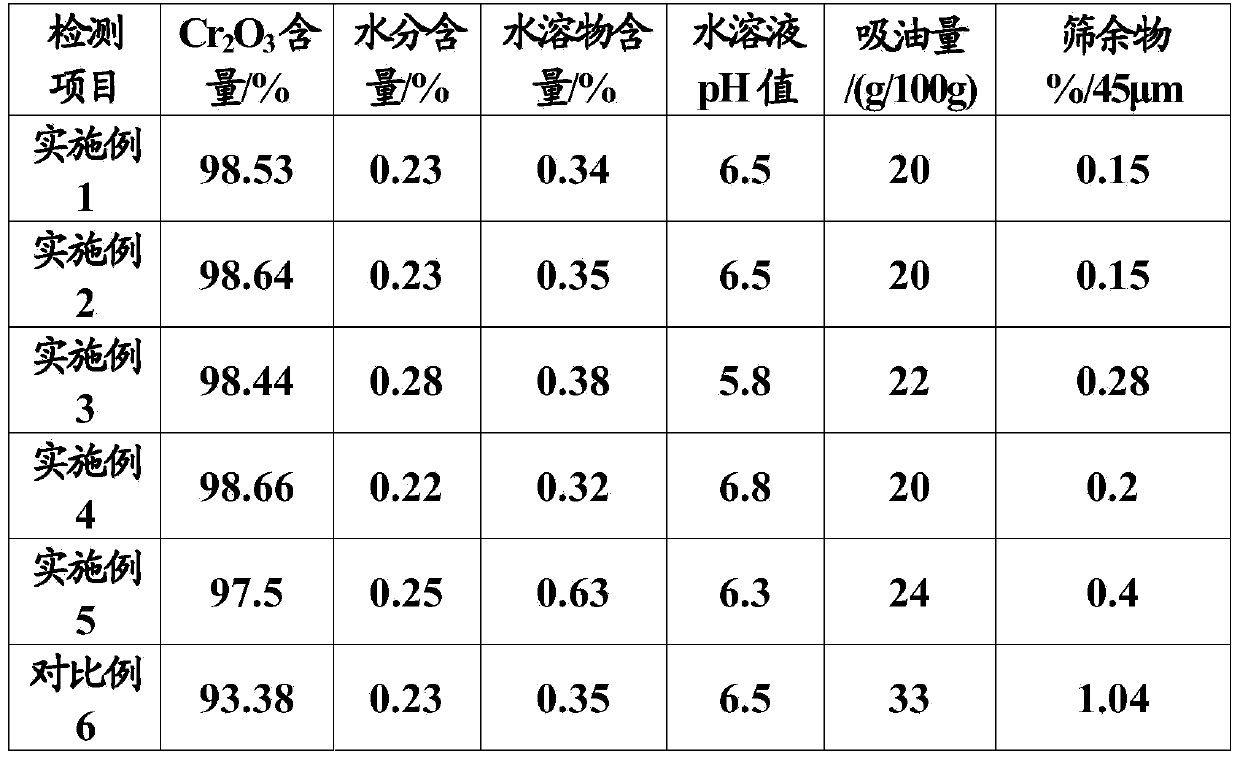

Examples

Embodiment 1

[0047] The hexavalent chromium content is expressed as Na 2 Cr 2 o 7 Be counted as 104g / L and sulfuric acid content is 1000ml naphthoquinone production waste liquid and COD is 25g / L and pH is 3.5 500ml vitamin K3 production waste water is added in the pressure reactor, under stirring, the gained reaction mixture is heated at 150 ℃ and 0.3MPa for 0.5h to carry out the redox reaction.

[0048] After the reaction, 39 g of sodium metabisulfite was added to the feed liquid by lowering the temperature and pressure to convert all unreduced hexavalent chromium in the feed liquid into trivalent chromium. Then, adjust feed liquid pH to 7.0 with sodium hydroxide, obtain intermediate product Cr(OH) 3 Precipitate, then carry out suction filtration, obtain filter cake and filtrate. The COD of the filtrate was 80 mg / L, and the hexavalent chromium content was 4.9 mg / L.

[0049] Put the separated filter cake into a high-temperature furnace and calcinate at 900°C for 2 hours, then quickly ...

Embodiment 2

[0051] The hexavalent chromium content is expressed as Na 2 Cr 2 o 7 Be counted as 87g / L and sulfuric acid content is 1000ml naphthoquinone production waste liquid and COD is 20g / L and pH is 1.0 500ml vitamin K3 production waste water is added in the pressure reactor, under stirring, the gained reaction mixture is heated at 180 ℃ and 0.5MPa for 2h to carry out the redox reaction.

[0052] After the reaction, 35.3 g of sodium metabisulfite was added to the feed liquid at lower temperature and pressure, to convert all unreduced hexavalent chromium in the feed liquid into trivalent chromium. Then, adjust feed liquid pH to 6.5 with sodium hydroxide, obtain intermediate product Cr(OH) 3 Precipitate, then carry out suction filtration, obtain filter cake and filtrate. The COD of this filtrate is 50 mg / L, and the hexavalent chromium content is 3.1 mg / L.

[0053] Put the separated filter cake into a high-temperature furnace and calcinate at 950°C for 1 hour, then quickly place it ...

Embodiment 3

[0055] The hexavalent chromium content is expressed as Na 2 Cr 2 o 7 Be counted as 118g / L and sulfuric acid content is 5000ml naphthoquinone production waste liquid and COD is 180g / L and pH is 0.6 500ml vitamin K3 production waste water is added in the pressure reactor, under stirring, the gained reaction mixture is heated at 100 Keep at ℃ and 3MPa for 3.5h to carry out redox reaction.

[0056] After the reaction, 108 g of sodium metabisulfite was added to the feed liquid by lowering the temperature and pressure to convert all unreduced hexavalent chromium in the feed liquid into trivalent chromium. Then, adjust feed liquid pH to 6.0 with sodium hydroxide, obtain intermediate product Cr(OH) 3 Precipitate, then carry out suction filtration, obtain filter cake and filtrate. The COD of this filtrate is 125 mg / L, and the hexavalent chromium content is 4.2 mg / L.

[0057] Put the separated filter cake into a high-temperature furnace and calcinate at 450°C for 4 hours, then quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com