Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize centralized recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

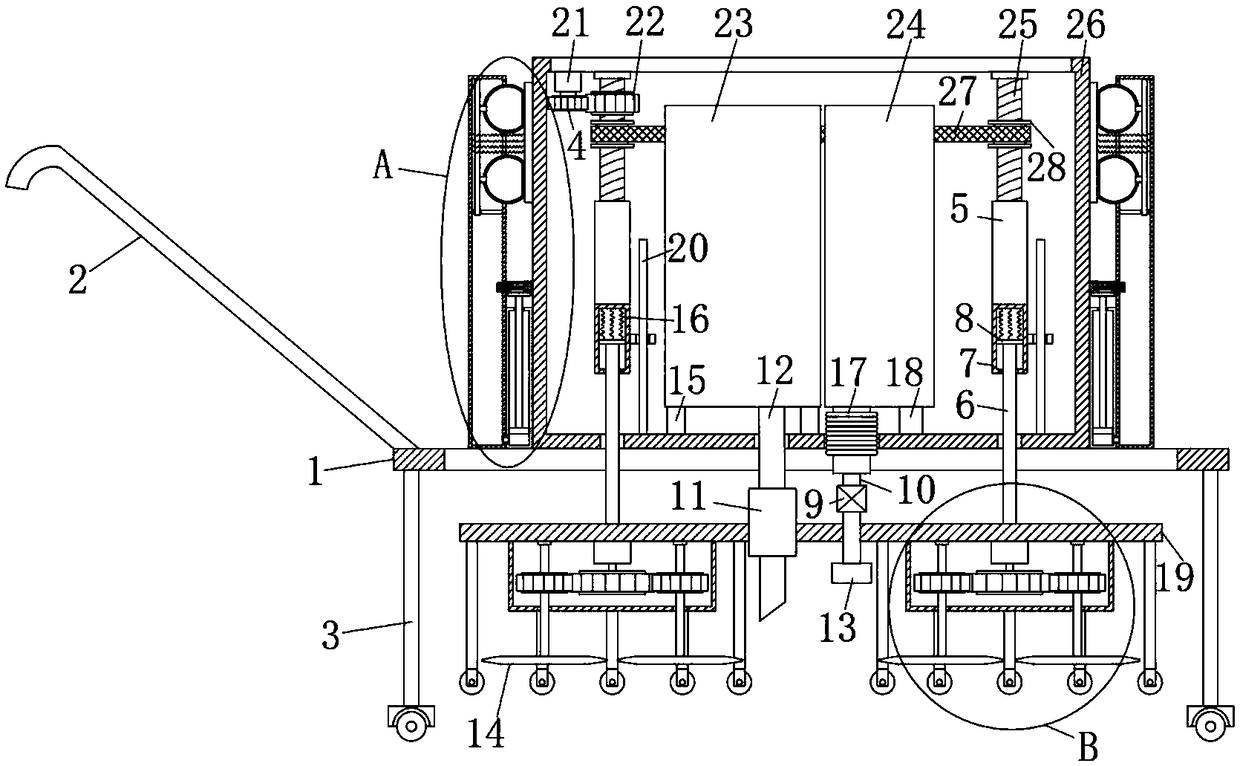

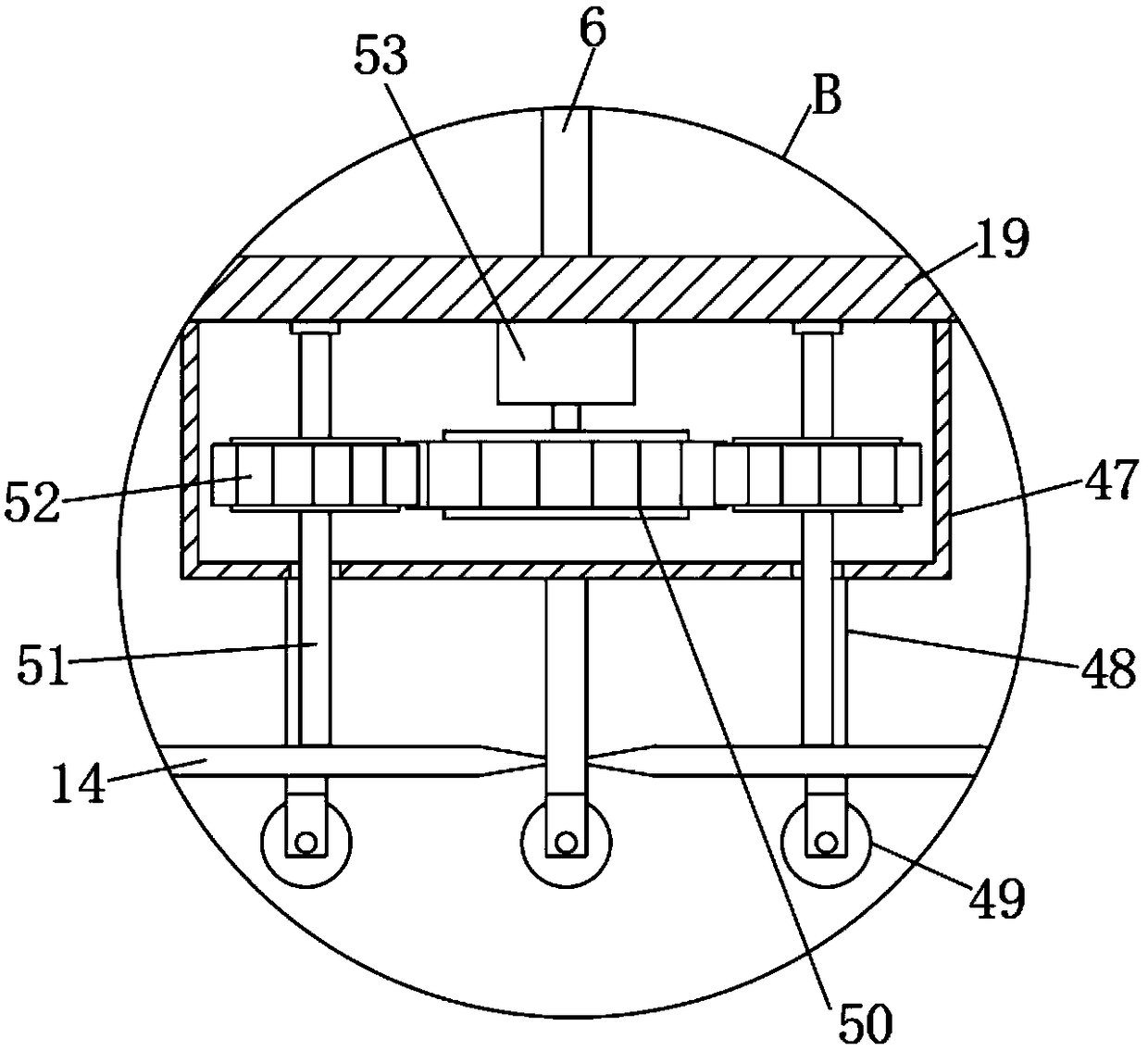

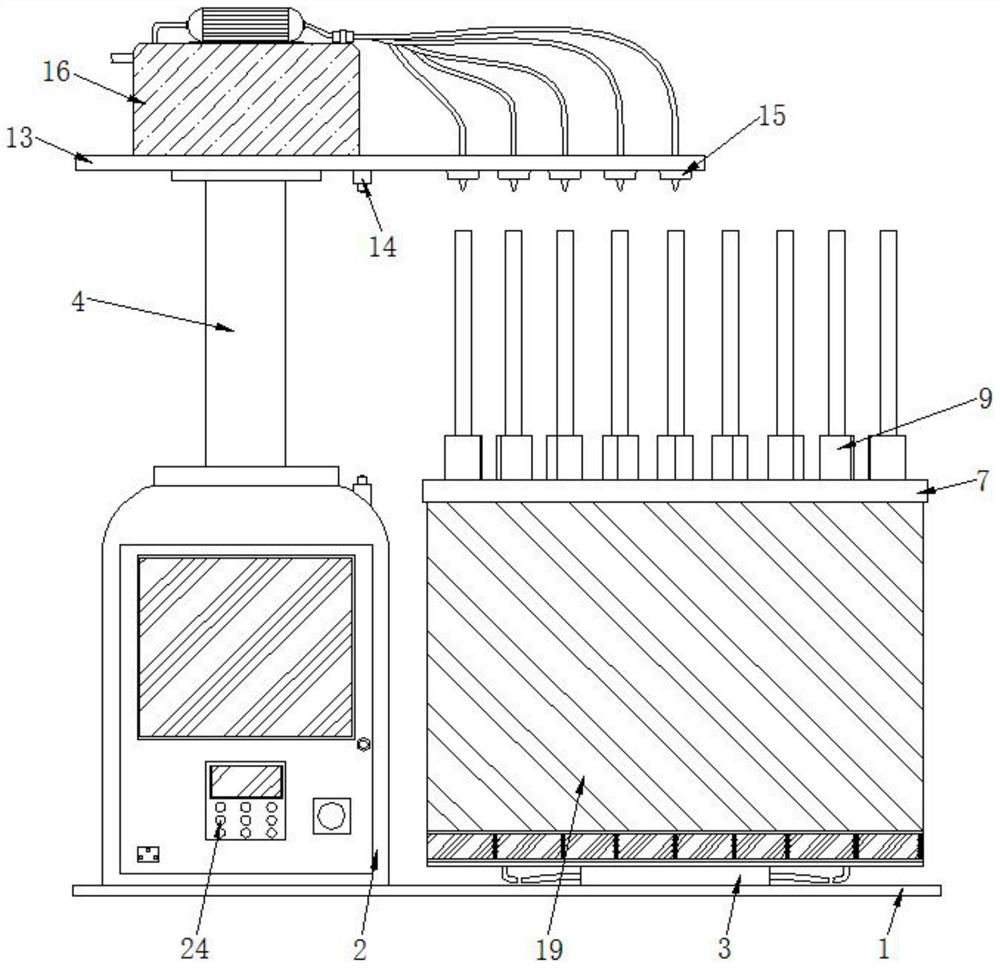

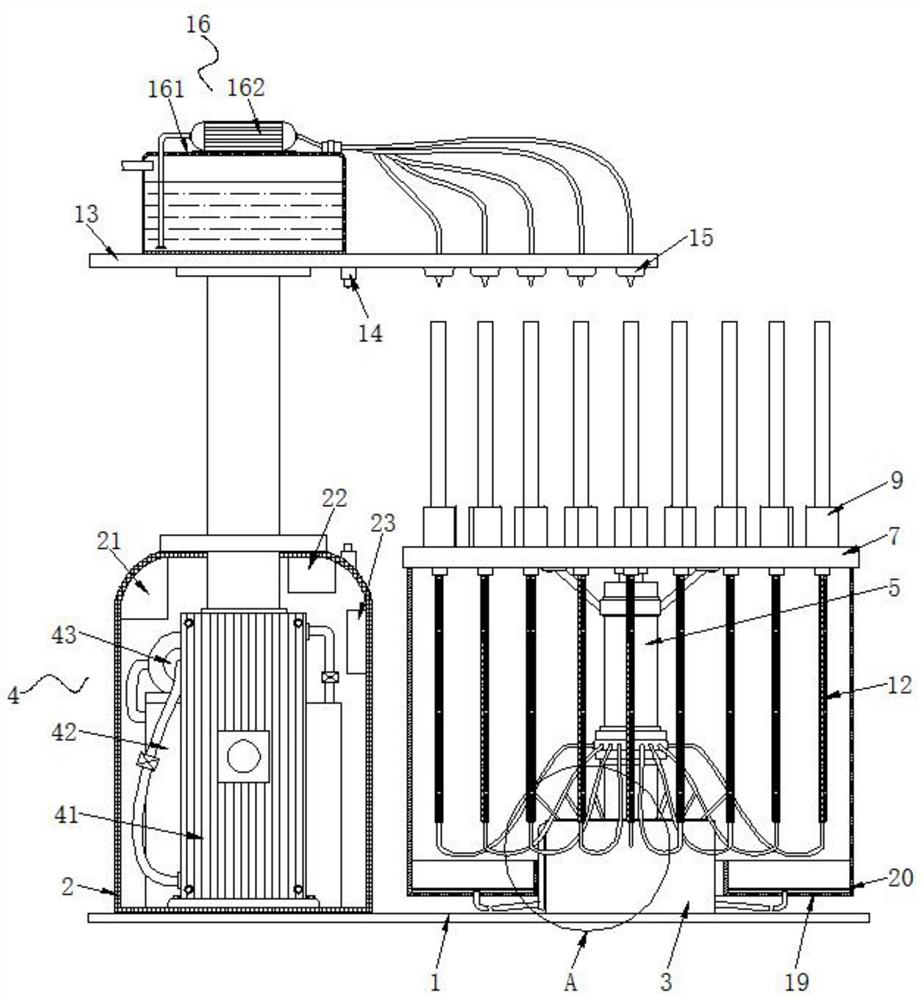

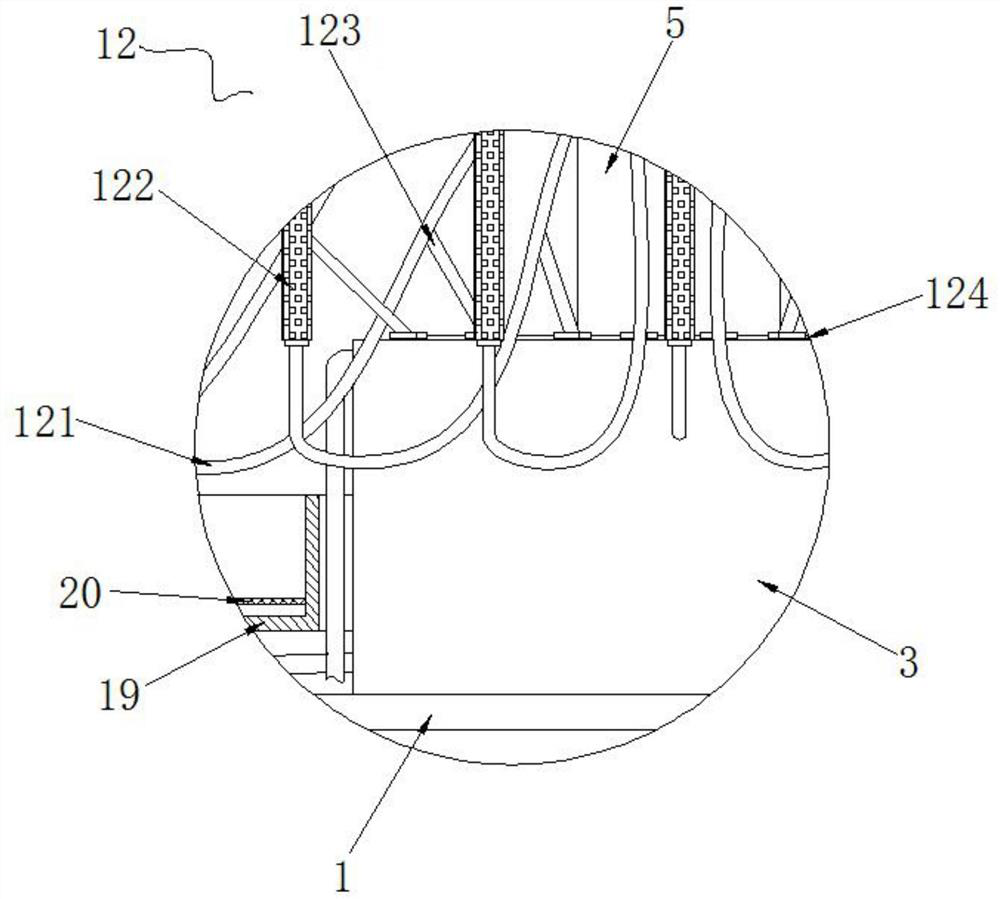

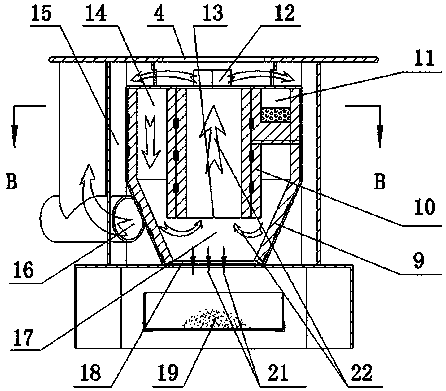

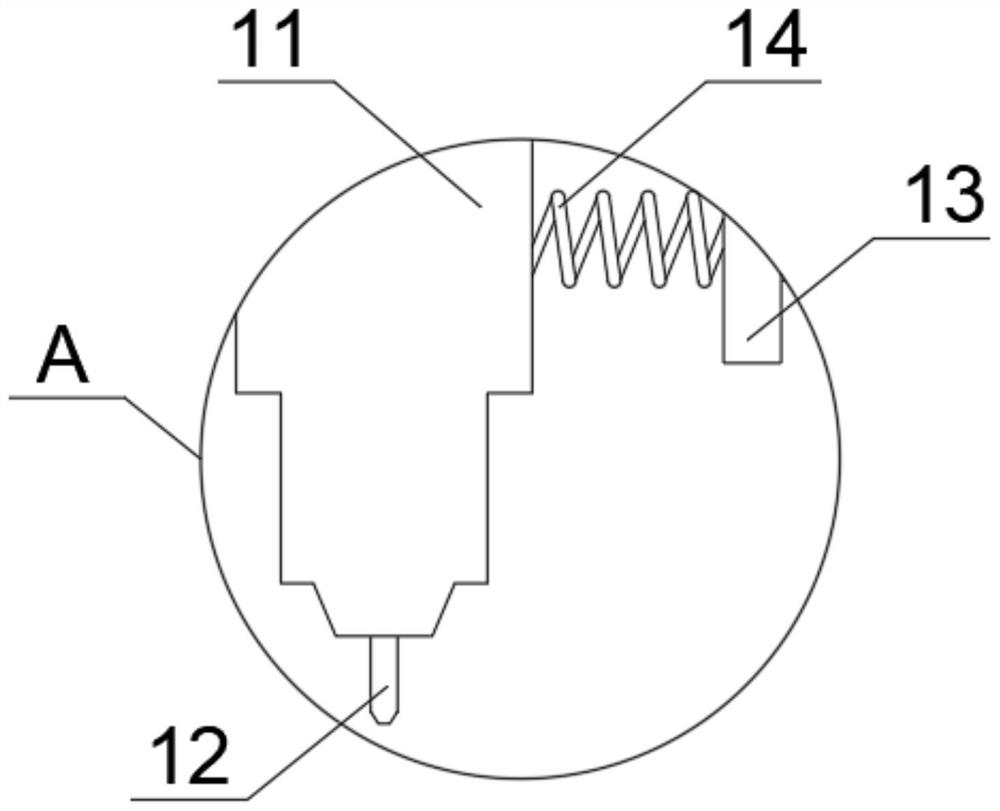

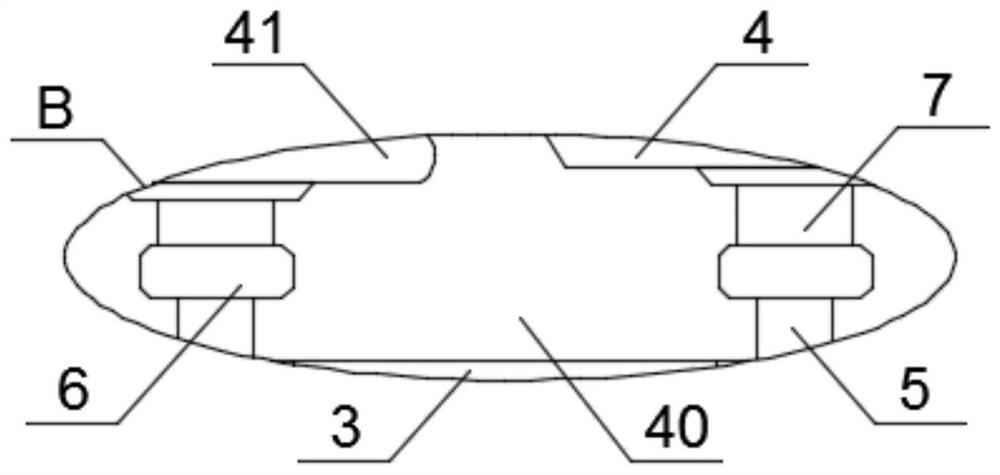

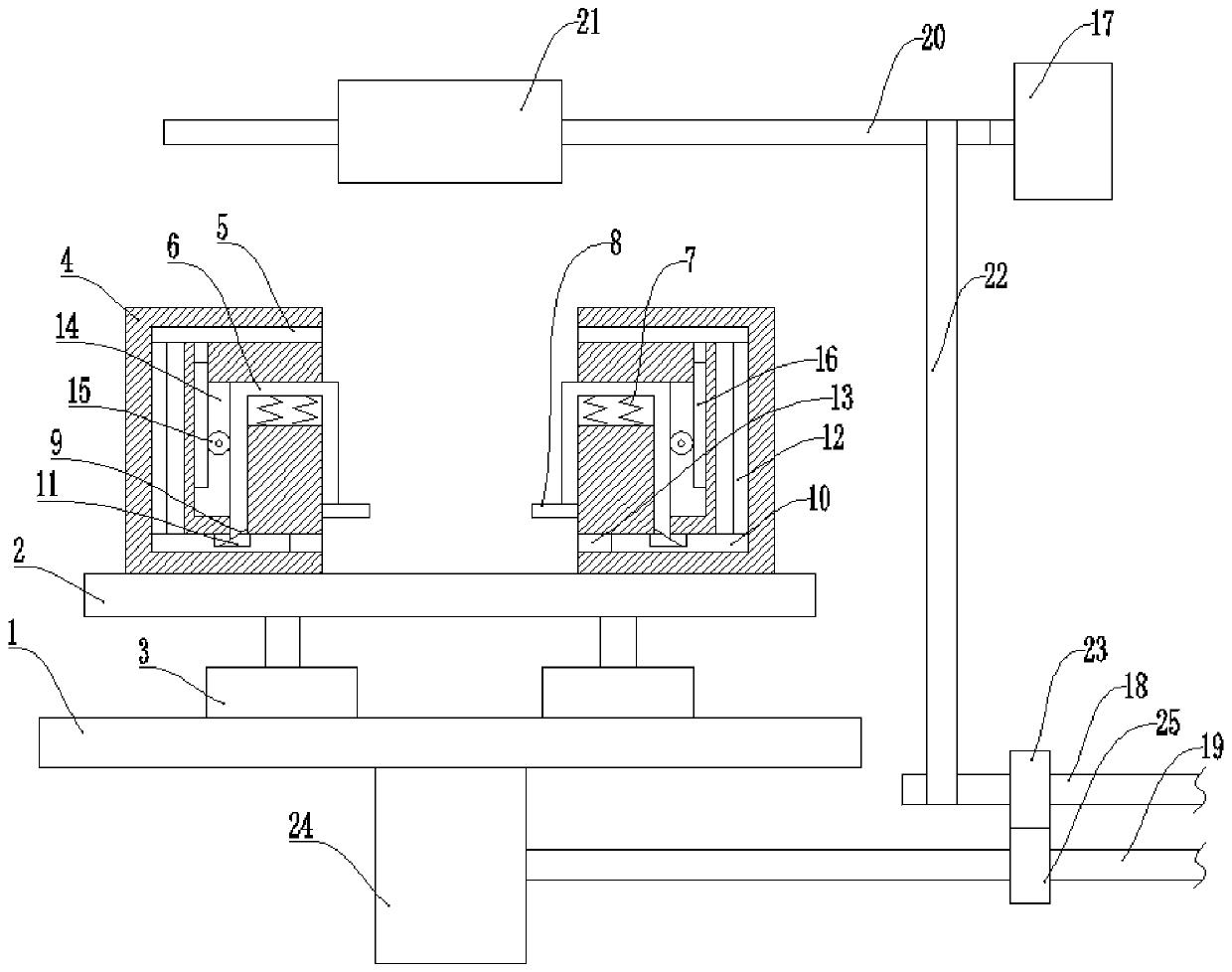

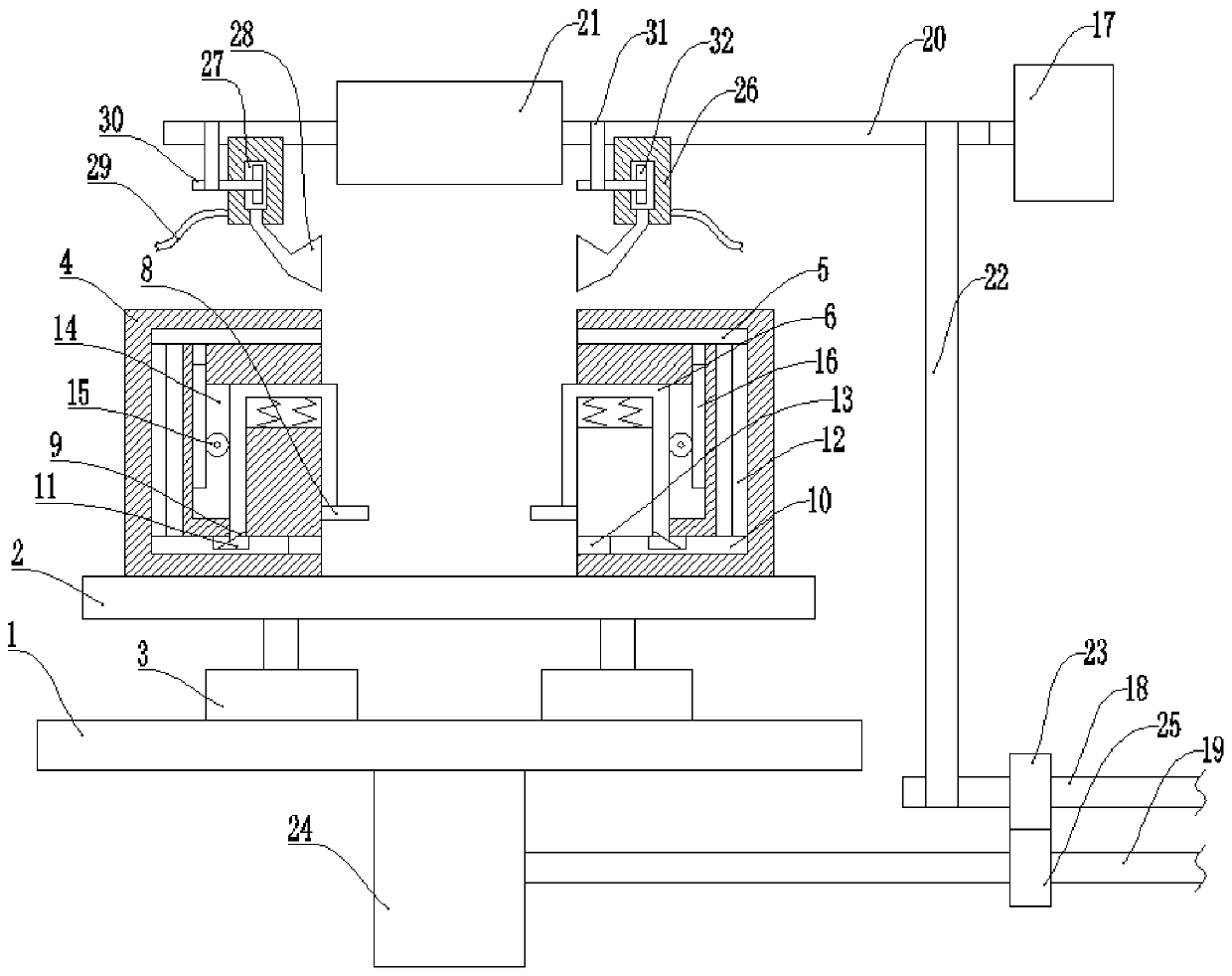

Biomass fuel burning equipment and burning method thereof

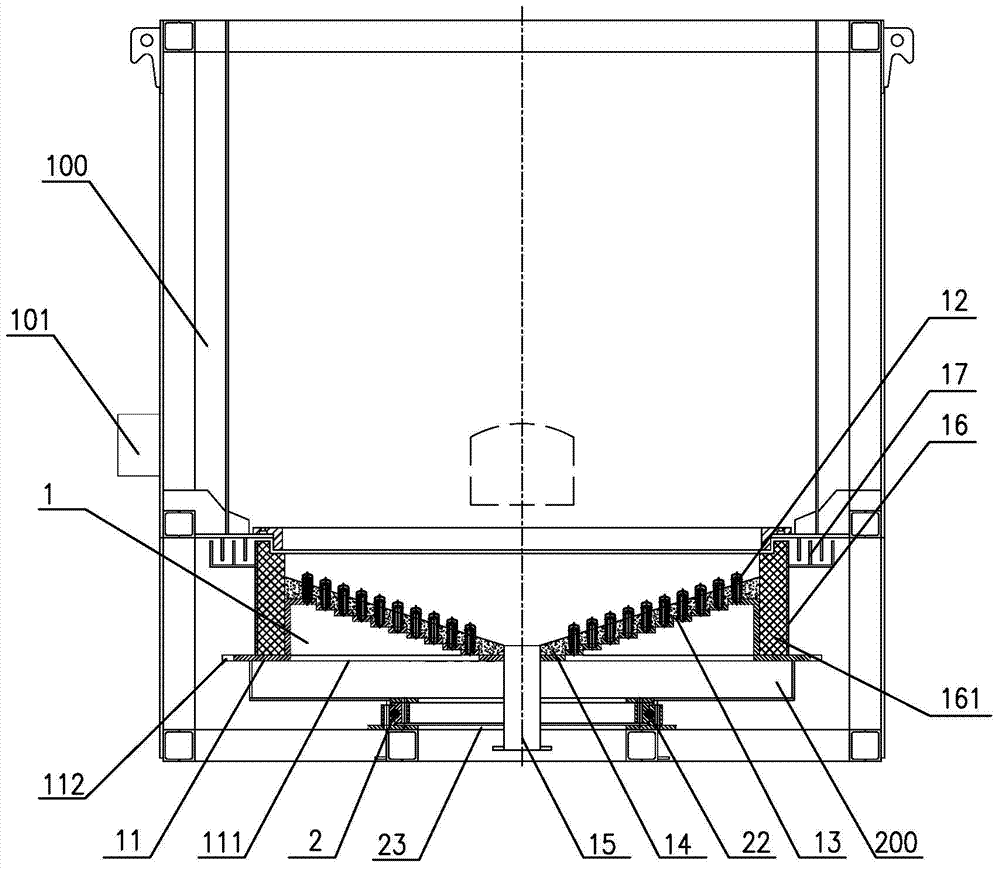

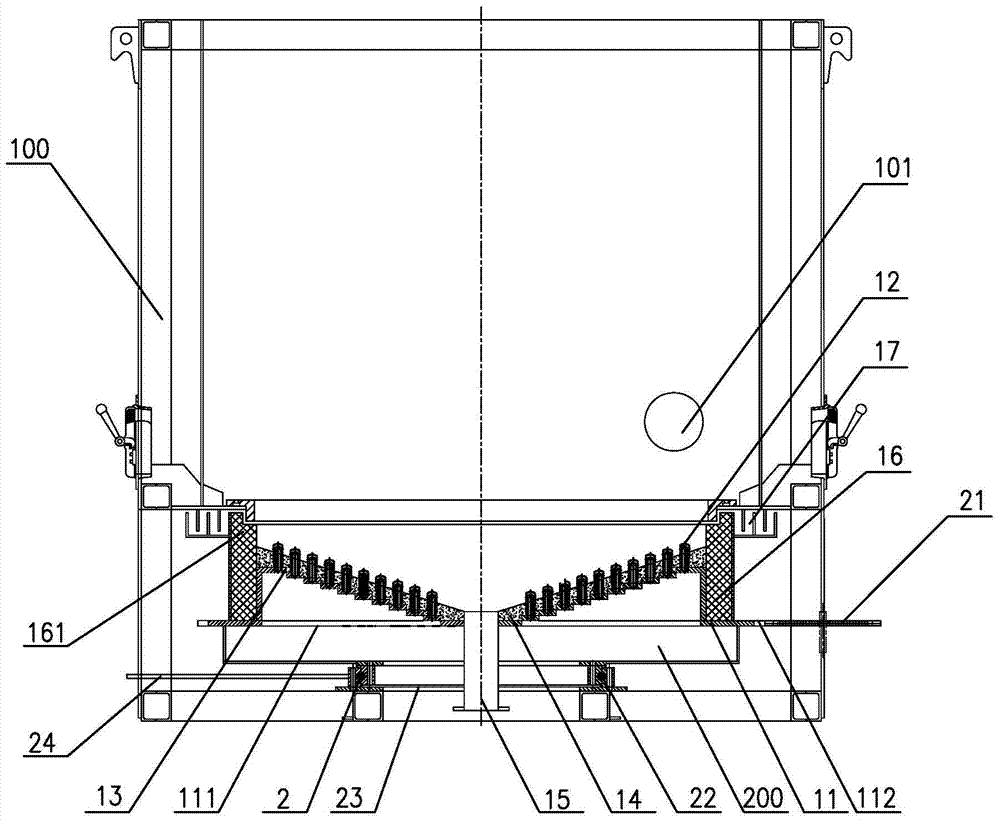

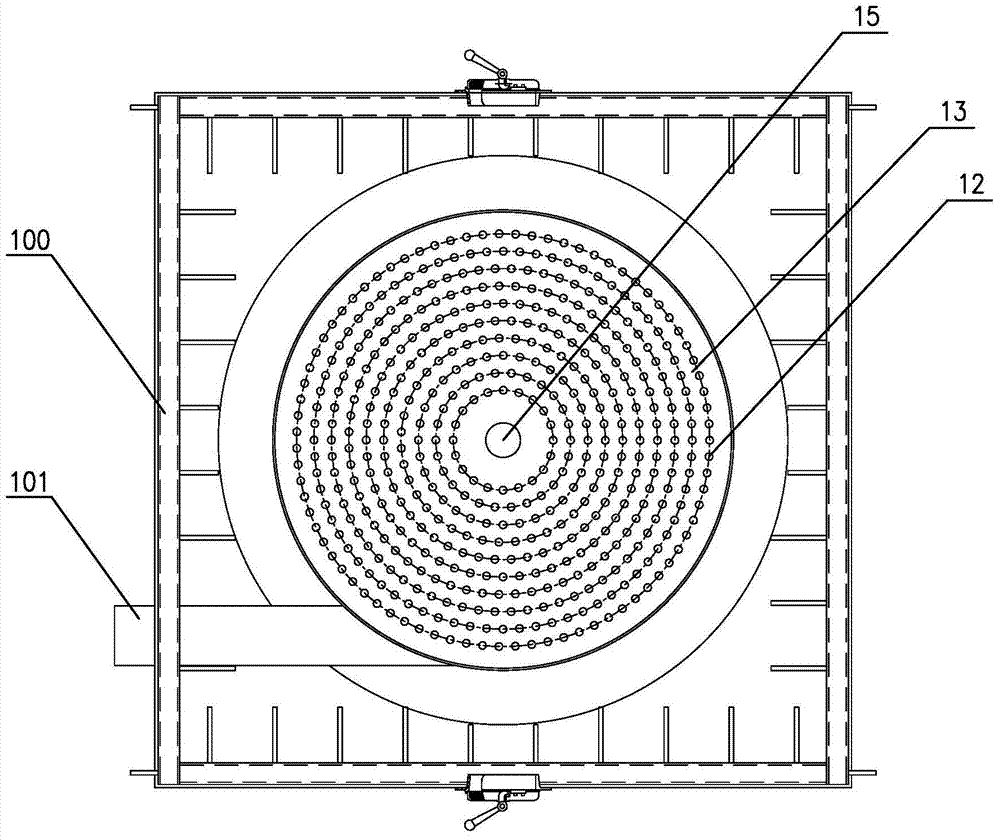

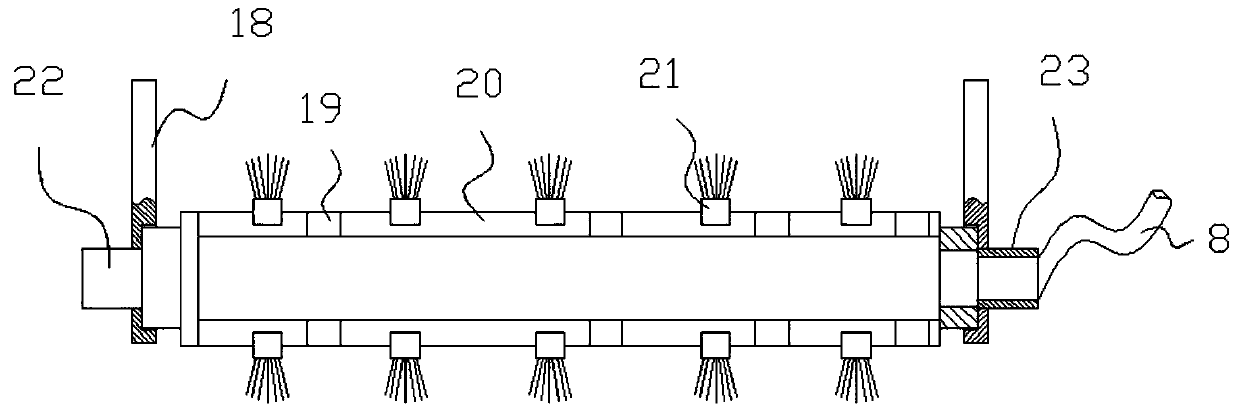

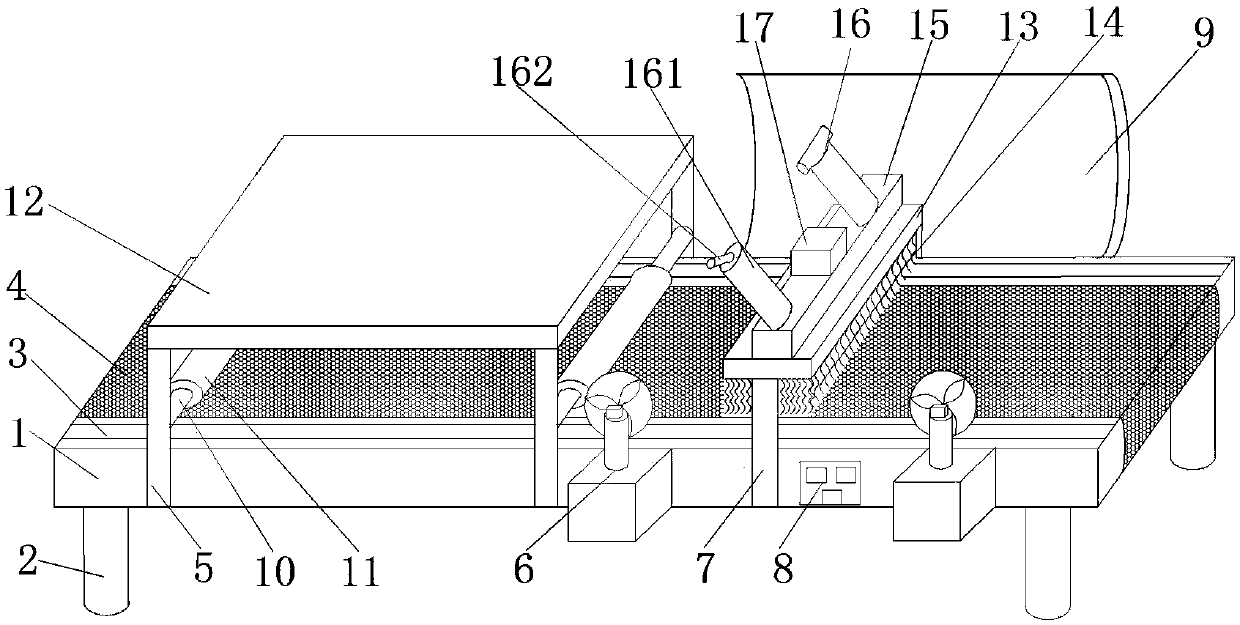

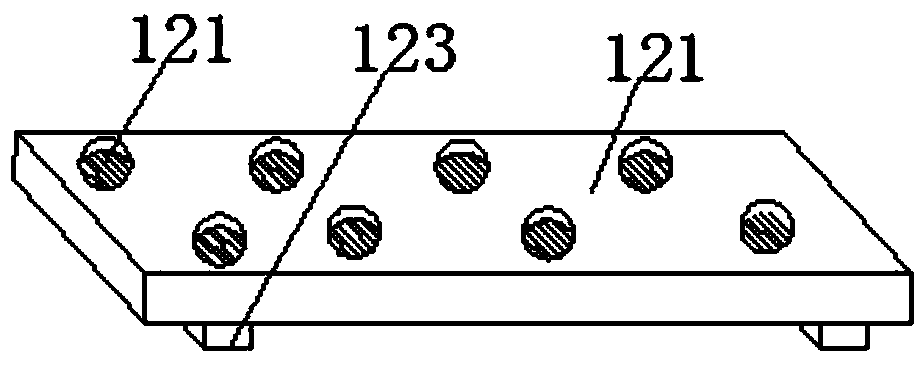

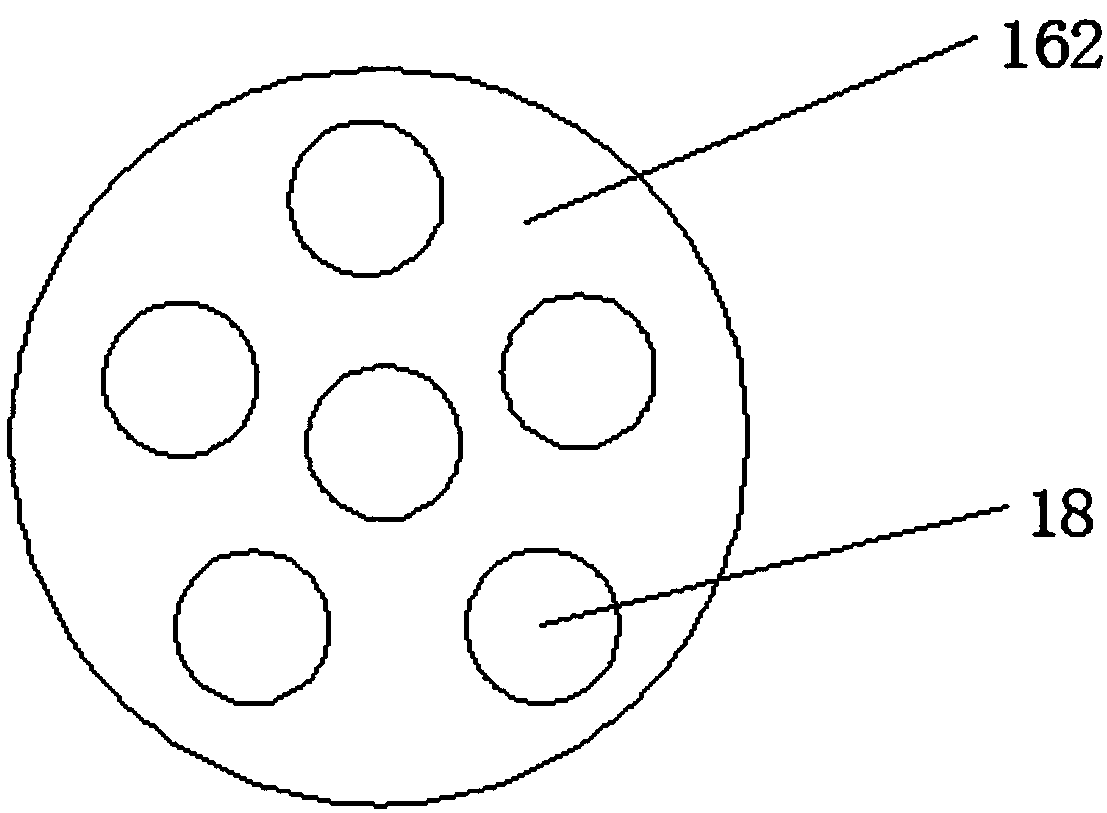

ActiveCN103542400ARealize centralized recyclingAvoid cloggingRevolving grateSolid fuel combustionAir heaterEngineering

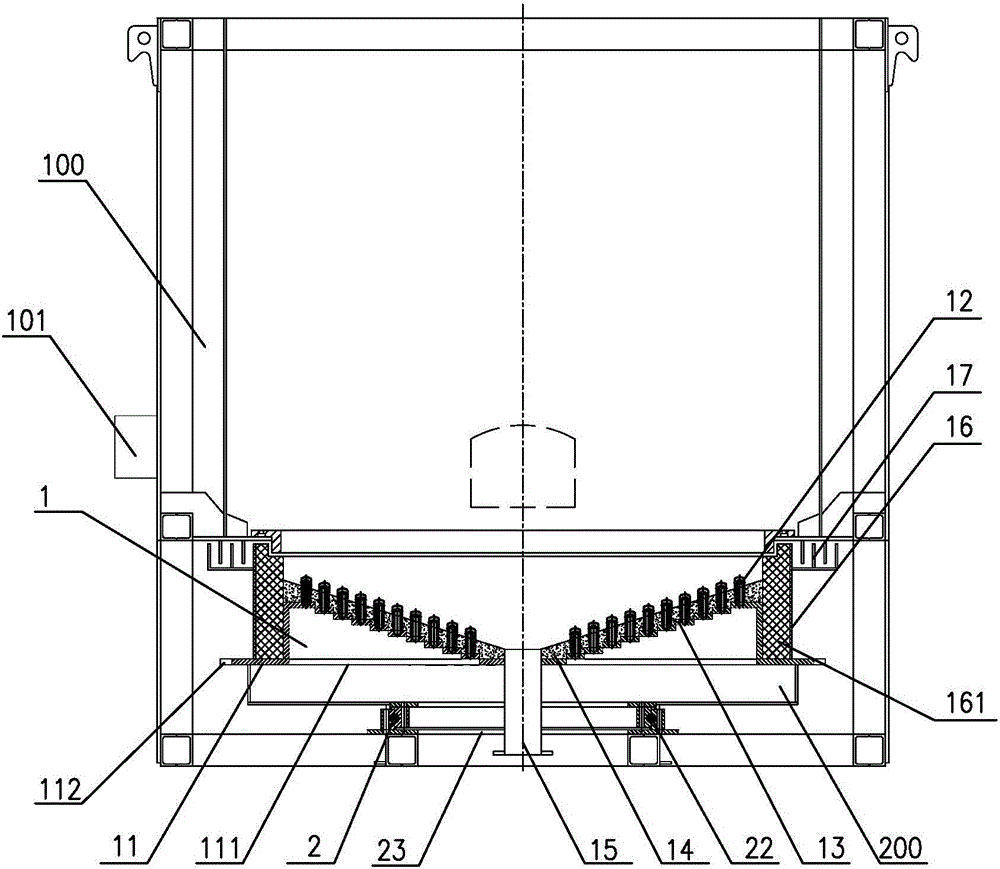

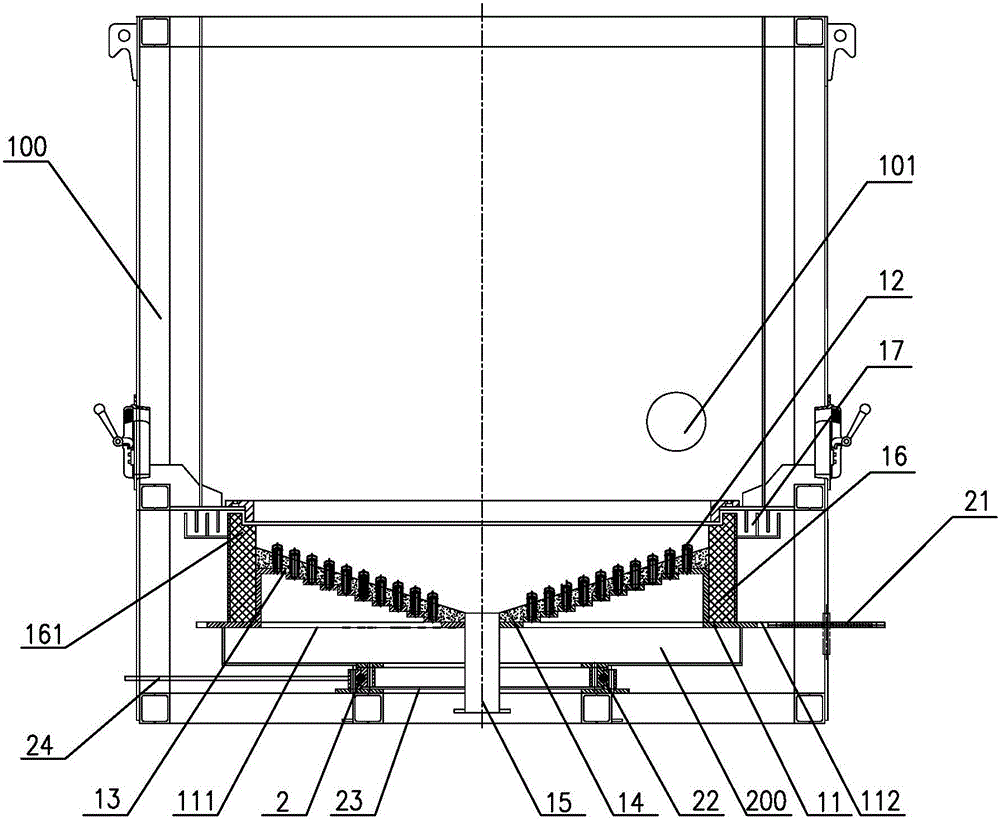

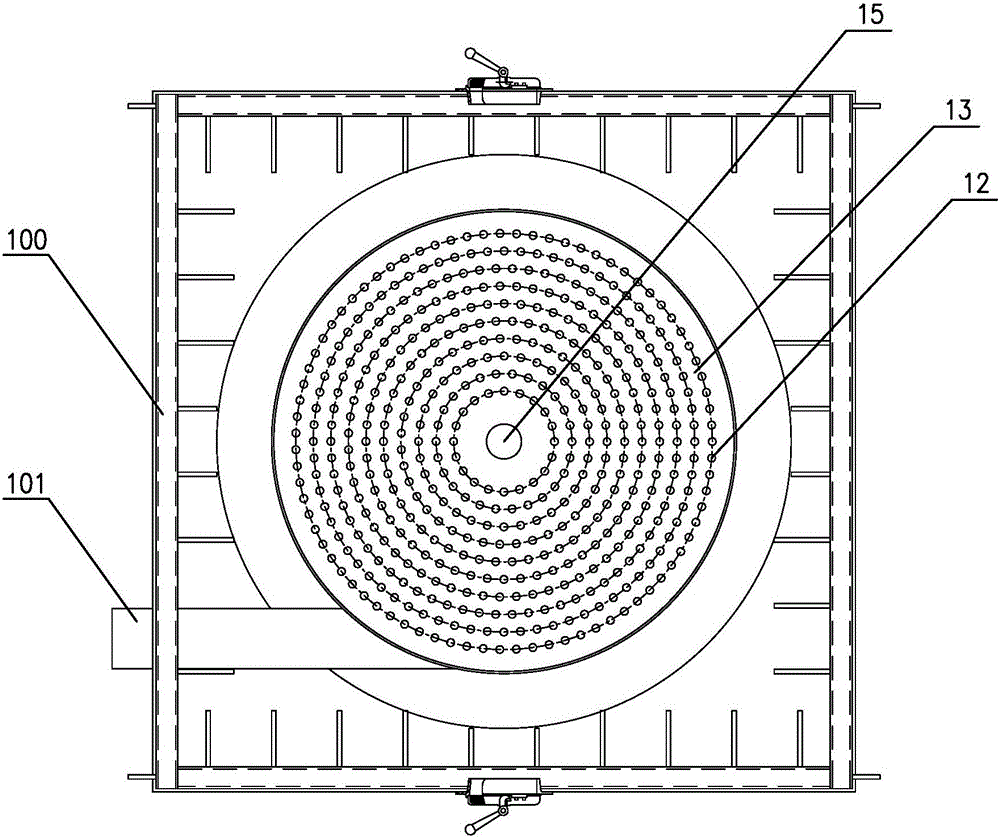

The invention relates to biomass fuel burning equipment and a burning method thereof. The biomass fuel burning equipment comprises a burning furnace and a blowing device, a rotatable fire grate and a fire grate rotation driving device are arranged in the burning furnace, the fire grate comprises a circular bottom rotating plate, a plurality of groups of funnel caps, fireproof clay layers, an ash pipe and a sealing plate, wherein the funnel caps are arranged above the bottom rotating plate, the fireproof clay layers are paved on the funnel caps, the ash pipe is connected to the circular center of the bottom rotating plate, and the sealing plate is fixed at the outer edge of the bottom rotating plate. The biomass fuel burning equipment and the burning method thereof are applicable to assorted boilers, water heaters, air heaters and the like, and are used for burning biomass energy, fuel is uniformly arranged and suspended on the fire grate to burn after entering the burning furnace, and burning efficiency is high. Ash after power burning can be discharged completely from the ash pipe, an air inlet system is prevented from being blocked by the ash during burning, and the ash is collected and recycled, is convenient to clean and free of affection on the environment.

Owner:泉州超然热能设备发展有限公司

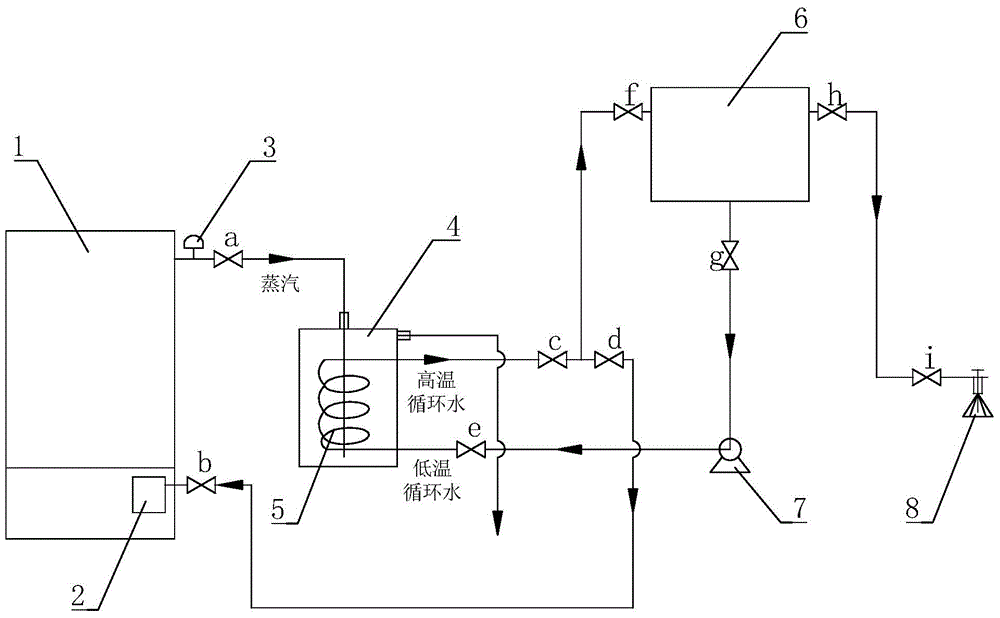

Process and system for using waste heat of steam of steam box

InactiveCN103604233ARealize centralized recyclingRaise the gradeOther heat production devicesEngineeringThermal water

The invention provides a process and a system for using waste heat of steam of a steam box. The waste heat of the steam of the steam box can be efficiently recycled, crossed gas mixing is avoided, the environment of an operation room is purified, and the energy utilization rate is increased. The process comprises the following steps of (1) recycling the heat of the steam; (2) transferring the stored heat; and (3) using the transferred heat. The system comprises the steam box, a heat storage water tank, a circulating water tank, a domestic hot water terminal, a connecting pipeline and a valve, wherein a steam outlet of the steam box is connected with a steam inlet of the heat storage water tank; a heat exchanger is arranged in the heat storage water tank; an outlet and an inlet of the heat exchanger are respectively connected with a high-temperature circulating water inlet formed in the upper portion of the circulating water tank and a low-temperature circulating water outlet formed in the bottom of the circulating water tank correspondingly; and the high-temperature circulating water outlet formed in the upper portion of the circulating water tank is connected with the domestic hot water terminal. The grade of the heat is increased by primary heat exchange, the heat is transferred by secondary heat exchange, and finally the heat is used at the domestic hot water terminal.

Owner:陕西华泰厨房设备有限公司 +1

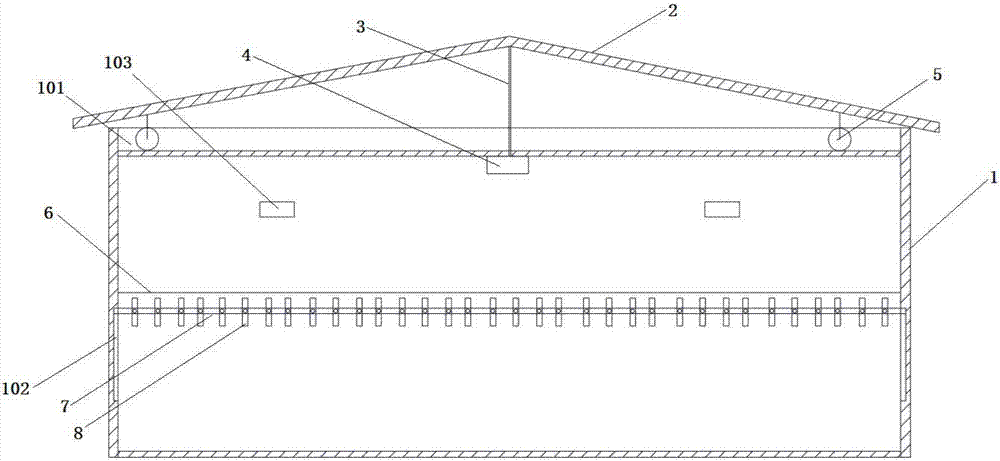

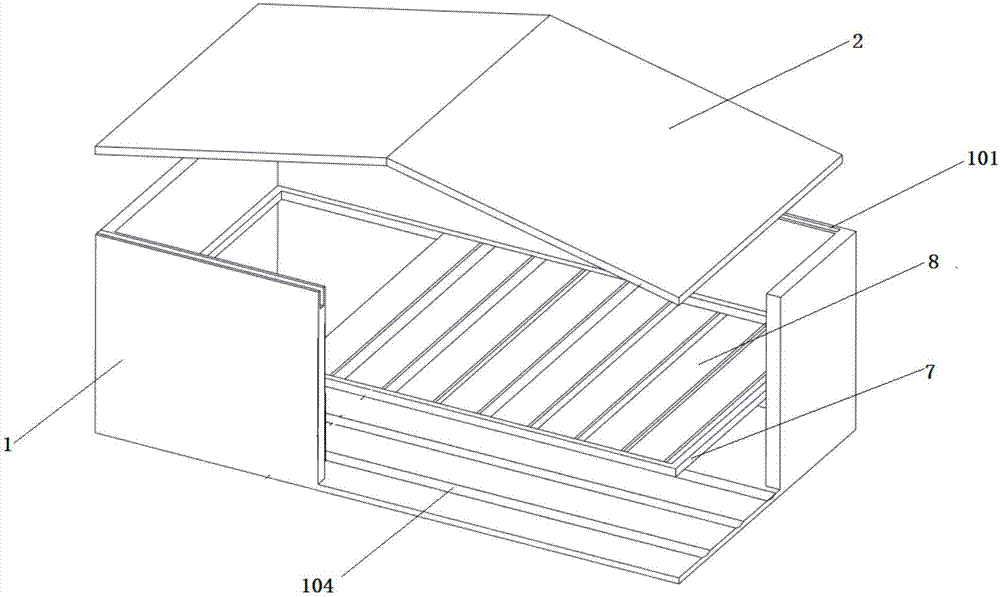

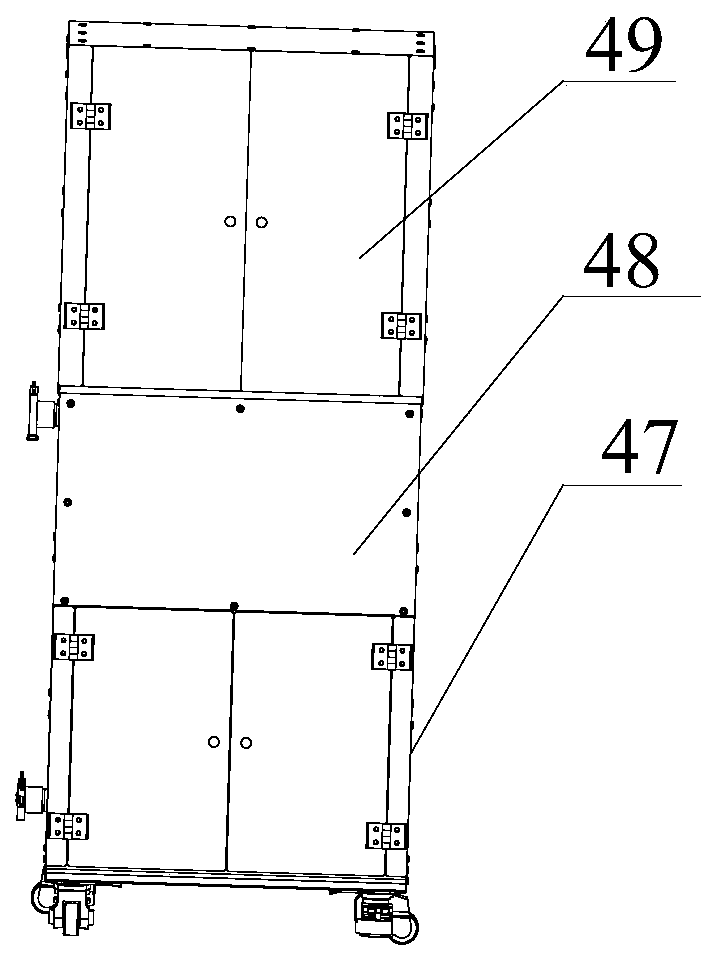

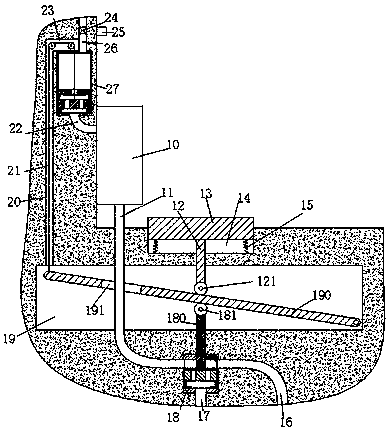

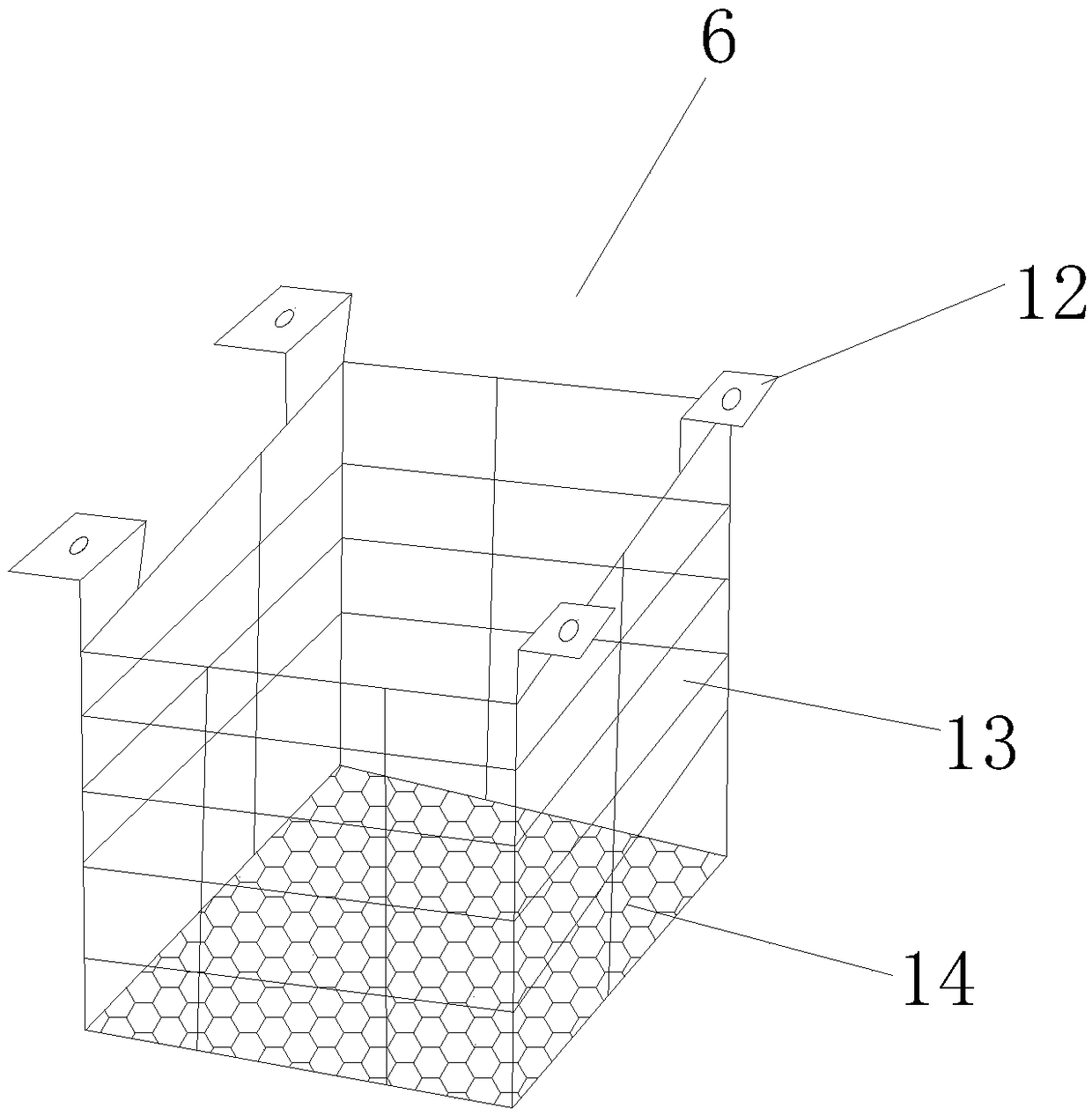

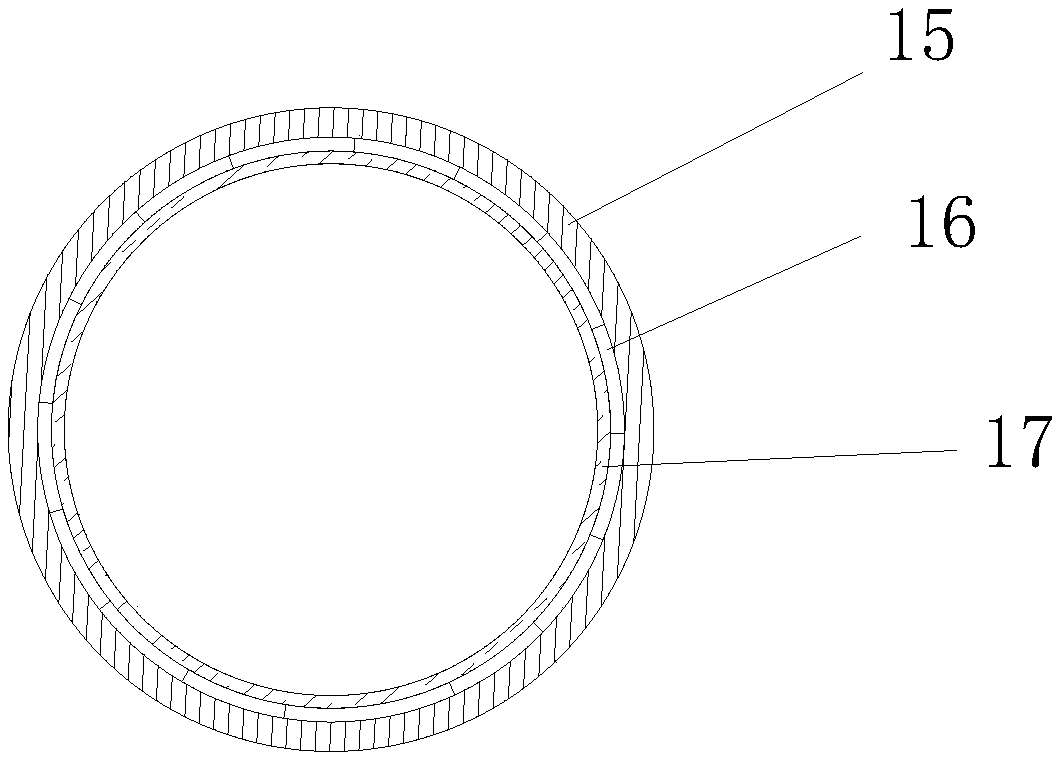

Intelligent ecological henhouse

InactiveCN107211911AReduce the amount of manual laborImprove cleaning efficiencyBird housingsPathogenEngineering

The invention discloses an intelligent ecological henhouse. The henhouse includes a rectangular henhouse body of a double-layer structure, an exposure opening and closing mechanism and a cleaning device, wherein the exposure opening and closing mechanism is arranged on the top face of henhouse body, and the cleaning device is arranged below the henhouse body. According to the intelligent ecological henhouse, a double-layer design is adopted, good feeding environment is ensured, infectious pathogens can be separated, the exposure opening and closing mechanism is designed, so that the henhouse has good air quality and light-catching environment, and a henhouse purifying role is played. Through the design of the cleaning device, feces in the henhouse can be automatically cleaned, the manual labor is reduced, the cleaning efficiency is improved, centralized recycle of the feces can be achieved, it is ensured that breeding environment is not polluted, and the intelligent ecological henhouse has advantages of being ecological, intelligent and the like.

Owner:陈建钧

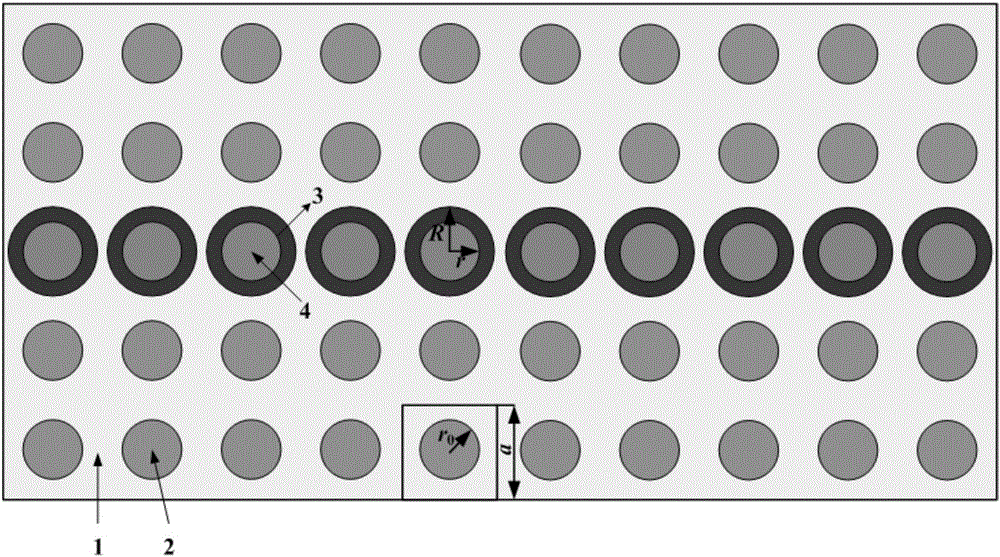

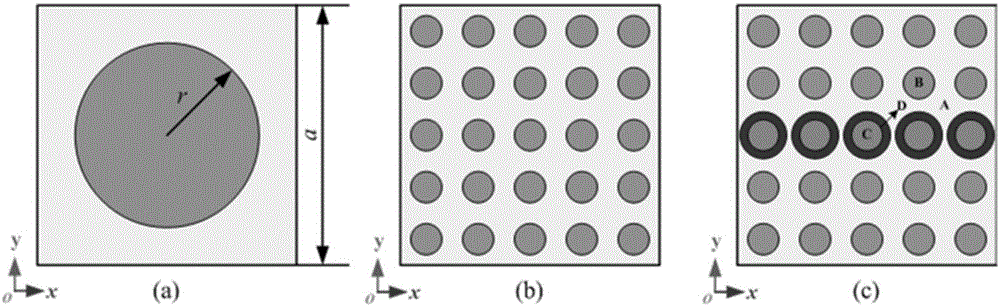

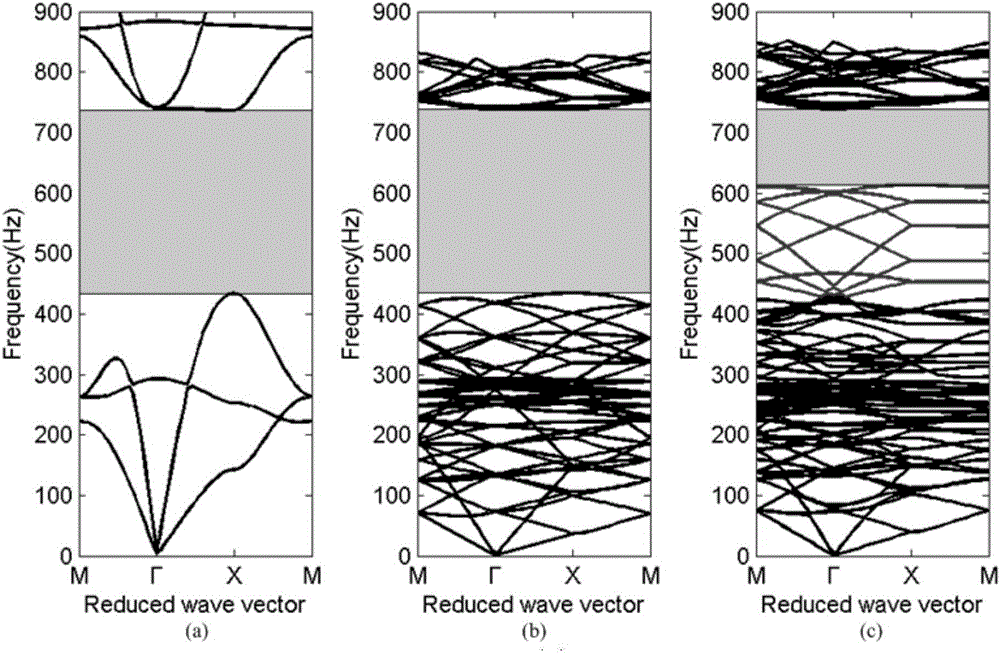

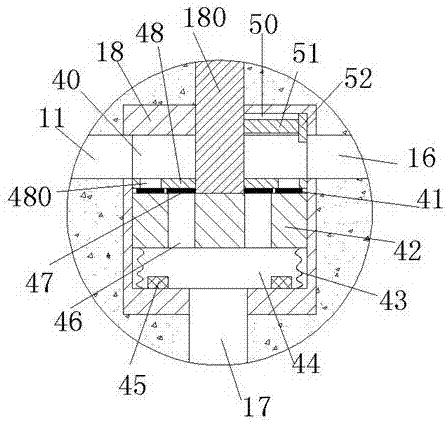

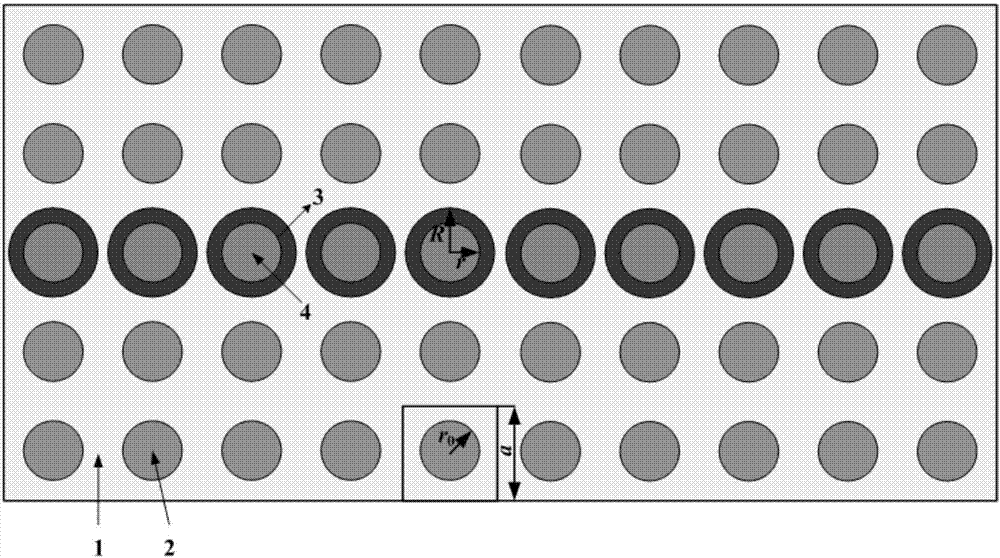

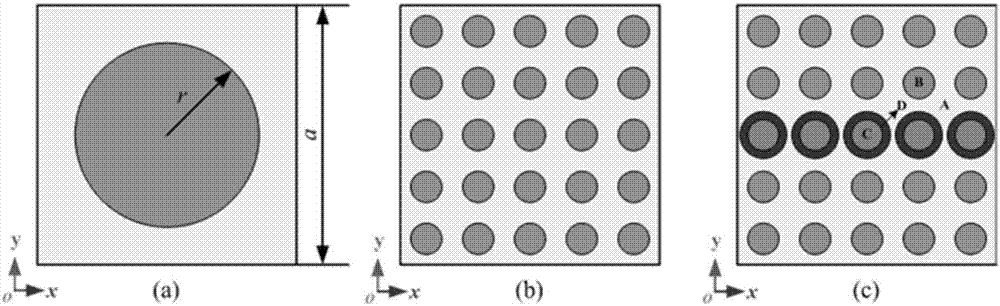

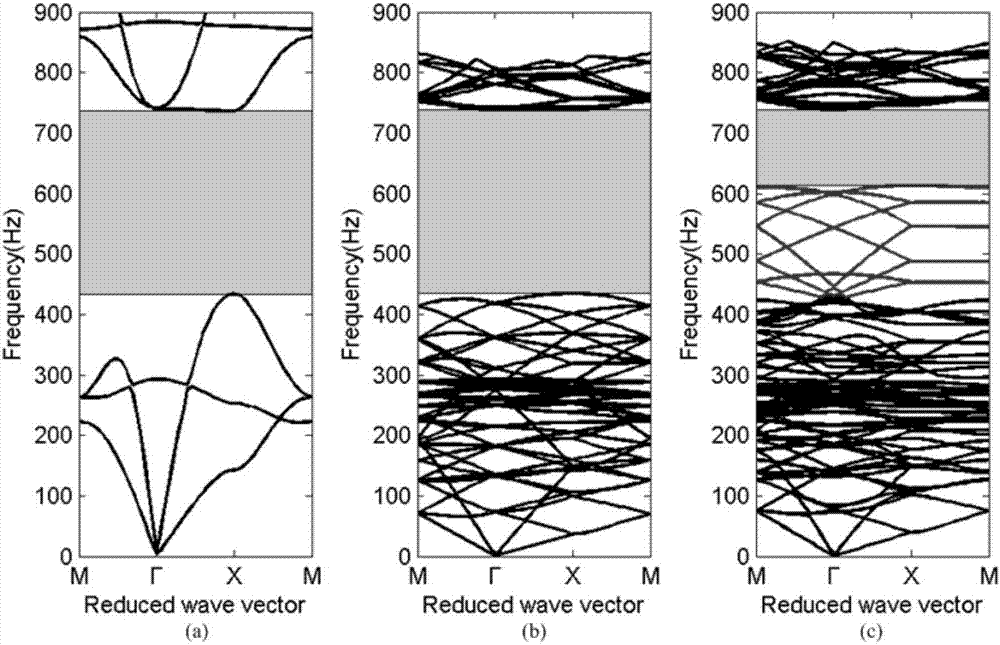

Broadband distributed vibration energy recovery system with composite material line defect photonic crystals

InactiveCN106130403ASolve the problem of narrow-band energy recoveryAchieve recyclingPiezoelectric/electrostriction/magnetostriction machinesBroadbandPhonon

The invention relates to a broadband distributed vibration energy recovery system with composite material line defect photonic crystals. The broadband distributed vibration energy recovery system comprises the composite material line defect photonic crystals, wherein the composite material line defect photonic crystals are embedded in a matrix through scatterers and are arranged in a periodical array in the matrix, in which one row of the scatterers are composite material line defect structures formed after polymer layers coat the defect scatterers, and the rest of the scatteres are lead cylinder scatterers. According to the system, the energy recovery system with great recovered energy and high conversion efficiency capable of realizing broadband distributed energy recovery can be obtained, the system can be used for realizing low-frequency broadband distributed vibration energy recovery of a naval ship structure, and self-powered energy is provided for naval ship system state monitoring wireless sensors and MEMS systems.

Owner:WUHAN UNIV OF TECH

Urban road green-belt weeding device

The invention discloses an urban road green-belt weeding device, which comprises a placing board, the bottom of the placing board is provided with a plurality of first supporting legs, and the bottomsof the plurality of first supporting legs are provided with universal wheels, the side wall of the placing board is provided with a communicating groove, the placing board is symmetrically provided with two limiting devices, a box body is disposed between the two limiting devices, the bottom side wall of the box body abuts against the side wall of the upper end of the placing board, the inner side of the box body is provided with a hollow cavity, the upper end of the box body is provided with a thorough opening communicating with the hollow cavity, and a lifting device is arranged in the hollow cavity. The weeding device of the invention is reasonable in structure design, can realize automatic cutting of weeds, improve the removal efficiency, can directly recover the removed weeds, reduces the workload of workers, can automatically select a herbicide spraying mode according to the actual demand for realizing weeding, and is convenient for sanitation workers to choose a weeding methodaccording to actual needs.

Owner:耿声俊

Automobile baffle grinding apparatus production device

PendingCN109940487ARealize the cleaning functionRealize centralized recyclingGrinding machine componentsElectrostatic cleaningBristleEngineering

The invention discloses an automobile baffle grinding apparatus production device. A first base is included, and the bottom four corner positions of the first base are fixedly connected with supporting columns; the top of the first base is sequentially provided with a water draining groove and a conveying belt in the width direction; the side wall of the first base is sequentially connected with first supporting rods, air blowers, second supporting rods and a first support in the horizontal direction; the side wall of the other side of the first base is sequentially connected with the first supporting rods, the second supporting rods and an adsorbing plate in the horizontal direction; the first supporting rods are symmetrically arranged into two sets; a roller shaft is rotationally connected between each set of the first supporting rods through a rotating shaft; a first bristle layer is fixedly connected to the outer wall of each roller shaft; the top ends of the first supporting rodsare fixedly connected with an electrostatic dust sucking plate; and the top ends of the second supporting rods are fixedly connected with a second base. The automobile baffle grinding apparatus production device is simple in structure, convenient to operate and capable of effectively preventing secondary pollution caused by scraps in the grinding process.

Owner:ZHEJIANG SHUNSHI AUTOMOBILE TECH

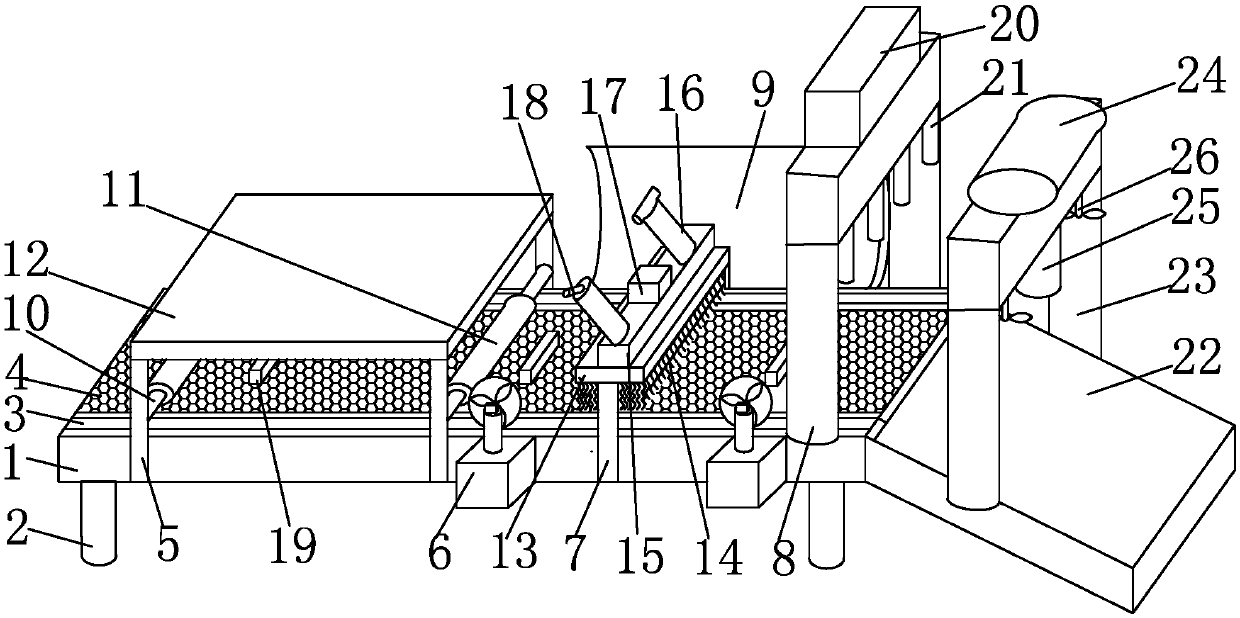

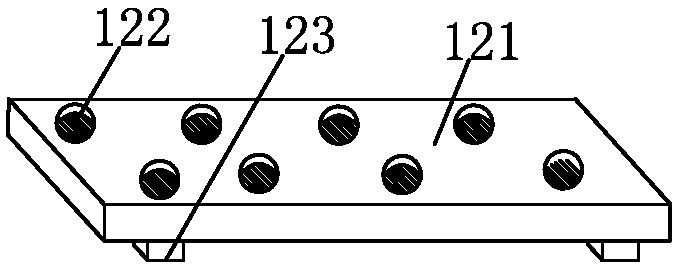

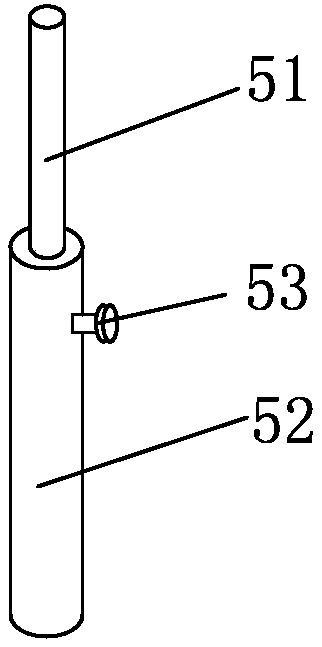

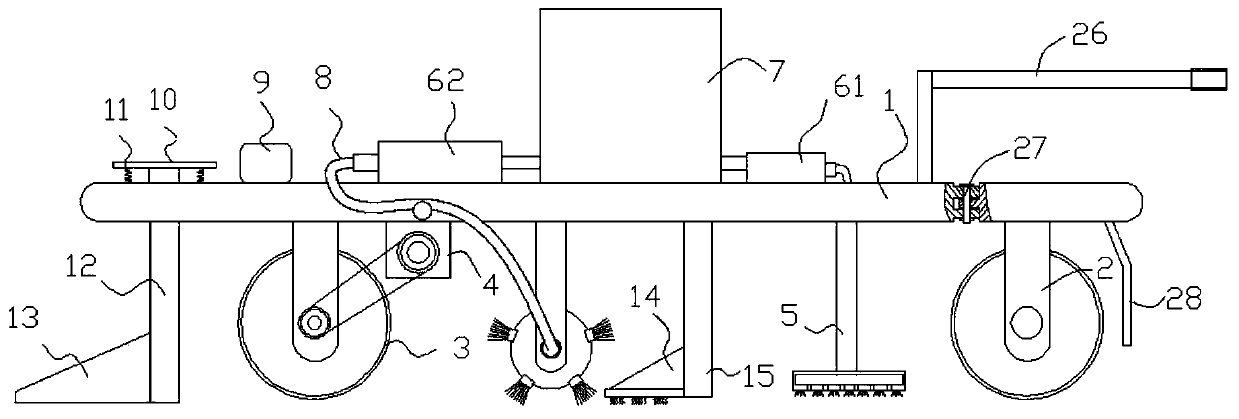

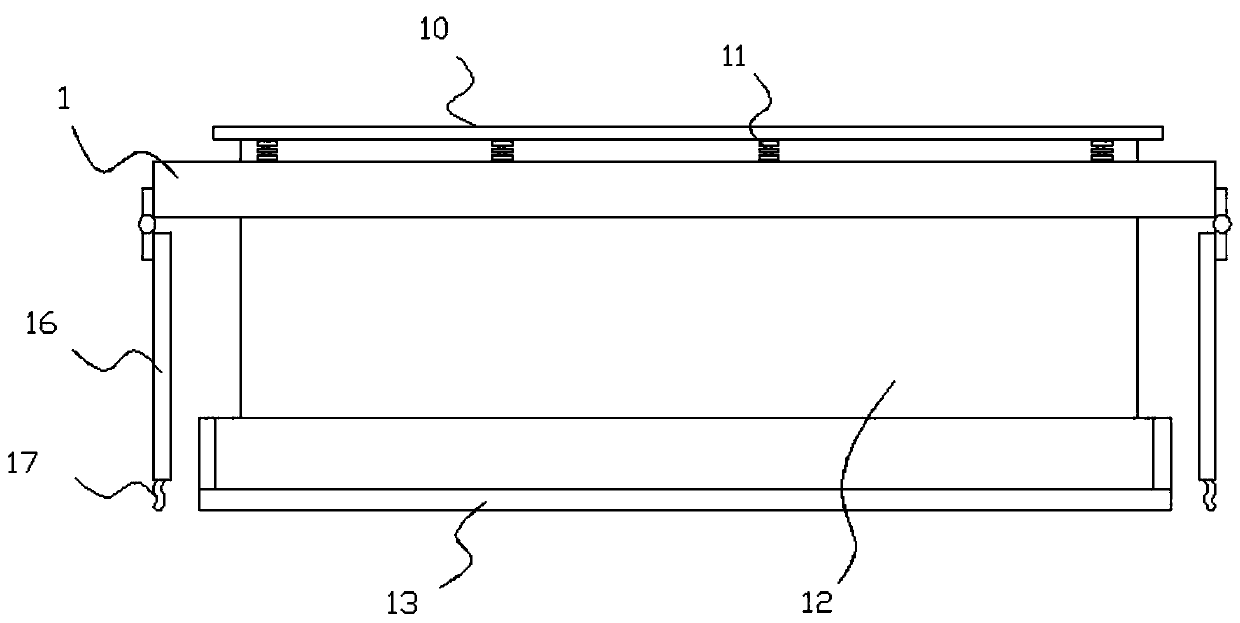

Multistage sweeping machine for self-propelled agricultural product processing workshop

InactiveCN109730586AGood cleaning effectImprove cleaning efficiencyMachine detailsFloor sweeping machinesProduct processingAgricultural engineering

The invention discloses a multistage sweeping machine for a self-propelled agricultural product processing workshop. The multistage sweeping machine comprises a base plate, a supporting frame, movingwheels and a first motor; the front end of the base plate is provided with a first clearing assembly, the middle of the base plate is provided with a second clearing assembly, and the rear end of thebase plate is provided with a third clearing assembly; the first clearing assembly comprises a top plate, a spring, a vertical plate and a first dustpan shovel, the vertical plate is shaped like a rectangular plate which is longitudinally arranged, the top end of the vertical plate penetrates through a strip-shaped hole and is connected with the top plate which is horizontally arranged, the top plate is located above the base plate and is fixedly connected with the base plate by the spring, and the bottom end of the vertical plate is connected with the first dustpan shovel; the second clearingassembly comprises a second motor, mounting plates, a rotating cylinder, a hairbrush and a driving rotating shaft, and the two mounting plates which are longitudinally arranged are symmetrically arranged on the bottom surface of the base plate; and the third clearing assembly comprises a first dust suction machine, a dust storage box, a connecting pipe, a bottom box and a through hole. The multistage sweeping machine is simple in structure, convenient to use, good in sweeping effect and capable of saving manpower.

Owner:合肥茗满天下茶叶有限公司

Industrial brush polishing treatment device

PendingCN107584398ARealize the cleaning functionRealize centralized recyclingPolishing machinesGrinding machine componentsBristleSoftware engineering

The invention discloses an industrial brush polishing treatment device which comprises a first base. Supporting columns are fixedly connected to four corners of the bottom of the first base, a water draining groove and a conveying belt are sequentially installed at the top of the first base in the width direction, first supporting rods, an air blower, a second supporting rod and a control switch are sequentially connected to the side wall of the first base in the horizontal direction, first supporting rods, a second supporting rod and an adsorption plate are sequentially connected to the otherside wall of the first base in the horizontal direction, the number of the first supporting rods are two symmetrically arranged groups, a rolling shaft is rotatably connected in each group of first supporting rods through a rotary shaft, a first brush bristle layer is fixedly connected to the outer wall of the rolling shaft, an electrostatic precipitation plate is fixedly connected to the top endof each first supporting rod, and a second base is fixedly connected to the top end of each second supporting rod. The industrial brush polishing treatment device is simple in structure and convenient to operate, and secondary pollution caused by chippings in the polishing process is effectively prevented.

Owner:安徽兴华制刷有限公司

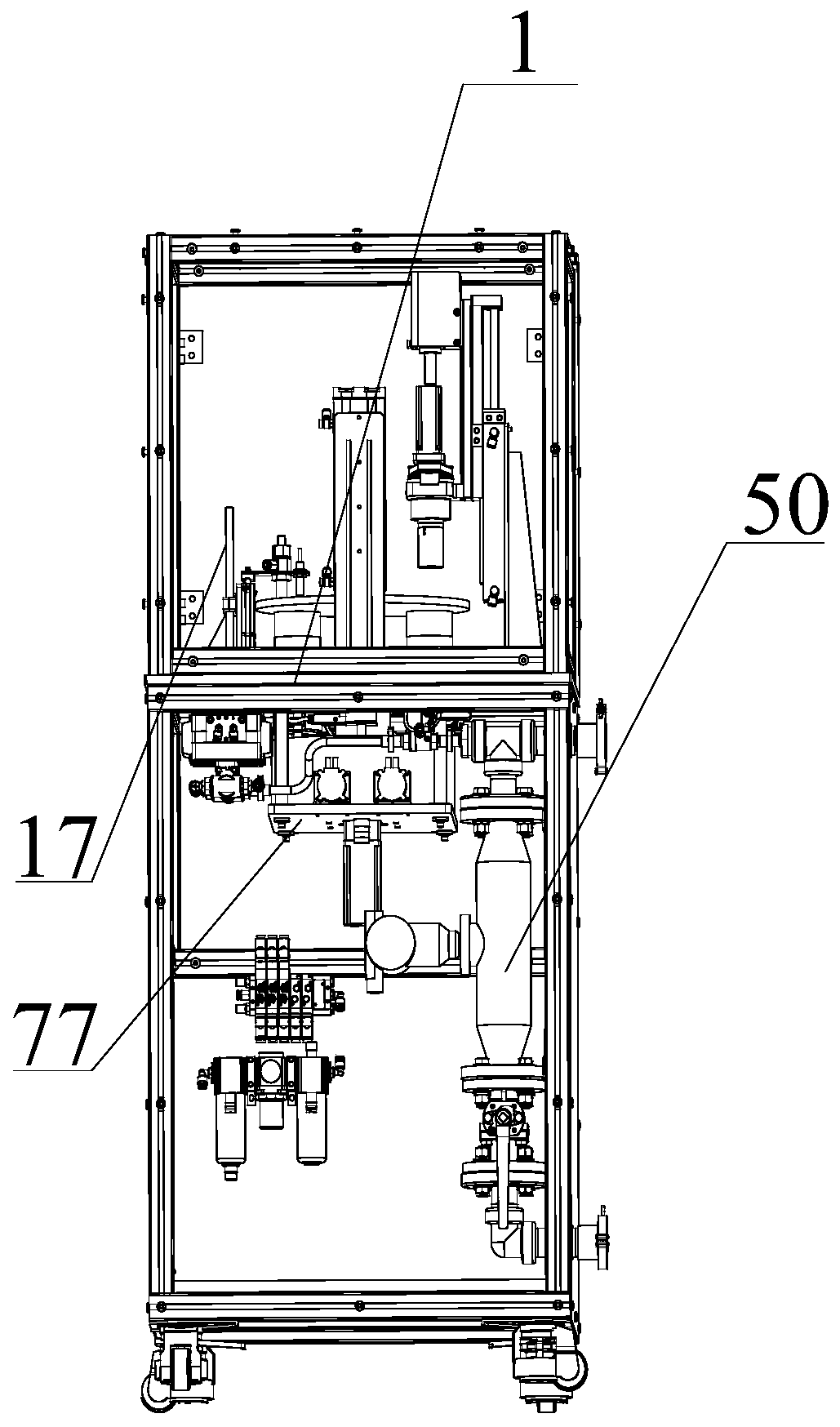

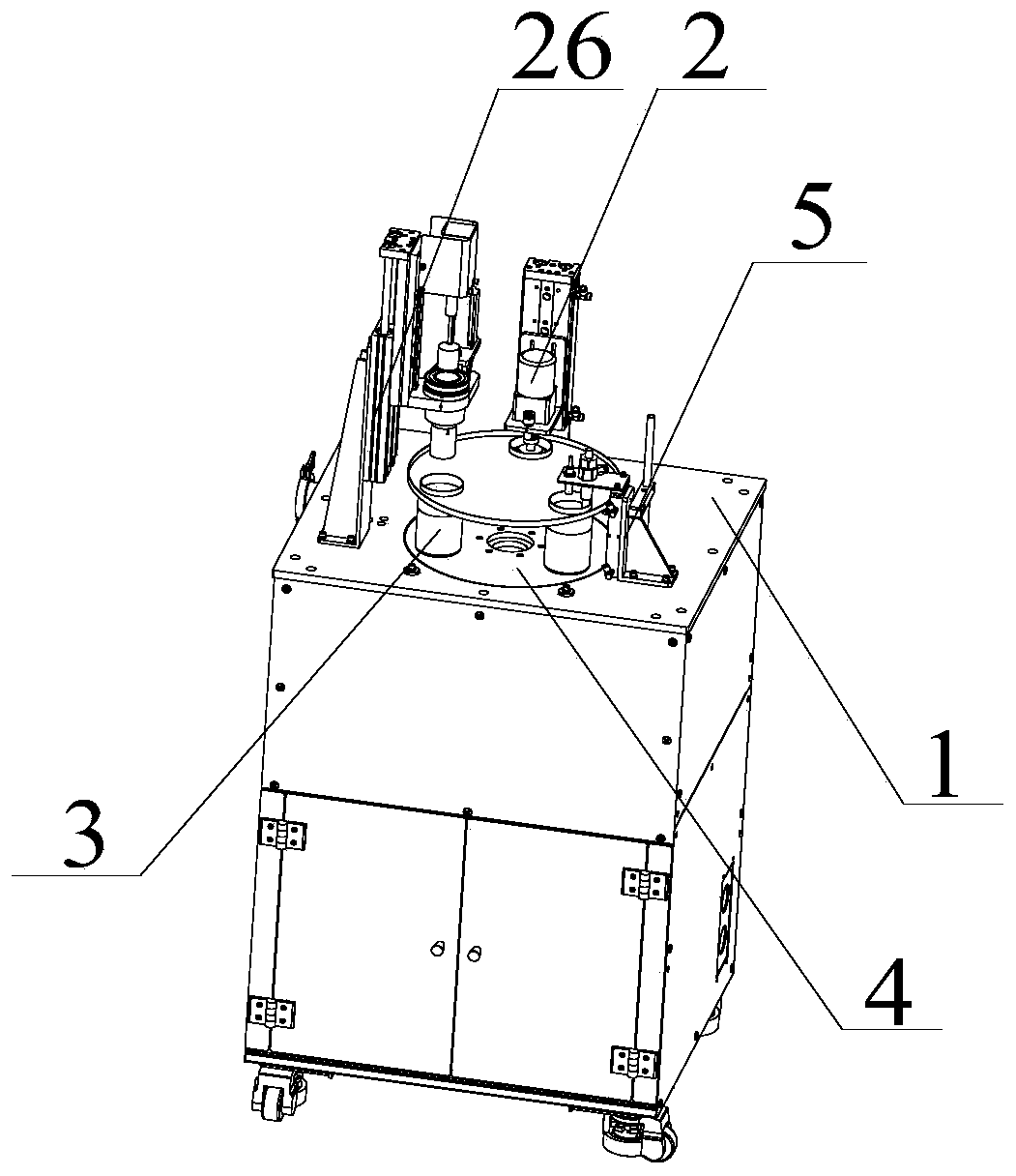

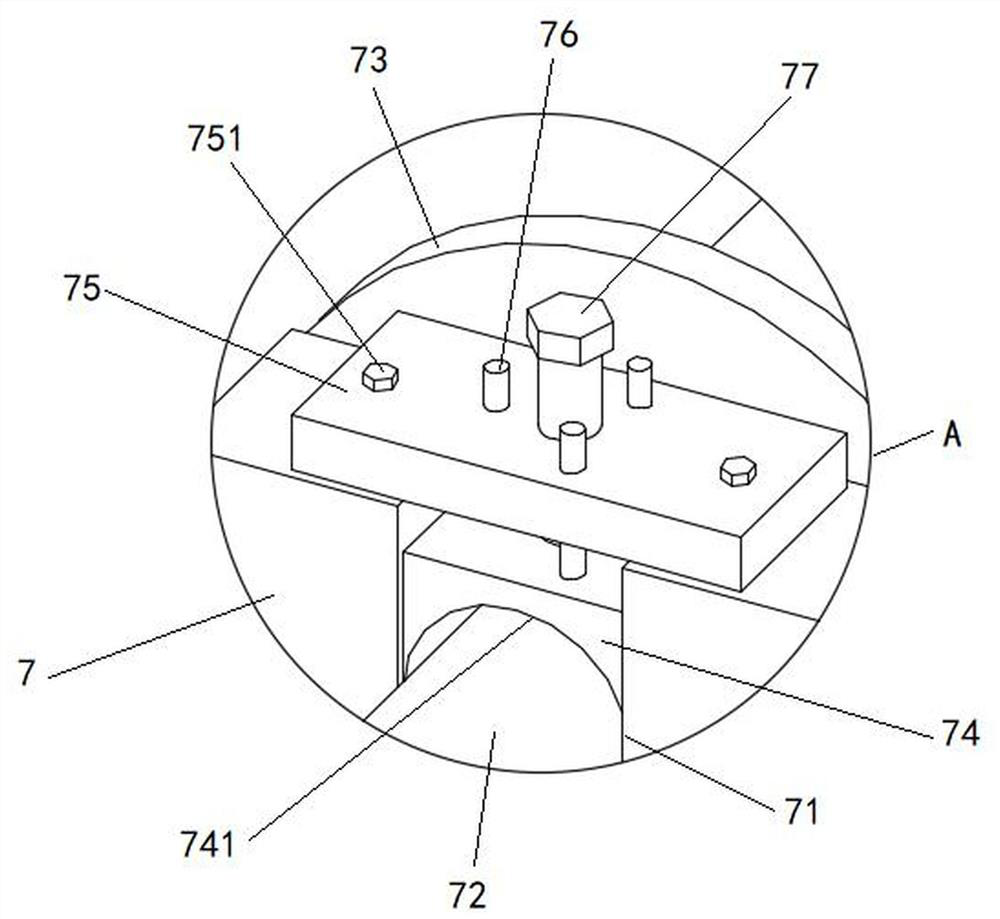

Drilling fluid comprehensive performance automatic detection system

The invention discloses a drilling fluid comprehensive performance automatic detection system, which comprises a viscosity measurement system and a water analysis system. The viscosity measuring system comprises a waste liquid barrel, a movable disc, a grouting assembly, a cleaning assembly and a measuring assembly. The water analysis system comprises an inner cup taking assembly, an inner cup recycling assembly and a filtrate detection assembly. The invention aims to provide the drilling fluid comprehensive performance automatic detection system to solve the problems of low automation degreeand labor consumption of drilling fluid viscosity and water analysis equipment in the prior art, thereby realizing the purposes of reducing the labor intensity and improving the automation degree of the drilling fluid performance detection process.

Owner:四川泰锐石油化工有限公司

Brother-series colored carbon powder collecting and treating method

InactiveCN104238331ARealize centralized recyclingHigh recovery efficiency of tonerElectrography/magnetographyIndex testMetallurgy

The invention aims to provide a brother-series colored carbon powder collecting and treating method which is high in recovery rate and good in recovered carbon powder quality. The method comprises the following steps of classifying residual brother-series colored carbon powder according to the models of products in different carbon powder boxes, and centrally collecting the residual brother-series colored carbon powder; analyzing the physical parameter of the residual colored carbon powder in each carbon powder box, and recording data; placing the residual carbon powder into a testing toner cartridge to test, and recording the test data; comparing the test data obtained in the former step with standard data to obtain the physical characteristic of the carbon powder with defects; treating the carbon powder according to the physical characteristic of the carbon powder with the defects; sieving the carbon powder by using a filter sieve, grading, adding positive conductive particles and a flow aid, and mixing; carrying out index test on the treated carbon powder, and recording data; and testing the carbon powder good in index test by using the toner cartridge to ensure that the carbon powder meets the application requirement. The brother-series colored carbon powder collecting and treating method can be applied to the field of residual carbon powder treatment.

Owner:KOLION TECH

HP-series colored carbon powder collecting and treating method

InactiveCN104238332ARealize centralized recyclingImprove efficiencyElectrography/magnetographyIndex testMetallurgy

The invention aims to provide a HP-series colored carbon powder collecting and treating method which is high in recovery rate and good in recovered carbon powder quality. The method comprises the following steps of classifying residual HP-series colored carbon powder according to the models of products in different carbon powder boxes, and centrally collecting the residual HP-series colored carbon powder; analyzing the physical parameter of the residual colored carbon powder in each carbon powder box, and recording data; placing the residual carbon powder into a testing toner cartridge to test, and recording the test data; comparing the test data obtained in the former step with standard data to obtain the physical characteristic of the carbon powder with defects; treating the carbon powder according to the physical characteristic of the carbon powder with the defects; drying the carbon powder, coarsely sieving the carbon powder by using a filter sieve, adding negative conductive particles and a flow aid, mixing, and finely sieving the carbon powder by using a filter sieve; carrying out index test on the treated carbon powder, and recording data; and testing the carbon powder good in index test by using the toner cartridge to ensure that the carbon powder meets the application requirement. The HP-series colored carbon powder collecting and treating method can be applied to the field of residual carbon powder treatment.

Owner:KOLION TECH

A kind of comprehensive utilization treatment method of aluminum ash

ActiveCN105347361BHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

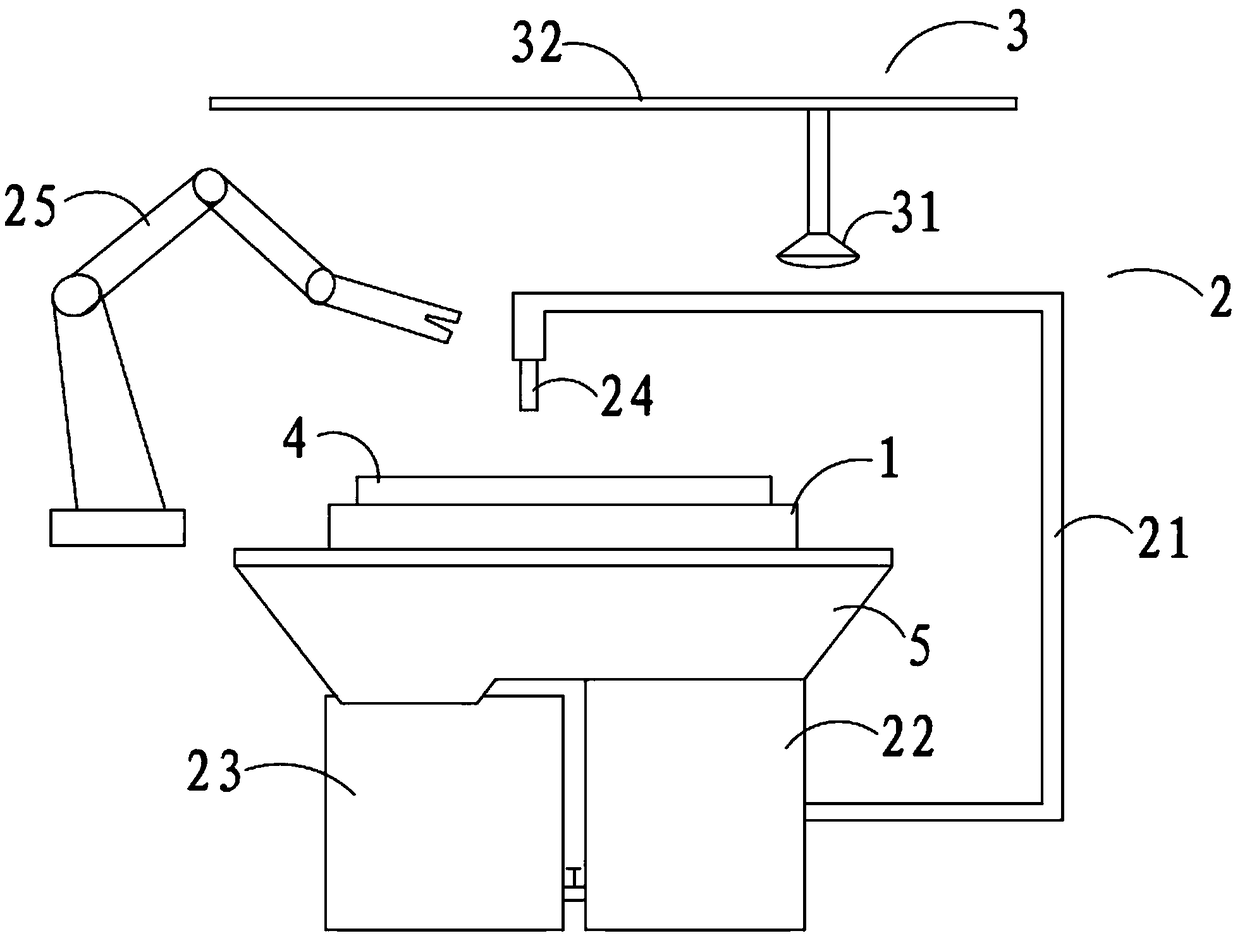

Cleaning and light curing equipment

PendingCN108749000ARealize light curingAchieve cleaningAdditive manufacturing apparatus3D object support structuresEngineeringLight curing

The invention provides cleaning and light curing equipment. The cleaning and light curing equipment comprises a workbench, a cleaning device and a light curing device; the cleaning device comprises acleaning pipeline, a storage container, a recovery container, a nozzle and a mechanical arm; one end of the cleaning pipeline is connected with the storage container; the other end of the cleaning pipeline extends to a space above the workbench and is connected with the nozzle; the recovery container is located below the workbench and recovers cleaning liquid after cleaning; the mechanical arm islocated on one side of the workbench and clamps the nozzle; the light curing device comprises a light curing lamp and a sliding rail; the light curing lamp is arranged on the sliding rail in a slidingmanner and is controlled to make lifting motion by a telescopic air cylinder; and the sliding rail is located above the workbench. The cleaning and light curing equipment can continuously achieve light curing and cleaning of a 3D printing product, and has the relatively high light curing efficiency and the relatively high cleaning efficiency. Meanwhile, the centralized recovery of the cleaning liquid after the cleaning can be achieved.

Owner:苏州因钛智能科技有限公司

Vertical cleaning system for stainless steel pipe production

The invention discloses a vertical cleaning system for stainless steel pipe production. The vertical cleaning system comprises a base plate as well as a hydraulic case and a driving case which are sequentially and fixedly mounted at the top of the base plate from left to right; a hydraulic assembly is fixedly connected inside the hydraulic case through bolts; a protection barrel is fixedly connected at the top of the driving case; and a rotating shaft is rotationally connected inside the protection barrel through a bearing. The invention relates to the technical field of stainless steel pipe production equipment. According to the vertical cleaning system for stainless steel pipe production, every steel pipe can be well cleaned without mutual influence through separate, independent and simultaneous cleaning of the steel pipes and can be cleaned thoroughly, hole walls of the steel pipes are cleaned, defective products are greatly reduced, meanwhile, the multiple steel pipes can be cleaned in all directions at a time, non-stop loading and unloading can be realized in the cleaning process, loading and unloading operations can be performed by just one person, the cleaning efficiency ishigh, and the cleaning cost is greatly saved.

Owner:吕钢

Automobile baffle grinding tool production equipment

InactiveCN107971890ARealize the cleaning functionRealize centralized recyclingGrinding machinesGrinding feedersEngineeringAir blower

The invention discloses automobile baffle grinding tool production equipment. The automobile baffle grinding tool production equipment comprises a first base, supporting columns are fixedly connectedto the four corners of the bottom of the first base, a water draining channel and a conveying belt are sequentially mounted at the top of the first base in the width direction of the first base a setof,first supporting rods, air blowers, a second supporting rod and a first support are sequentially connected to the side wall of the first base in the horizontal direction, and the other set of firstsupporting rods, another second supporting rod and an adsorption plate are sequentially connected to the other side wall of the first base in the horizontal direction. The two sets of first supporting rods are symmetrically arranged, a roller shaft is rotatably connected to the position between each set of first supporting rods through a rotary shaft, and first brush layers are fixedly connectedto the outer walls of the roller shafts. An electrostatic dust suction plate is fixedly connected to the top ends of the first supporting rods, and a second base is fixedly connected to the top ends of the second supporting rods. The automobile baffle grinding tool production equipment is simple in structure and convenient to operate, and effectively prevents secondary pollution from being generated by chippings in the grinding process.

Owner:郑宾玲

Biomass fuel combustion stove without dust discharged from fire port and combustion method thereof

InactiveCN108488836AAvoid cloggingSolve the phenomenon that a large amount of dust is easy to be ejected at the craterDomestic stoves or rangesSolid fuel combustionCombustion chamberEngineering

The invention discloses a biomass fuel combustion stove without dust discharged from a fire port and a combustion method thereof. The stove comprises a stove base, a stove body and a stove surface; the stove body is arranged on the stove base, the stove surface is arranged at the top of the stove body, a middle sleeve, an inner stove chamber and a combustion chamber are arranged in the stove body,the inner stove chamber is arranged inside the middle sleeve, and a fuel gas channel allowing the gas flow to pass through is formed between the inner stove chamber and the middle sleeve; the combustion chamber is arranged at the middle upper part of the stove body and is located in the fuel gas channel between the inner stove chamber and the middle sleeve, a smoke discharging channel allowing the smoke to pass through is formed between the middle sleeve and the stove body, a smoke outlet and a fuel filling port are further formed in the stove body, the fuel filling port communicates with thecombustion chamber, and the smoke outlet is formed in the middle lower part of the stove body and communicates with the smoke discharging channel; and an air inlet is further formed in the stove body, and the air inlet communicates with the combustion chamber through an air pipe. By adopting the combustion stove and the combustion method, the structure is simple, the use is convenient, no dust isdischarged from the fire port of the combustion stove after combustion, and the stove and the method are suitable for being vigorously popularized and used.

Owner:黄学新

Elevator production metal plate machining equipment

PendingCN113084258ANo offsetHigh precisionFeeding apparatusPositioning apparatusGear wheelElectric machinery

The invention discloses elevator production metal plate machining equipment. The elevator production metal plate machining equipment comprises an outer frame, a machining table and a mounting plate, a fixing mechanism is arranged on the top wall of the machining table, a machining groove is formed in the outer frame, a connecting plate is fixedly mounted on the inner bottom wall of the machining groove, a mechanism groove is jointly formed between the connecting plate and the machining groove, and three first lead screws which are arranged in parallel are rotationally connected to the top wall of the connecting plate. According to the elevator production metal plate machining equipment, a driving motor drives a rotating rod to rotate, at the moment, a first bevel gear and a second bevel gear are meshed to rotate, then first lead screws are driven to rotate to be matched with first ball nuts, connecting rods are driven to move, the height of a machining table and the height of an air blower are adjusted at the same time, and it is guaranteed that metal plate cutting work is smoothly conducted; and the air blower generates flowing air from left to right, metal plate waste generated by cutting on the machining table is blown into a collecting box, and therefore centralized recycling of the metal plate waste is achieved, and centralized treatment of the metal plate waste is facilitated.

Owner:诸校军

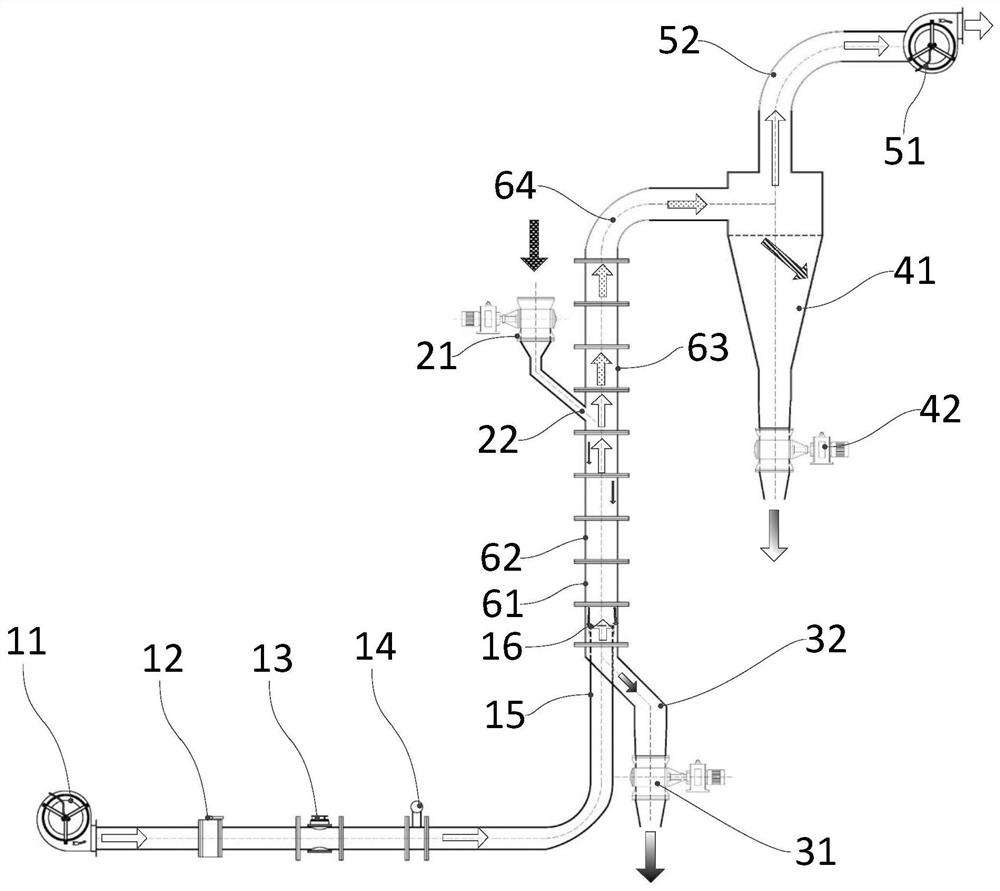

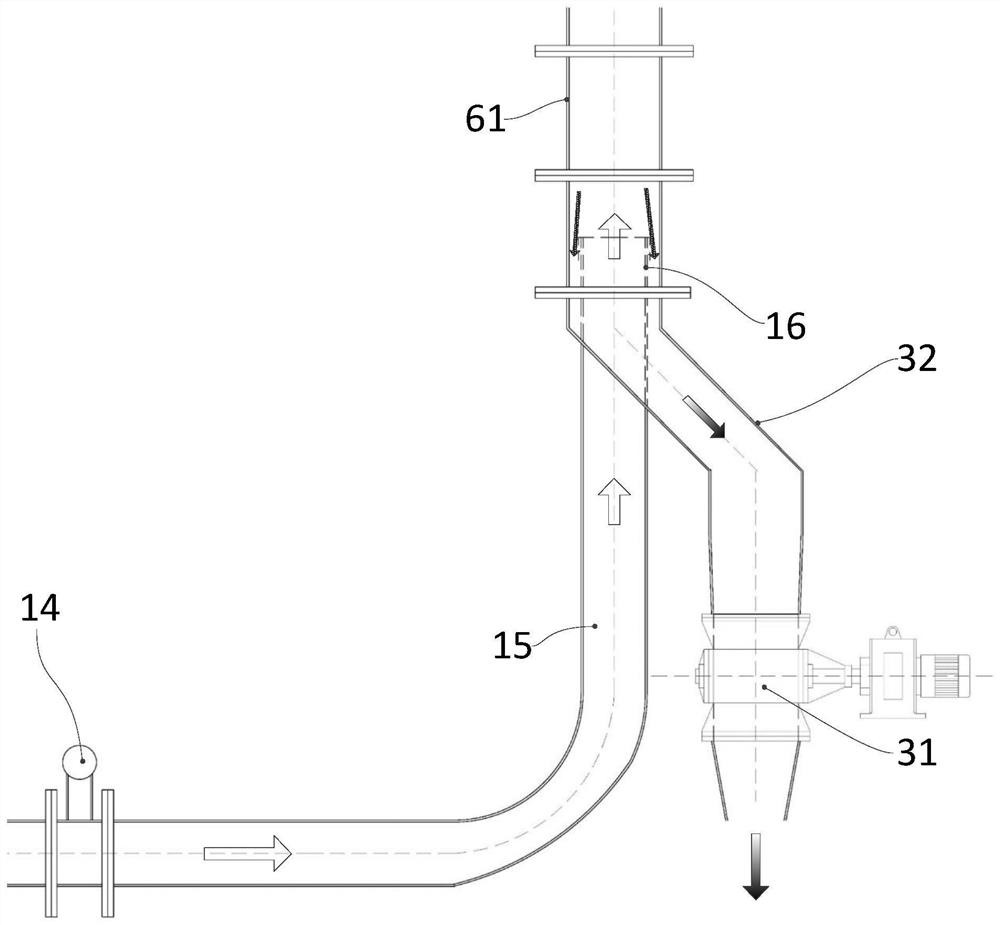

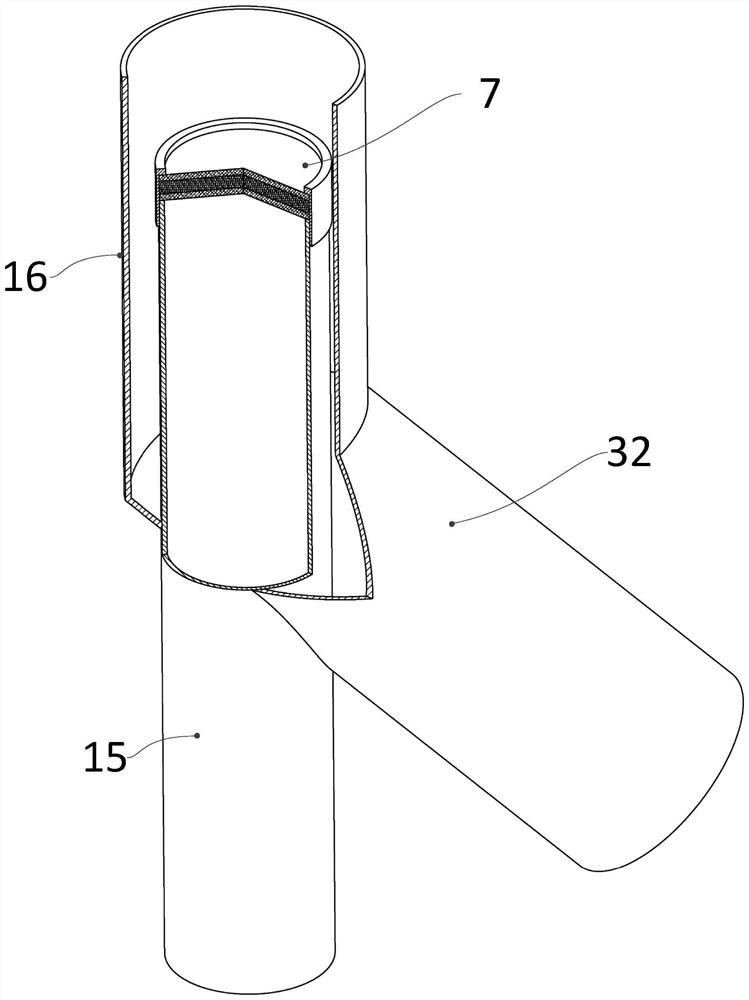

Active pulsating air flow sorting system

PendingCN111804587ARealize sortingRealize centralized recyclingGas current separationVortex flow apparatusDust controlCopper foil

The invention relates to an active pulsating air flow sorting system. The system comprises a sorting air flow generating segment, a feeding segment, a first discharging segment, a second discharging segment, a dust removing segment and a sorting segment; the sorting air flow generating segment is horizontally arranged at the bottom; a feeding machine is arranged on the feeding segment; a feeding hopper is connected with the top of the feeding machine; a discharging port of the feeding machine is inwardly connected with the middle part of the sorting segment; the first discharging segment is arranged at the bottom of the sorting segment; the second discharging segment is a cyclone separator; an air inlet of an air inducing machine of the dust removing segment is connected with an air outletof the cyclone separator via an air ventilating bent pipe; and the sorting segment is a vertically arranged air duct. According to the active pulsating air flow sorting system, a special structural design is made based on size and specification of copper foil and aluminum foil contained in waste battery broken products, sorting and integral recycling of the two kinds of materials are realized, and the recycling efficiency is greatly improved.

Owner:JIANGSU HUAHONG TECH STOCK +1

DELL-series carrier collecting and treating method

InactiveCN104238333ARealize centralized recyclingQuality improvementElectrography/magnetographyIndex testColored

The invention aims to provide a DELL-series carrier collecting and treating method which is high in recovery rate. The method comprises the following steps of classifying residual DELL-series colored carbon powder according to the models of products in different carbon powder boxes, and centrally collecting the residual DELL-series colored carbon powder; analyzing the physical parameter of the residual colored carrier in each carbon powder box, and recording data; placing the residual carrier mixed carbon powder into a testing toner cartridge to test, and recording the test data; comparing the test data obtained in the former step with standard data to obtain the physical characteristic of carriers with defects; treating the carrier according to the physical characteristic of the carrier with the defects; drying the carriers, coarsely sieving the carriers by using a filter sieve, adding negative conductive particles and a flow aid, mixing, and finely sieving the carriers by using a filter sieve; carrying out index test on a mixture of the treated carriers and the carbon powder, and recording data; and testing the carbon powder good in index test by using the toner cartridge to ensure that the carriers meet the application requirement. The DELL-series colored carbon powder collecting and treating method can be applied to the field of carbon powder treatment.

Owner:KOLION TECH

An organic fertilizer collecting device

The invention discloses an organic fertilizer collecting device. The organic fertilizer collecting device comprises a urine pool fixedly arranged on a wall body, a urethra tube connected with a urine collecting cylinder and a connecting tube connected with a dirt discharge system; a placing cavity is arranged in the ground surface; a rotating frame is rotatably arranged at the right lower end of the placing cavity by using a rotating pin shaft; a first through connecting hole is formed in the left end of the rotating frame; a collecting device is fixedly arranged at the lower end of the placing cavity; the collecting device comprises a first sleeve shell; a first cavity is formed in the first sleeve shell; a first barrier plate is fixedly arranged in the first cavity; the first barrier plate separates the first cavity into a first upper cavity and a first lower cavity; a first sliding block is arranged in the first lower cavity in an up-and-down sliding mode; a first top arm is fixedly arranged at the middle end of the upper end surface of the first sliding block; the upper end of the first top arm penetrates through the first barrier plate and the first sleeve shell and penetrates into the placing cavity; a second through connecting hole for connecting the first upper cavity and the first lower cavity is formed in the first barrier plate in a bilateral symmetry mode.

Owner:河北跃洋生物科技有限公司

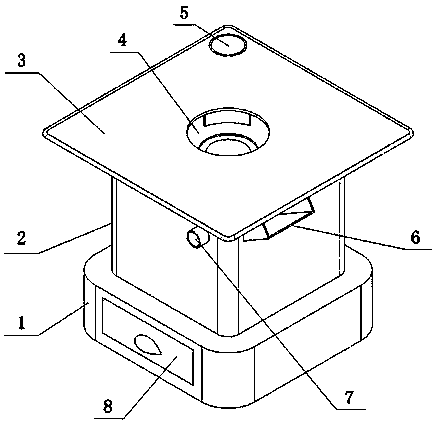

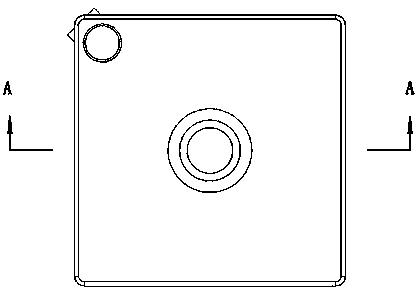

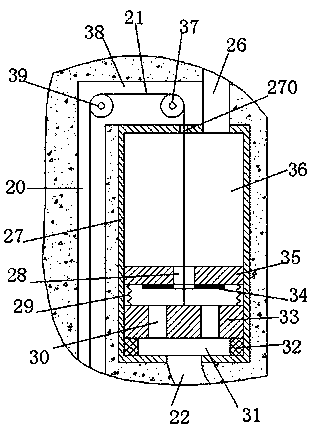

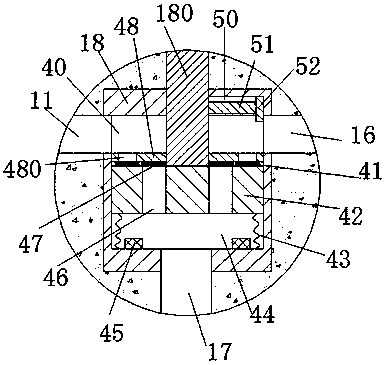

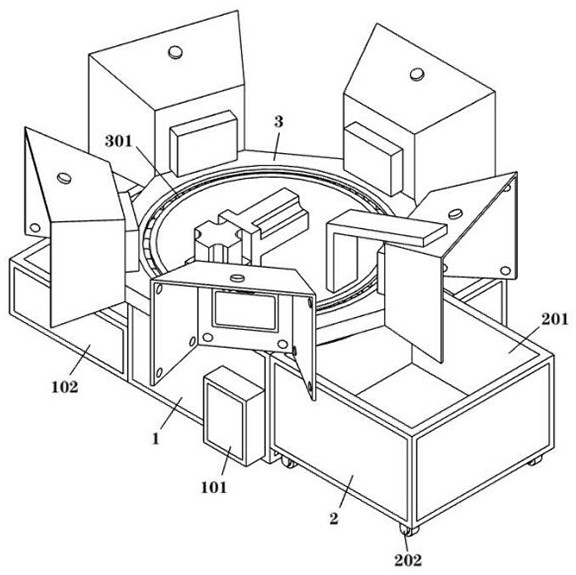

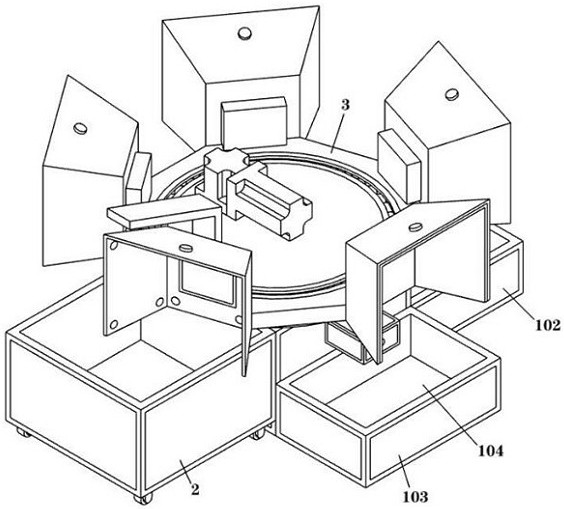

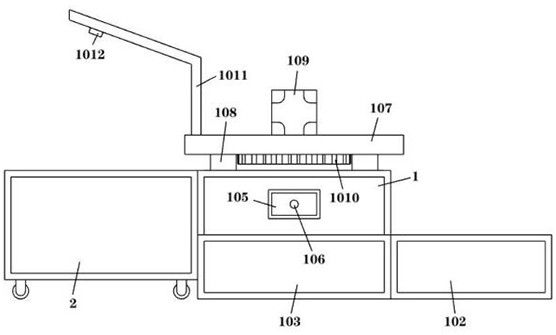

An infection-free nucleic acid detection device based on an intelligent robot

ActiveCN113628625BReduce labor intensityAvoid contactSurgical needlesVaccination/ovulation diagnosticsNucleic acid detectionEngineering

The invention provides an infection-free nucleic acid detection device based on an intelligent robot, which relates to the technical field of nucleic acid detection and solves the problem of nucleic acid detection. Generally, medical personnel wearing protective clothing perform nucleic acid sampling on nucleic acid detection personnel one by one. The sampling method The labor intensity is high, which has caused a great burden to the medical staff. An infection-free nucleic acid detection device based on an intelligent robot, including a bearing base, the rotating block has a decagonal block structure as a whole, and a set of nucleic acid detection auxiliary mechanisms are fixedly installed on five of the ten side end faces of the rotating block. The infection-free nucleic acid detection device of the present invention abandons the previous method of nucleic acid sampling one by one by medical staff, adopts individual nucleic acid sampling, and assists individual nucleic acid sampling through a nucleic acid detection auxiliary mechanism, helping individuals succeed in individual nucleic acid sampling. The contact between medical staff and nucleic acid testing personnel also reduces the labor intensity of medical staff.

Owner:徐州智云安全技术研究院有限公司

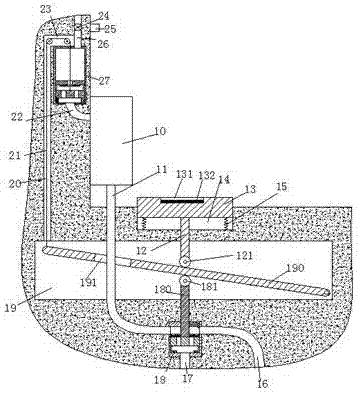

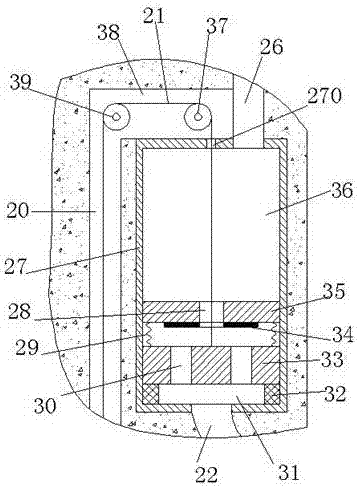

A kind of biomass fuel combustion equipment and combustion method thereof

ActiveCN103542400BRealize centralized recyclingAvoid cloggingRevolving grateSolid fuel combustionEngineeringCombustion process

The invention relates to biomass fuel burning equipment and a burning method thereof. The biomass fuel burning equipment comprises a burning furnace and a blowing device, a rotatable fire grate and a fire grate rotation driving device are arranged in the burning furnace, the fire grate comprises a circular bottom rotating plate, a plurality of groups of funnel caps, fireproof clay layers, an ash pipe and a sealing plate, wherein the funnel caps are arranged above the bottom rotating plate, the fireproof clay layers are paved on the funnel caps, the ash pipe is connected to the circular center of the bottom rotating plate, and the sealing plate is fixed at the outer edge of the bottom rotating plate. The biomass fuel burning equipment and the burning method thereof are applicable to assorted boilers, water heaters, air heaters and the like, and are used for burning biomass energy, fuel is uniformly arranged and suspended on the fire grate to burn after entering the burning furnace, and burning efficiency is high. Ash after power burning can be discharged completely from the ash pipe, an air inlet system is prevented from being blocked by the ash during burning, and the ash is collected and recycled, is convenient to clean and free of affection on the environment.

Owner:泉州超然热能设备发展有限公司

Multi-grade filtering tank for coating wastewater

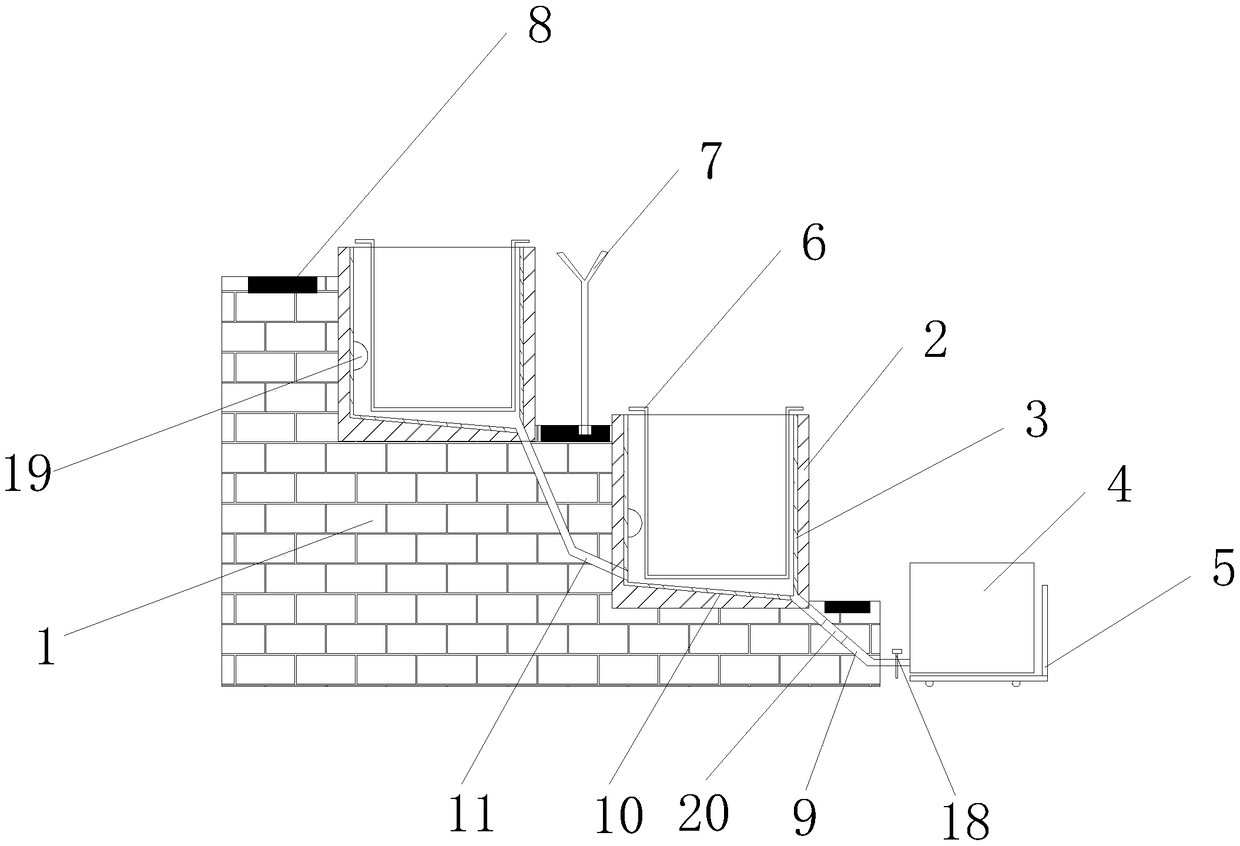

InactiveCN109231517ARealize centralized recyclingImprove structural strengthPaint waste treatmentTreatment involving filtrationBrickWastewater

The invention belongs to the technical field of coating and in particular relates to a multi-grade filtering tank for coating wastewater. The multi-grade filtering tank comprises a brick-made ladder platform, a filtering tank, a filtering net basket, a movable cart and a wastewater collection tank, wherein an anticorrosion layer is arranged on a tank surface of the filtering tank; the filtering tank comprises an inclined tank bottom; the ladder platform is provided with a blowdown pipe; the filtering net basket is arranged in the filtering tank; the wastewater collection tank is arranged on the movable cart; the wastewater collection tank is provided with a connection pipe with a switch; the movable cart is arranged at the outer side of the ladder platform. The multi-grade filtering tank for the coating wastewater is novel in structure; a dual filtering tank manner is adopted and the coating wastewater can be treated again; meanwhile, the filtering net basket is used for conveniently fishing dreg in the wastewater; the filtering net basket has high strength; an anti-collision structure is arranged and a vibration absorption effect is realized, so that the filtering tank can be prevented from being crashed; the filtering tank comprises the inclined tank bottom so that water is convenient to discharge; the wastewater collection tank is arranged and can realize centralized recycling of the wastewater.

Owner:重庆兴渝新材料研究院有限公司

Furniture plate production method

InactiveCN111319103APrecise positioningImprove stabilityOther plywood/veneer working apparatusWood compressionMechanical engineeringMaterials science

Owner:重庆德沃木制品加工有限公司

Cable recovery system for electric power engineering

InactiveCN113470902AEasy separationImprove recycling efficiencyBasic electric elementsApparatus for removing/armouring cablesPower engineeringStructural engineering

The invention discloses a cable recovery system for electric power engineering, and relates to the technical field of electric power engineering equipment. A peeling mechanism is arranged in the middle of a mounting platform; cable tensioning mechanisms are arranged on the mounting platform on the two sides of the peeling mechanism; a first guide mechanism and a second guide mechanism are respectively arranged on the mounting platform on two sides of the two cable tensioning mechanisms; the first guide mechanism comprises a first guide roller; the second guide mechanism comprises a second guide roller and a third guide roller; a discharging mechanism is arranged on the mounting platform on one side of the first guide mechanism; and a material receiving mechanism I and a material receiving mechanism II are arranged on the mounting platform on one side of the second guide mechanism. According to the invention, through the cable recycling and peeling device composed of the peeling mechanism, the cable tensioning mechanism, the guiding mechanism, the discharging mechanism and the receiving mechanism, the cable core and the rubber layer of the waste or scrapped cable can be rapidly separated.

Owner:南京勤扬机电科技有限公司

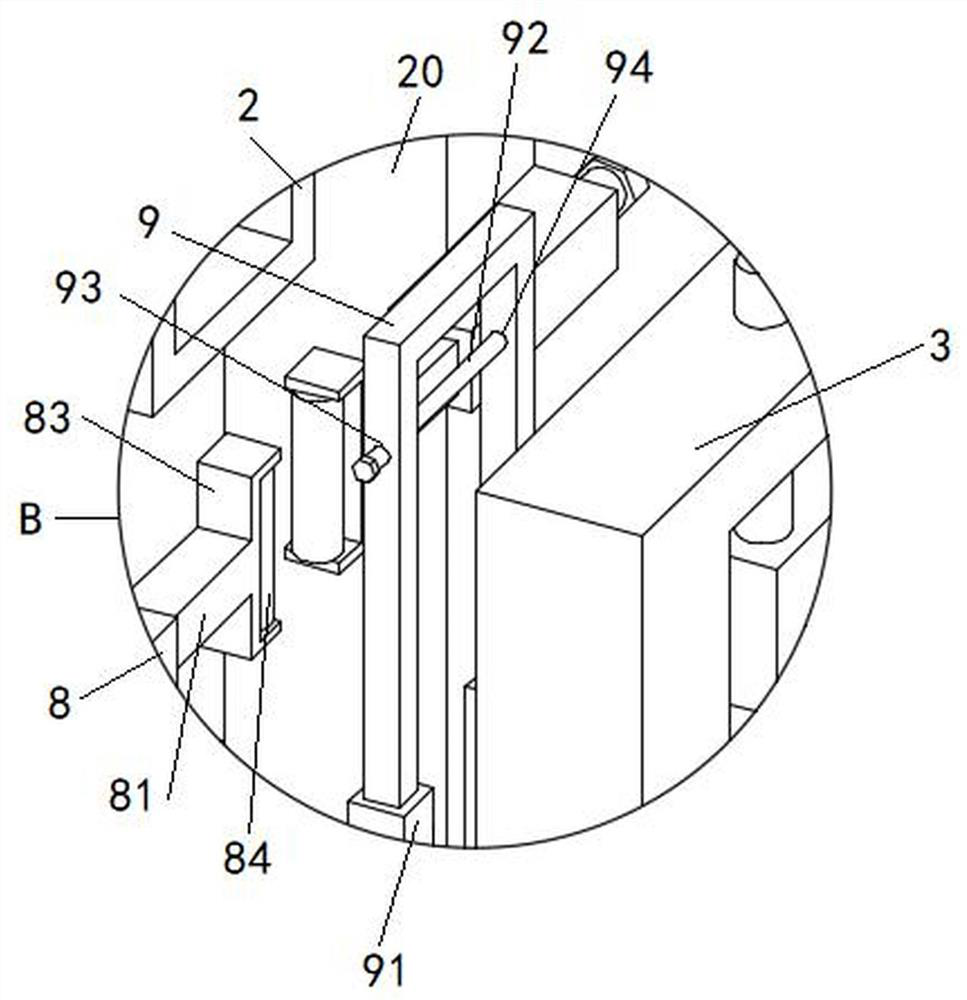

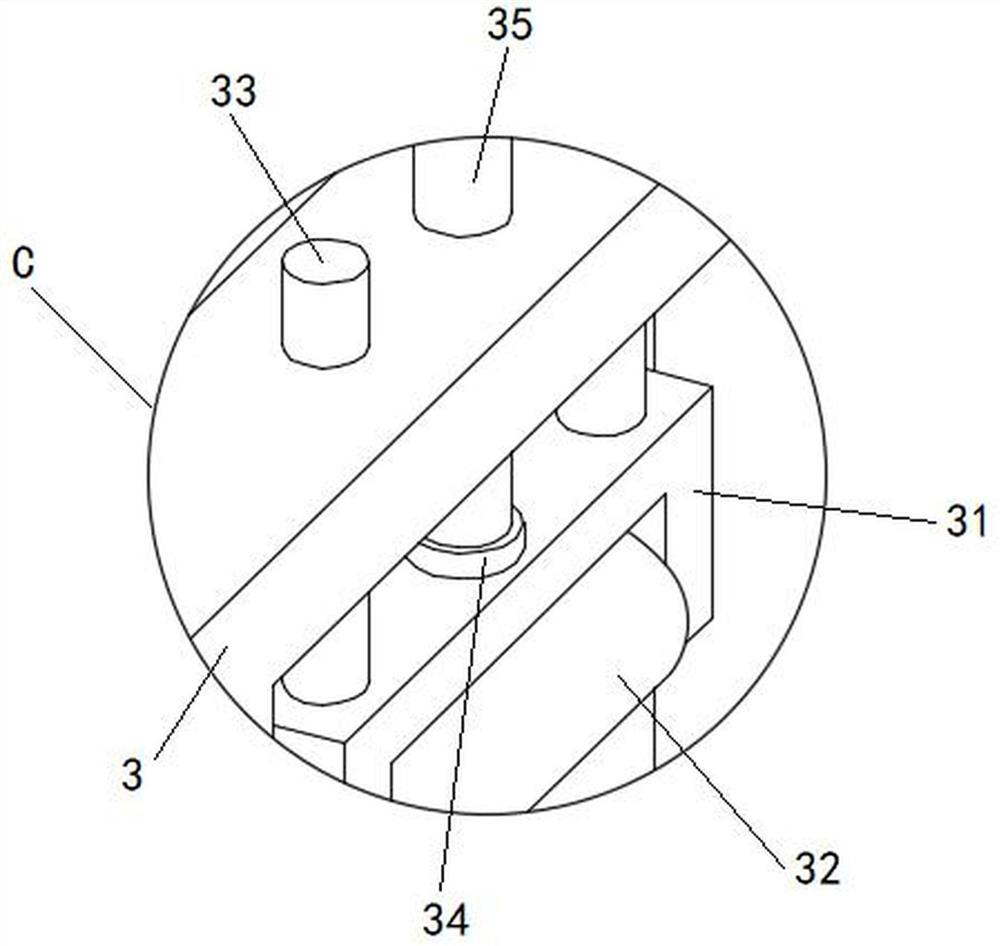

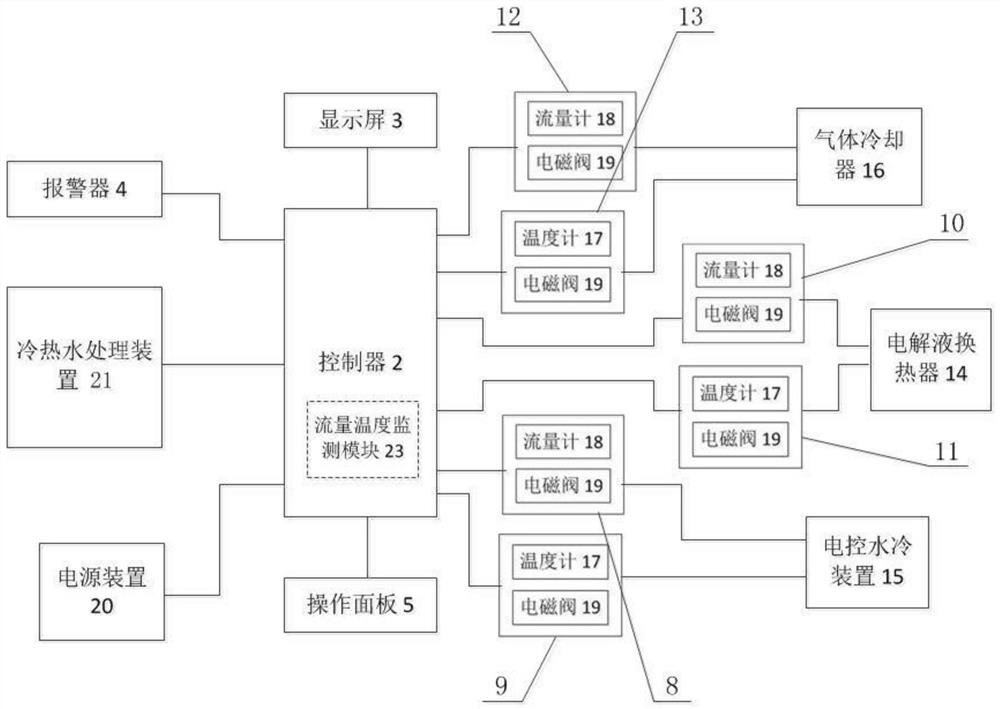

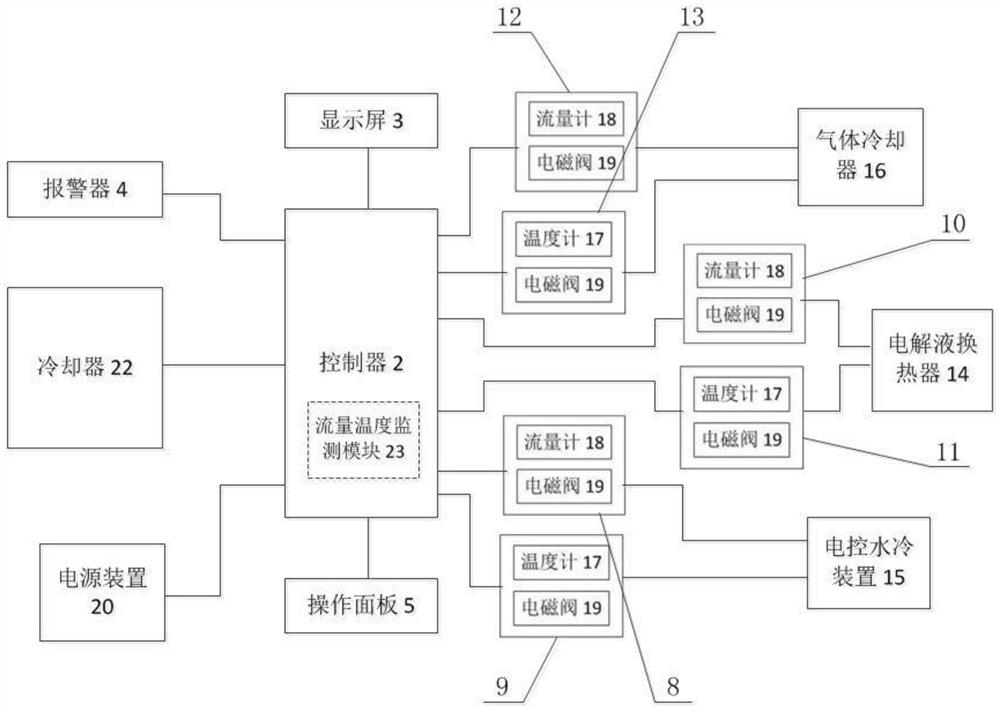

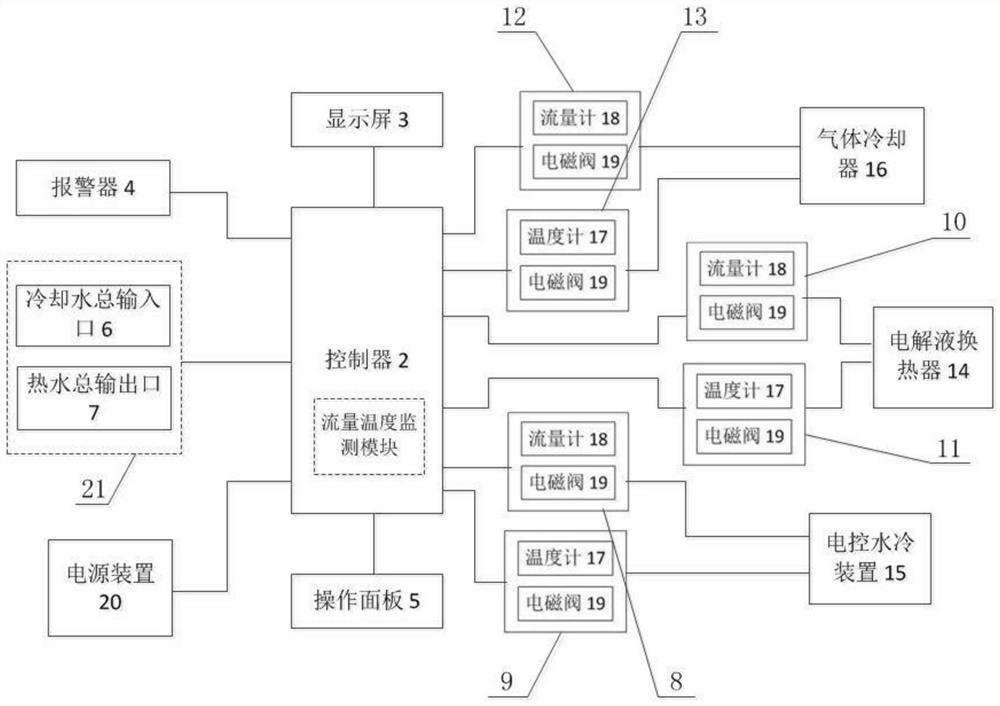

Waste heat recovery management and control platform of large-scale alkaline water electrolysis hydrogen production device

PendingCN114807960AImprove processing efficiencyRealize centralized recyclingElectrolysis componentsSimultaneous control of multiple variablesElectrolytic agentGas cooler

The invention discloses a waste heat recovery management and control platform of a large-scale alkaline water electrolysis hydrogen production device, which comprises a platform body and a controller arranged in the platform body, the first cooling water supply port, the first hot water recovery port, the second cooling water supply port, the second hot water recovery port, the third cooling water supply port and the third hot water recovery port are all arranged on the platform body, and the electric control water cooling device, the electrolyte heat exchanger and the gas cooler are correspondingly connected with the supply ports and the recovery ports. The power supply device is arranged in the platform body and connected with the controller, the cold and hot water treatment device is connected with the controller, each supply port is provided with an electromagnetic valve, each recovery port is provided with a thermometer, and the thermometers and the electromagnetic valves are connected with the controller. According to the management and control platform, centralized recovery of waste heat is achieved, the heat treatment efficiency is improved, the temperature in the hydrogen production process is adjusted by adjusting the flow, and the whole recovery adjustment control process is stable and accurate.

Owner:SICHUAN HUANENG HYDROGEN TECH CO LTD +9

Waste recovery device for civil engineering

InactiveCN112122165AEliminate potential safety hazardsTo achieve the purpose of recycling iron wasteSortingConvertersMedicine

The invention discloses a waste recovery device for civil engineering. The waste recovery device comprises a vertical plate, a bottom plate and a top plate, the top surface of the vertical plate is connected with the top plate, the bottom surface of the vertical plate is connected with the bottom plate, and the vertical plate, the top plate and the bottom plate form a U shape. A first metal sensor, a second metal sensor, a first suction device and a second suction device are arranged on the bottom plate. A positioner, a converter, a controller and a display are respectively arranged on the topplate. First, the first metal sensor is used for detecting iron waste on a construction site, then the second metal sensor is used for suction other metal on the construction site, a user starts andstops the first suction device or the second suction device to suck waste on the construction site, and the purposes of recycling the waste and eliminating potential safety hazards are achieved. The iron waste is sucked on a magnetic suction block, and the rest of the metal waste is sucked into a suction box by a suction machine, so that the purpose of classifying, sucking and recycling the metalwaste is achieved.

Owner:陕西工业职业技术学院

Improved type organic fertilizer collecting and taking device

InactiveCN107989146AWill not diluteRealize centralized recyclingUrinalsLavatory sanitoryEngineeringOrganic fertilizer

The invention discloses an improved type organic fertilizer collecting and taking device. The device comprises a urine pool fixedly installed on a wall body, a urethra pipe connected with a urine collecting tube, and a connecting pipe connected with a sewage discharging system; a placing cavity is formed in the ground, a rotating frame is rotatably mounted on the lower right end of the placing cavity through a rotation pin shaft, a first through connection hole is formed in the left end of the rotating frame, and the collecting and taking device is fixedly installed at the lower end of the placing cavity; the collecting and taking device includes a first casing shell, a first cavity body is formed in the first casing shell, a first baffle plate is fixedly installed in the first cavity body, the first baffle plate divides the first cavity body into a first upper cavity body and a first lower cavity body through obstruction, a first sliding block capable of sliding up and down is installed in the first lower cavity body, a first top arm is fixedly installed in the middle of the upper end surface of the first sliding block, the first top arm is in through connection with the first baffle plate and the first casing shell and penetrates into the first placing cavity, and second through connection holes communicated with the first upper cavity body and the first lower cavity body areformed in the first baffle plate in a bilateral symmetry mode.

Owner:广州正顺机械技术开发有限公司

A Broadband Distributed Vibration Energy Recovery System for Line-defect Phononic Crystals of Composite Materials

InactiveCN106130403BRealize centralized recyclingSolve the problem of narrow-band energy recoveryPiezoelectric/electrostriction/magnetostriction machinesPhotonicsEnergy recovery

The invention relates to a broadband distributed vibration energy recovery system with composite material line defect photonic crystals. The broadband distributed vibration energy recovery system comprises the composite material line defect photonic crystals, wherein the composite material line defect photonic crystals are embedded in a matrix through scatterers and are arranged in a periodical array in the matrix, in which one row of the scatterers are composite material line defect structures formed after polymer layers coat the defect scatterers, and the rest of the scatteres are lead cylinder scatterers. According to the system, the energy recovery system with great recovered energy and high conversion efficiency capable of realizing broadband distributed energy recovery can be obtained, the system can be used for realizing low-frequency broadband distributed vibration energy recovery of a naval ship structure, and self-powered energy is provided for naval ship system state monitoring wireless sensors and MEMS systems.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com