Broadband distributed vibration energy recovery system with composite material line defect photonic crystals

A vibration energy recovery and phononic crystal technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of unsatisfactory conversion efficiency and less energy recovery , to achieve the effect of large recovery energy and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

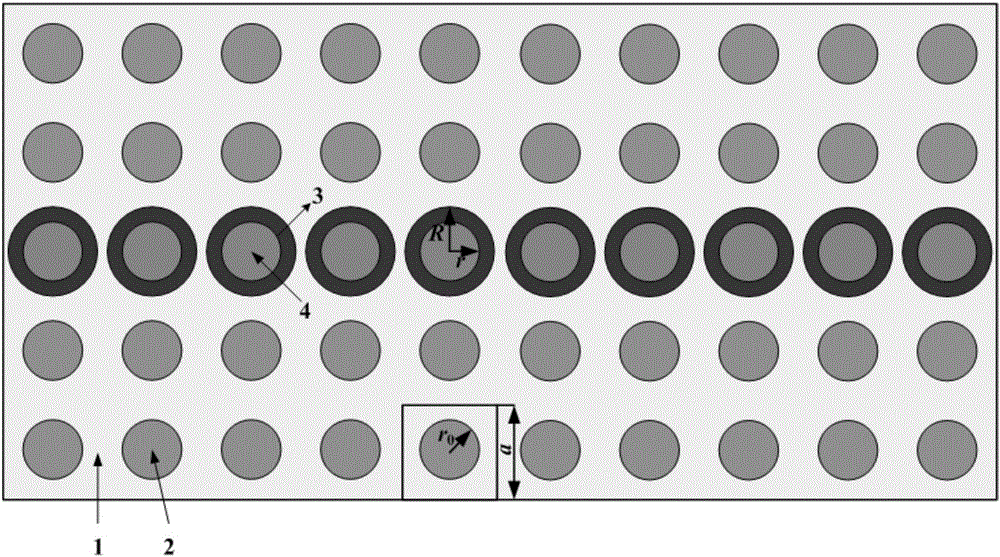

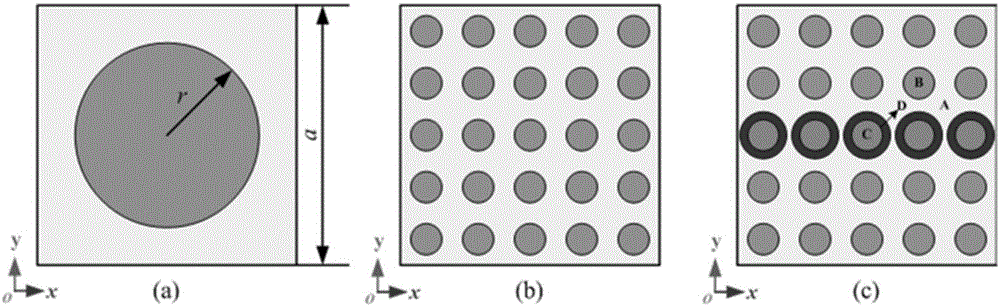

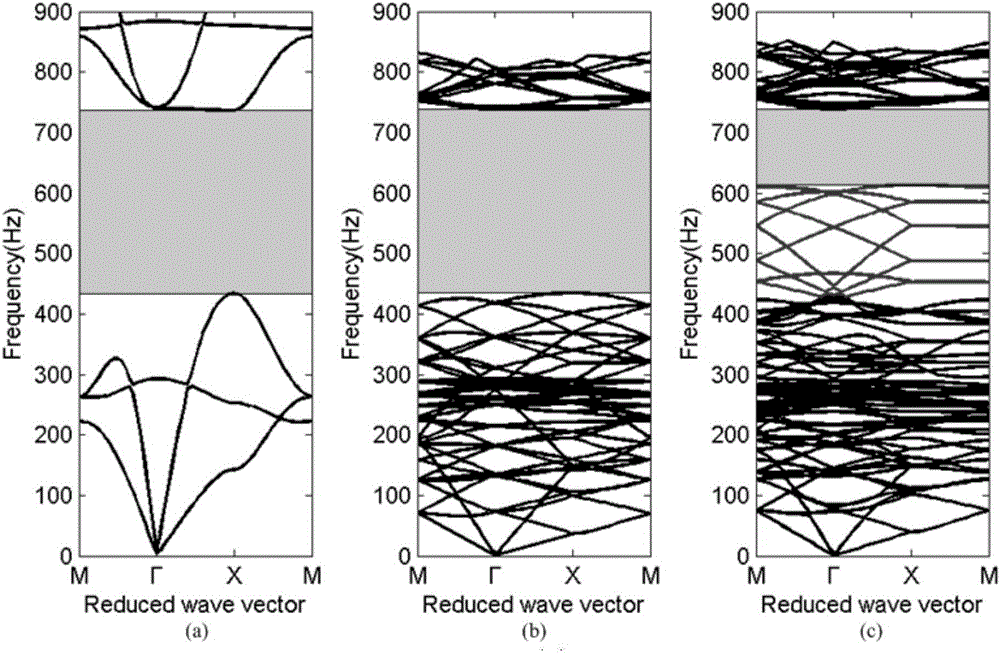

[0020] In the broadband distributed vibration energy recovery system based on the line-defect phononic crystal composite material according to the present invention, the ideal phononic crystal is formed by the lead column B distributed in the silicone rubber matrix A according to the periodic lattice of the square lattice, and the line The defective material is an aluminum core material composed of a silicon rubber D coated with an aluminum column C, and a piezoelectric material is embedded in the silicon rubber D to realize vibration energy recovery. The lattice constant of the ideal phononic crystal unit cell is a, the radius of the lead column scatterer is r; the radius of the aluminum column in the unit structure of the line defect material is r, and the radius of the silicone rubber D is R. figure 1 and figure 2 (c) is a schematic diagram of the structure of the line-defect phononic crystal composite material (structural parameters: a=10mm; r=3.5mm; R=4.5mm).

[0021] M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com