A method for collecting platinum group metals in spent catalysts by pickling sludge

A technology of spent catalysts and platinum group metals, applied in the direction of improving process efficiency, etc., can solve the problems of serious secondary pollution, large waste water output, heavy metal pollution, etc., and achieve the effect of reducing raw material costs, high recovery rate, and low energy consumption recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

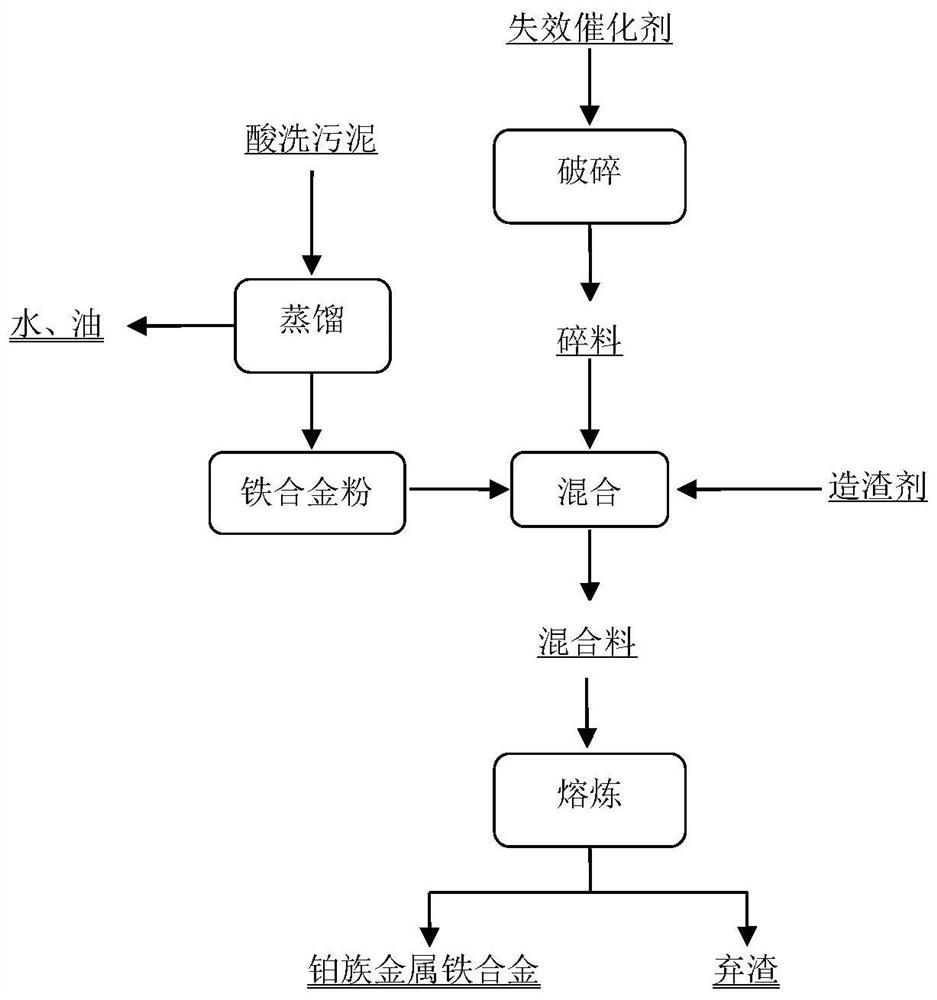

Method used

Image

Examples

Embodiment 1

[0028] The pickling sludge was dehydrated at 120°C for 40 minutes, and then deoiled at 250°C for 60 minutes to obtain ferroalloy powder. 20wt% ferroalloy powder is mixed with 50wt% spent automobile catalyst scrap and 30wt% slagging agent to obtain a mixture, wherein the slagging agent consists of 25wt% CaO, 2wt% Na 2 CO 3 , 2wt% CaF 2 , 1wt% borax composition. The mixture was heated to 1450°C for 60 minutes, and the slag phase and iron phase were separated to obtain iron alloy rich in platinum group metals and waste slag. The capture rate of platinum group metals was 98.8%, and the grade of platinum group metals in the slag phase was 2.8g / t .

Embodiment 2

[0030] The pickling sludge was dehydrated at 119°C for 10 minutes, and then deoiled at 180°C for 120 minutes to obtain ferroalloy powder. 20wt% ferroalloy powder was mixed with 50wt% spent petroleum catalyst scrap and 30wt% slagging agent to obtain a mixture, wherein the slagging agent consisted of 30wt% CaO. The mixture was heated to 1300°C for smelting for 180 minutes, and the slag phase and iron phase were separated to obtain iron alloy rich in platinum group metals and waste slag. The capture rate of platinum group metals was 90%, and the grade of platinum group metals in the slag phase was 5g / t.

Embodiment 3

[0032]The pickling sludge was dehydrated at 118°C for 15 minutes, and then deoiled at 200°C for 115 minutes to obtain ferroalloy powder. 15wt% ferroalloy powder mixed with 65wt% expired chemical catalyst scraps and 20wt% slagging agent to obtain a mixture, wherein the slagging agent consists of 17wt% CaO and 3wt% Na 2 CO 3 composition. The mixture was heated to 1350°C for smelting for 170 minutes, and the slag phase and iron phase were separated to obtain iron alloy rich in platinum group metals and waste slag. The capture rate of platinum group metals was 90.8%, and the grade of platinum group metals in the slag phase was 4.8g / t .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com