Recovery device and recovery method of metallic copper of waste printed circuit board

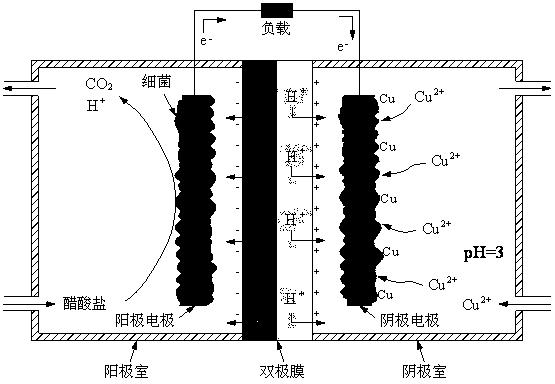

A printed circuit board and metal copper technology, which is applied to the recovery device and recycling field of metal copper in waste printed circuit boards, can solve problems such as equipment corrosion and high energy consumption in the electrolysis process, and achieve low energy recovery, reduce emissions, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

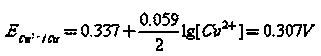

[0069] The process flow of the present invention includes: preparation of metal copper recovery device in waste printed circuit boards, enrichment of electrochemically active microorganisms at the anode of microbial batteries, oxidant Fe 3+ Generation, conversion of metallic copper in waste printed circuit boards to Cu 2+ and Cu 2+ Reduction to metallic copper realizes the recycling of metallic copper. The present invention is further described in conjunction with following example.

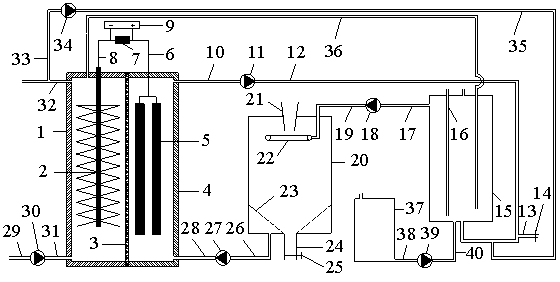

[0070] 1. Metal copper recovery device in waste printed circuit boards:

[0071] The structure of metal copper recovery device in waste printed circuit board is as follows: figure 2 As shown, it includes: microbial fuel cell anode chamber 1, carbon fiber brush anode electrode 2, bipolar membrane 3, microbial fuel cell cathode chamber 4, graphite plate cathode electrode 5, wire 6, resistor 7, wire 8, data acquisition system 9, Connecting pipe 10, liquid delivery pump 11, connecting pipe 12, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com