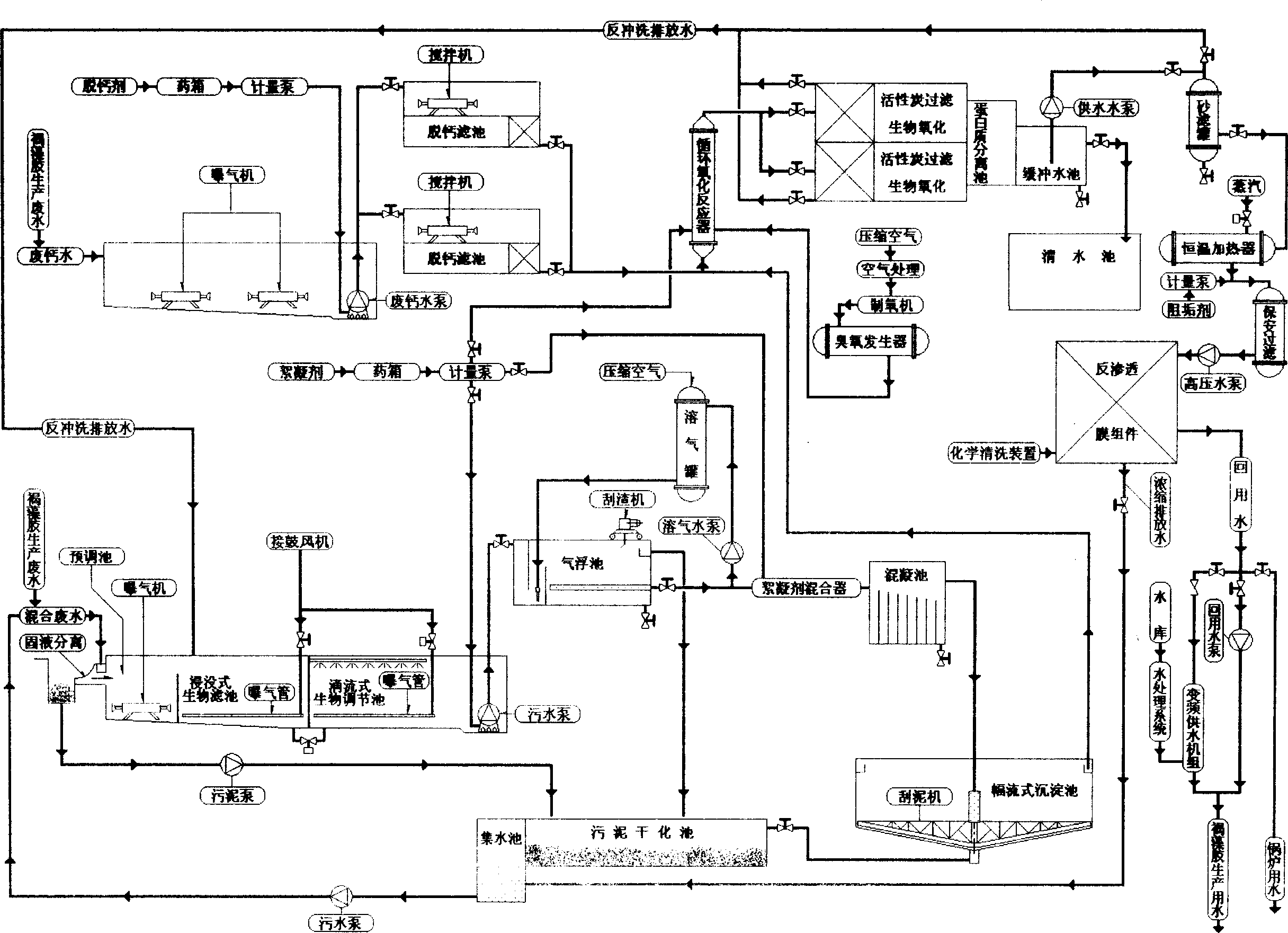

Process for treating, circulation recovering and reutilizing zero-discharge of algin production waste water

A technology for producing wastewater and recycling it, applied in sustainable biological treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc. The effect of low cost and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The process of the present invention will be further described below by taking the production of one ton of alginate to produce about 690 tons of waste calcium water and about 390 tons of mixed wastewater as an example.

[0039]As shown in the attached figure, the waste calcium water and mixed wastewater produced by the production of alginate undergo the following treatment processes:

[0040] a. Treatment of waste calcium water

[0041] a.1 Pretreatment of waste calcium water: Flow about 690 tons of waste calcium water into the calcium wastewater regulating tank by itself. The main functions of the calcium wastewater regulating tank are: first, to adjust the amount of buffered temporary water, because the valley peak of drainage is relatively large, and The designed decalcification reaction capacity is low (80m 3 / h); the second is to carry out aeration and oxidation pretreatment on the waste calcium water with the bottom-mounted aeration mixer, and carry out conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com