Multiple guide shell gas circulating bioreactor bacteria ore leaching and ore leaching bacteria culture

A technology of bioreactors and reactors, applied in the direction of improving process efficiency, etc., can solve the problems of affecting ore leaching efficiency, complex structure, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

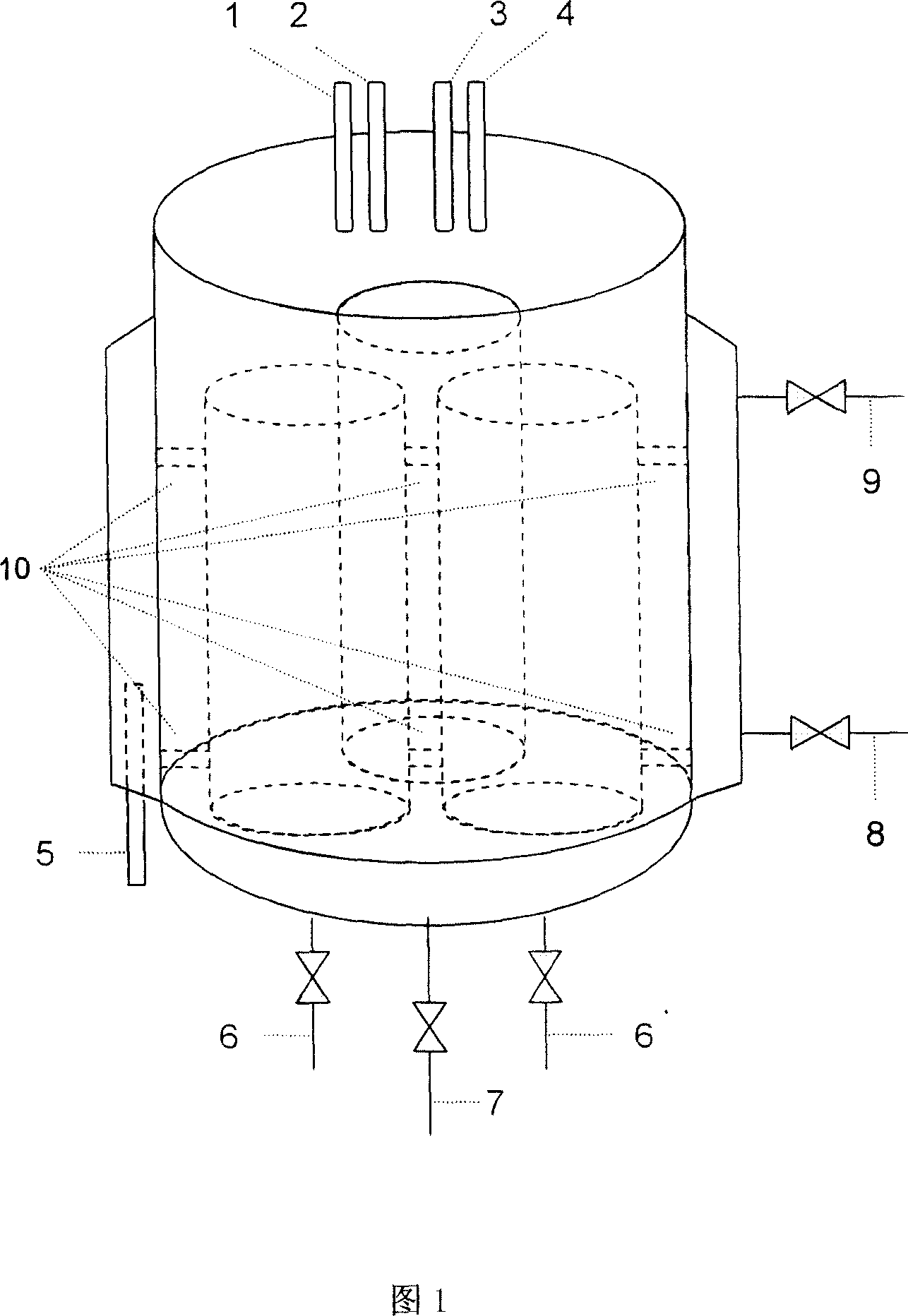

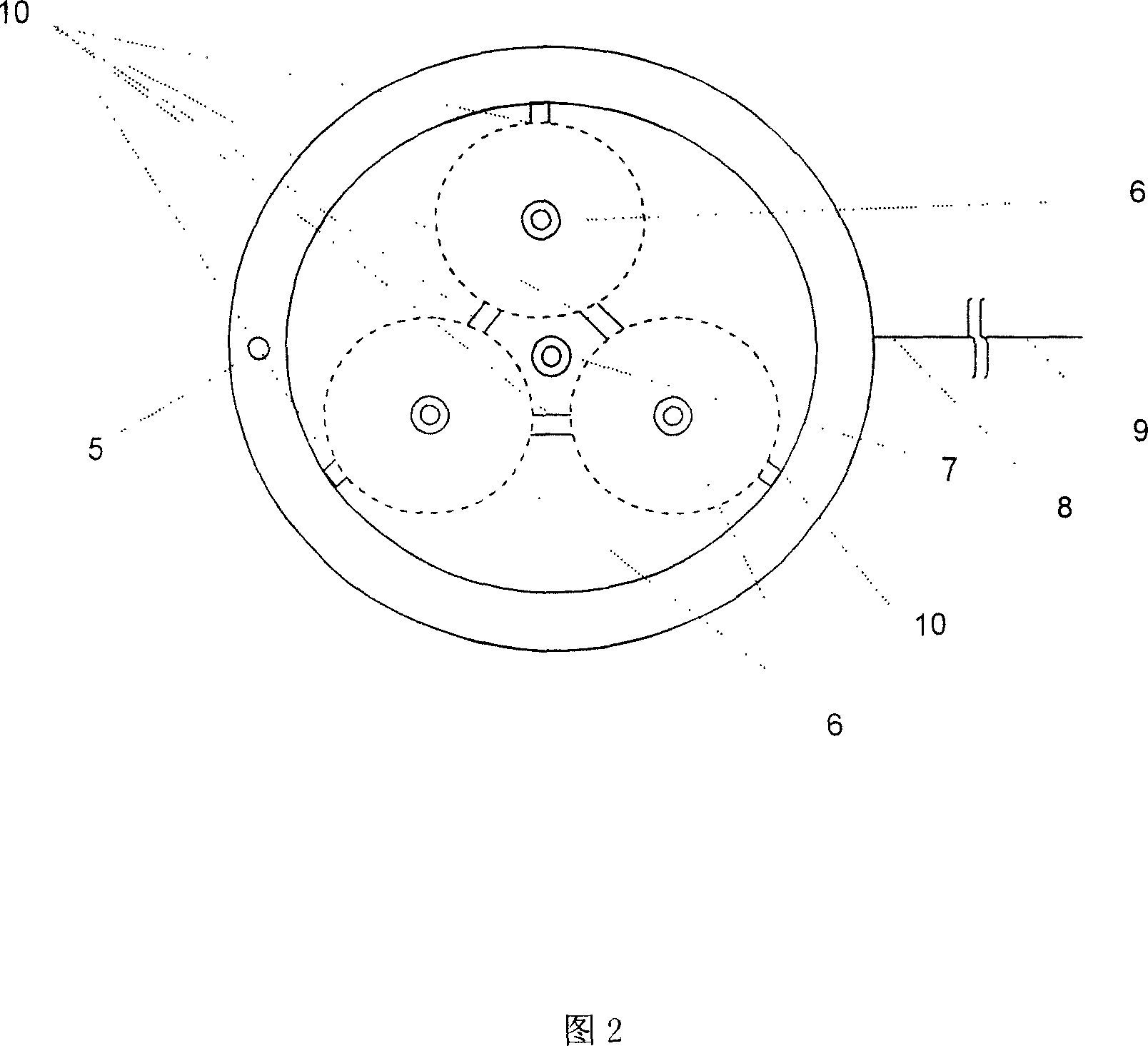

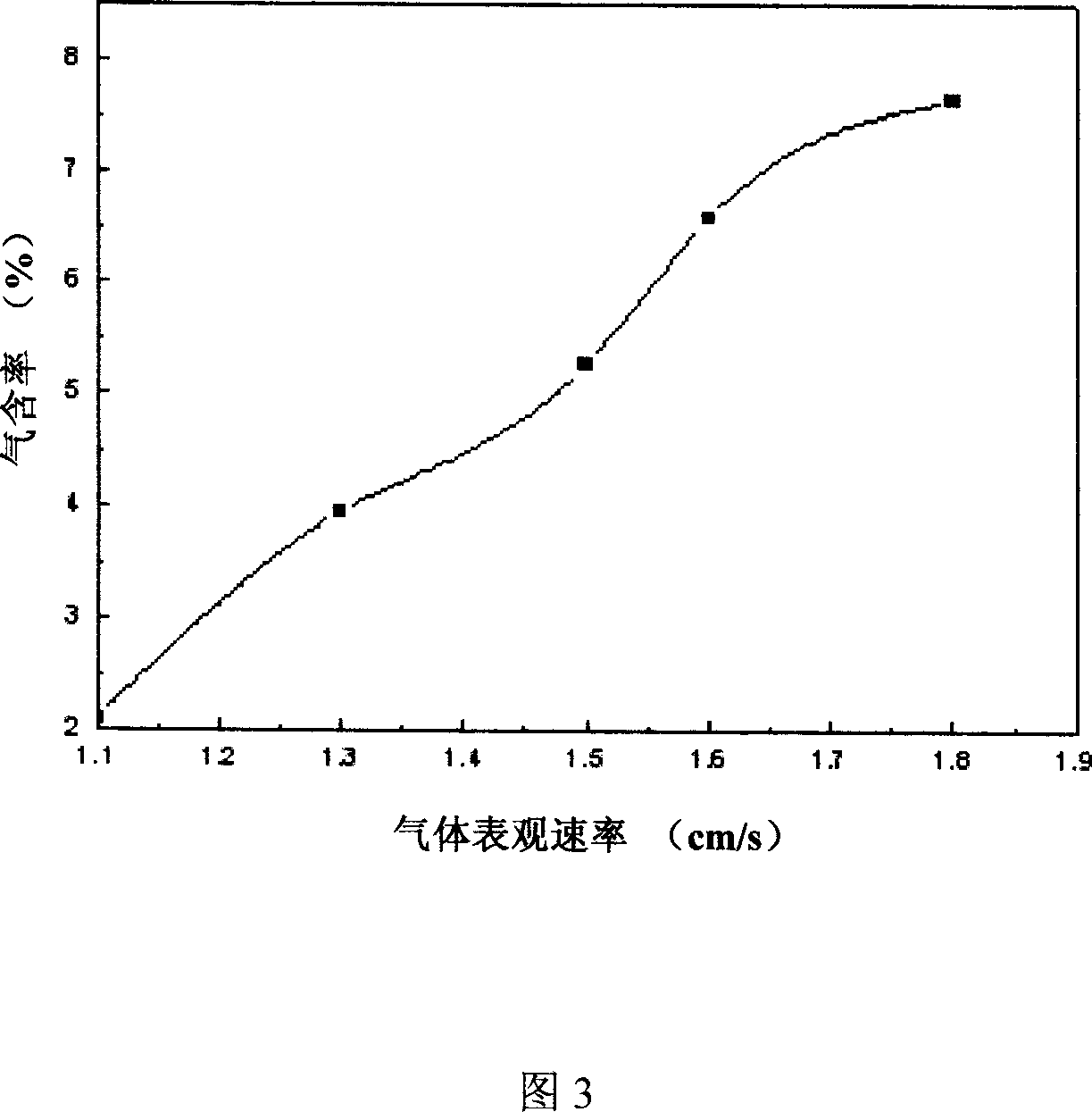

[0049] Example 1 Air circulation bioreactor with three diversion cylinders The pH of arsenic-containing gold concentrate is 2.0, and the biological pre-oxidation and arsenic removal bioreactor is made of plexiglass at 40°C and contains three diversion cylinders; the total volume of the reactor 10L, working volume 7L; reactor tank height 1000mm, diameter 120mm; guide tube height 600mm, diameter 70mm.

[0050] Gold ore powder, with a particle size of 200 mesh, contains 56.0g / t gold, 10.04% arsenic, and 14.60% sulfur.

[0051] Bacterial species: Thiobacillus caldus MTH-04 and Leptospirillum ferrooxidans MLH04.

[0052] Strain preparation and inoculation: Thiobacillus caldus MTH-04 and Leptospirillum ferrooxidans MLH04 respectively use Starky-S 0 Culture medium and 9K medium, 300mL Erlenmeyer flask with 100mL liquid volume, 40°C, pH 2.0, shaker 100r / min shaking culture until late exponential. The two bacterial solutions are mixed at a ratio of 1:1, the inoculation amount is 10% ...

Embodiment 2

[0060] Example 2 Three-diffuser gas circulation bioreactor, arsenic-containing gold concentrate pH 3.0, biological pre-oxidation and arsenic removal at 40°C

[0061] The initial pH of the slurry is 3.0, the temperature is 40° C., and other conditions are the same as in Example 1.

[0062] After 6 days of leaching reaction, the arsenic removal rate reached 88.4%.

Embodiment 3

[0063] Example 3 Three-diffuser gas circulation bioreactor, arsenic-containing gold concentrate, pH 2.0, biological pre-oxidation and arsenic removal at 43°C

[0064] The initial pH of the pulp is 2.0, the temperature is 43° C., and other conditions are the same as in Example 1.

[0065] After 6 days of leaching reaction, the arsenic removal rate reached 87.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com