Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

539results about How to "Easy to salvage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

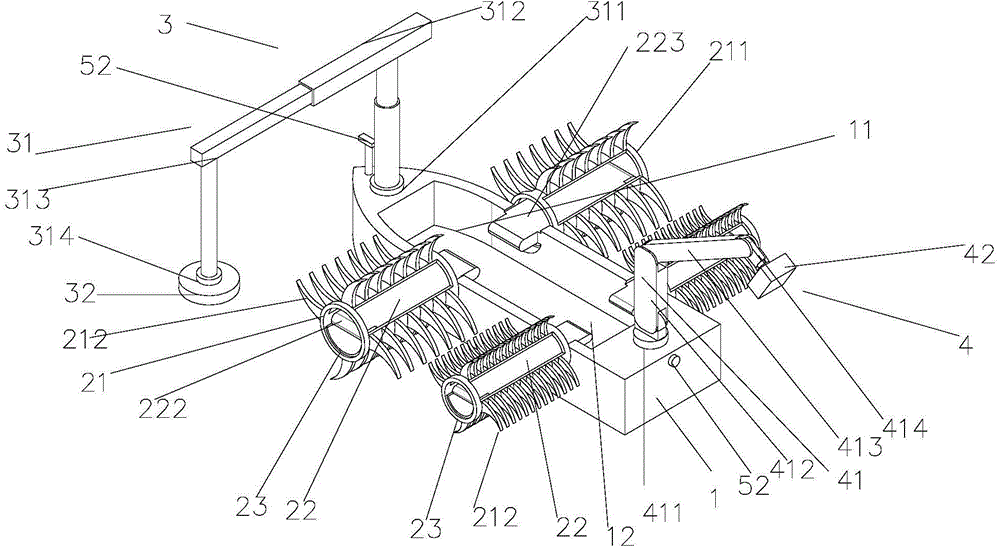

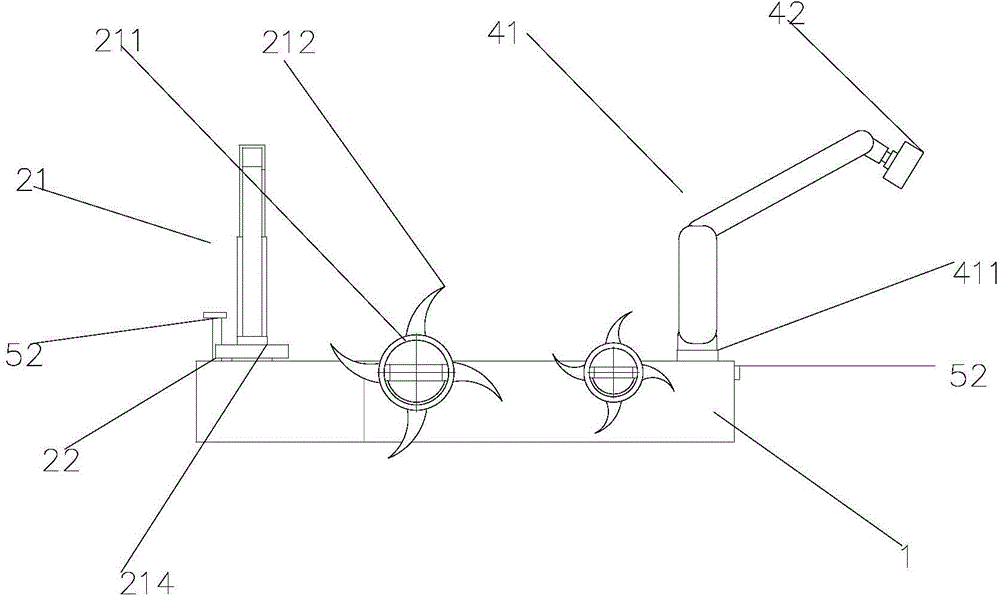

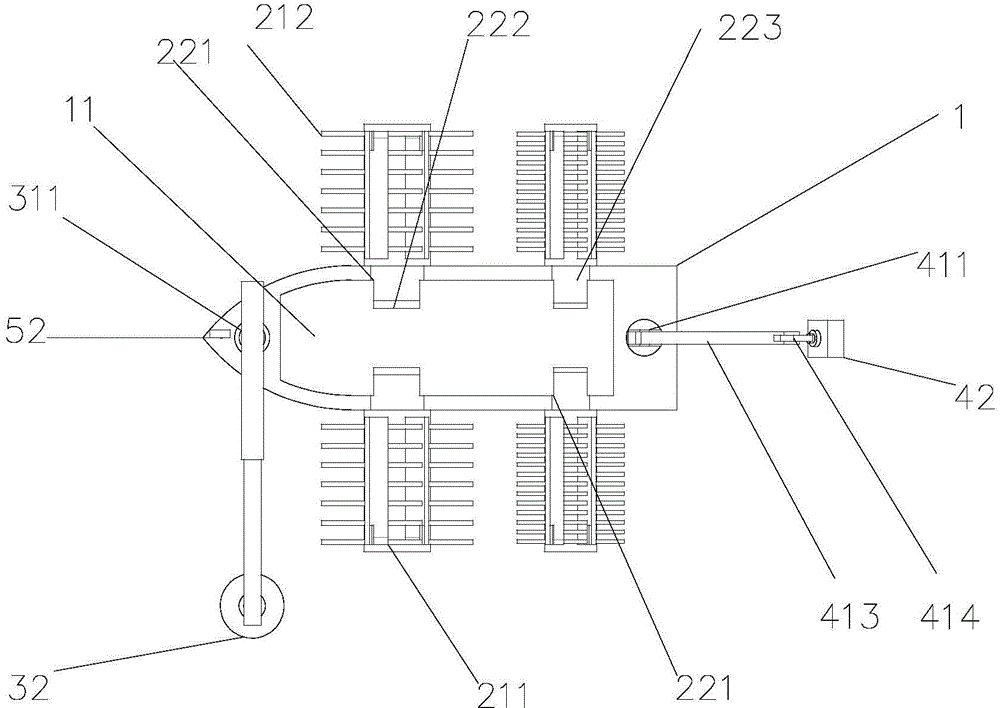

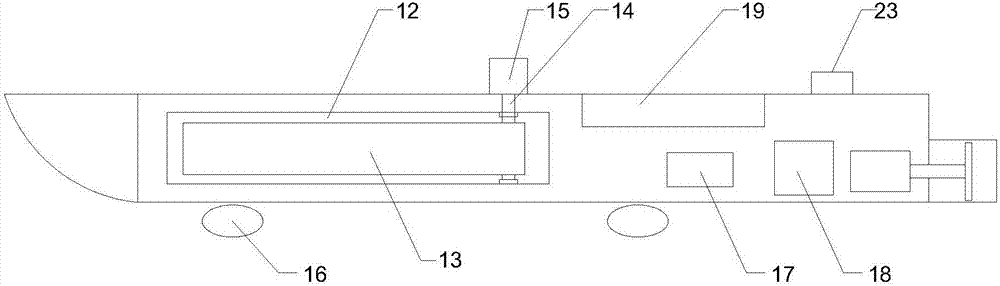

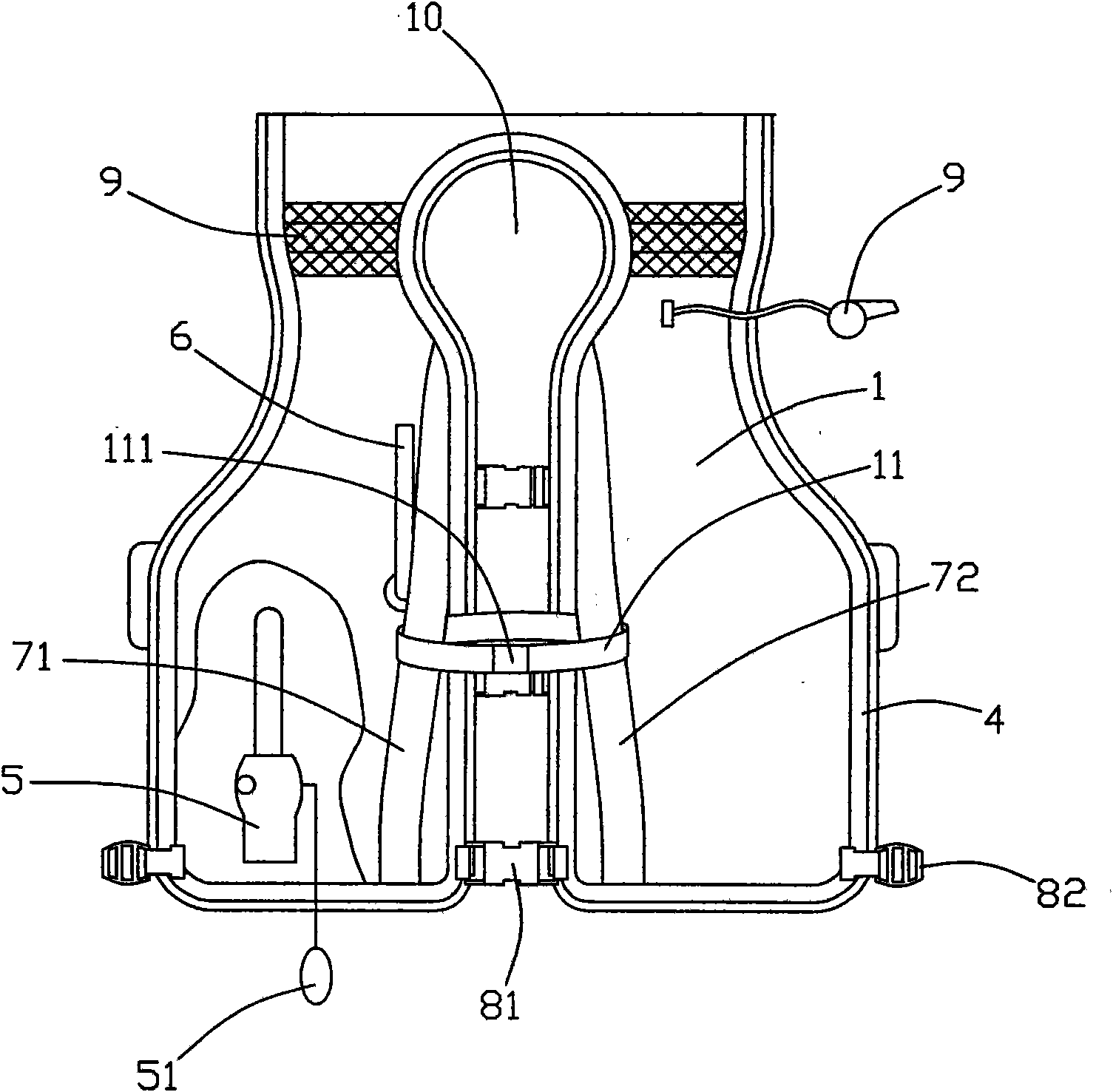

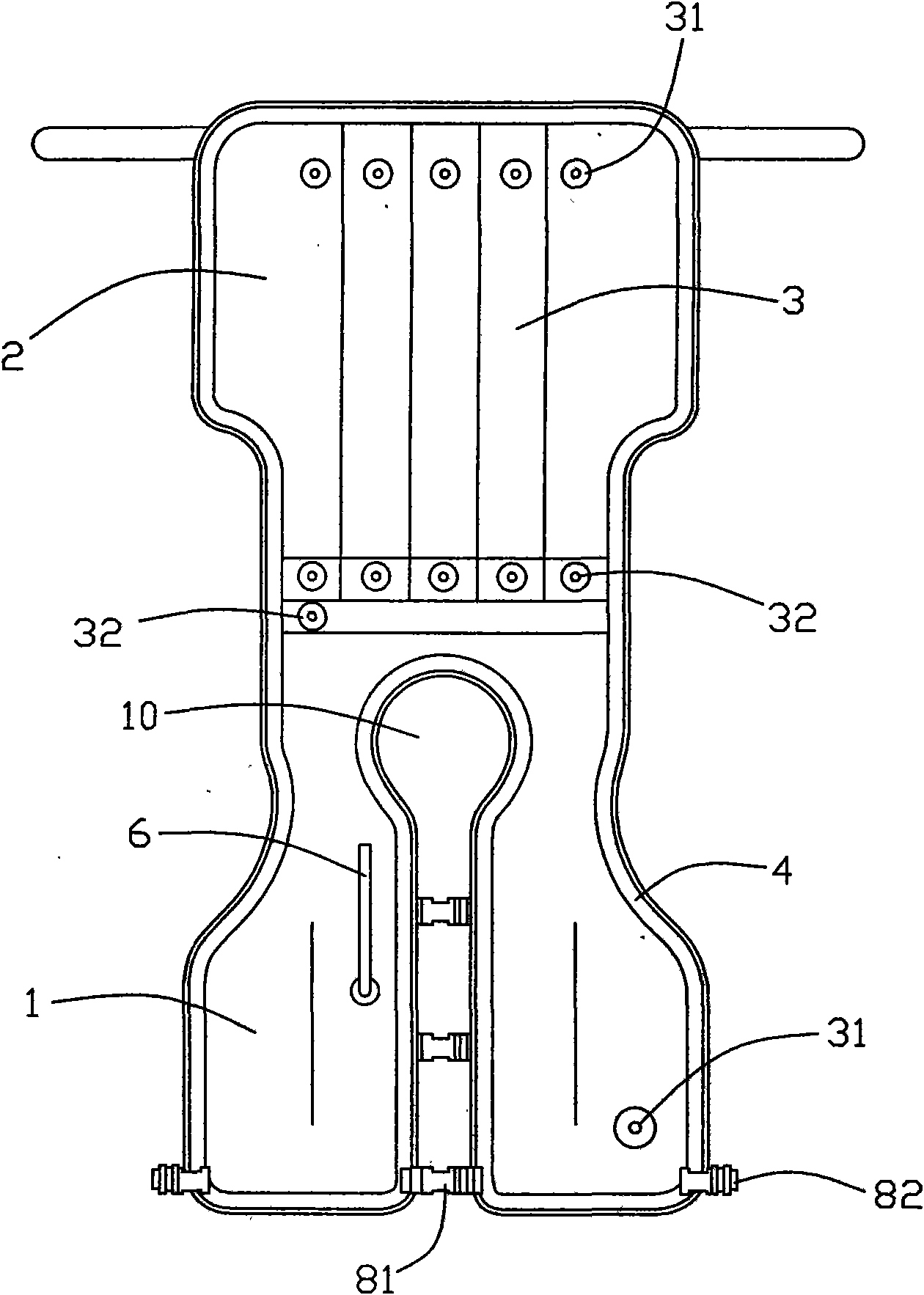

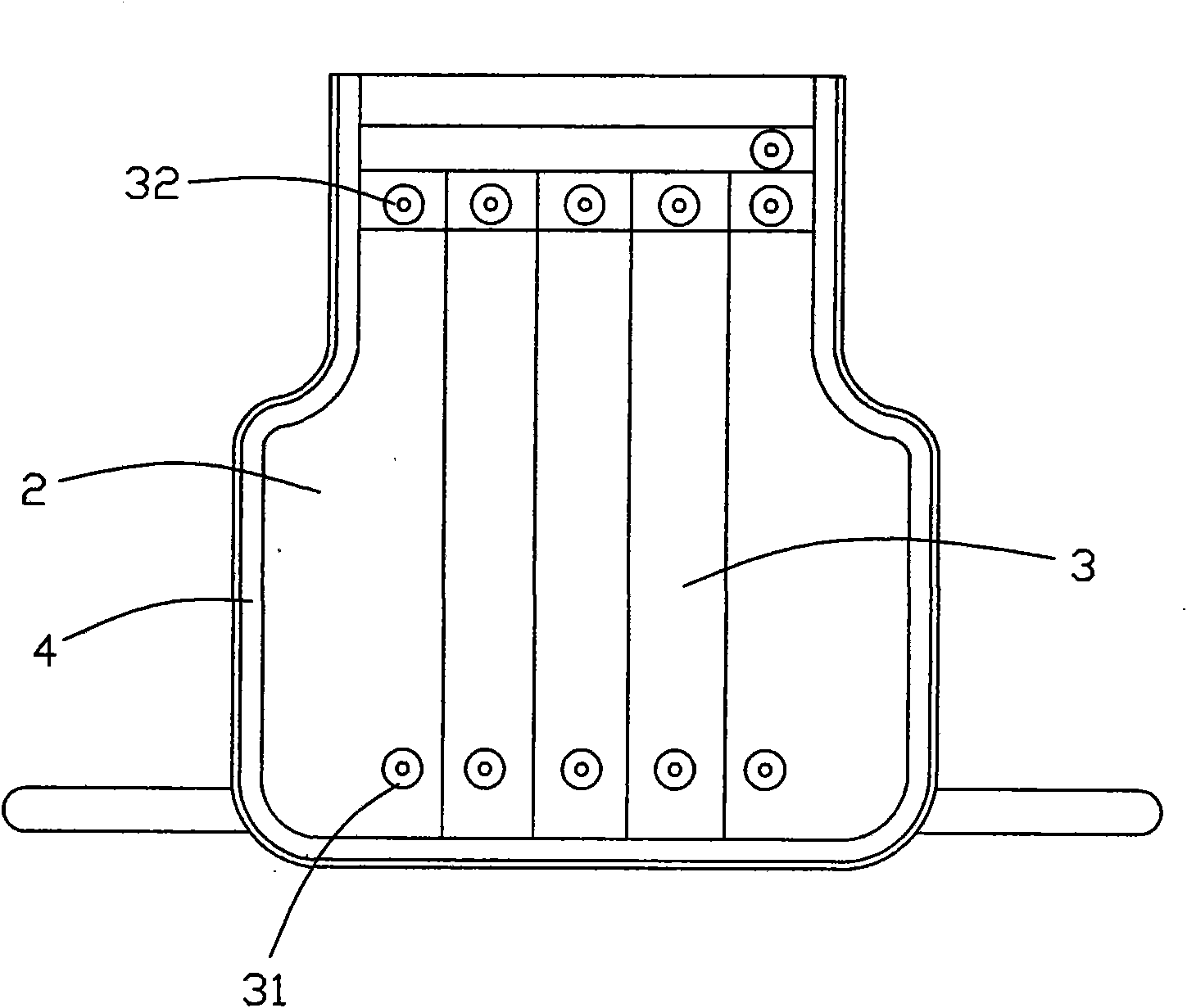

Environment-friendly type river and lake controlling and cleaning equipment

ActiveCN106759196APlay a dredging roleKeep water cleanWater cleaningWaterborne vesselsCompression deviceWater quality

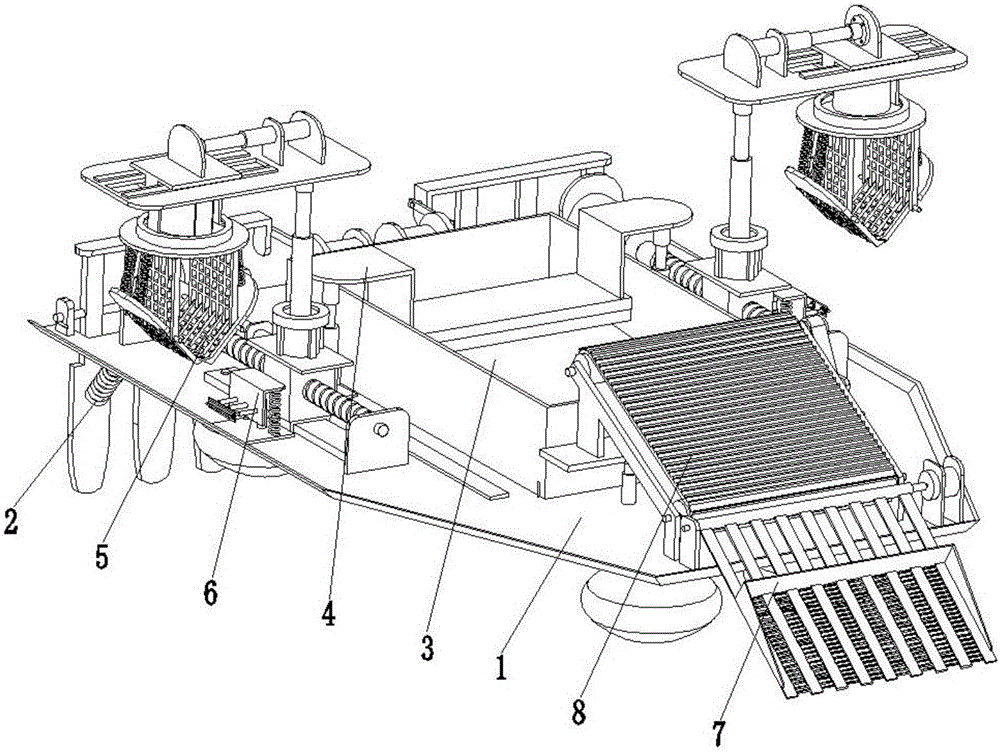

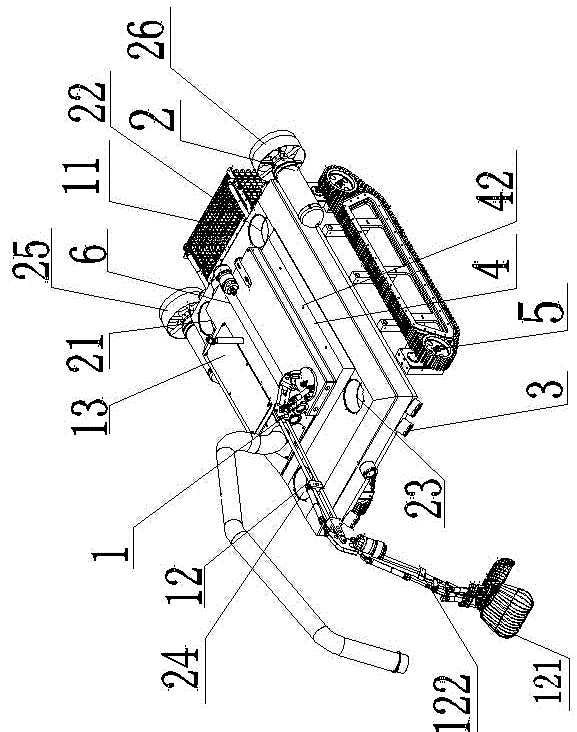

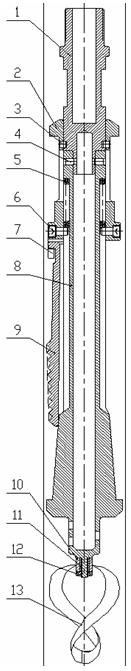

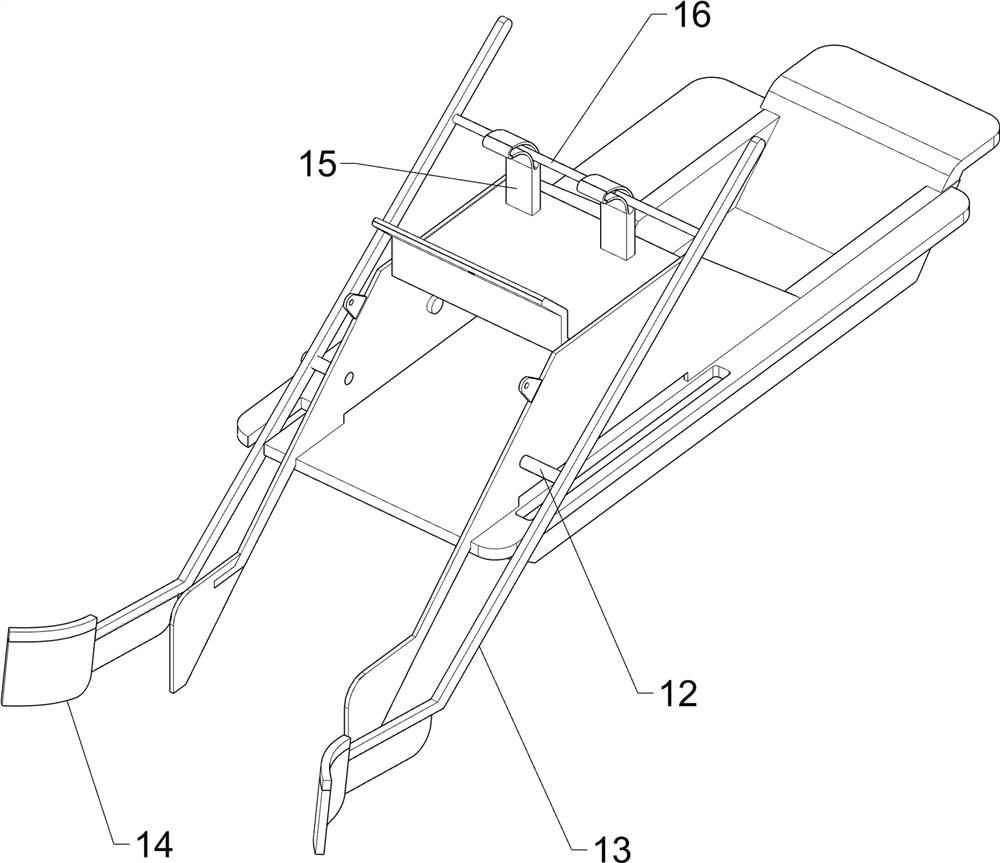

The invention relates to environment-friendly type river and lake controlling and cleaning equipment. The environment-friendly type river and lake controlling and cleaning equipment comprises a boat body, power devices, a storage slot, a compression device, movable gripping devices, cut-off devices, a salvaging device and a conveying device, wherein the power devices are symmetrically mounted at the left side and the right side behind the boat body separately along the longitudinal central axis of the boat body; the compression device is positioned above the storage slot; the movable gripping devices are separately positioned at the left side and the right side of the compression device; the cut-off devices are positioned at the outer sides of the movable gripping devices; the salvaging device is positioned in front of the boat body; and the conveying device is positioned between the salvaging device and the storage slot. The environment-friendly type river and lake controlling and cleaning equipment integrates the functions of floating force adjusting, water-surface travelling, waste compacting, aquatic plant gripping, garbage salvaging, garbage conveying and the like, realizes the functions of eliminating aquatic plants in rivers and lakes as well as floating waste on the water surface, achieves the effect of dredging the rivers and the lakes, keeps water in the rivers and the lakes clean, is high in integral mechanical degree, is complete in function and is high in operating efficiency.

Owner:广东祥实建设有限公司

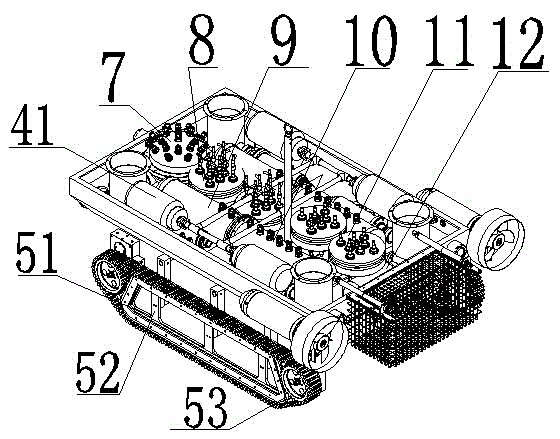

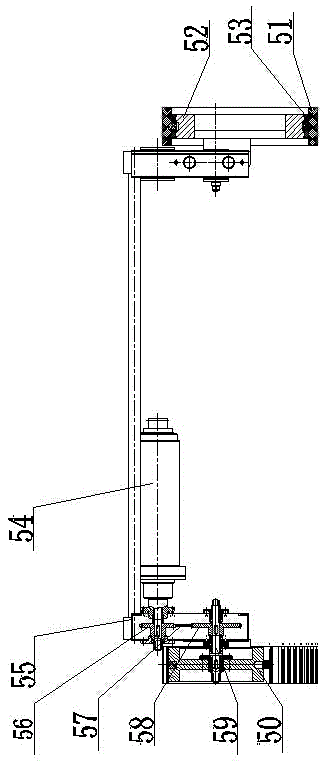

Multifunctional operation type underwater robot

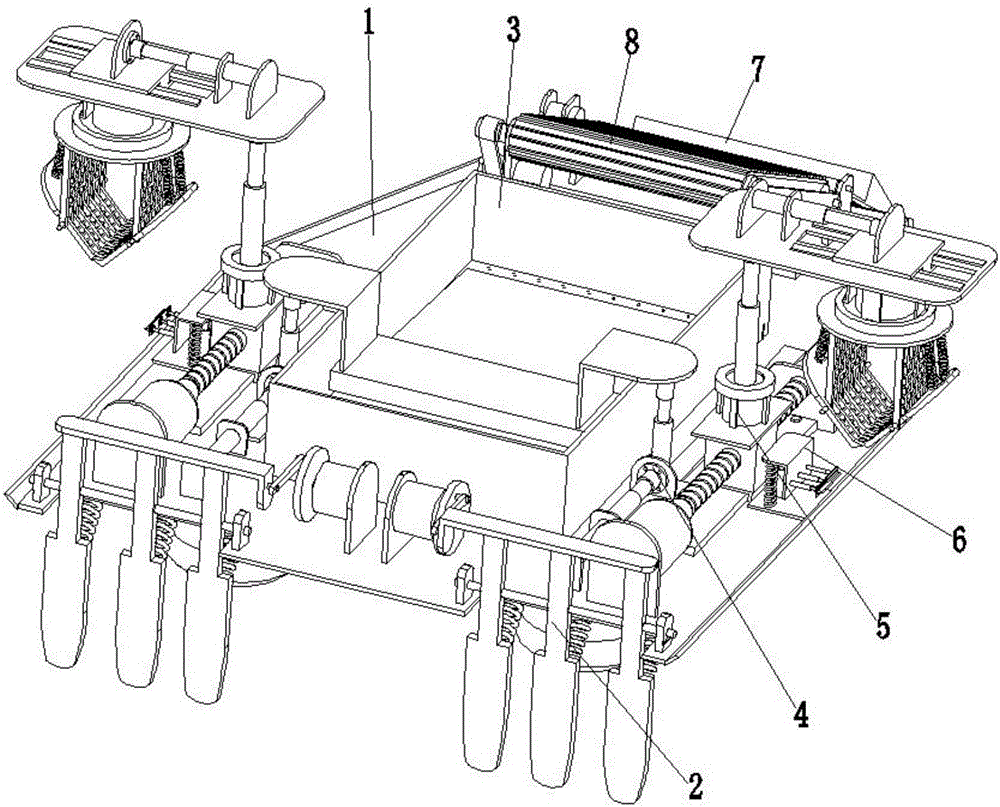

A multifunctional operation type underwater robot comprises a picking device, driving devices, camera shooting and illumination devices, floating devices, a walking device and a shell. The picking device is arranged on the top of the shell. The four corners and the tail of the shell are provided with the driving devices. The floating devices are distributed at the four corners and the two sides of the shell. The camera shooting and illumination devices are fixed to the picking device and the shell. The walking device is arranged at the lower portion of the shell. The underwater robot has the function of accurate seabed positioning, has the advantages of facilitating fishing and being large in range, meanwhile, can dynamically adjust buoyancy and is strong in cross-country capacity.

Owner:QINGDAO SEA ROBOT CO LTD

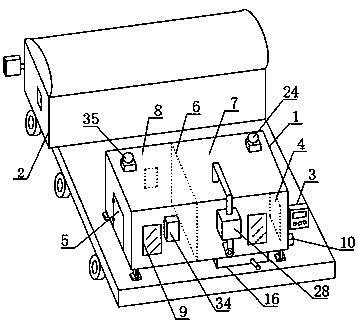

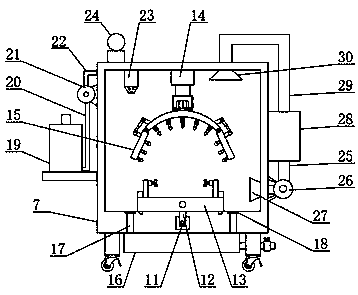

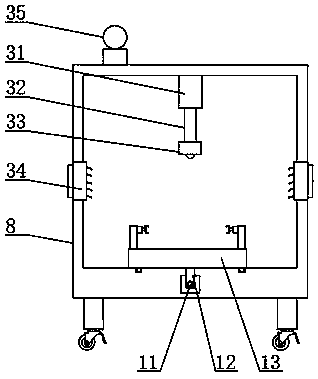

Mobile environment-friendly paint spraying booth

InactiveCN109604101AEasy to paintImprove painting efficiencyPretreated surfacesCoatingsHydraulic cylinderInternal cavity

The invention discloses a mobile environment-friendly paint spraying booth in the technical field of paint spraying. The paint spraying booth comprises a paint spraying booth body and a transport vehicle; an inner cavity of the paint spraying booth body is divided by a dividing plate into a paint spraying chamber located on the right side and a drying chamber located on the left side; a driving mechanism is mounted in the center of the inner wall of the top of the paint spraying chamber; a dust sensor is mounted on the back side of the inner wall of the top of the paint spraying chamber; the top end of a filtering box is connected with the bottom end of an air inlet pipe; the top end of the air inlet pipe extends to the top of an inner cavity of the paint spraying chamber; an air inlet cover is mounted at the top end of the air inlet pipe; and the bottom of a hydraulic cylinder I is connected with a detecting mechanism through a telescopic rod I. According to the paint spraying booth,an upper paint spraying pipe cooperates with side paint spraying devices on two sides, clamped workpieces are rotated by 180 degrees by two rotation motors, and two-side paint spraying is performed onthe workpieces, so that the paint spraying efficiency for the workpieces is improved effectively; and the workpieces after paint spraying are dried by the aid of a fan with heat produced by a heatingresistance wire II during working, so that environmental pollution caused by waste gas and waste liquids which are produced during paint spraying is avoided.

Owner:袁大力

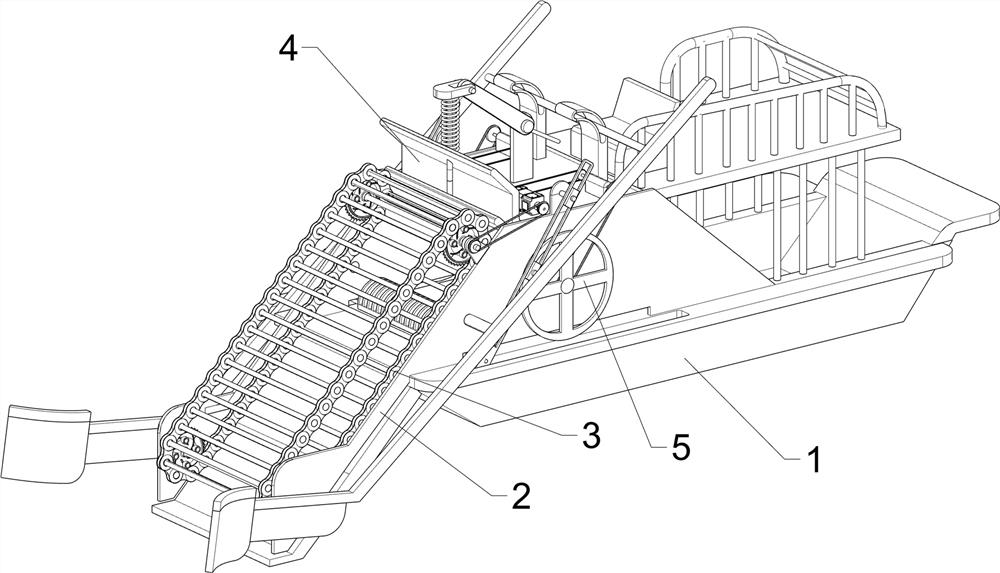

Fishing ship of garbage on water

ActiveCN104627328AImprove the environmentOvercome efficiencyWaterborne vesselsSpecial purpose vesselsLitterEngineering

The invention discloses a fishing ship of garbage on water. The fishing ship comprises a ship body, a garbage pickup device and a garbage conveying device, wherein the ship body is provided with a garbage storage cabin; the garbage pickup device is connected with the ship body and is used for fishing the garbage on water; the garbage conveying device is used for conveying the fished garbage to the garbage storage bin; the garbage pickup device comprises a rotary cylinder capable of rotating with respect to the axis and a trap which is connected to the rotary cylinder and extends outward; the rotary cylinder extends to water surface from the ship body and is provided with a garbage passing hole; the rotary cylinder rotates so as to drive the trap to rotate and enable the garbage on water lifted by the trap to enter the garbage conveying device from the garbage passing hole. According to the fishing ship of garbage on water, the garbage falls off from the garbage passing hole depending on the self-gravity to the garbage conveying device, and is brought into the garbage storage bin by the garbage conveying device; the fishing ship can fish the garbage conveniently and rapidly; the water surface environment can be improved conveniently; the defects of low efficiency, high risk and high labor intensity in fishing of the garbage on water surface can be overcome, so that the labor force is liberated, the labor intensity is lowered and the labor efficiency is improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Flying parameter recorder capable of floating on water

ActiveCN103646444AEasy to findEasy to salvageRegistering/indicating working of vehiclesAviationDetonator

The invention belongs to the technical field of avionics and in particular relates to a flying parameter recorder capable of floating on the water. The flying parameter recorder comprises an upper separable component and a lower mounting frame which is directly fixed on an airplane, wherein a recorder component is arranged in the separable component filled with a foaming material; an electric initiator is arranged on the mounting frame; after the airplane crashes into the water, the electric detonator in the flying parameter recorder is detonated to be on fire, so that the separable component and the mounting frame fixed on the air plane can be separated from each other, and the separable component is pushed out and floats on the water. Under the common action of a water sensor, a battery box, a relay and a throwing separation device, the flying parameter recorder can enable the separable component to be popped out of the mounting frame to be popped out of the airplane body after falling into the water, so that the separable component can be prevented from sinking to the bottom of the water together with the airplane and can be easily found by searching staff.

Owner:SHAANXI QIANSHAN AVIONICS

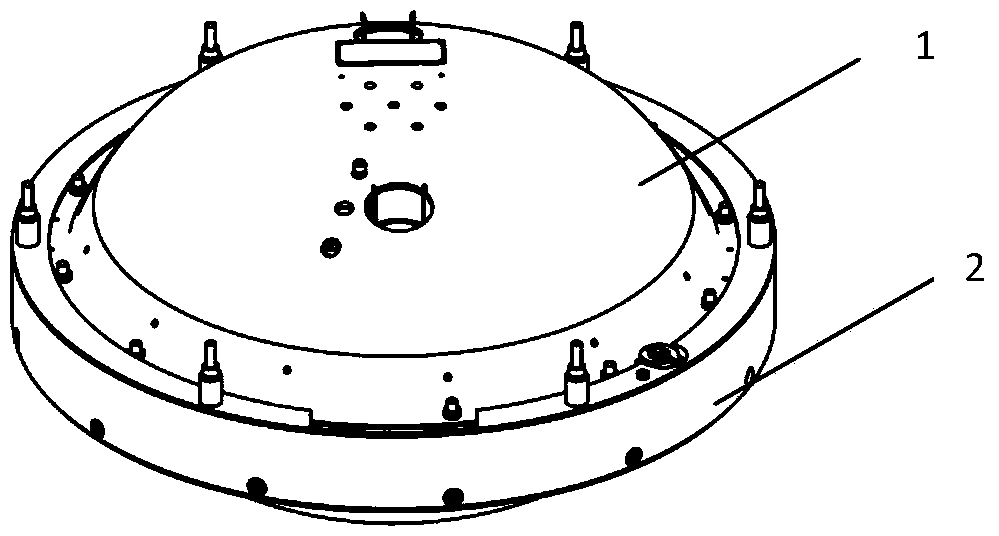

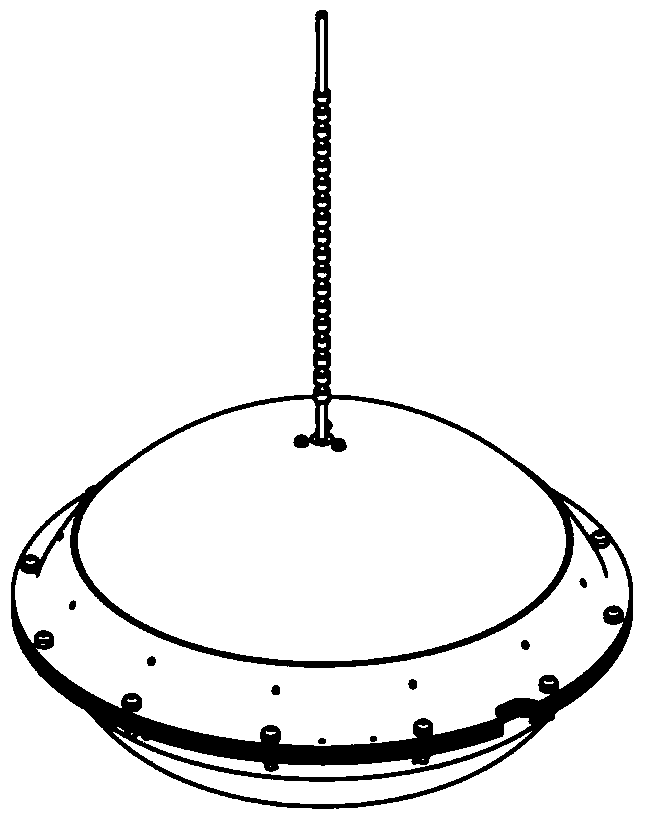

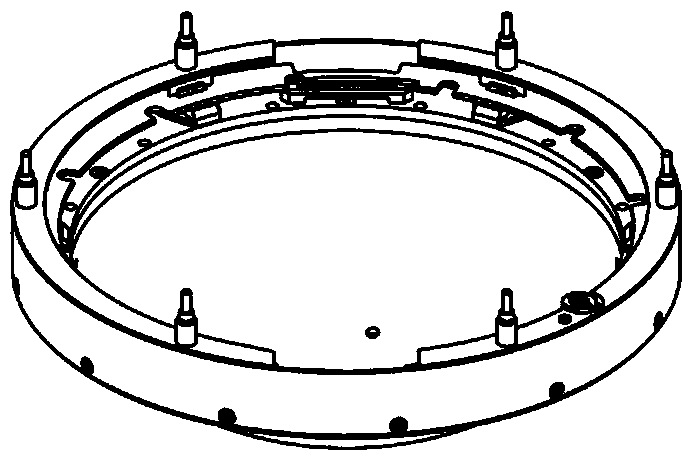

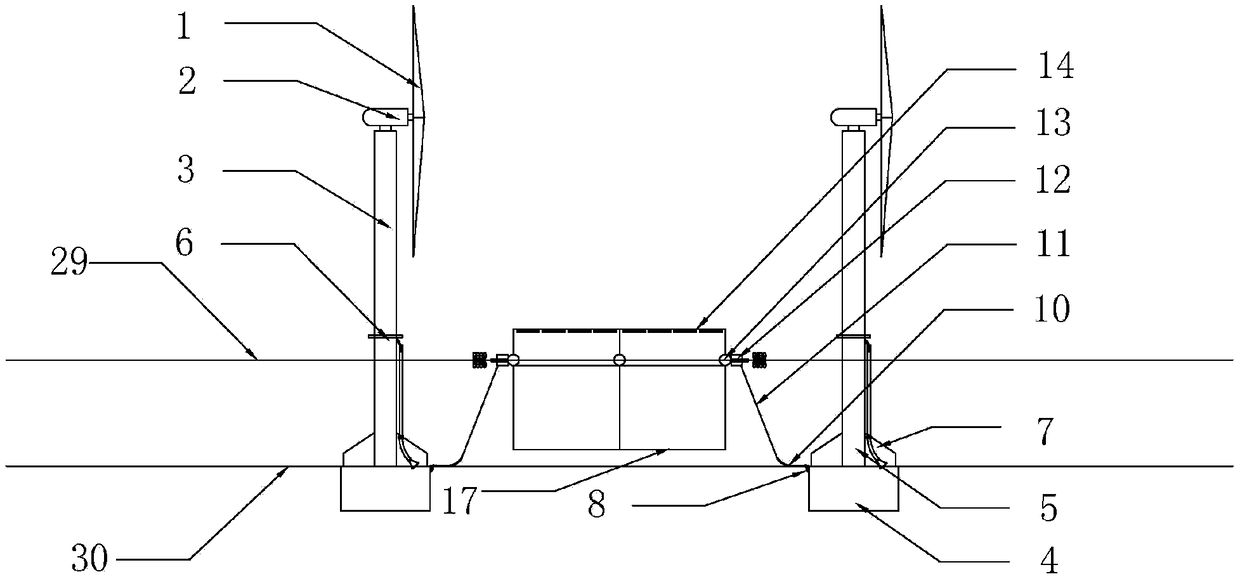

Integrated system of offshore wind, photovoltaic power generation and cage farming

PendingCN109263819ALow costEasy to salvageClimate change adaptationAgricultural fishingElectricityNacelle

The invention provides an integrated system for offshore wind power generation, photovoltaic power generation and cage farming in order to overcome the problem of high cost of developing and constructing offshore wind power generation equipment, offshore photovoltaic equipment and cage farming equipment separately in the prior art. The system includes a plurality of wind power generation devices including blades, nacelle, tower drum and anchoring foundation. The invention is characterized in that a buoy structure is arranged between the wind power generation devices, a photovoltaic power generation device is arranged above the buoy structure, and an aquaculture cage device is arranged below the buoy structure. The invention combines offshore wind power with photovoltaic power generation and aquaculture, and reduces the total cost of construction, production and operation of photovoltaic power generation project and aquaculture cage project; the photovoltaic power generation device andthe aquaculture cage device can move up and down freely with the sea surface, resist the sea waves to a certain extent, and ensure the safety and stability of the structure.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Preparation method of magnetic bacteria cellulose aerogel oil absorption material

ActiveCN104017233AThin diameterMicrostructural regulationOther chemical processesFermentationFiberMagnetic carbon

A preparation method of a magnetic bacteria cellulose aerogel oil absorption material, and relates to a method for preparing an oil absorption material. The aim of the invention is to provide the preparation method of the magnetic bacteria cellulose aerogel oil absorption material. A bacterial cellulose aerogel is modified into a carbon nanometer fiber aerogel oil absorption material, and magnetic particles are added to the prepared aerogel, so that magnetic substances can be conveniently used for salvage and recovery after oil absorption and are beneficial to collecting. The method comprises the steps as follows: 1, cultivation of bacterial cellulose; 2, preparation of bacterial cellulose aerogel; 3, preparation of the carbon nano fiber aerogel absorption material; and 4, preparation of the magnetic carbon nanofiber aerogel oil absorption material. The invention prepares magnetic carbon nanofiber aerogel from bacterial cellulose, the preparation method is simple, novel in design and environment-friendly, and has good biocompatibility, high absorption efficiency and convenience for fishing, and can be reused for many times.

Owner:HARBIN INST OF TECH

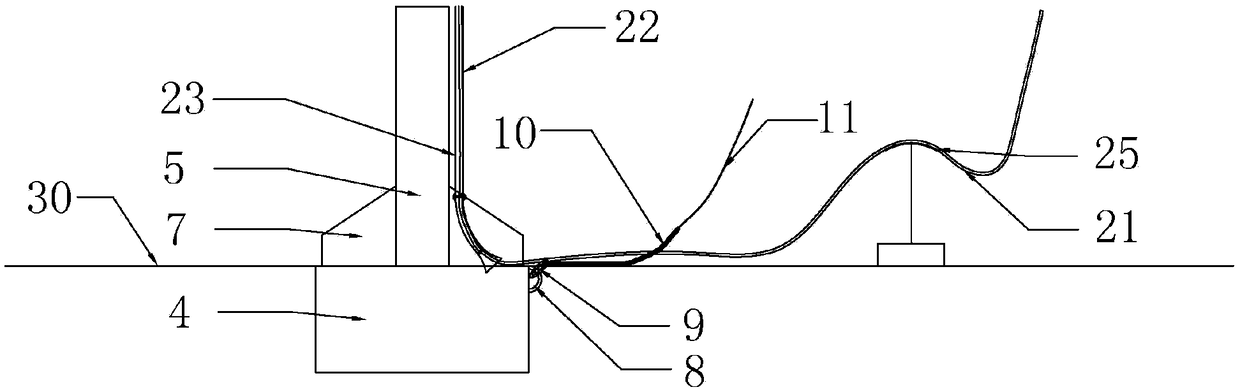

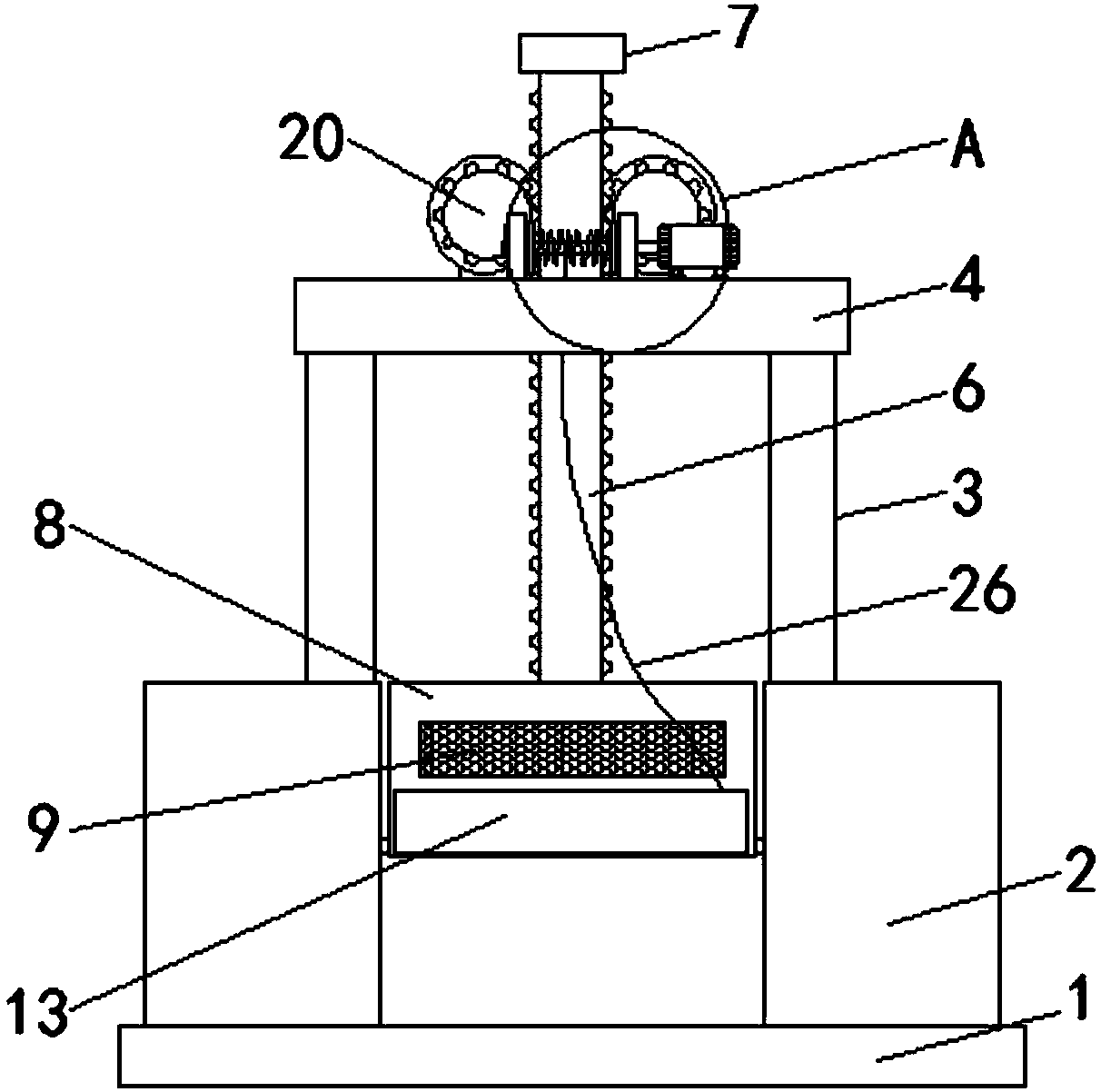

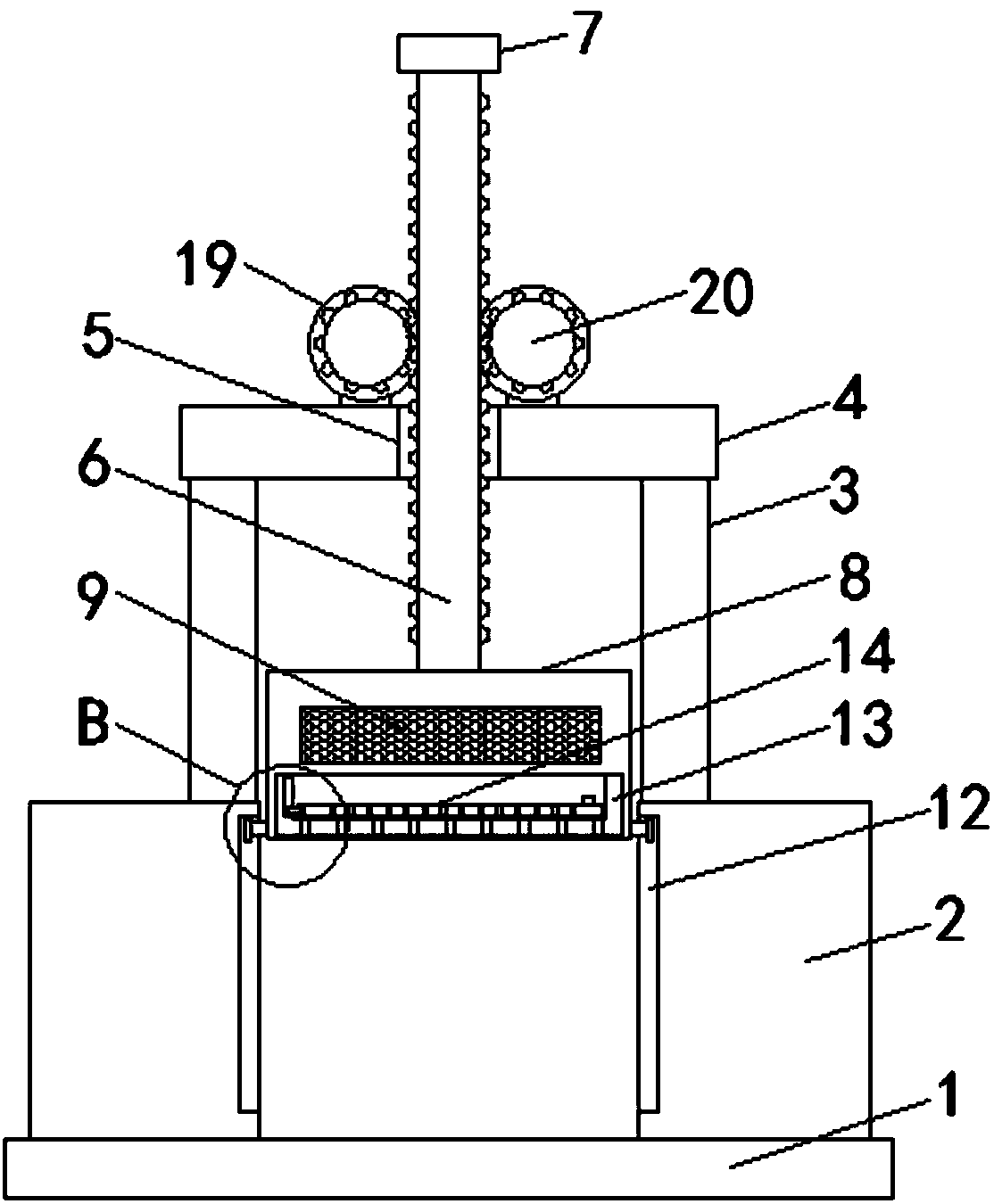

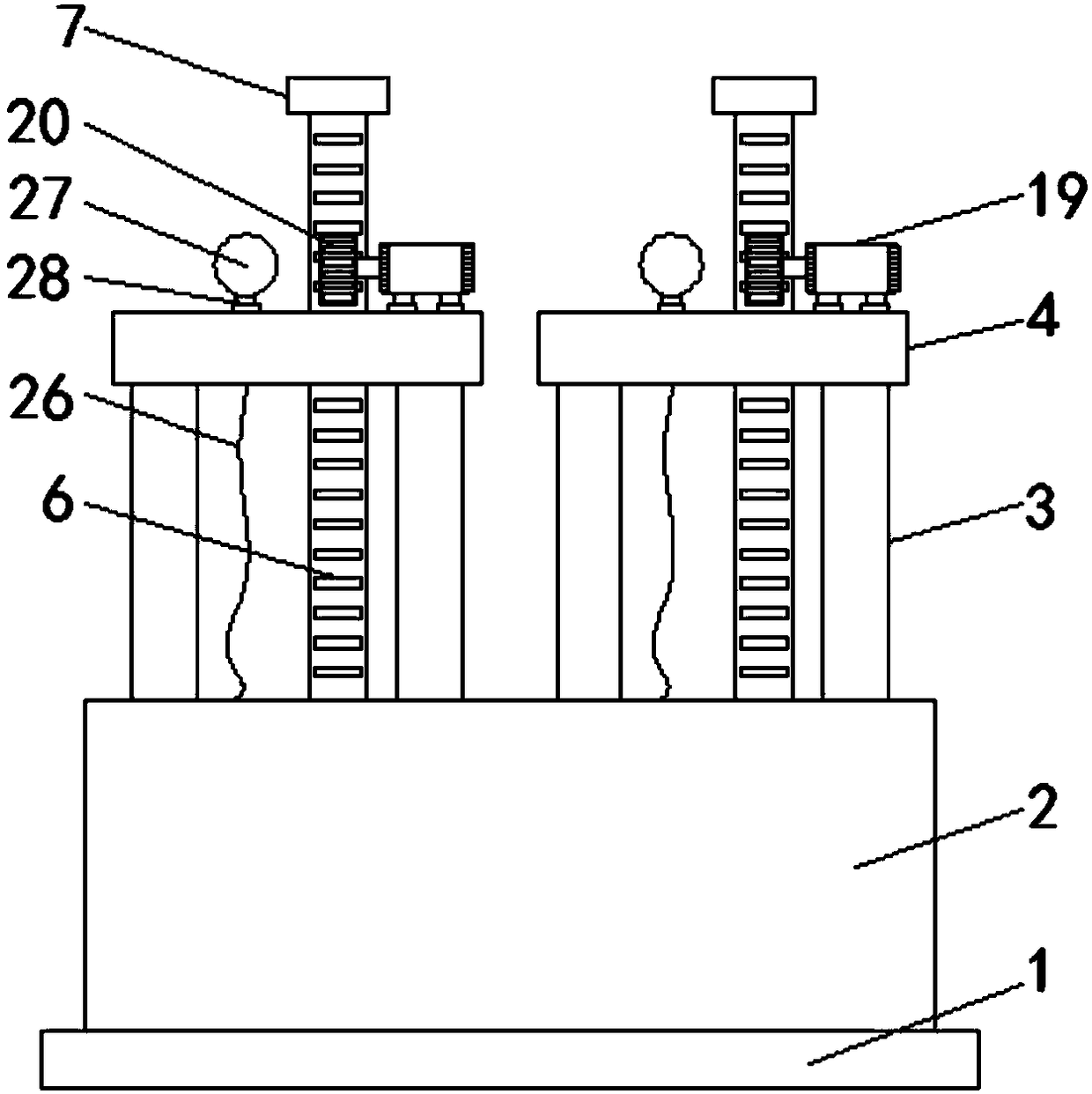

Floating object intercepting and collecting device for stream course clearing

The invention relates to the technical field of stream course clearing and discloses a floating object intercepting and collecting device for stream course clearing. The floating object intercepting and collecting device for stream course clearing comprises a base; two foundation piles are fixedly installed on the top of the base; four supporting columns are fixedly installed on the tops of the two foundation piles; mounting plates are fixedly installed among the tops of the four supporting columns on the front side and the back side; square holes are formed in the tops of the two mounting plates; and two-side racks are arranged inside the square holes in penetrating and inserted modes. According to the floating object intercepting and collecting device for stream course clearing, two intercepting plates are arranged between the two foundation piles, when the front two first drive motors lift the front intercepting plate, the back intercepting plate descends through the back two firstdrive motors, operation is conducted repeatedly and alternately in such way, floating objects are effectively prevented from flowing away with the stream, pollution to the downstream is effectively prevented, passage of a ship can be facilitated through such alternate running, and ship traffic jam is avoided.

Owner:叶丁卫

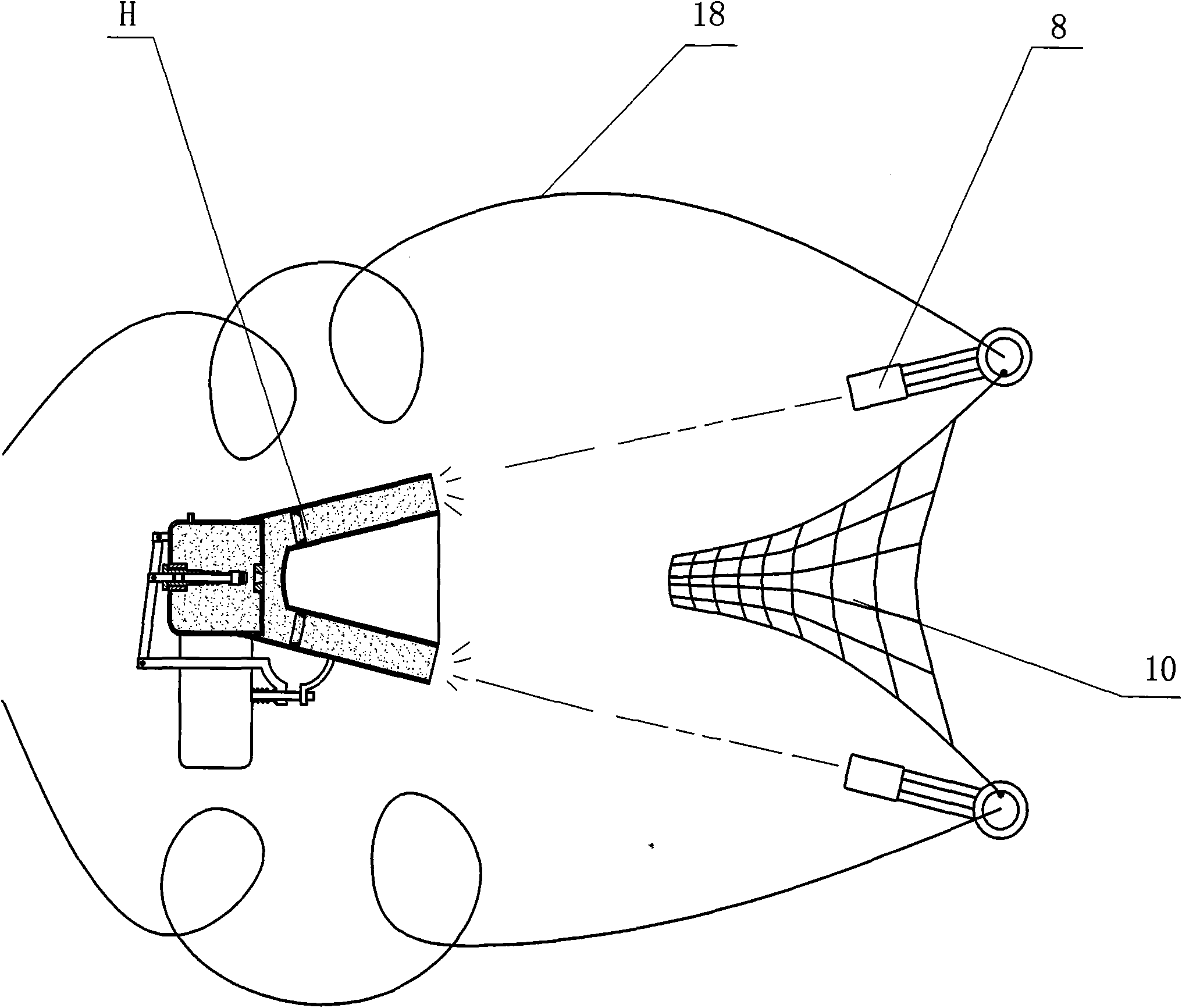

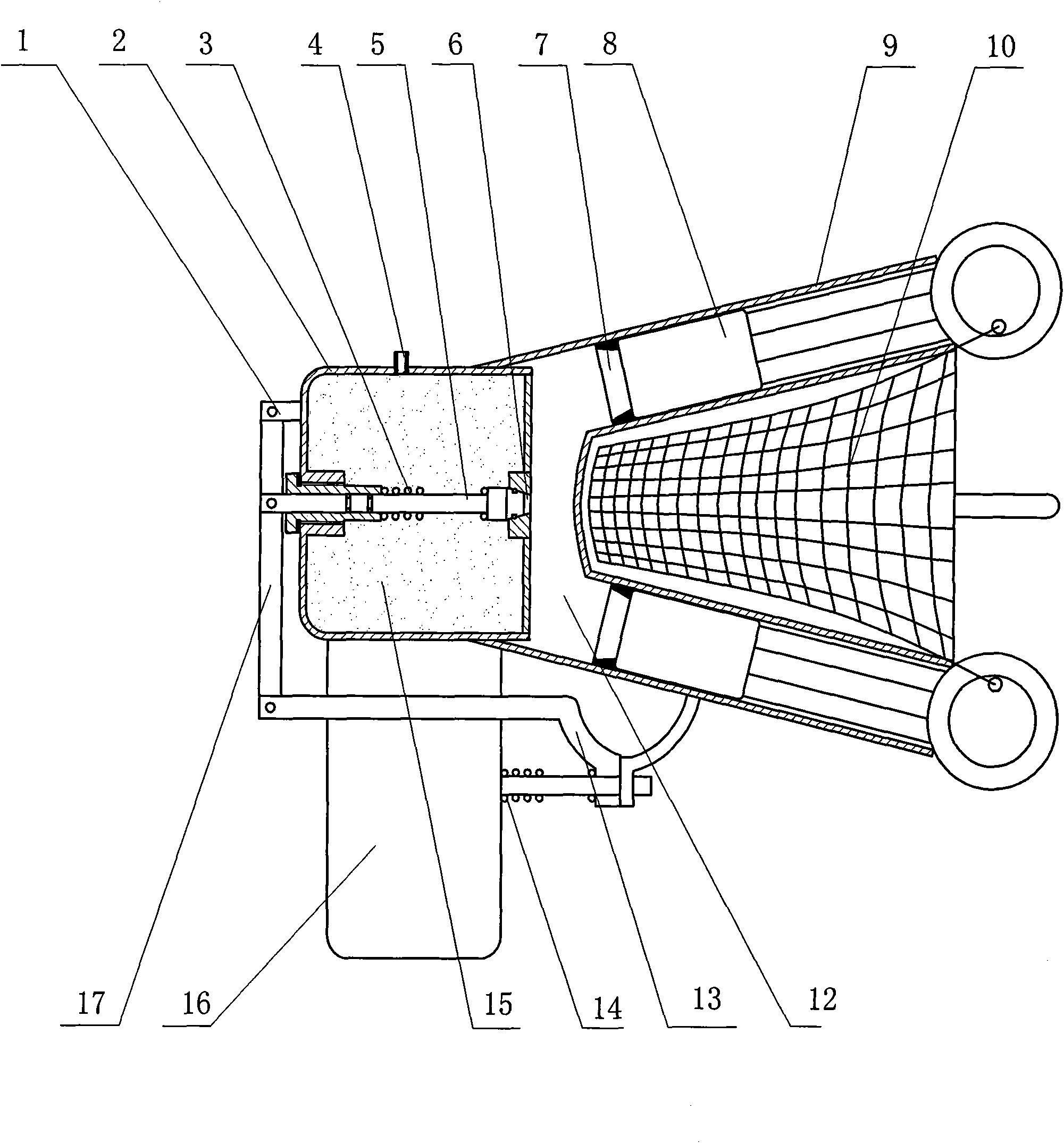

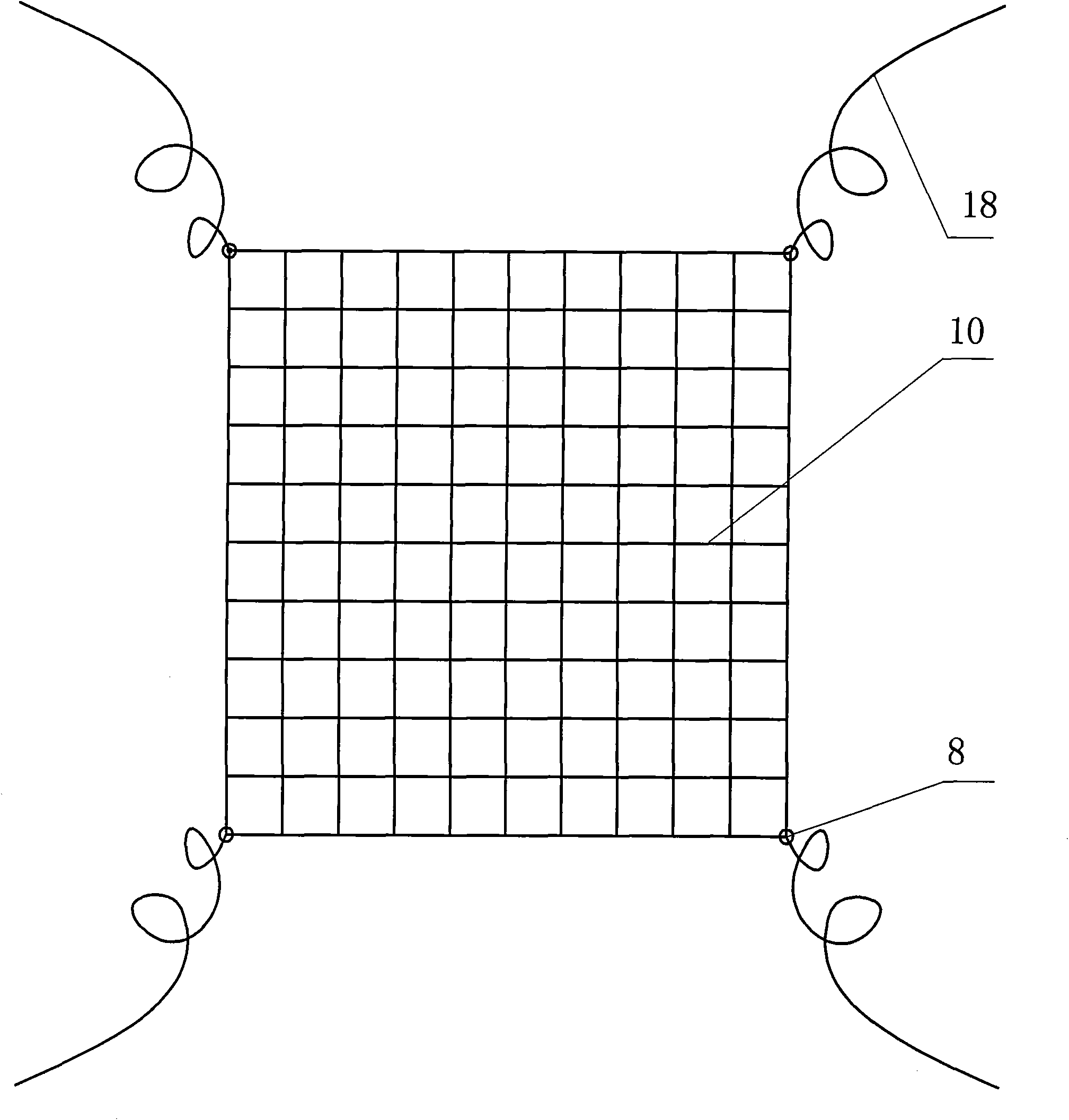

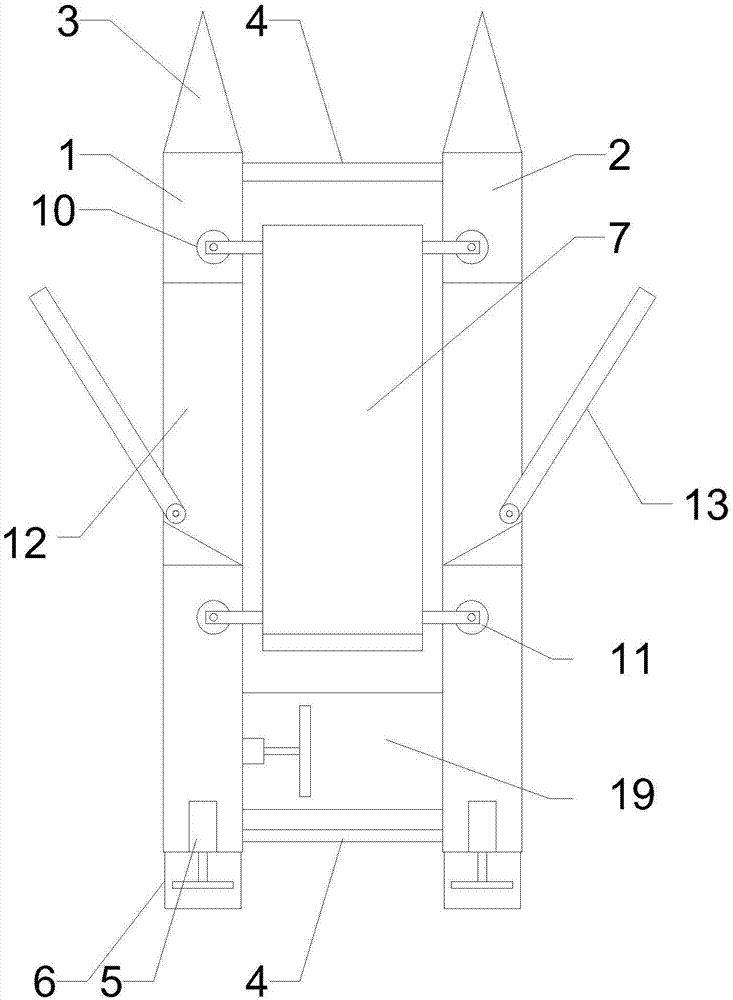

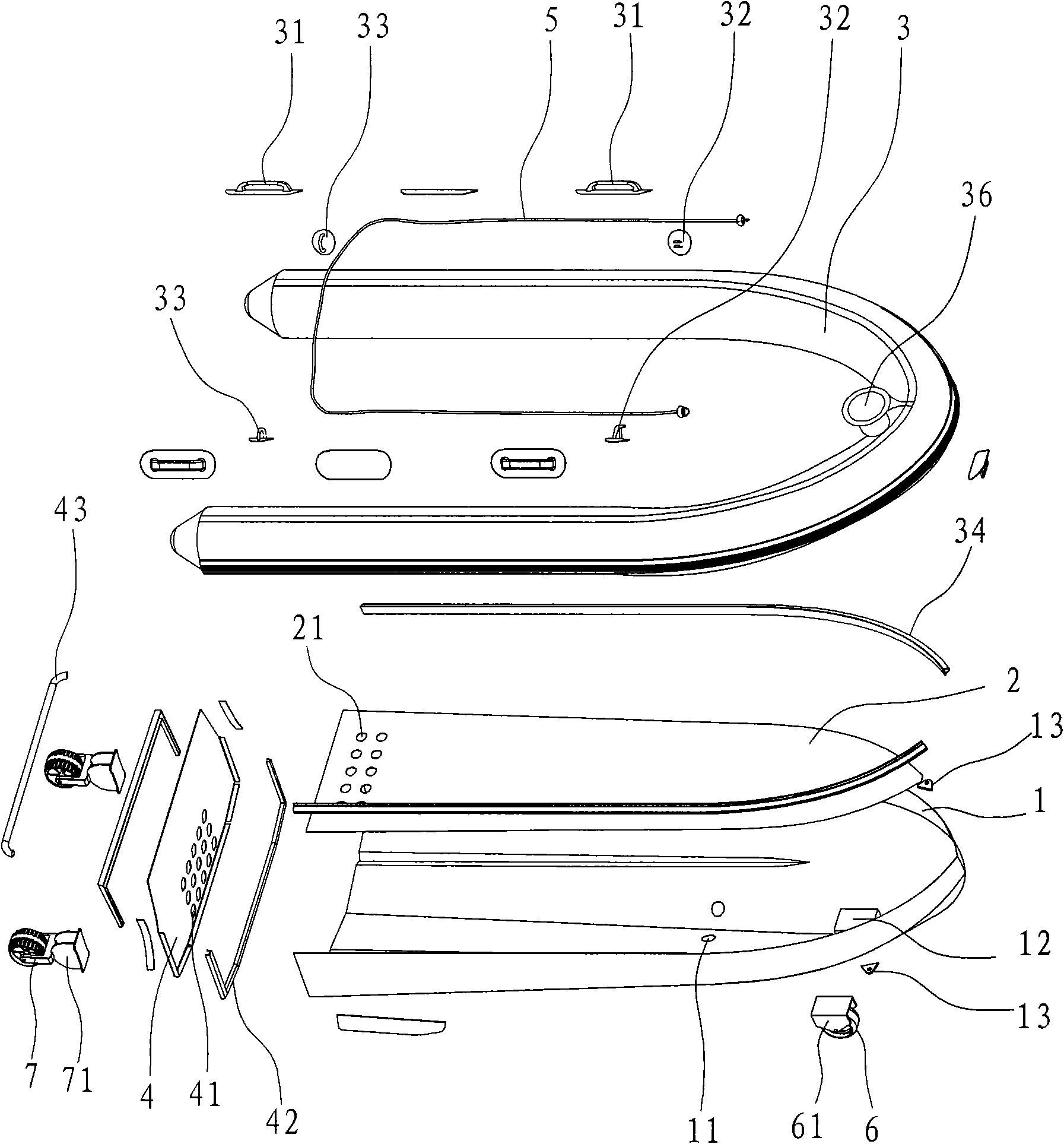

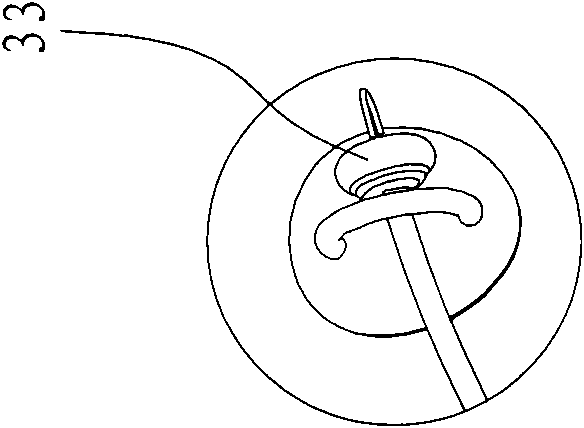

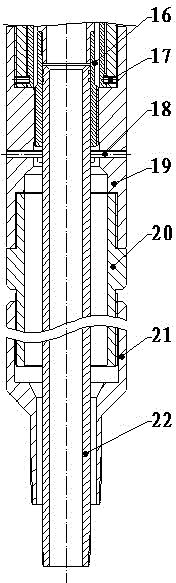

Cod-end structure for recovering marine returning capsule in high sea state

InactiveCN101885374AEasy to catchEasy to salvageLife-raftsAir-sea rescue devicesEngineeringString bag

The invention relates to the field of aerospace, in particular to a cod-end structure for recovering a marine returning capsule in a high sea state. The cod-end structure comprises a guide component and a catching component, wherein triangular, rectangular, pentagonal or hexagonal peaks are tied with a balance-weight guide ring (8) respectively at the periphery of a guide net which has a silk screen structure, and the balance weight guide rings are tied with a guide rope (18) respectively; the mouth part of the string bag-shaped cod-end (20) has a plurality of metal rings (19), a plurality of guide ropes (18) are uniformly distributed and pass through the metal rings (19) at corresponding positions, a lifting rope (22) passes through the metal rings (19) in turn, one end of the lifting rope (22) is shaped as a rope loop and connected with a shackle (22a), while the other end penetrates outside from a round hole of the shackle (22a), and the central position of the outer back part of the cad-end (20) is connected with a tail traction rope (21). The cod-end structure for recovering the returning capsule in a high sea state can implement a two-step salvage method, so the returning capsule (G) can be easily caught and recovered under the relative shaking condition; and a target can be exactly seized by the guide component and easily and smoothly caught and covered by the catching component, so the returning capsule (G) can be recovered and lifted reliably.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Applicaton method of scrap tires in process of steadily converting alga type lake into grass type lake

The present invention belongs to the technical field of ecological restoration, and provides an application method of scrap tires in a process of steadily converting an alga type lake into a grass type lake. Directed at the problems such as large wind and wave disturbance from large shallow lakes, difficulty in automatically gathering floating cyanobacteria in a downwind salvage zone, easiness for captive waterhyacinth in an open water to escape, lack of shelters for benthos and bivalve benthos, difficulty in rooting and proneness to floating for submersed plants at the bottom of hardground lakes and easiness for newborn shoots of delivered conchs, mussels, corbiculae, large cladocera and aquatic plants to be grazed by fishes and the like, a plurality of scrap tires are used as a component in the application method. The components comprise: multi-channel buoyant-raft type scrap tire wave absorption bands, a floating type scrap tire wave-permeable breakwater, oddly toroidal-shaped waters between a plurality of canted trapezoidal-shaped buoyant-raft type scrap tire wave absorption bands, a floating type scrap tire captivity fence, a scrap tire copying bottomless pot, a scrap tire artificial reef, and enclosures of a non-fish area and a little-fish area are cooperatively disposed. By applying the method, the purpose of steadily converting the alga type lake into the grass type lake is achieved.

Owner:史建新

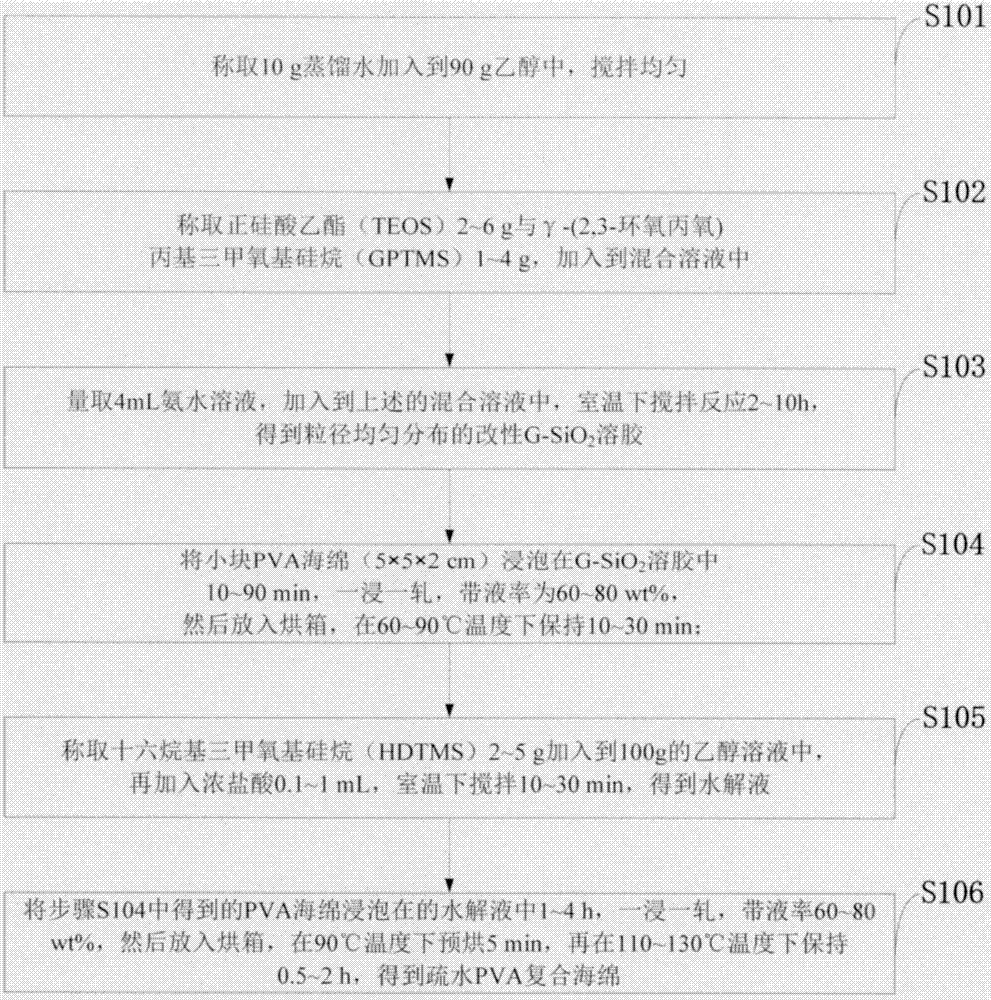

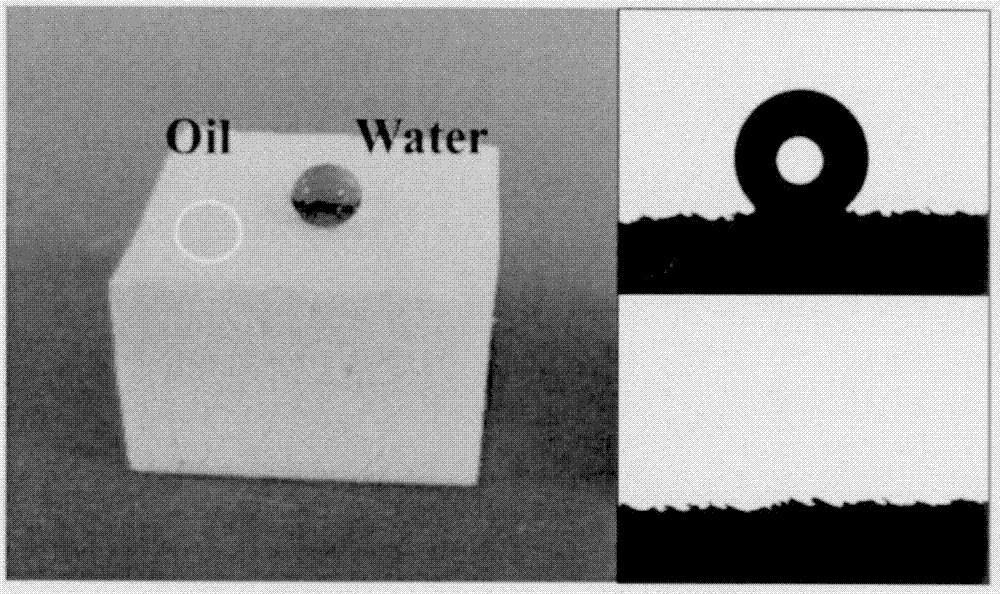

Preparation method for high-strength hydrophobic polyvinyl alcohol composite sponge

ActiveCN107226925ASimple methodGood acid and alkali resistanceLiquid separationSurface energySolvent

The invention discloses a preparation method for a high-strength hydrophobic polyvinyl alcohol composite sponge. A two-step solution impregnation method is employed in the invention and comprises the following steps: with 2 to 6 wt% ethyl orthosilicate and 1 to 4 wt% of gamma-(2,3-epoxypropoxy)propyltrimethoxysilane as raw materials, a mixture of ethanol and water in a mass ratio of 9: 1 as a solvent, 2 to 6 v / v% of ammonia water as a catalyst, carrying out a stirring reaction at room temperature for 2 to 10 h so as to prepare a G-SiO2 sol and subjecting a sponge to impregnation and deposition so as to construct a rough structure; and with 2 to 8 wt% of hexadecyltrimethoxysilane as a surface modifier and 0.1 to 1 v / v% of hydrochloric acid as a catalyst, subjecting the sponge to hydrophobic and low-surface-energy modification. The hydrophobic PVA sponge provided by the invention has good acid and alkali resistance, good high-salinity resistance and high oil absorption rate and can be repeatedly used 20 times or more.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Water surface comprehensive rescue system and method

InactiveCN104743084ALow priceFlexible hoverAir-sea rescue devicesRemote controlled aircraftMarine engineeringFixed wing

The invention discloses a water surface comprehensive rescue system and a water surface comprehensive rescue method. A fixed-wing unmanned machine and a multi-rotor-wing unmanned machine are combined to complete the water surface rescue; cruise monitoring is carried out by utilizing the advantage of long time of endurance of the fixed-wing unmanned machine, and the state of the water surface is monitored, while the multi-rotor-wing unmanned machine has the characteristic of hovering flexibility and can flexibly complete specific motions of rescue; the fixed-wing unmanned machine and the multi-rotor-wing unmanned machine are combined to achieve the aim of rapid rescue; to-be-rescued people wear colorful pull rings and pull the pull rings on hands when encounter near-drowning, then a near-drowning region displays a color different from the peripheral water body, and a color sensor of the fixed-wing unmanned machine senses the situation, so that the rescue speed is accelerated; the pull rings are provided with dye floccules capable of floating, are convenient to fish, cannot pollute the environment, and can be recycled; the colorful hand rings are low in price.

Owner:XUZHOU FLY DREAM ELECTRONICS & TECH

High-efficiency hot dip galvanizing production line

ActiveCN105861970AQuick removalEasy to salvageHot-dipping/immersion processesAcid washingEngineering

The invention discloses a high-efficiency hot dip galvanizing production line which comprises a lifting appliance, a zinc pot, an acid washing tank, a water washing tank, a cosolvent tank and a cooling tank. The high-efficiency hot dip galvanizing production line can quickly remove bubbles on the workpiece surface in the workpiece galvanizing process, can gather the zinc ash on the surface before the workpiece is taken out of the zinc pot so as to prevent the adhesive pollution, can enable the reflux motion of the acid liquor in the acid washing tank so as to increase the contact reaction rate between the acid liquor and acid-washed workpiece, can monitor the concentration of the acid liquor in real time, can enable the water washing of the workpiece to proceed more quickly and thoroughly, can enable the contact between the workpiece and cosolvent more uniformly and quickly, can eliminate the influence of the impurities and stains attached to the workpiece surface on the cosolvent treatment so as to effectively ensure the feed quality of the subsequent procedure, and can enable the water cooling heat transfer of the acid washing wastewater for the hot dip galvanizing cooling tank so as to save the water resources and enhance the wastewater utilization efficiency, thereby saving the production cost.

Owner:浙江慧钢技术发展股份有限公司

Water surface suspension garbage cleaning device

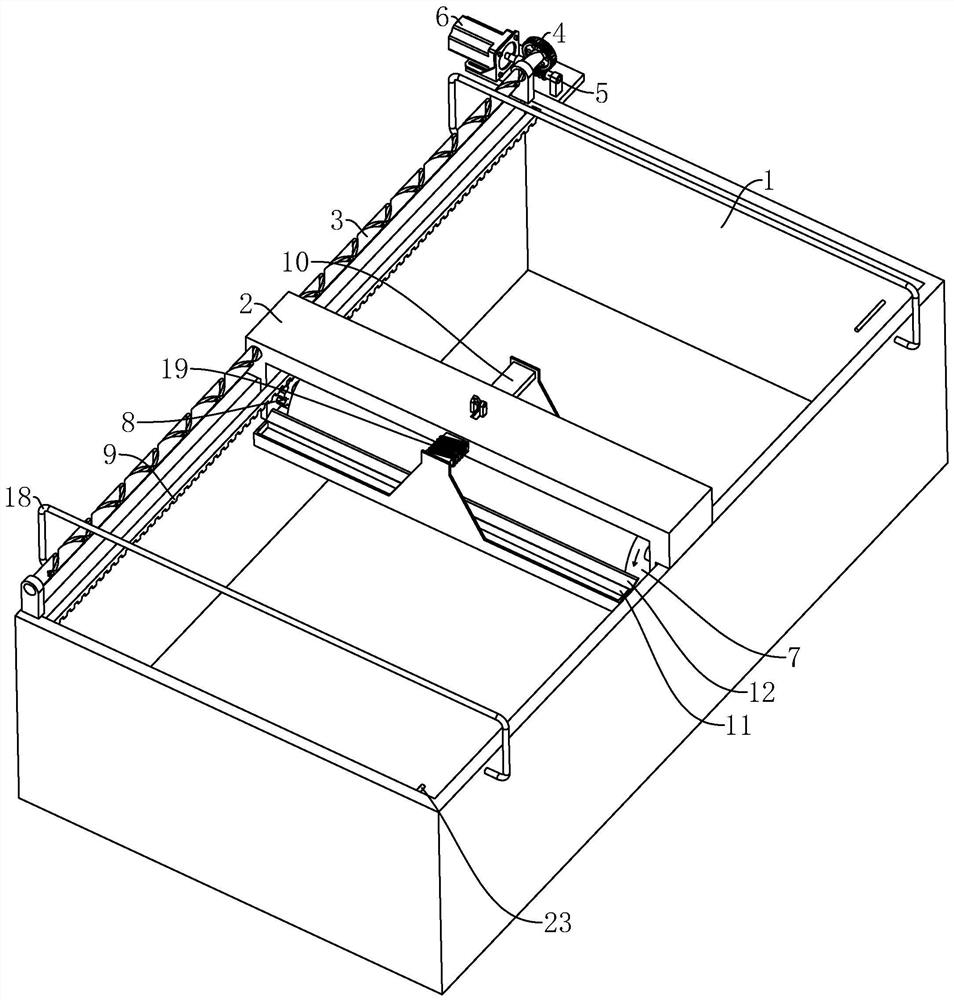

InactiveCN107161294AAdjust draftIncrease salvage areaWater cleaningWaterborne vesselsRefuse collectionWaste collection

The invention discloses a water surface suspended garbage cleaning device, comprising a left hull and a right hull; a through groove is arranged in the middle of the left hull and the right hull, and an extension plate is arranged in the through groove; There is a salvage plate, and the end of the salvage plate is fixedly connected with an inclined plate; a collection box is arranged on the right side of the salvage plate, and the collection box is fixedly connected with the left hull and the right hull by bolts; The plate is connected with a horizontal hydraulic device, and the bottom of the collecting box is provided with evenly distributed fine holes. The invention is provided with a double hull, a rotating extension plate and a salvage plate, so that the garbage salvage area is large and the salvage efficiency is improved; the present invention is provided with a garbage collection, extrusion and dehydration device, which squeezes and dehydrates the garbage, and improves the single rate of garbage collection. The salvage volume and the transportation volume can be increased; the invention is provided with an airbag adjustment device to adjust the draught depth of the hull, which is convenient for salvage.

Owner:吴蕴仪

Underwater life jacket

The invention relates to a underwater life jacket, comprising a front part and a back part; wherein the back part is provided with at least two independent air bags, and the front part is provided with at least one air bag; the front part is further provided with a high-pressure gas tank and each air bag is provided with an independent air valve, the air valves are connected with the high-pressure gas tank by a pipeline and are provided with a shared control switch; two inflatable salvage belts are arranged at the two sides of the opening of the front part; the upper and lower ends of the salvage belts are both communicated with the pipeline. The life jacket is provided with a plurality of air bags, when one of the air bags is broken, the overall life-saving function of the life jacket is not greatly impacted, as a result, the performance thereof is greatly improved; in addition, the life jacket is further provided with a salvage belt structure, in very emergent cases, the salvage belts tightly cling to the life jacket in a flat manner, thus taking up no space; in case of emergency, the salvage belts are inflated and bulge outwards, so as to facilitate rescue work.

Owner:罗金光

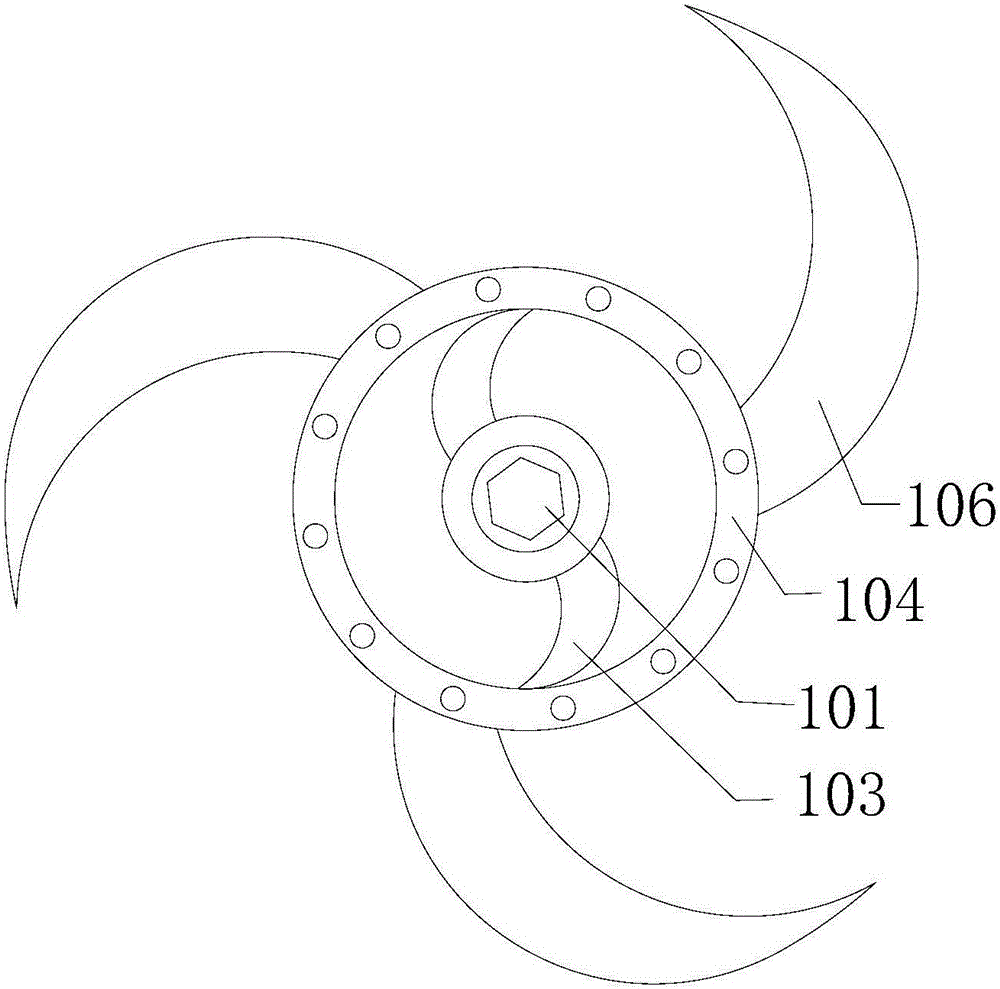

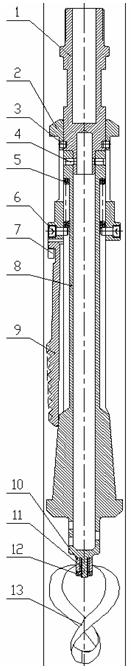

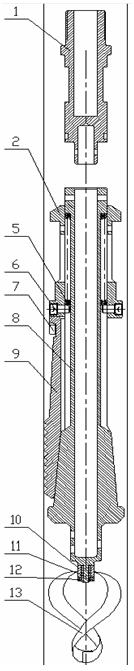

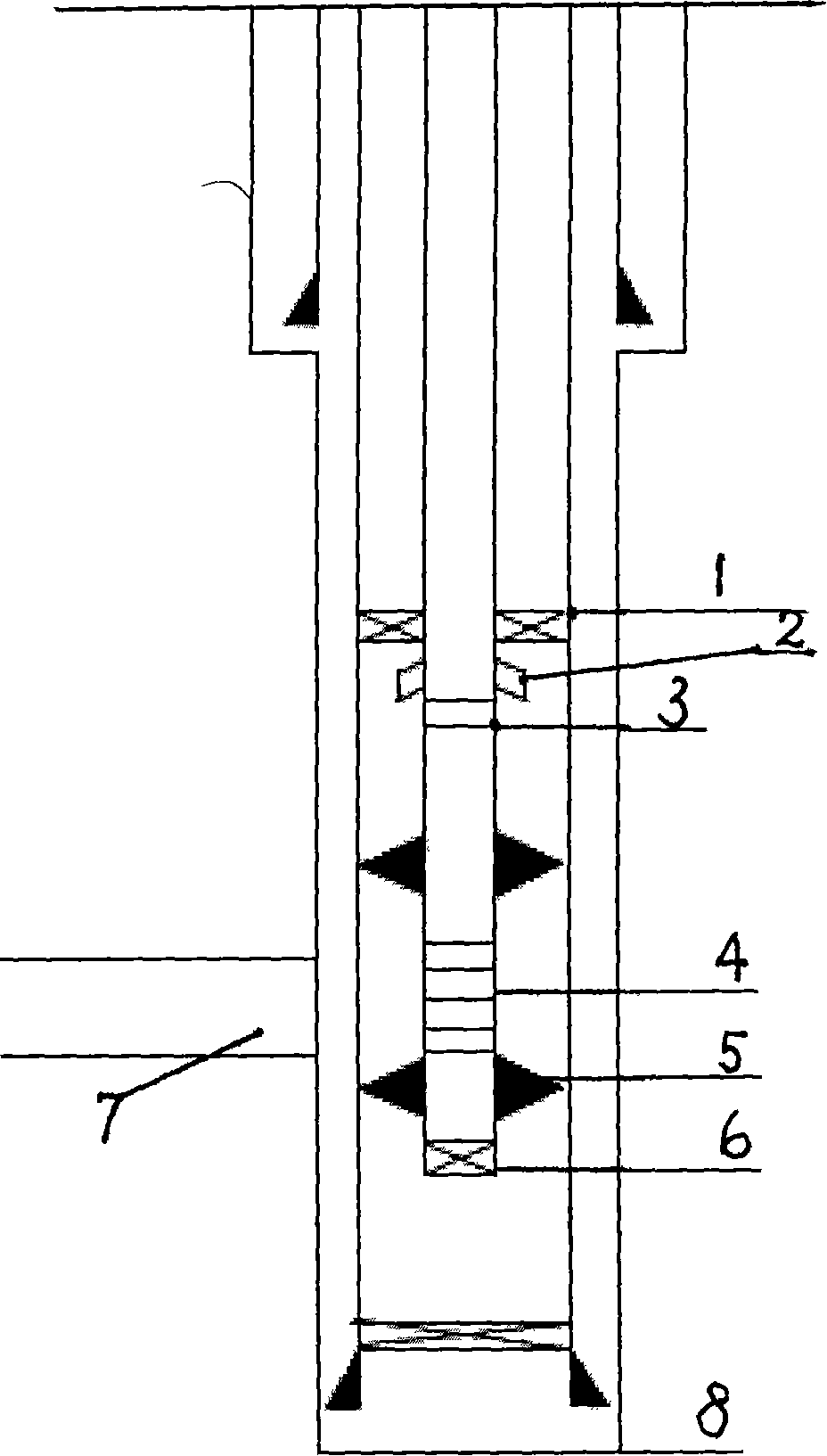

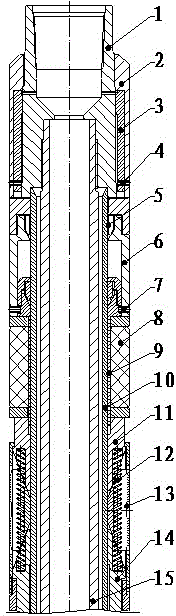

Retrievable underground foaming agent mixing device

The invention relates to a retrievable underground foaming agent mixing device which is used for implementing the action effect of foam draining and gas production in a gas field, solving the difficulty that the action effect of the foam draining and gas production technology is influenced by insufficient mixing of a foaming agent and shattering of foam fluid. The following technical scheme is adopted: the upper end of a releasing joint is provided with a threaded button to be connected with a conventional releasing joint, and the lower end of the releasing joint is provided with a stepped platform and a pin hole; the lower end of an outer tube is provided with a screw hole, and the tail end of the outer tube is connected with a slips carrying ring; the upper end of a core tube is provided with a pin hole, a spring slot is arranged at the middle of the core tube, the tail end of the core tube is circumferentially provided with an orifice, a stepped shaft and a ball groove, a core tubesleeve is connected on the releasing joint by a pin; a spring is arranged in the spring slot; the outer tube is sheathed on the core tube and is connected by a pin in the pin hole in a releasing joint platform; the upper end of a slips is connected with the slips carrying ring, and the tail end of the slips is contacted with the core tube; the ball is arranged in the ball groove, and a hub is arranged on the ball; a locking nut is connected with the stepped shaft at the tail end of the core tube; and a rotating blade is connected with the hub. The retrievable underground foaming agent mixing device has a simple structure, is wide in application scope, can give full play to the action effect of the foam draining and gas production technology, and can be used in a water outlet gas well adopting the foam draining and gas production technology.

Owner:SOUTHWEST PETROLEUM UNIV

Copper-removal composition used for secondary lead refining and application thereof

The invention discloses a copper-removal composition used for secondary lead refining. The copper-removal composition is composed of 30-45 wt% of Fe, 40-55 wt% of S, 3-15 wt% of SiO2 and 0.0002-0.02 wt% of lead powder. The copper-removal composition is added into liquid lead for a copper removal reaction, copper dross is fished out after the reaction to obtain liquid lead with copper removed, and refined lead is obtained after the liquid lead with copper removed is subjected to fluxing cleaning through caustic soda flakes and ingot casting. The invention further provides an application of the copper-removal composition in secondary lead refining. According to the copper-removal composition, the removal rate to copper in the liquid lead is high; smoke and odor do not exist in the copper removal reaction, and the working environment is good.

Owner:ZHEJIANG TIANNENG POWER SOURCE MATERIAL

Oil gelling agent for treating oil spill on sea

InactiveCN106746685AStrong oil condensation abilityClotting time poleFatty/oily/floating substances removal devicesSeawater treatmentCeramic particleMicrometer

The invention discloses an oil gelling agent for treating oil spill on the sea. The oil gelling agent is lightweight inorganic powder prepared by performing flame-spraying and surface hydrophobic modification on inorganic ceramic particles, the apparent density of the lightweight inorganic powder is 0.1-0.95g / cm<3>, and the particle size of the lightweight inorganic powder is 1-20 micrometers. The oil gelling agent can safely, fast and simply recycle leaked low-coagulation chemical oil such as gasoline, diesel oil, crude oil and marine diesel oil.

Owner:浙江慈航海洋环保科技发展有限公司 +1

Small boat for fishing floating corpses

InactiveCN101612981AAchieve salvagePrevent slipping outWaterborne vesselsSpecial purpose vesselsWater flowEngineering

The invention discloses a small boat for fishing floating corpses, comprising a small boat main body and a stern board group which is matched with the rear body of the small boat main body and is provided with a water outlet; the small boat main body comprises a boat body, a deck fixed in the boat body and a buoy separating from the boat body; the bottom part of the boat body is provided with a water inlet, the rear part of the deck is provided with the water outlet, and a ballast tank water flow channel is formed between the deck and the boat body. When the fishing operation is implemented, the floating corpse can be dragged into the boat tank from the rear part of the small boat main body smoothly, a stern board is closed to prevent the floating corpse from smoothing out of the small boat, thus being capable of realizing fishing of the floating corpse; while, the setting of the water inlet at the bottom part of the boat body and the water outlet at the rear part of the deck forms a ballast tank water flow channel, so as to lead the small boat to be capable of being dragged in water smoothly without overturning; therefore, the small boat has better practical value, leads the operation of fishing the floating corpse to be convenient and be easy to operate, avoids direct contact of an operator and the floating corpse and leads the fishing operation to be more sanitary.

Owner:XIAMEN FEIPENG IND CO LTD

Well-repairing process for casing deformed oil and water well

The invention relates to a casing deformation oil-water well repair technics. The sand-washing technology and the anti-sand technics with a gravel-filled string are adopted by the invention. Sand is first washed to a preset position with a specially made sand-washing tool, and then the anti-sand string is put into the well. A certain amount of quartz sand is filled outside the string to complete the well. Thus, a well bore hole is reinforced and an oil flow or water injection passage is formed, so as to reach the purpose of production recovery for an oil well and water injection recovery for a water injection well. The casing deformation oil-water well repair technics provided by the invention avoids the overhaul procedure. The sand prevention work can be directly carried out, the well repair cost is reduced, and the construction period is shortened. Moreover, when the sand is effectively prevented, the intention is provided with a certain channelizing effect for an oil layer, which is favorable for increasing the oil well output or the water injection amount of the water injection well.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

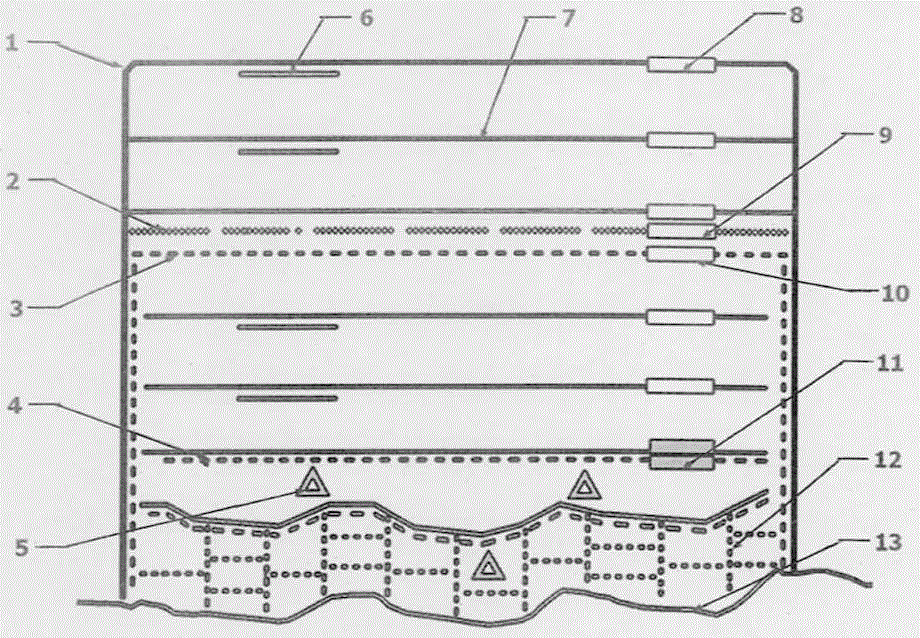

Roasting-starting method of aluminium reduction cell with bulge-structure cathode

InactiveCN101736364AEasy to salvageReduce workloadElectrical resistance and conductanceFluid electrolytes

The invention discloses a roasting-starting method of an aluminium reduction cell with a bulge-structure cathode. The bulged upper surface of the cathode carbon block is laid with a layer of coke grains, or a layer of mixed paste of coke grains and binder above the layer of coke grains; and a carbon anode is placed on the upper surface of the coke grains or the paste. When the coke grain resistor of the reduction cell is roasted to 500-800 DEG C, aluminium water is poured through an aluminium outlet, when the coke grain resistor is roasted to 950 DEG C by continuous energization, the aluminium outlet is opened, liquid electrolyte is poured, and the anode is lifted to execute wet starting of the reduction cell; or the coke grain resistor is roasted to 960-980 DEG C continuously, the liquid electrolyte is poured through the aluminium outlet, and simultaneously, the anode is lifted, the cell voltage is increased, and the reduction cell is started in a wet method directly. In the method, the used coke grains are less, the current and the temperature distribution on the surface of the cathode carbon block are uniform, thus avoiding cracking on the surface of the cathode carbon block owning to partial overheat.

Owner:NORTHEASTERN UNIV

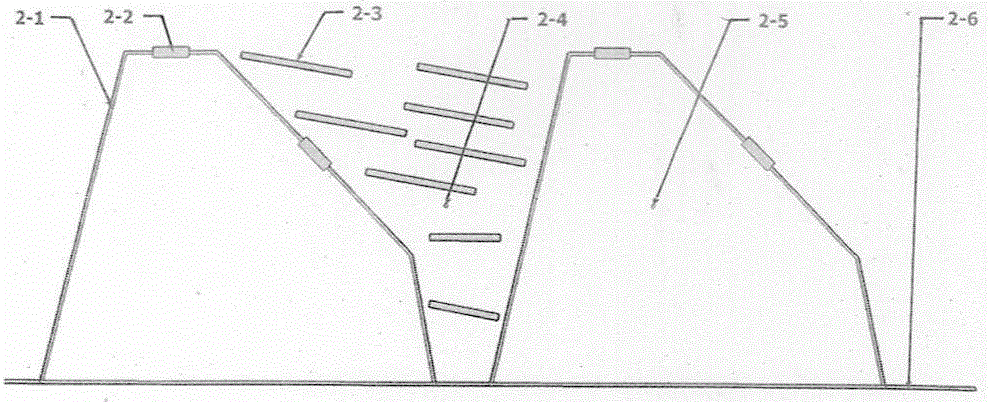

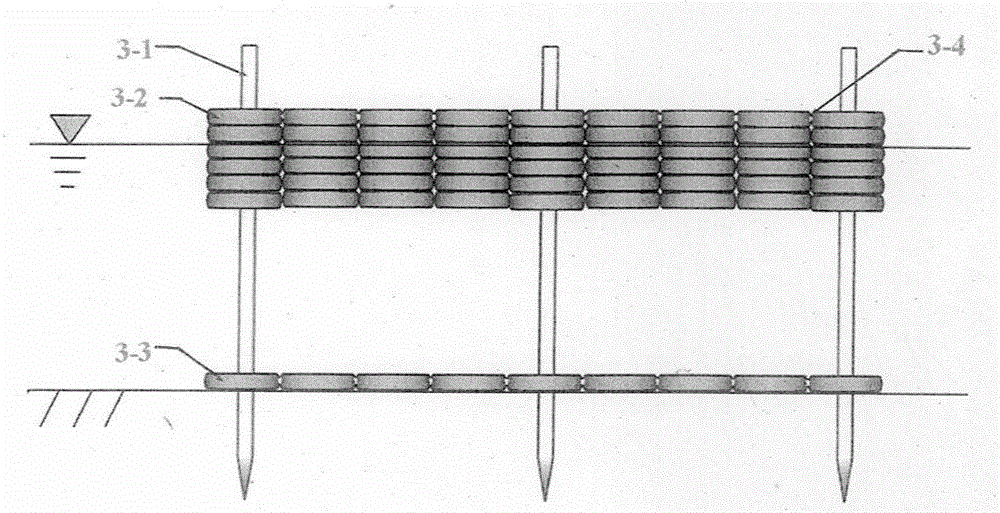

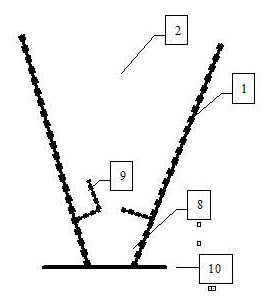

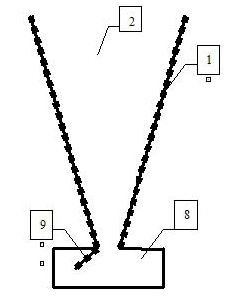

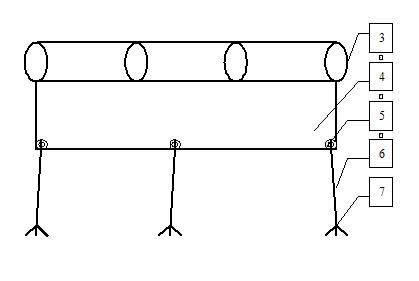

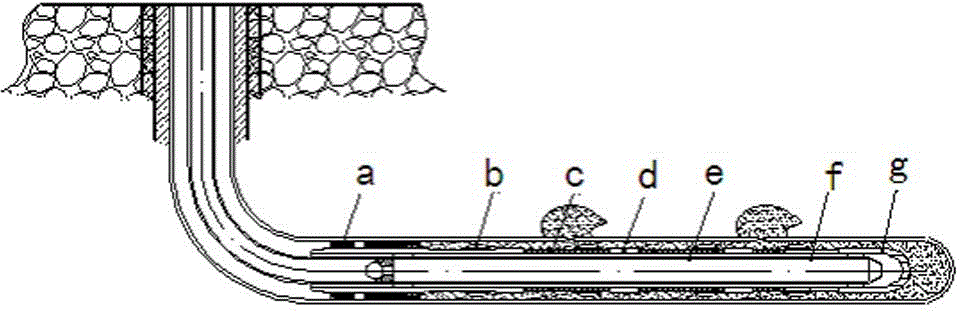

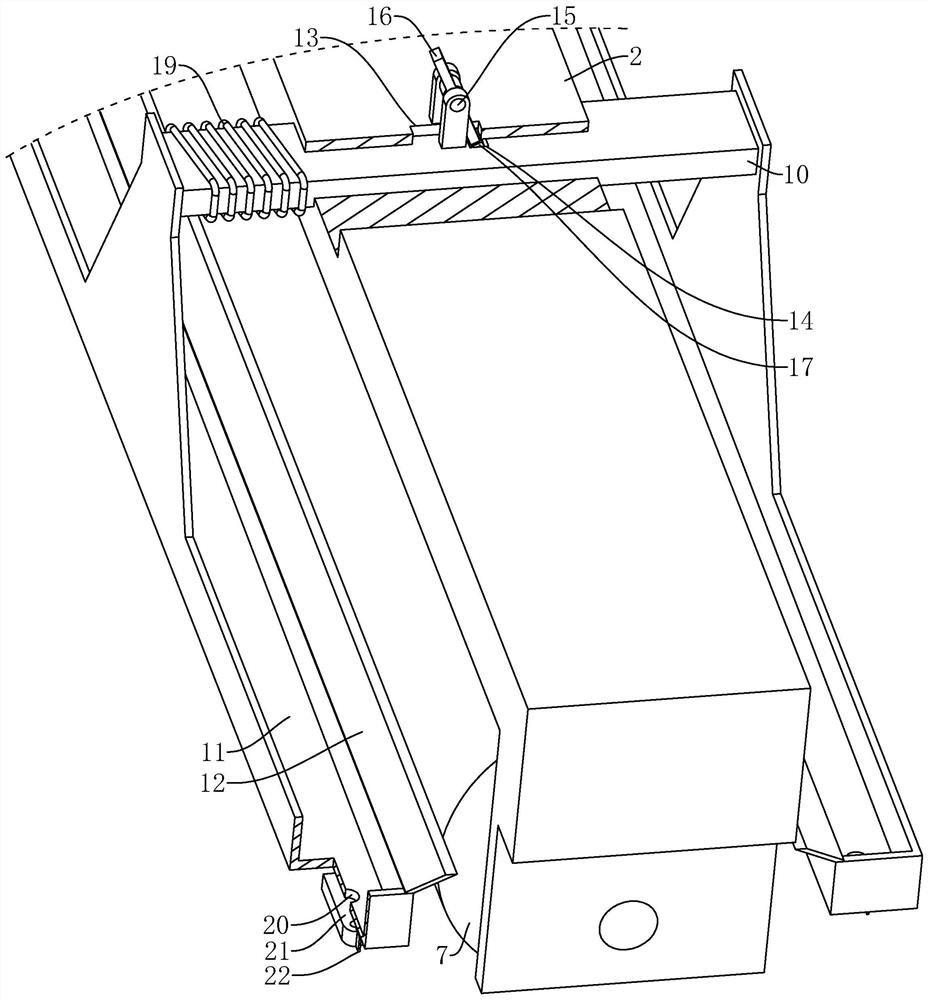

Method and device for capturing water bloom cyanophytes by using trap

InactiveCN101929145AImprove harvesting efficiencySimple structureWater cleaningFisheryEnvironmental engineering

The invention discloses a method and a device for capturing water bloom cyanophytes by using a trap. The method comprises the following steps of: A, arranging a floating fence to form a horn mouth shape at a perennial leeward port of a lake or a reservoir; B, arranging a movable fence at the position at a distance of 20 meters from the bottom of the horn mouth so as to form a trapezoid or square cyanophytes gathering trap at the bottom; C, when wind is blown to the inside of the horn mouth, opening the movable fence to make algal bloom enter the trap, when the wind is blown reversely, closing the movable fence to prevent the algal bloom entering the trap from being blown out by the wind, and capturing the cyanophytes at the bottom of the trap; and D, arranging waterproof cloth serving as a skirt curtain below the floating fence so as to prevent the algal bloom from escaping from the bottom of the floating fence, and straightening downwards and fixing the skirt curtain by using an anchor. The device for capturing the water bloom cyanophytes is characterized in that: a foam plastic cylindrical buoy is connected with the skirt curtain; the skirt curtain is connected with an iron hoop; and an anchor line is respectively connected with the iron hoop and the anchor. The device for capturing the water bloom cyanophytes has the advantages of easy method, simple and convenient operation, high efficiency of capturing the water bloom cyanophytes, simple structure, low price and high capturing efficiency. The method and the device are widely suitable for capturing the water bloom cyanophytes in the lake, the reservoir and the like.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Construction method for filling gravel in horizontal oil well pipe

ActiveCN104948145AReduce labor intensityShorten working timeCleaning apparatusFluid removalSand filterOil well

The invention relates to a construction method for filling gravel in a horizontal oil well pipe. The method comprises the following steps that firstly, a bottom gravel filling valve, a fine sand filtering pipe, a melting centering device, a bi-directional hot melting type thermal stress compensator, a de-blocking releasing suspending packer, a washing pipe and an oil pipe are connected together in the design sequence, and are descended to the pre-set position of a casing pipe; secondly, circulating well washing is carried out, pressing is carried out by throwing a hollow steel ball, and a packer is subjected to sealing; thirdly, sealing examining is carried out on the packer, and releasing is carried out on the packer; fourthly, a pipe column is lifted up, reverse circulating is carried out to wash out the hollow steel ball; fifthly, the pipe column is decentralized, and filling working is carried out; sixthly, the pipe column is lifted up, the reverse circulating washing is carried out on the well; seventhly, the pipe column is taken out, and the filling working is completed. The construction method for filling the gravel in the horizontal oil well pipe has the advantages that the pipe column only needs to be decentralized once, and the working can be completed. On the premise of guaranteeing the gravel filling quality, the construction technology is simplified, the working cycle is shortened, and the construction disk is lowered.

Owner:SLOF KANGBEI IND & TRADING

Municipal lake floating garbage salvage ship

ActiveCN111891302AQuick salvageEasy to collectWater cleaningWaterborne vesselsElectric machineryBiology

The invention relates to a salvage ship, and in particular relates to a municipal lake floating garbage salvage ship. The municipal lake floating garbage salvage ship is rapid in salvage and convenient to collect and transport. The municipal lake floating garbage salvage ship comprises a ship body, and a supporting frame is arranged on the ship body; the salvage ship further comprises a baffle plate arranged on the supporting frame, a conveying mechanism arranged on the supporting frame, and a pushing mechanism which is arranged on the supporting frame. The salvage ship has the beneficial effects that the effects of rapid fishing and convenient collection and transportation are achieved; by starting a double-shaft motor, the conveying mechanism and the pushing mechanism are driven to operate at the same time, then through cooperation of the conveying mechanism and the pushing mechanism, when the conveying mechanism rapidly fishes garbage, the conveying mechanism collects the garbage ina centralized mode, and meanwhile, the ship body further facilitates transportation of the garbage; and the right end of a connecting plate is pulled upwards, so that an extrusion block moves downwards to extrude blocked garbage, and normal falling of the garbage is recovered.

Owner:山东瀚海振华重工科技有限公司

Hot-galvanizing machining device

ActiveCN113106371AEasy to salvageImprove cleaning efficiencyHot-dipping/immersion processesCleaning using toolsEngineeringMachining

The invention relates to the field of hot galvanizing and particularly relates to a hot-galvanizing machining device. The hot-galvanizing machining device comprises a galvanizing tank, wherein a sliding frame and a sliding mechanism are arranged on the galvanizing tank; a horizontal attachment roller partially immersed in molten zinc is rotatably connected to the sliding frame; a rotating mechanism for driving the attachment roller to rotate towards a forward movement direction of the sliding frame is arranged on the galvanizing tank; the sliding frame is connected with a sliding rod perpendicular to the attachment roller in a sliding manner; two ends of the sliding rod are fixedly connected with collecting grooves; a scraping plate is arranged on one side, facing towards the attachment roller, of each collecting groove; an adjusting mechanism for driving the sliding rod to move and adjust positions of two scraping plates when the attachment roller moves forwards is also arranged on the sliding frame; a scraping plate located on one side of the forward movement direction of the attachment roller abuts against the attachment roller; and a scraping plate located on the other side of the attachment roller is separated from the attachment roller. According to the hot-galvanizing machining device, manual removal of impurities is changed into mechanical automatic removal, so that workers can conveniently fish the impurities on the surface of the molten zinc; and the removal efficiency of the impurities is effectively improved.

Owner:浙江航峰铁塔有限公司

Process for manufacturing corrosion resistant low-chromium tubing and casing in CO2 and H2S coexisted environment

ActiveCN101407019AEnhanced ability for stress corrosion cracking (SSC)Increase low temperature transformation tissue compositionProcess efficiency improvementElectric furnaceElectric arc furnacePetroleum

The invention relates to the technical field of oil pipe material, in particular to a process for preparing a corrosion resistant low-chromium oil sleeve under the coexisting environment of CO2 and H2S. The invention overcomes the problems existing in the prior art. The technical proposal provided by the invention is that the process for preparing the corrosion resistant low-chromium oil sleeve under the coexisting environment of CO2 and H2S orderly comprises the following steps: 1. steel-making, wherein an electrified arc furnace is used to directly reduce iron and pig iron to obtain base metal, the base metal is refined in a ladle furnace and alloyed twice, and finally gas in the base metal is removed; 2. rolling, wherein the correct size of the material required is obtained by the step; and, 3. heat treatment and finishing. Compared with the prior art, the process has the advantages that the material prepared by the process has good CO2 / H2S corrosion resistance and economical efficiency; when used in the underground mining, the material can replace the common carbon steel; and the cost is no more than 150 percent higher than that of the oil sleeve material in the same level, but the material can bring much more benefits.

Owner:XIAN MAURER PETROLEUM ENG LAB

Ecological water treatment method

InactiveCN102765814AAvoid heavy pollutionRestore ecological purification functionBiological water/sewage treatmentFishingNutrient

The invention provides an ecological water treatment method. By adding blue algae liquid and an active biological water purifying agent into rivers, lakes or ponds, the capability of grabbing a large quantity of nutrients for beneficial microbes is enhanced, and propagation and growth of the beneficial microbes are accelerated, so that the beneficial microbes become pilot active microbes and can quickly absorb and degrade organic substances in the water and inhibit other harmful microbes; and in the blue algae bacteria rising process, nitrogen, phosphorus nutrients, heavy metals and other suspended substances in the water are adsorbed and fixed to facilitate fishing and collection to form raw materials for efficient organic fertilizers, so that the consumption of fertilizers is reduced, the blue algae is changed into valuable and usefulness, good treatment of treating dirt with dirt is realized, the water becomes transparent and clear, healthy growth of aquatic organisms and plants in the water under full photosynthesis is facilitated, the ecological purification function of the water is quickly recovered, and the original ecological balance of the water is finally recovered.

Owner:HAO YUAN TE CONTROL

Blue algae treating agent containing alfalfa roots and preparation method thereof

InactiveCN104445453AGrowth inhibitionPromote growthSpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processCarrageenanBrick

The invention discloses a blue algae treating agent containing alfalfa roots. The blue algae treating agent is prepared from the following raw materials in parts by weight: 40-60 parts of clays, 20-30 parts of brick slag, 20-30 parts of alfalfa roots, 14-18 parts of aluminum potassium sulfate, 5-7 parts of calcined gypsum, 9-13 parts of calcium chloride, 6-9 parts of ferric oxide, 8-10 parts of rice chaff, 13-17 parts of sophora alopecuroide, 2-3 parts of carrageenan, 12-15 parts of ammonium alum, proper amount of water and 3-4 parts of adsorption auxiliaries. According to the blue algae treating agent, the alfalfa roots are used, so that nitrogen content of water quality is increased, N / P ratio is increased, and the growth of the blue algae can be inhibited; by adding rice chaff and sophora alopecuroide, the growth of the blue algae can also be inhibited, and the growth of green algae is promoted; meanwhile, the clays and the brick slag which are subjected to high-temperature treatment and grinded are cooperatively used and are high in suspension property, so that the adsorbability to the blue algae is high and the blue algae is easy to fish out. Not by using a chemical or physical method, the treating agent can inhibit the growth of the blue algae for a long time, cannot destroy the biological balance, is suitable for preventing and controlling the blue algae and can also remove heavy metal ions and organic pollutants in the water at the same time.

Owner:WUHU XIANGRONG FOOD

Novel efficient paint mist flocculant and preparation method thereof

InactiveCN103848489AAchieve separationEnhanced tack-free effectWater/sewage treatment by flocculation/precipitationWastewaterMelamine

The invention relates to a chemical agent for removing excessively sprayed oil paint waste water and a preparation method of the chemical agent, a novel efficient paint mist flocculant is characterized by comprising an adhesive-eliminating agent A and a flocculant B in volume ratio of 0.5: (0.5-1), the adhesive-eliminating agent A is polysilicic acid modified tripolycyanamide prepared from tripolycyanamide, alkali metal silicate, aldehydes and an auxiliary C, the flocculant B is a polymer formed by non-ionic monomers through polymerization. The paint mist flocculant prepared by the method is low in free formaldehyde content, low in cost and high in paint mist removing rate.

Owner:WUHAN UNIV OF TECH

Surface garbage salvage vessel

ActiveCN107628206AHigh degree of automationCompact structureWater cleaningPropulsion power plantsPollutionAutomation

The invention provides a surface garbage salvage vessel which comprises a vessel body, a garbage salvage device, garbage collecting devices, a garbage conveying device and a control center. The garbage salvage device is arranged at the front end of the vessel body, the garbage collecting devices are arranged on the periphery of the vessel body and are fixedly connected to the vessel body through supporting pillars at bottoms of the garbage collecting devices, garbage dampers are arranged on the periphery of the garbage conveying device, a garbage conveying belt is arranged on the surface of the garbage conveying device, and the control center is arranged in the vessel body. By the arrangement, garbage on the water surface can be cleaned through the salvage vessel, automation degree is high, problems about low manual salvage efficiency, serious potential safety hazard, high salvage cost and small salvage range are effectively solved, the surface garbage salvage vessel is compact in structure and continuous and convenient in operation, difficulty in collecting the garbage on the water surface is reduced, and the environment pollution bought by the garbage of the water surface is alleviated.

Owner:NANTONG LECROY MACHINE TOOL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com