Method for recovering nickel from nickel-containing wastewater by using microbial electrolytic cell

A microbial electrolysis cell and nickel wastewater technology, which is applied in the fields of process efficiency improvement, photographic technology, instruments, etc., can solve the problems of serious equipment corrosion and high energy consumption in the electrolysis process, achieve low energy recovery, reduce emissions, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The process flow of the invention includes: preparation of the microbial electrolytic cell, enrichment of electrochemically active microorganisms in the anode of the microbial electrolytic cell and recovery of elemental nickel. The present invention is further described in conjunction with following examples.

[0057] 1. Preparation of nickel recovery unit:

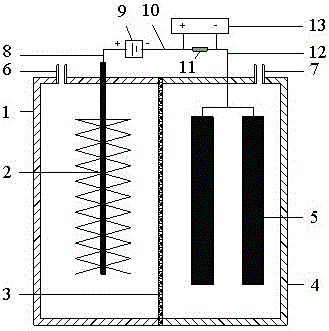

[0058] The structure of the nickel recovery unit is as follows: image 3 As shown, it includes: anode chamber 1, carbon fiber brush anode electrode 2, proton exchange membrane 3, cathode chamber 4, graphite plate cathode electrode 5, anode chamber inlet 6, cathode chamber inlet 7, wire 8, potentiostat 9. Wire 10, resistor 11, titanium wire 12 and data acquisition system 13.

[0059] The anode chamber 1 and the cathode chamber 4 are respectively made of polymethyl methacrylate (PMMA) to form a cavity of 4 cm × 8 cm × 11 cm. On the top of the anode chamber 1 and the cathode chamber 4 of the microbial electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com