Process for regenerating, recovering and reutilizing low-concentration organic waste water

An organic wastewater, low-concentration technology, used in aerobic process treatment, water pollutants, sustainable biological treatment, etc. problems, to achieve the effect of easy backwashing, low operating and maintenance costs, and fast filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

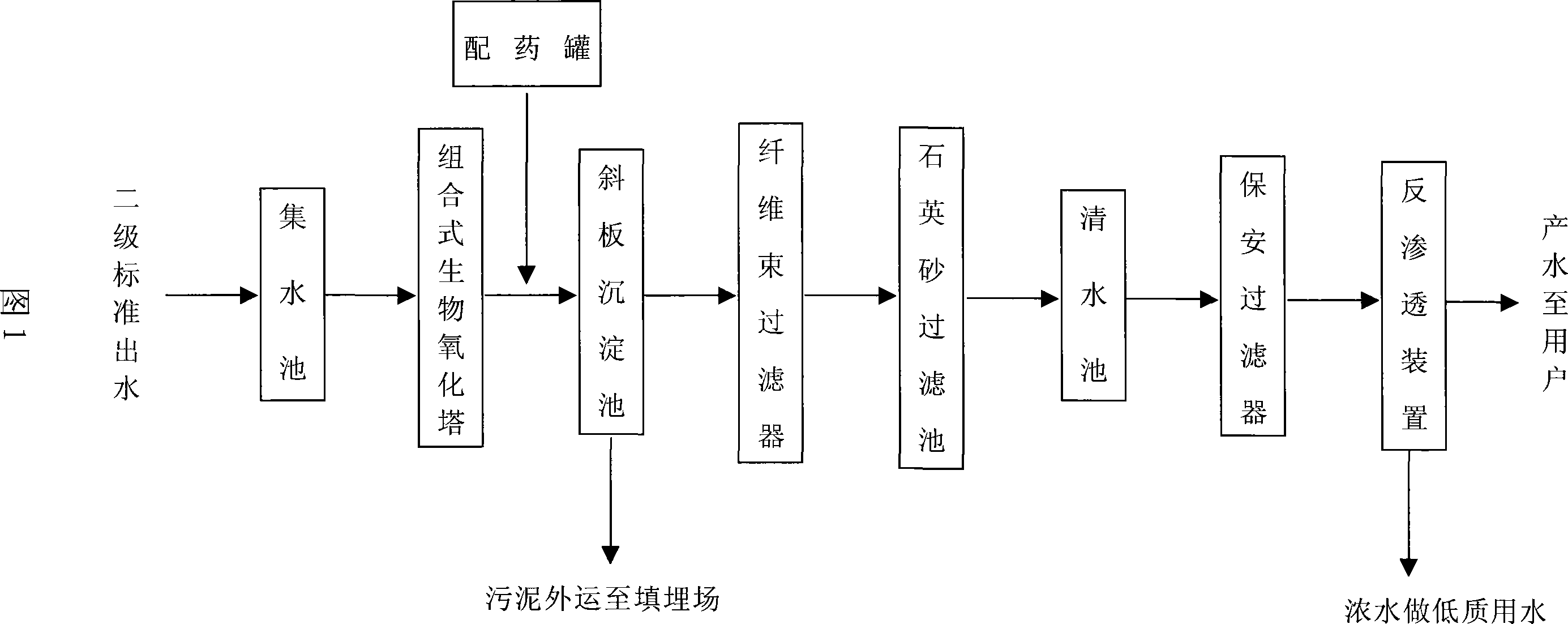

[0033] A city sewage treatment plant 600m 3 / h Secondary standard effluent is regenerated and reused in thermal power plants

[0034] Adopt the inventive method to process, and its process is as follows:

[0035] The first step, influent water quality, national standards and removal rate

[0036] The secondary standard effluent water quality requirements are COD≤100mg / L, BOD 5 ≤30mg / L, ammonia nitrogen ≤25mg / L, turbidity (no requirement) (GB 18918-2002). The technology of the present invention requires that the influent water quality is controlled within this standard. The water quality required by the user should meet the GB / T19923-2005 standard: COD≤50mg / L, BOD 5 ≤10mg / L, turbidity≤3NTU, ammonia nitrogen≤10mg / L (when the heat exchanger of the circulating cooling water system is made of copper, the ammonia nitrogen index of the circulating cooling water should be less than 1mg / L).

[0037] The second step of processing:

[0038] a) The secondary standard effluent of the...

Embodiment 2

[0044] A petrochemical plant 150m 3 / h petrochemical low-concentration wastewater regeneration and reuse treatment

[0045] The first step, influent water quality, national standards and removal rate

[0046] The effluent water quality requirements of petrochemical plant wastewater treatment workshops are COD≤100mg / L, ammonia nitrogen≤25mg / L, petroleum ≤5mg / L, and turbidity (no requirement) (GB 18918-2002). The process of the present invention requires that the influent water quality be controlled within this standard; the water quality required by the user should meet the GB / T19923-2005 standard: COD≤50mg / L, BOD 5 ≤10mg / L, turbidity≤3NTU, ammonia nitrogen≤10mg / L (when the heat exchanger of the circulating cooling water system is made of copper, the ammonia nitrogen index of the circulating cooling water should be less than 1mg / L);

[0047] The second step of the process

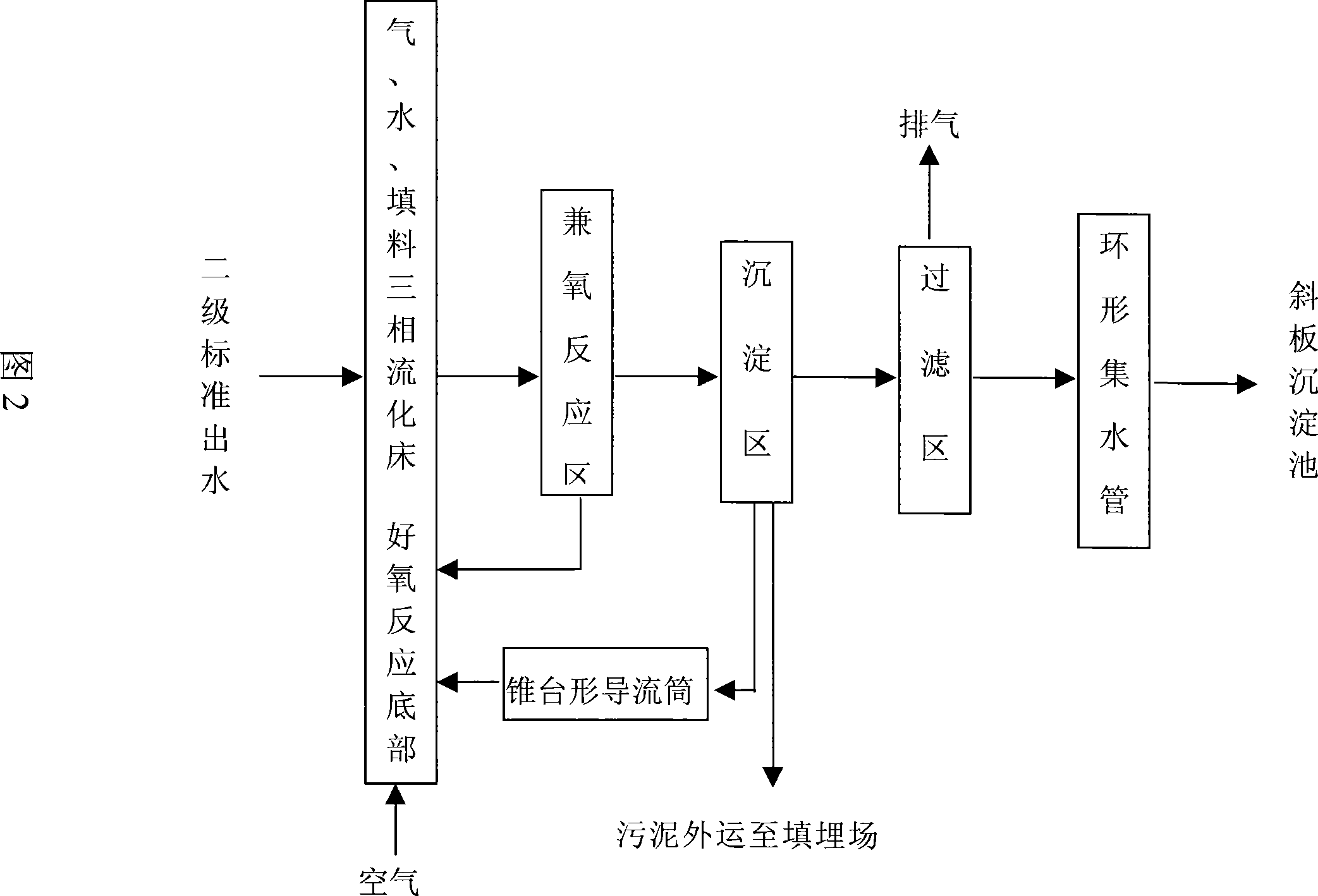

[0048] a) Firstly, pump the standard outlet water from the wastewater purification workshop of the pet...

Embodiment 3

[0055] A city sewage treatment plant 400m 3 / h Secondary standard effluent regenerated and reused in chemical plants

[0056] Adopt the inventive method to process, and its process is as follows:

[0057] The first step, influent water quality, national standards and removal rate

[0058] The secondary standard effluent water quality requirements are COD≤100mg / L, BOD 5 ≤30mg / L, ammonia nitrogen ≤25mg / L, turbidity (no requirement) (GB 18918-2002). The technology of the present invention requires that the influent water quality is controlled within this standard. The water quality required by the user should meet the GB / T19923-2005 standard: COD≤50mg / L, BOD 5 ≤10mg / L, turbidity≤3NTU, ammonia nitrogen≤10mg / L (when the heat exchanger of the circulating cooling water system is made of copper, the ammonia nitrogen index of the circulating cooling water should be less than 1mg / L);

[0059] The second step of the process

[0060]a) The secondary standard effluent of the urban se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com