Preparation method for high-strength hydrophobic polyvinyl alcohol composite sponge

A technology of composite sponge and polyvinyl alcohol, which is applied in separation methods, chemical instruments and methods, and liquid separation, can solve the problems of unfavorable material salvage, storage and transportation, poor mechanical strength, etc., and achieves simple methods, high oil absorption efficiency, and good The effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

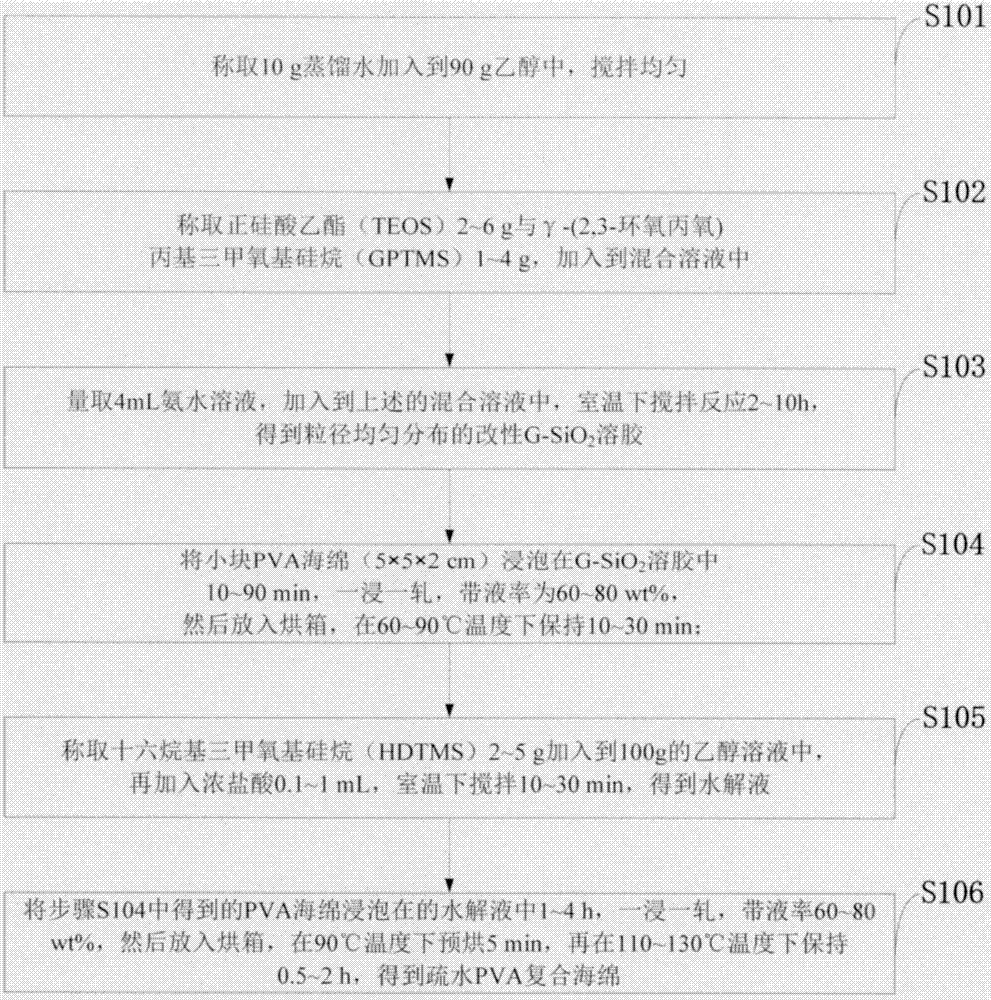

[0031] Such as figure 1 As shown, the preparation method of the high-strength hydrophobic polyvinyl alcohol composite sponge provided by the embodiments of the present invention comprises the following steps:

[0032] S101: Weigh 10 g of distilled water and add it to 90 g of ethanol, and stir evenly;

[0033] S102: Weigh 2-6 g of tetraethyl orthosilicate (TEOS) and 1-4 g of γ-(2,3-glycidoxy)propyltrimethoxysilane (GPTMS), and add them into the mixed solution;

[0034] S103: Measure 4 mL of ammonia solution, add it to the above mixed solution, stir and react at room temperature for 2-10 hours, and obtain modified G-SiO with uniform particle size distribution 2 Sol;

[0035] S104: Soak a small piece of PVA sponge (5×5×2cm) in G-SiO 2 Put in the sol for 10-90 minutes, dipping and rolling, the liquid-carrying rate is 60-80wt%, then put it into an oven, and keep it at a temperature of 60-90°C for 10-30 minutes;

[0036] S105: Weigh 2 to 5 g of hexadecyltrimethoxysilane (HDTMS) ...

Embodiment 1

[0046] (1) Take by weighing 10g distilled water and join in 90g ethanol, stir;

[0047] (2) Weigh 2 g of tetraethyl orthosilicate (TEOS) and 1 g of γ-(2,3-glycidyloxy)propyltrimethoxysilane (GPTMS), and add them to the mixed solution of (1);

[0048] (3) Measure 2 mL of ammonia solution, add it to the above mixed solution, stir and react at room temperature for 2 hours, and obtain modified G-SiO with uniform particle size distribution. 2 Sol;

[0049] (4) Soak a small piece of PVA sponge (10×10×2cm) in the G-SiO 2 In the sol for 30 minutes, dipping and rolling, the liquid-carrying rate is 70wt%, and then put it into an oven and keep it at 60°C for 30 minutes;

[0050] (5) Weigh 2 g of hexadecyltrimethoxysilane (HDTMS) and add it to 100 g of ethanol solution, then add 0.1 mL of concentrated hydrochloric acid, and stir at room temperature for 30 min to obtain a hydrolyzate;

[0051] (6) Soak the PVA sponge obtained in (4) in the hydrolyzed solution of (5) for 1h, dip and roll...

Embodiment 2

[0054] (1) Take by weighing 10g distilled water and join in 90g ethanol, stir;

[0055] (2) Weigh 3 g of tetraethyl orthosilicate (TEOS) and 2 g of γ-(2,3-glycidyloxy)propyltrimethoxysilane (GPTMS), and add them to the mixed solution of (1);

[0056] (3) Measure 4 mL of ammonia solution, add it to the above mixed solution, stir and react at room temperature for 4 hours, and obtain modified G-SiO with uniform particle size distribution. 2 Sol;

[0057] (4) Soak a small piece of PVA sponge (5×5×1cm) in the G-SiO 2 In the sol for 60 minutes, one dipping and one rolling, the liquid-carrying rate is 75wt%, then put it into an oven, and keep it at a temperature of 90°C for 10 minutes;

[0058] (5) Weigh 5 g of hexadecyltrimethoxysilane (HDTMS) and add it to 100 g of ethanol solution, then add 0.5 mL of concentrated hydrochloric acid, and stir at room temperature for 20 min to obtain a hydrolyzate;

[0059] (6) Soak the PVA sponge obtained in (4) in the hydrolyzed solution of (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com