Multi-grade filtering tank for coating wastewater

A technology for paint wastewater and filter tank, applied in the field of paint, can solve the problems of low output, serious pollution, less conspicuous pollution, etc., and achieve the effects of novel structure, avoidance of crash and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

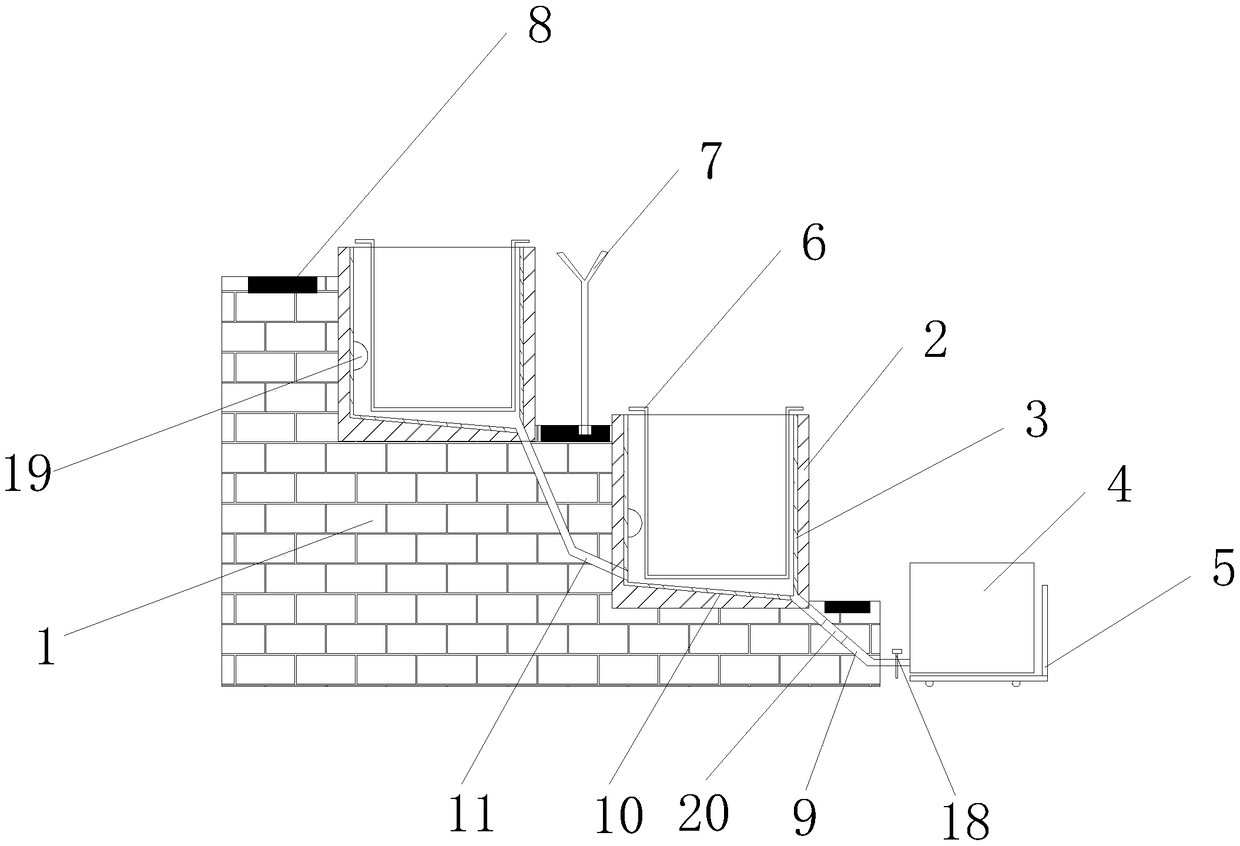

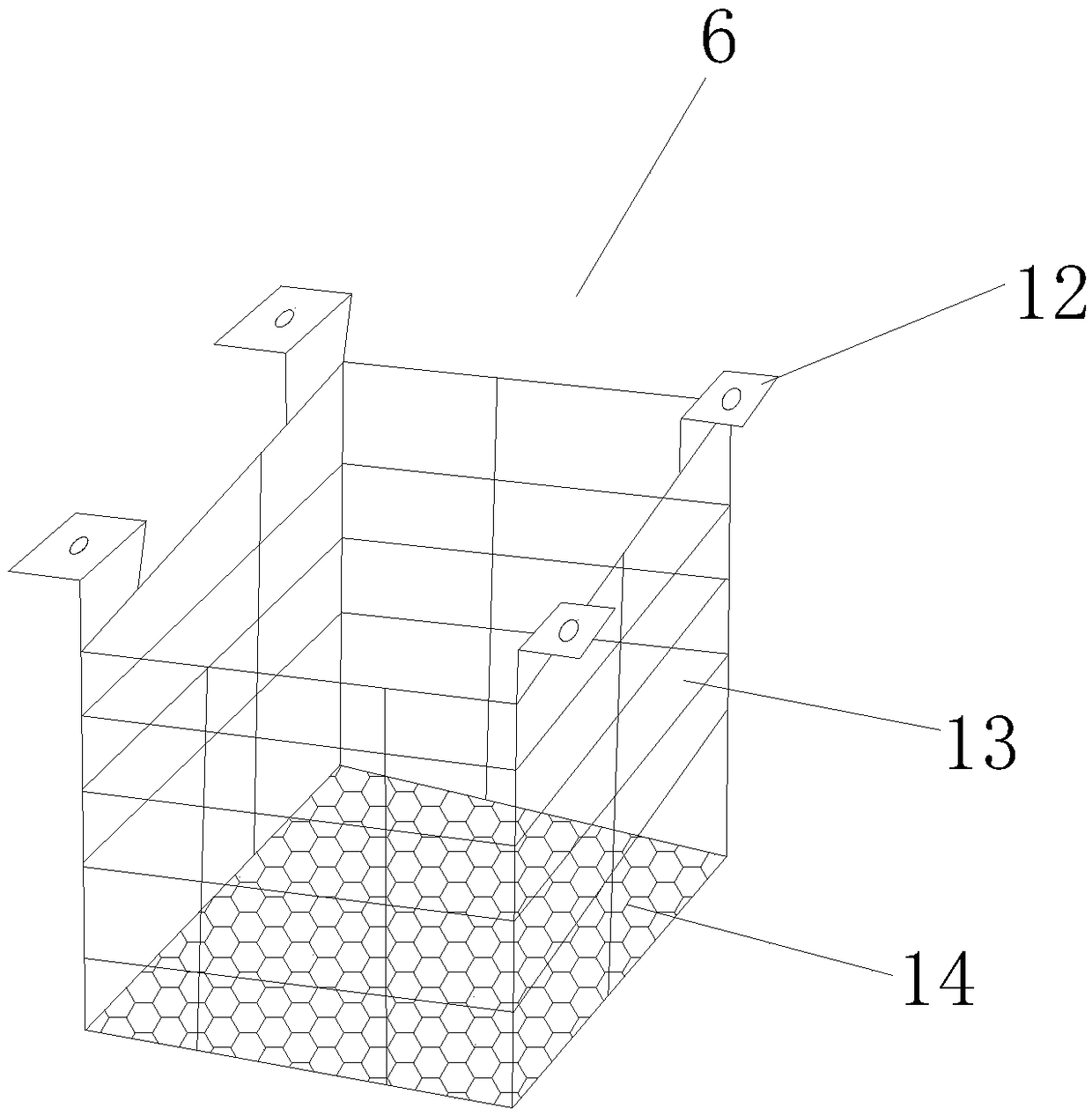

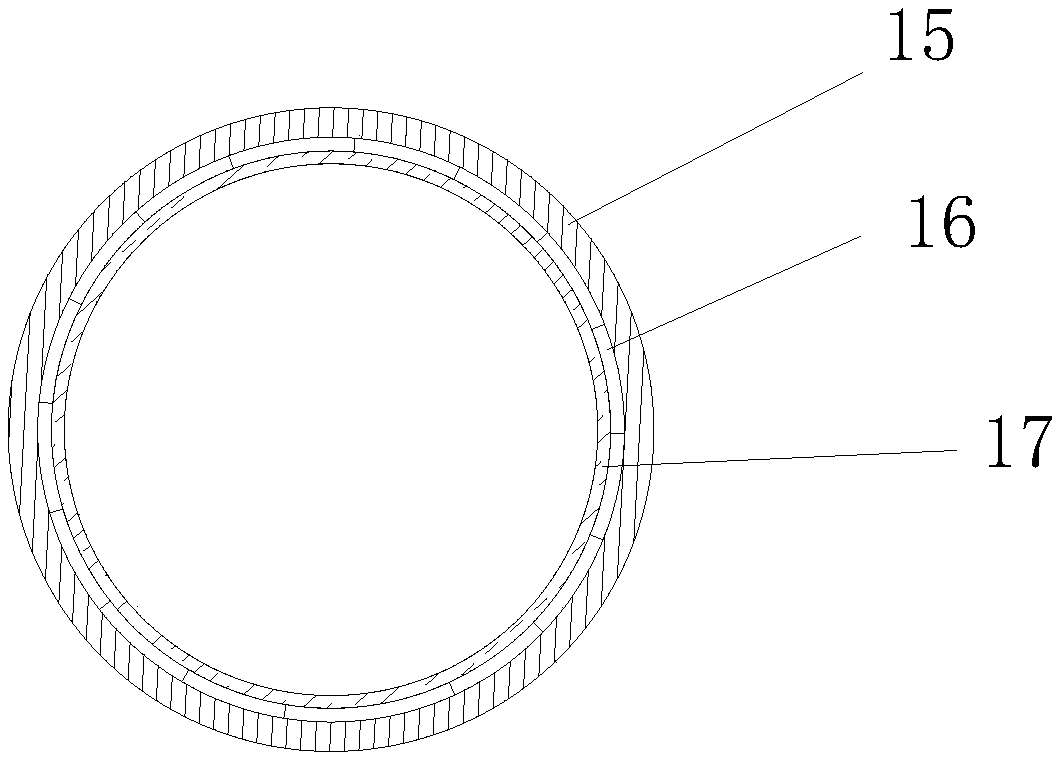

[0023] Such as Figure 1-5 Shown, a kind of paint waste water multi-stage filter pool, comprises brick manufacturing step platform 1, filter tank 2, screen basket 6, mobile trolley 5 and waste water collecting tank 4; Described step platform 1 contains the first step, the second Step and the third step, the second step and the third step are provided with a filter tank 2 near the position of the wall; the inner wall of the filter tank is provided with a mounting plate, and the mounting plate is fixed to the inner wall of the filter tank by bolts; on the mounting plate An air flotation machine 19 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com