Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

511 results about "Keto acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

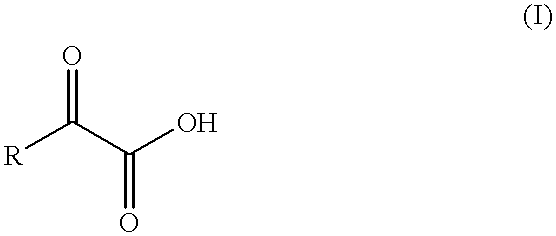

Keto acid. Keto acids are organic compounds that contain a carboxylic acid group and a ketone group. In several cases, the keto group is hydrated. The alpha-keto acids are especially important in biology as they are involved in the Krebs citric acid cycle and in glycolysis.

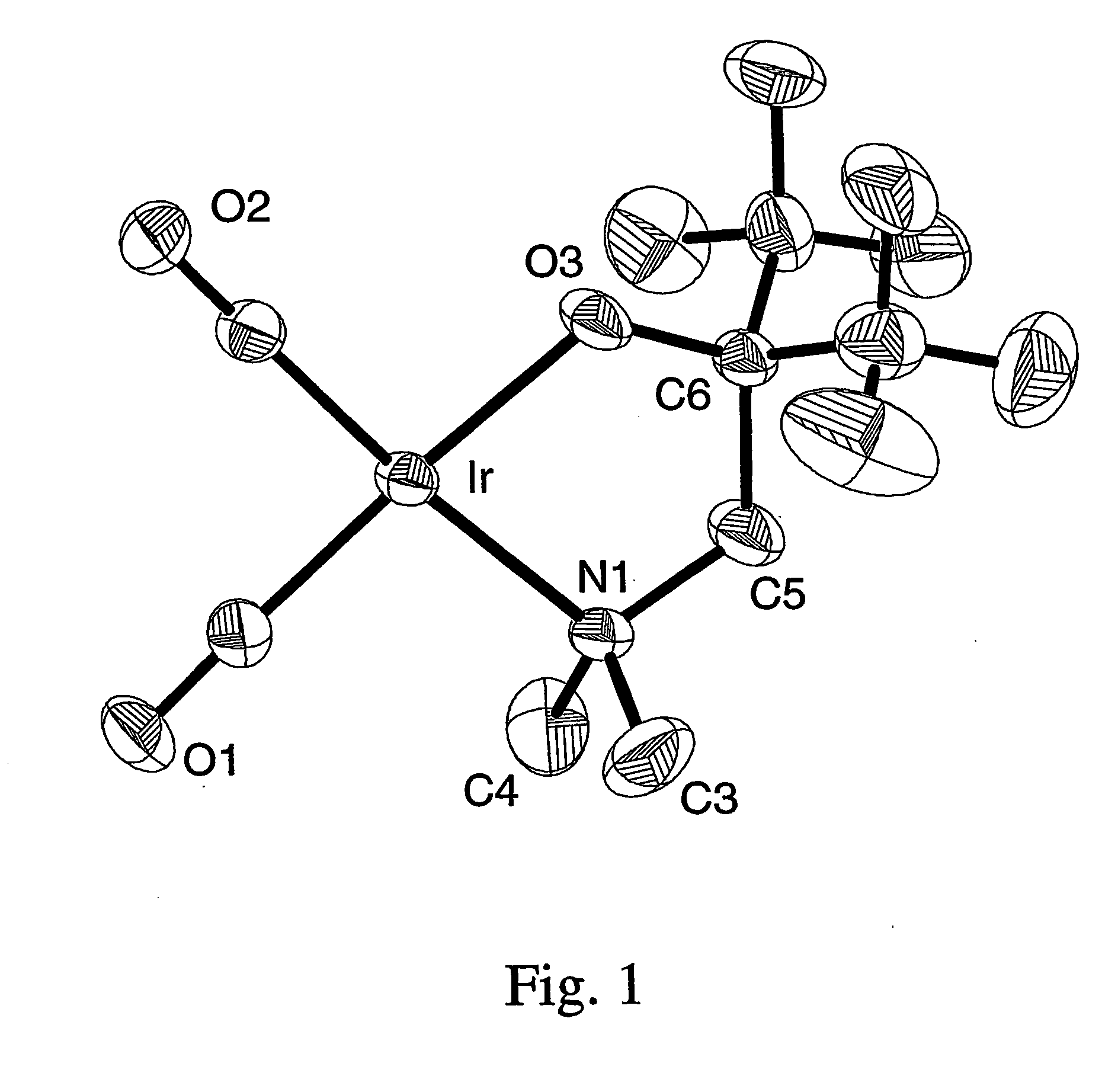

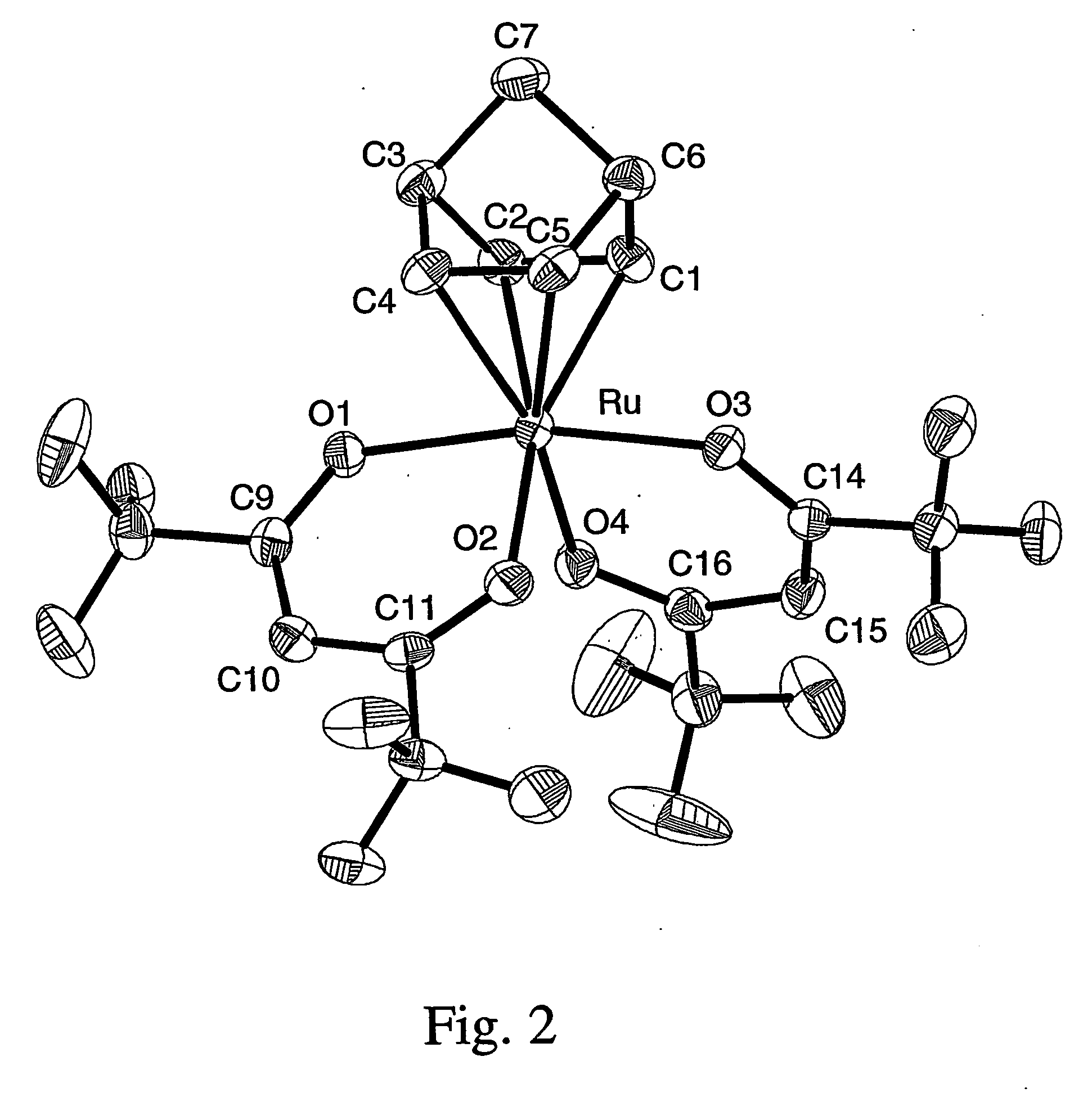

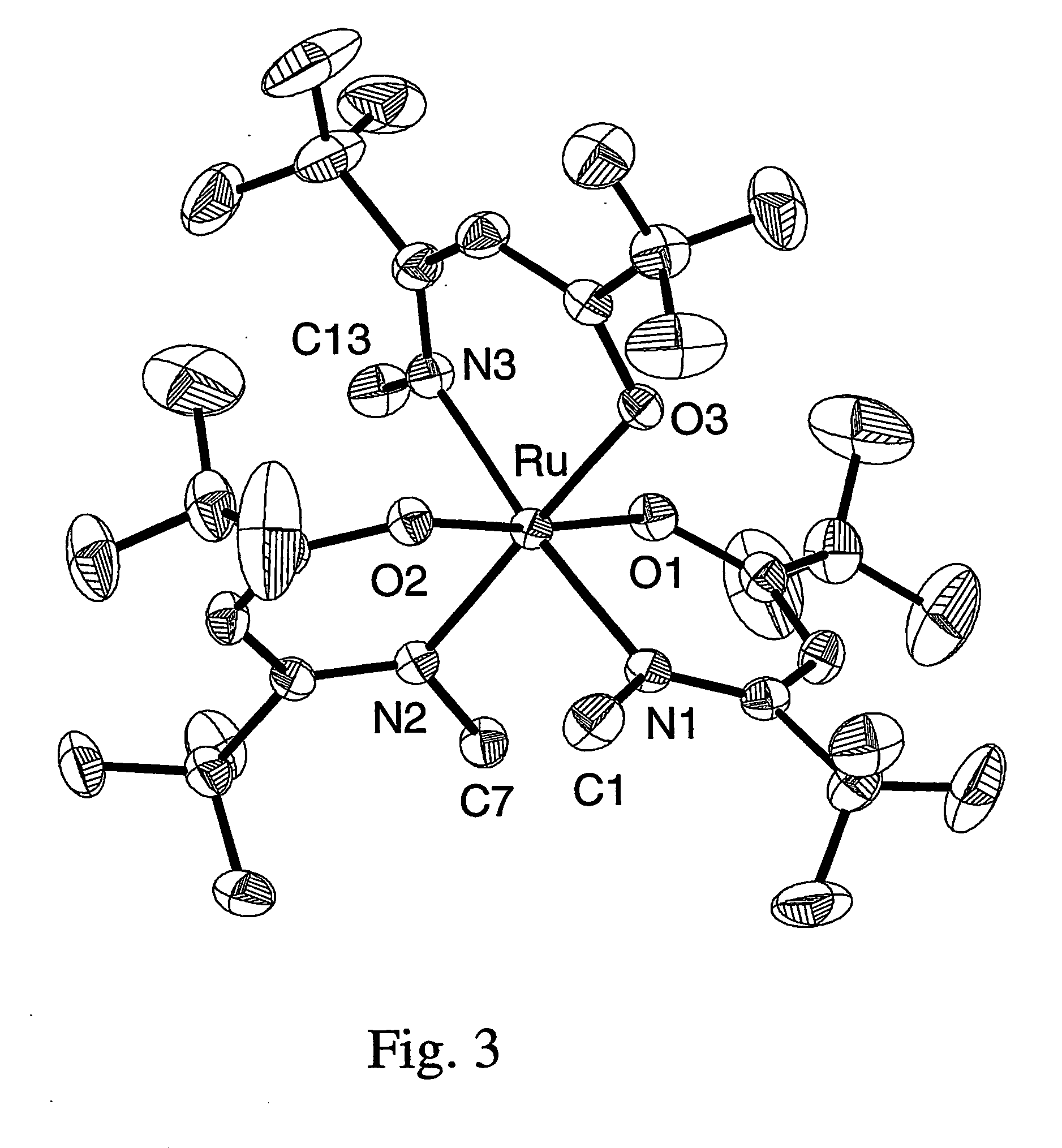

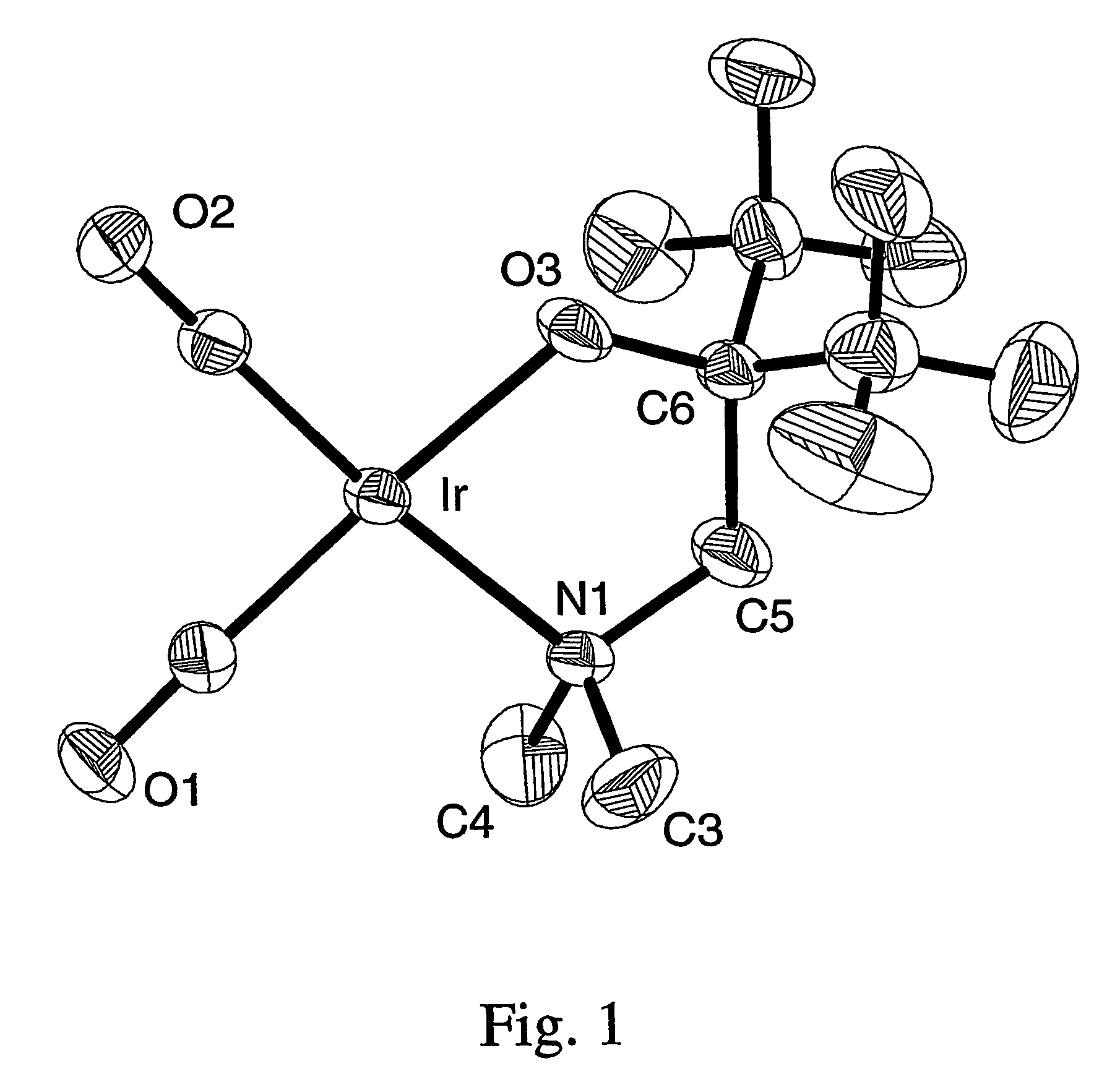

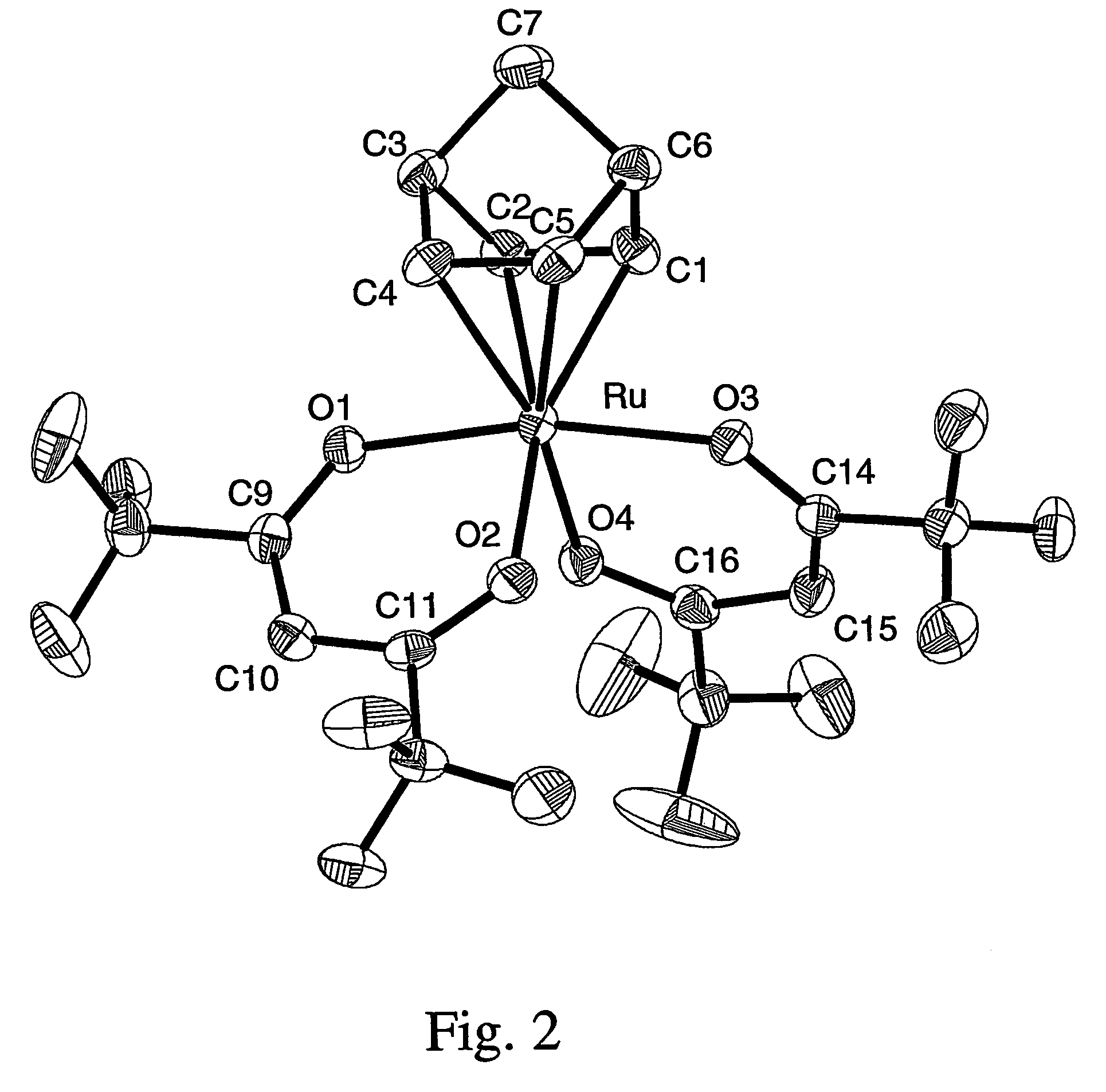

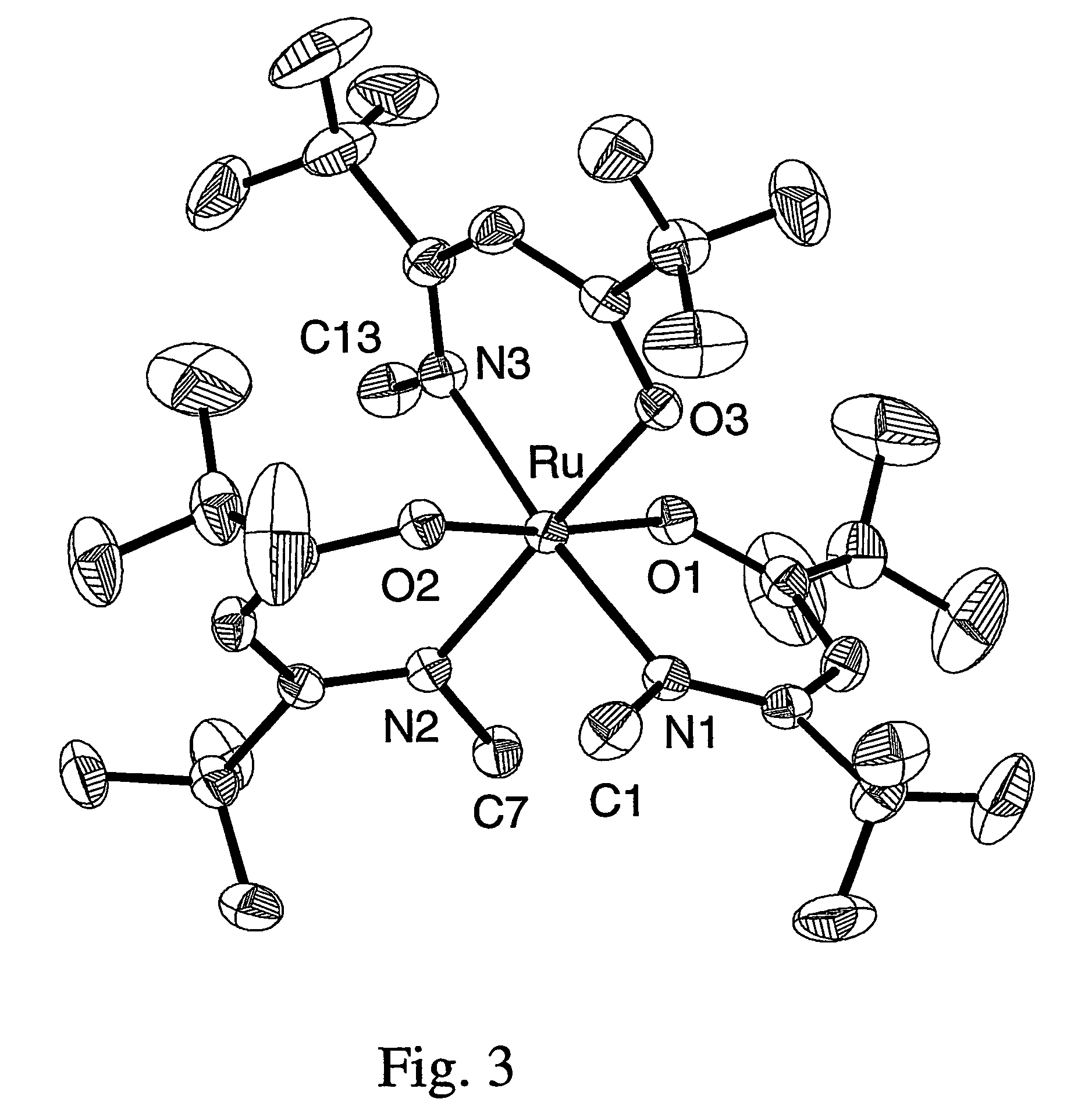

Volatile noble metal organometallic complexes

InactiveUS20050033075A1Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIridiumIodide

A series of noble metal organometallic complexes of the general formula (I): MLaXb(FBC)c, wherein M is a noble metal such as iridium, ruthenium or osmium, and L is a neutral ligand such as carbonyl, alkene or diene; X is an anionic ligand such as chloride, bromide, iodide and trifluoroacetate group; and FBC is a fluorinated bidentate chelate ligand such as beta diketonate, beta-ketoiminate, amino-alcoholate and amino-alcoholate ligand, wherein a is an integer of from zero (0) to three (3), b is an integer of from zero (0) to one (1) and c is an 10 integer of from one (1) to three (3). The resulting noble metal complexes possess enhanced volatility and thermal stability characteristics, and are suitable for chemical vapor deposition(CVD) applications. The corresponding noble metal complex is formed by treatment of the FBC ligand with a less volatile metal halide. Also disclosed are CVD methods for using the noble metal complexes as source reagents for deposition of noble metal-containing films such as Ir, Ru and Os, or even metal oxide film materials IrO2, OsO2 and RuO2.

Owner:NATIONAL TSING HUA UNIVERSITY +1

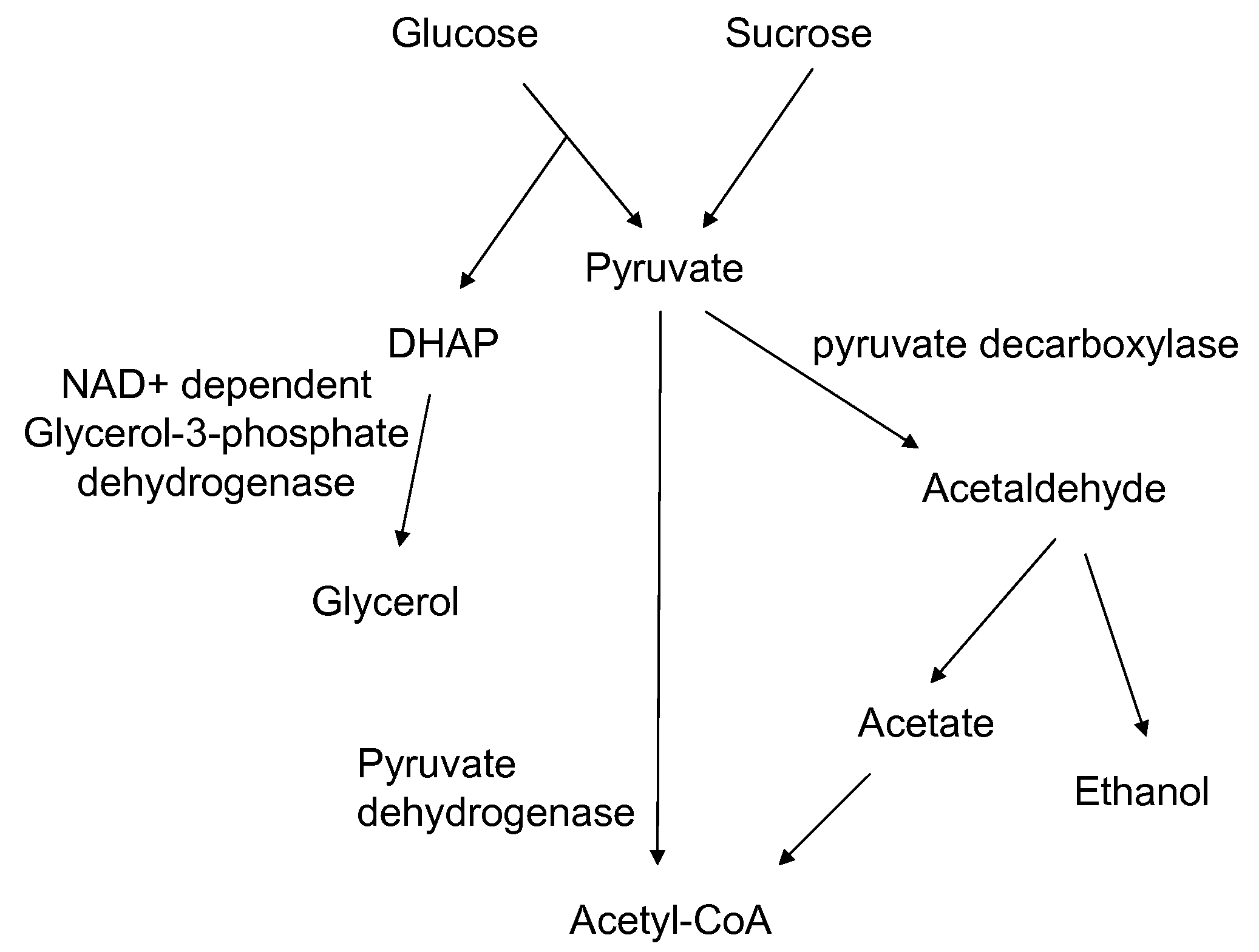

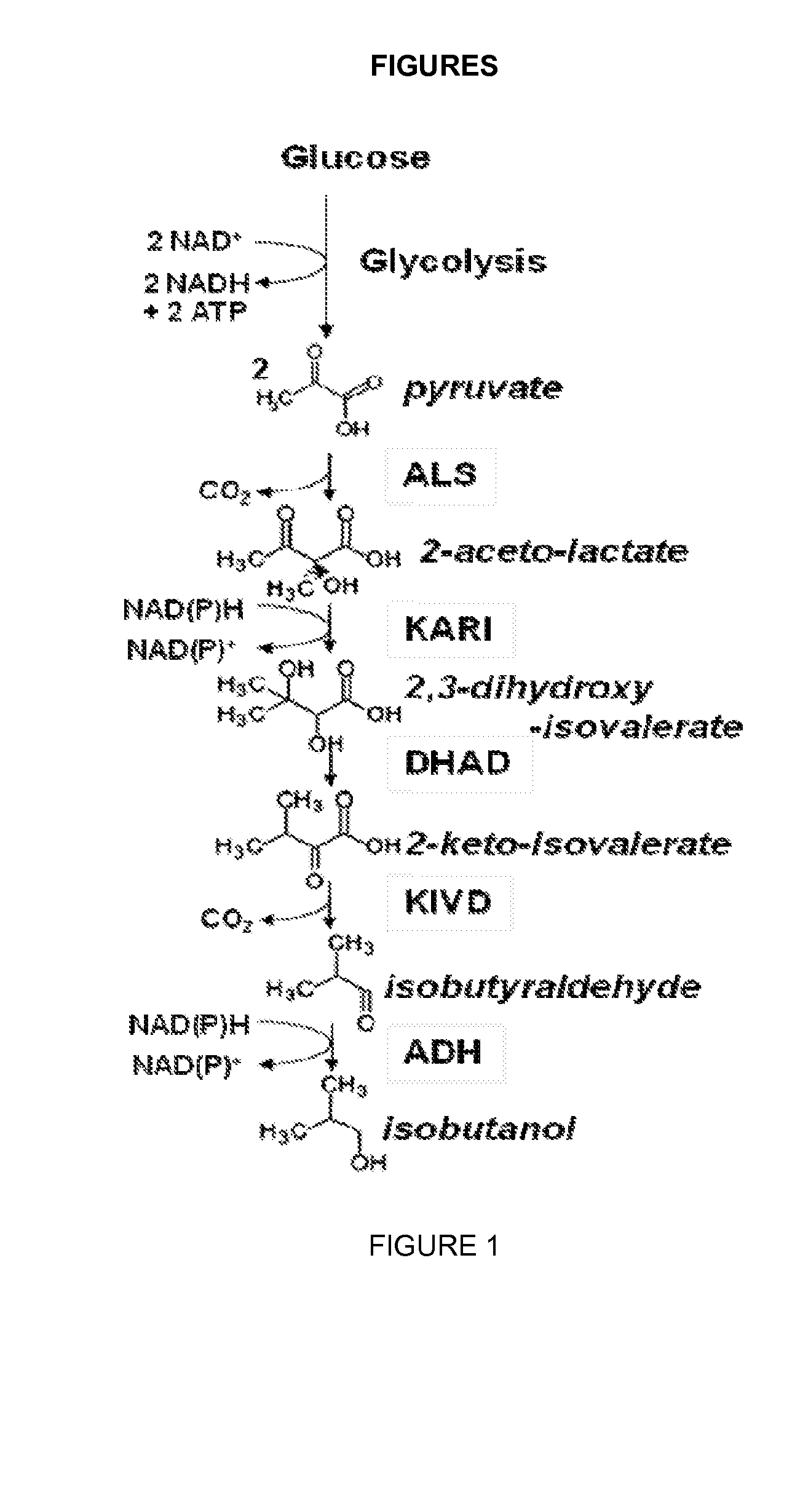

Enhanced pyruvate to acetolactate conversion in yeast

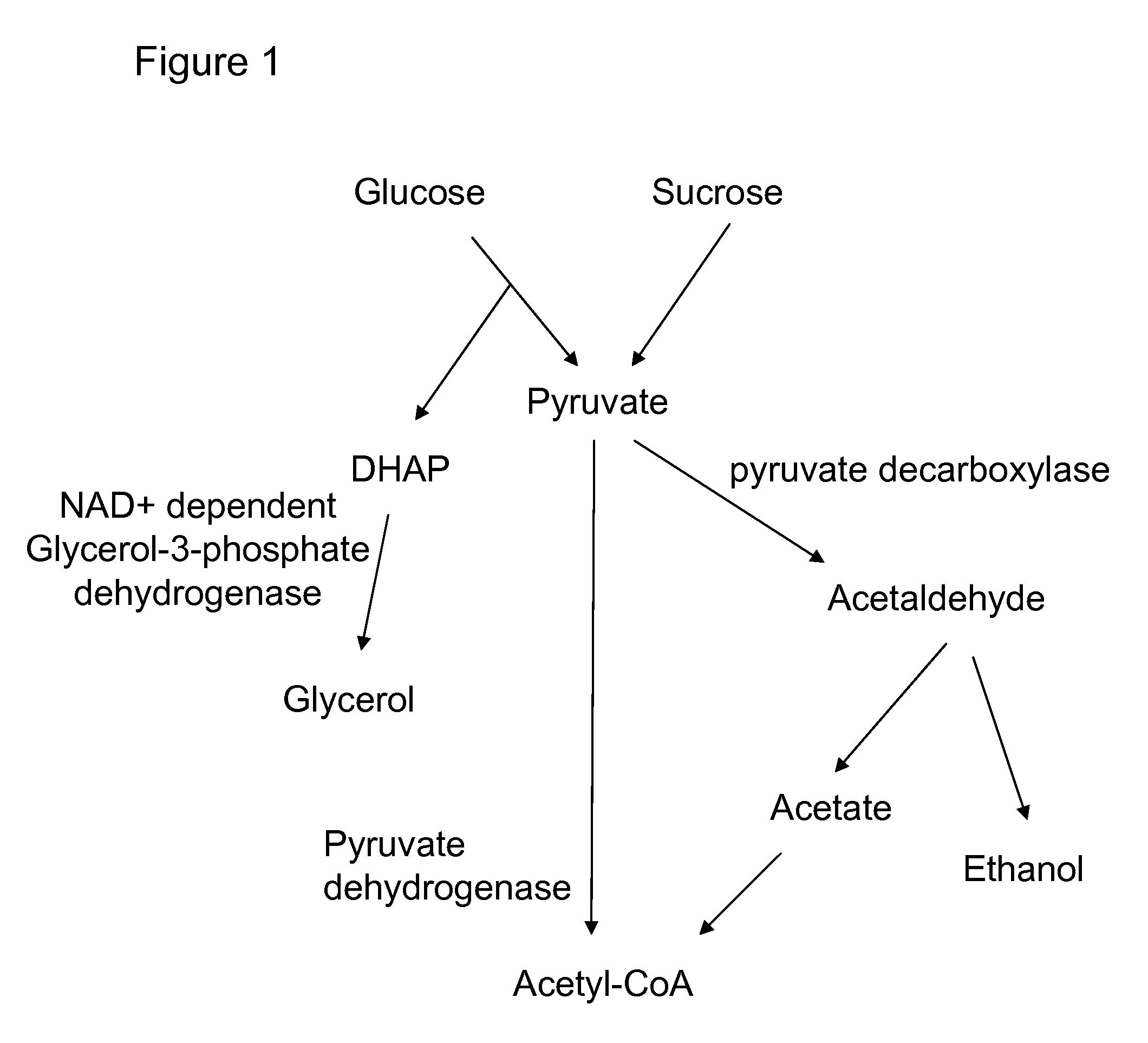

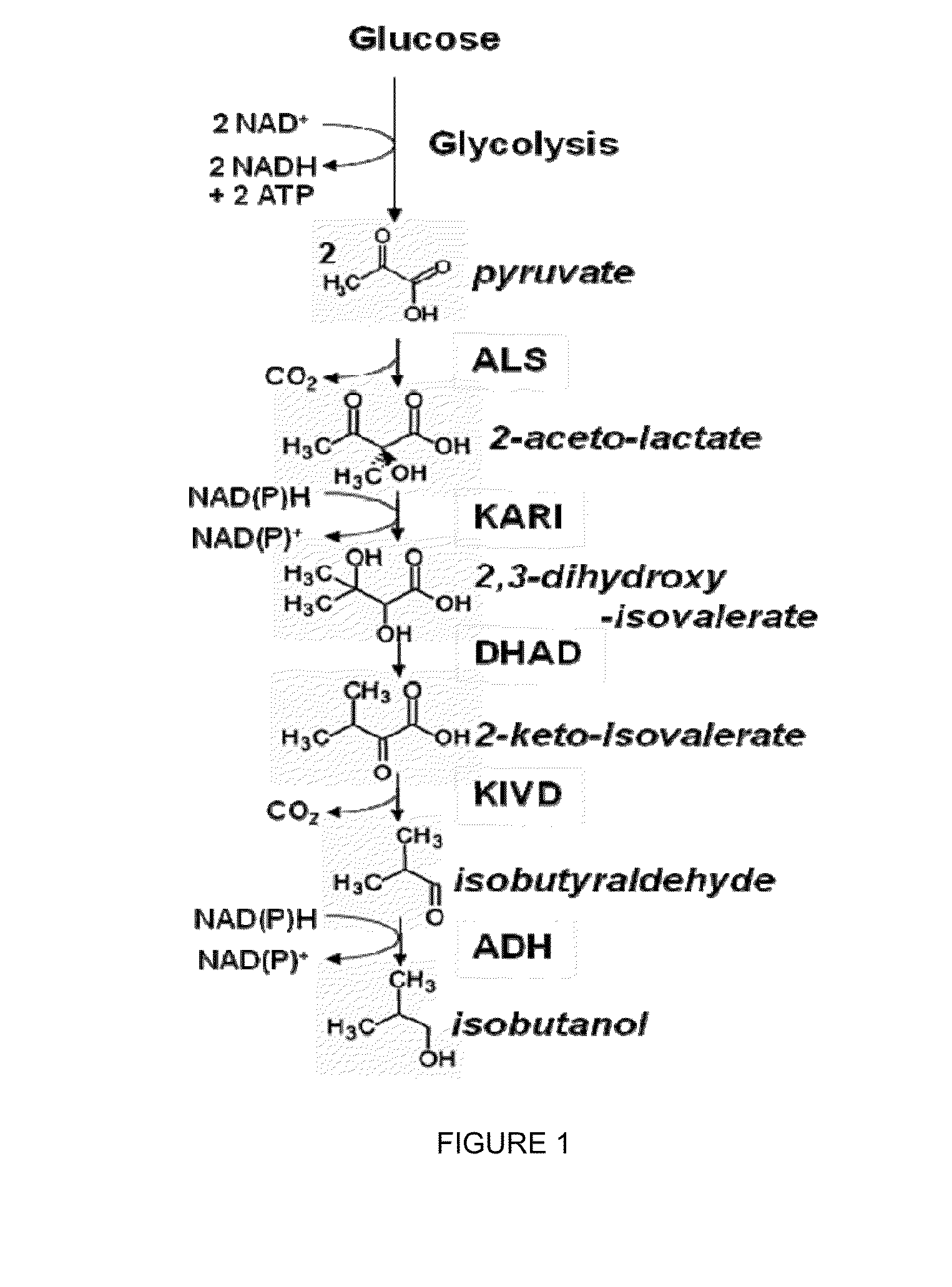

ActiveUS20090305363A1Improve throughputReduction of pyruvate decarboxylase activityFungiTransferasesYeastCytosol

A high flux in conversion of pyruvate to acetolactate was achieved in yeast through expression of acetolactate synthase in the cytosol in conjunction with reduction in pyruvate decarboxylase activity. Additional manipulations to improve flux to acetolactate are reduced pyruvate dehydrogenase activity and reduced glycerol-3-phosphate dehydrogenase activity. Production of compounds having acetolactate as an upstream intermediate benefit from the increased conversion of pruvate to acetolactate in the described strains.

Owner:GEVO INC

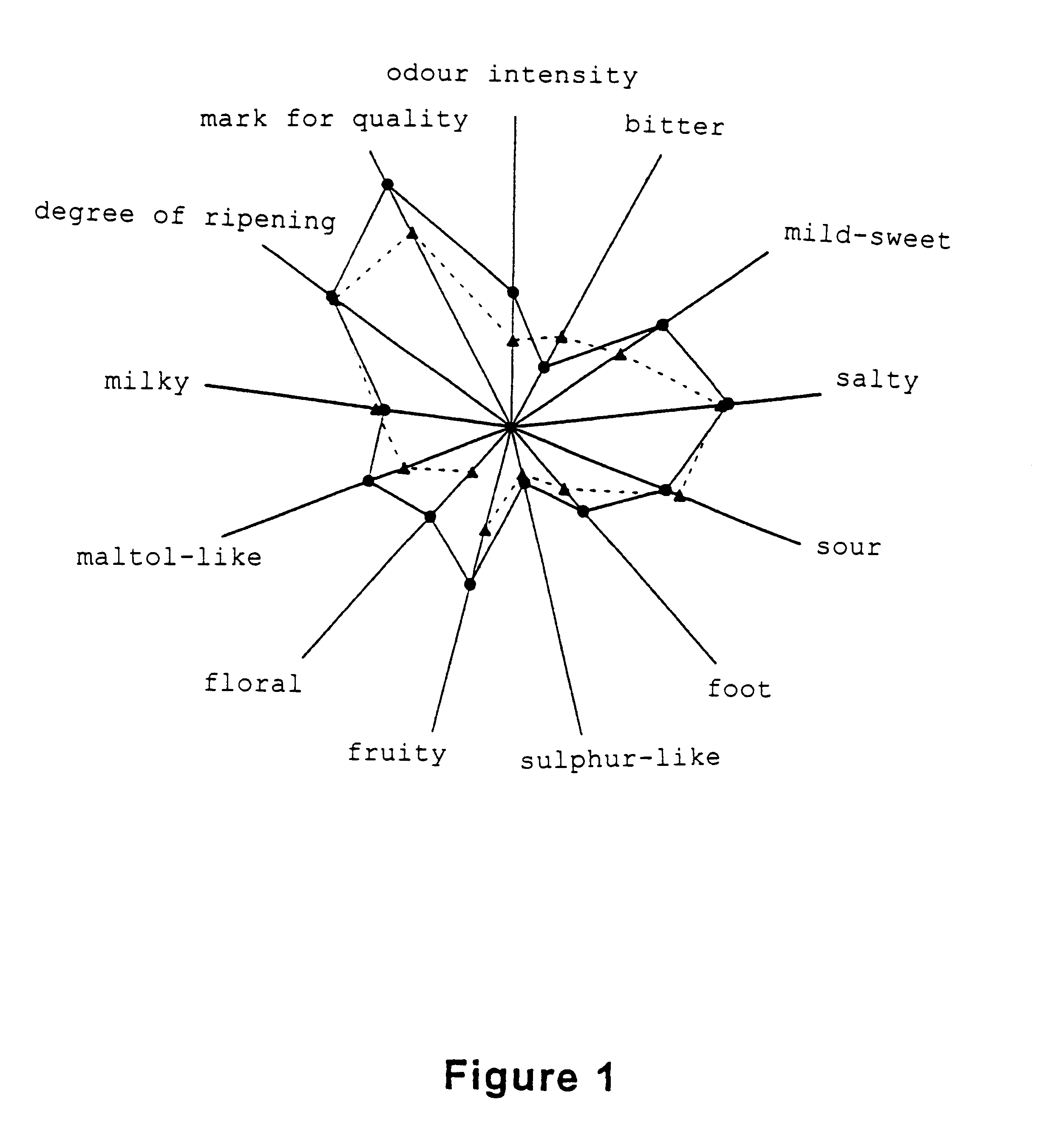

Flavor enhancing methods

InactiveUS6287620B1Improve roundnessEnhances juicy characterMilk preparationDough treatmentKetopinic acidPropanoic acid

alpha-keto acids and certain precursors and derivatives thereof, particularly those selected from the group which consists of glyoxylic acid, 2-oxo-propanoic acid, 2-oxo-butanoic acid, 3-methyl-2-oxo butanoic acid, 3-methyl-2-oxo pentanoic acid, 4-methyl-2-oxo pentanoic acid, 3-hydroxy-2-oxo-propanoic acid, oxalacetic acid, 2-oxo-glutaric acid, 2-oxo-3-phenyl-propanoic acid, 3-(4-hydroxy-phenyl)-2-oxo-propanoic acid, 2-oxo-1H-indole-3-propanoic acid, 2-oxo-1H-imidazole-4-propanoic acid, 4-methylthio-2-oxo-butanoic acid, 3-mercapto-2-oxo-propanoic acid, 3-hydroxy-2-oxo-butanoic acid, 6-amino-2-oxo-hexanoic acid and 5-guanido-2-oxo-pentanoic acid, and precursors and derivatives thereof that are capable of being formed from or releasing said acids in the use medium, are useful as flavouring ingredients. Such ingredients are useful for preparing flavouring compositions and a wide variety of flavoured foodstuffs to which they impart greater creaminess and bulkiness so that they have heightened effect in the mouth and generally an enhanced mouthfeel. They are also useful for enhancing the sweetness of foods sweetened with natural or artificial sweeteners, and giving it a more natural character.

Owner:FIRMENICH SA

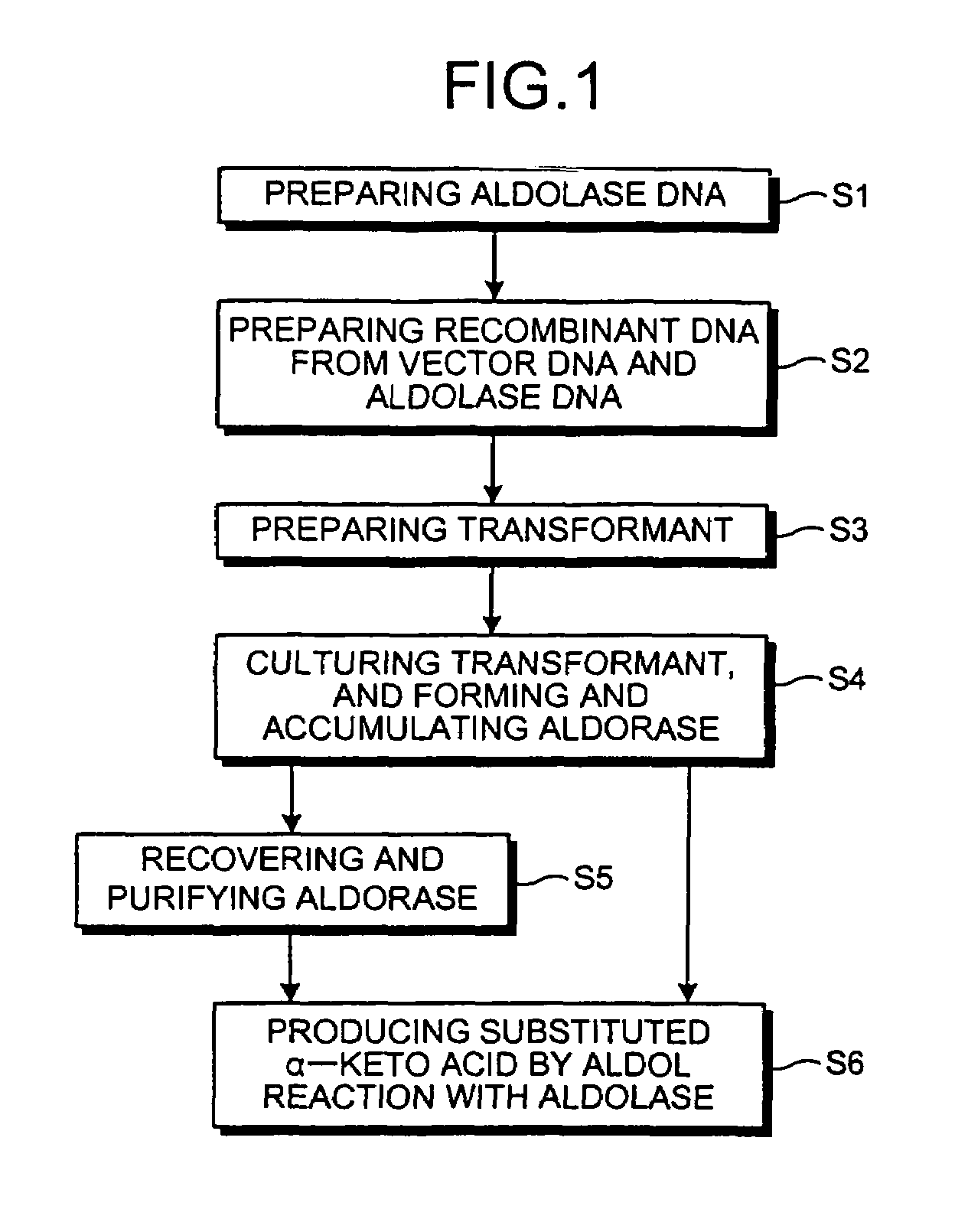

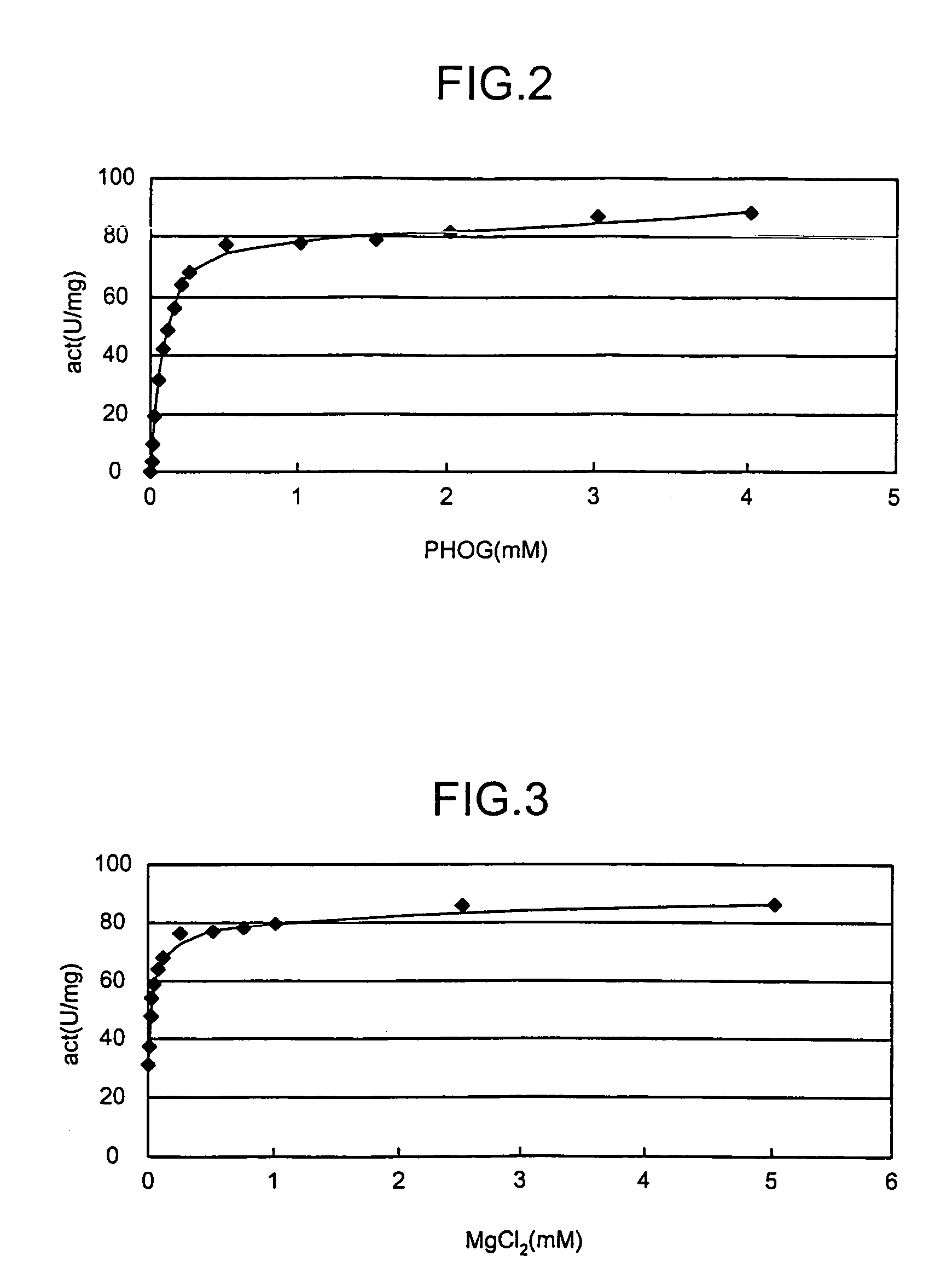

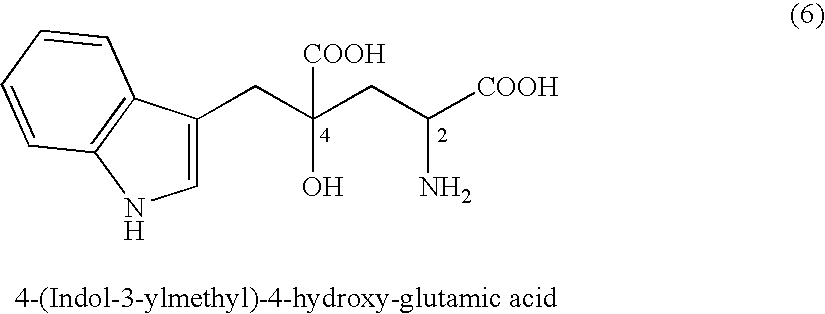

Novel aldolase and production process of substituted alpha-keto acids

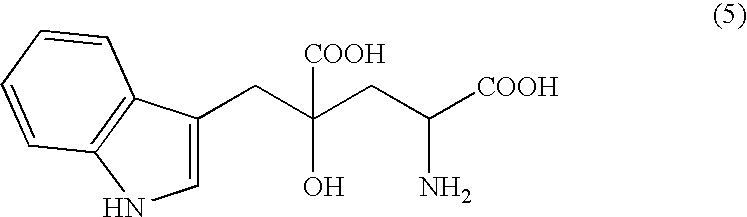

4-(Indol-3-ylmethyl)-4-hydroxy-2-oxoglutarate, which is useful as an intermediate in the synthesis of monatin, may be synthesized from indole pyruvic acid and pyruvic acid (and / or oxaloacetic acid) by using a novel aldolase derived from the genus Pseudomonas, Erwinia, Flavobacterium, or Xanthomonas.

Owner:AJINOMOTO CO INC

New Flux Composition and Process For Use Thereof

ActiveUS20100175790A1Minimizing and eliminating fluxEliminate residueWelding/cutting media/materialsThin material handlingLevulinic acidSoldering

The invention relates to a composition of matter comprising a soldering flux, wherein the flux consists essentially of a combination of a fluxing agent and a solvent, and wherein the fluxing agent comprises a keto acid such as levulinic acid or acetylbutyric acid. The flux may also comprises an ester acid, or comprises a mixture of the keto acid with the ester acid. The solvent comprises a mixture of a tacky solvent with a non-tacky solvent. The invention also relates to a process comprising soldering at least two surfaces together, each of which comprises a metal area to which solder can adhere by employing the following steps in any order: applying solder to at least one of the metal areas, aligning the metal areas so that they are superimposed over one another, heating at least one of the areas to a temperature that comprises at least the melting temperature of the solder. The last step comprises joining the superimposed areas to one another. The process employs the flux composition operatively associated with the solder, and in one embodiment the invention comprises a mixture of the flux composition with powdered solder. In another embodiment, the process comprises IMS, C4 and C4NP processes and the solder comprises a lead free solder. The invention also comprises a product produced by the foregoing process or processes.

Owner:TAIWAN SEMICON MFG CO LTD

Method and composition for treating mammalian diseases and injuries caused by the over-expression of peroxynitrite

The present invention provides a method for treating wounds and diseases in mammals, caused by mammalian cells involved in an inflammatory response, by altering indigenous in vivo levels of peroxynitrous acid, and salts thereof. The method comprises contacting the mammalian cells with a therapeutically effective amount of a reactive oxygen species mediator, wherein the reactive oxygen species mediator is selected from the group consisting of pyruvates, pyruvate precursors, α-keto acids having four or more carbon atoms, precursors of α-keto acids having four or more carbon atoms, and the salts thereof, wherein mediation of reactive oxygen species results in mediation of peroxynitrous acid. The present invention further provides a pharmaceutical composition for treating wounds and diseases in mammals, caused by mammalian cells involved in an inflammatory response, by altering indigenous in vivo levels of peroxynitrous acid, and salts thereof.

Owner:NORTH CELL PHARMA INC

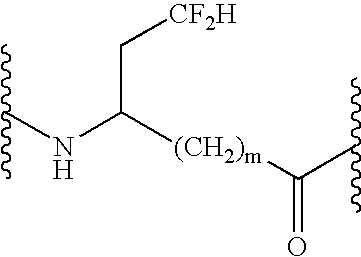

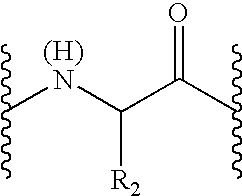

Peptide inhibitors of hepatitis C virus NS3 protease

InactiveUS6867284B1Organic compound preparationTripeptide ingredientsProteinase activityHcv hepatitis

Fluorinated oligopeptides, especially those having 4,4-difluoro-2-amino butyric acid at the C terminus, may be effective inhibitors of hepatitis C virus NS3 protease. Examples of hexapeptides of the invention, optimized for binding in the S1 specificity pocket of the enzyme, may display IC50s at the sub-micromolar level. Embodiments of tripeptides of the invention, having a keto-acid group at the C-terminus are, likewise, potent inhibitors of NS3 protease.

Owner:IST DI RICERCHE DI BIOLOGIA MOLECOLARE P ANGELETTI

Enzymatic reactions in the presence of keto acids

ActiveUS7445911B2Efficient and high yieldImprove bioavailabilityCarbon-nitrogen lyasesOxidoreductasesLyaseKeto acid

Conversion in vitro of X-Gly to X-alpha-hydroxy-Gly or X—NH2 (X being a peptide or any other compound having a carbonyl group capable of forming a covalent bond with glycine) is accomplished enzymatically in the presence of keto acids, or salts or esters thereof, to provide a good yield without the necessity of catalase or similar enzymatic reaction enhancers. Peptidylglycine α-amidating monooxygenase (PAM) is a preferred enzyme for catalyzing the conversion. Alternatively, peptidylglycine α-hydroxylating monooxygenase (PHM) is utilized to convert X-Gly to X-alpha-hydroxy-Gly which may be recovered, or optionally may be simultaneously or sequentially converted to an amide by either a Lewis base or action of the enzyme peptidyl α-hydroxyglycine α-amidating lyase (PAL). Both PHM and PAL are functional domains of PAM.

Owner:ENTERIS BIOPHARMA

Aldolase and production process of substituted alpha-keto acids

4-(Indol-3-ylmethyl)-4-hydroxy-2-oxoglutarate, which is useful as an intermediate in the synthesis of monatin, may be synthesized from indole pyruvic acid and pyruvic acid (and / or oxaloacetic acid) by using a novel aldolase derived from the genus Pseudomonas, Erwinia, Flavobacterium, or Xanthomonas.

Owner:AJINOMOTO CO INC

New flux composition and process for use thereof

InactiveUS20080124568A1Minimize and substantially eliminate flux residueProcess can be minimizedWelding/cutting media/materialsThin material handlingLevulinic acidSoldering

The invention relates to a composition of matter comprising a soldering flux, wherein the flux consists essentially of a combination of a fluxing agent and a solvent, and wherein the fluxing agent comprises a keto acid such as levulinic acid or acetylbutyric acid. The flux may also comprises an ester acid, or comprises a mixture of the keto acid with the ester acid. The solvent comprises a mixture of a tacky solvent with a non-tacky solvent. The invention also relates to a process comprising soldering at least two surfaces together, each of which comprises a metal area to which solder can adhere by employing the following steps in any order: applying solder to at least one of the metal areas, aligning the metal areas so that they are superimposed over one another, heating at least one of the areas to a temperature that comprises at least the melting temperature of the solder. The last step comprises joining the superimposed areas to one another. The process employs the flux composition operatively associated with the solder, and in one embodiment the invention comprises a mixture of the flux composition with powdered solder. In another embodiment, the process comprises IMS, C4 and C4NP processes and the solder comprises a lead free solder. The invention also comprises a product produced by the foregoing process or processes.

Owner:GLOBALFOUNDRIES INC

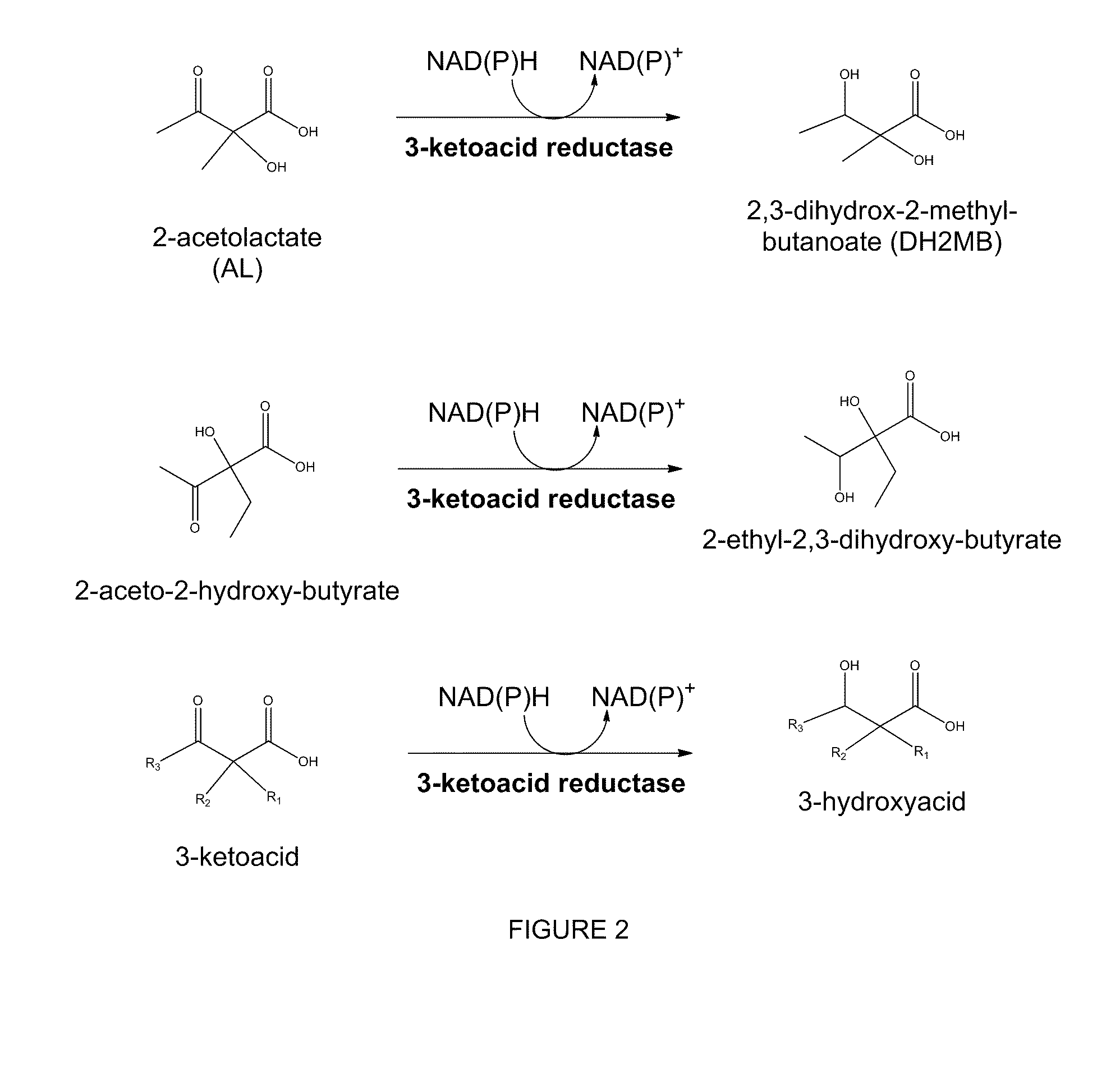

Modified alcohol dehydrogenases for the production of fuels and chemicals

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:CALIFORNIA INST OF TECH +1

Process of producing glutamate derivatives

InactiveUS7297800B2Efficient productionOrganic chemistryFermentationGlutamic Acid DerivativesMedicinal chemistry

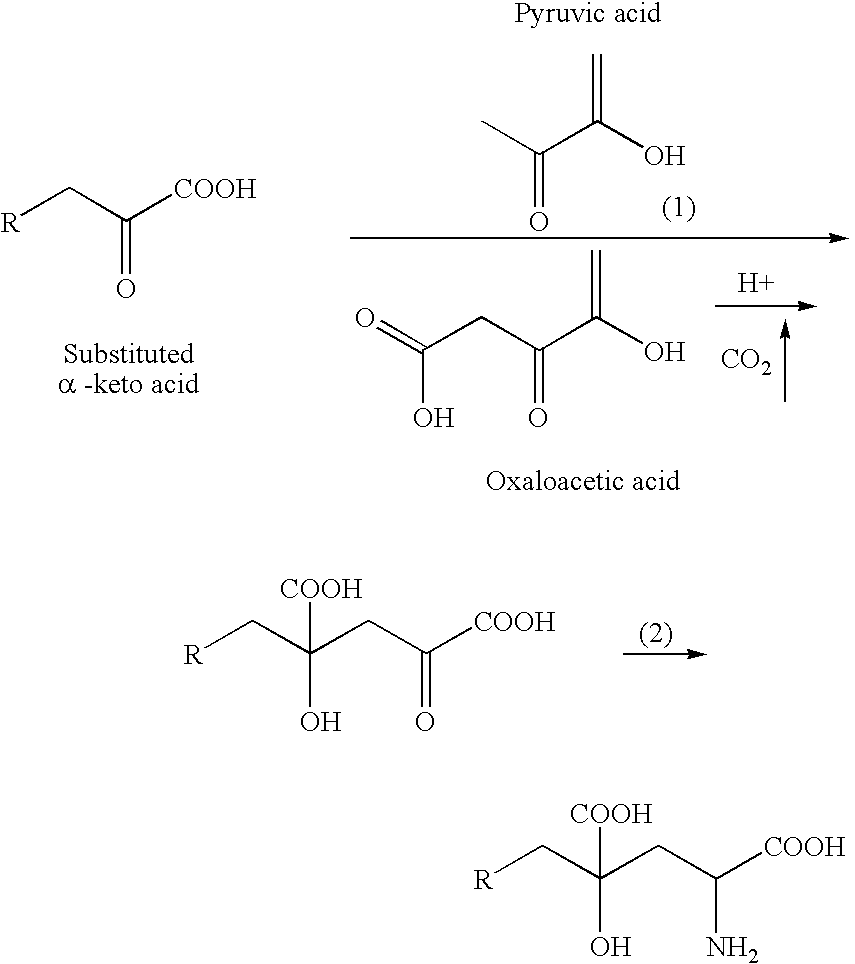

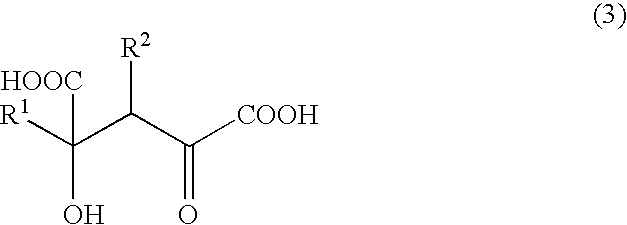

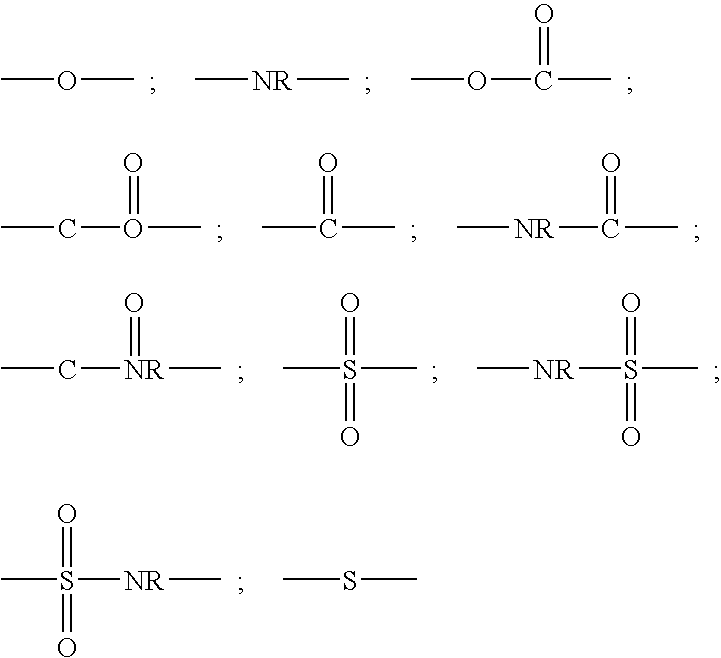

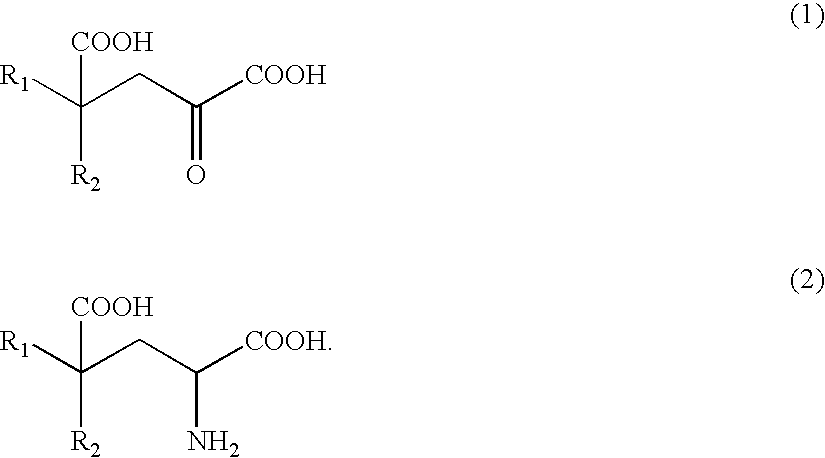

The present invention relates to a process for producing efficiently glutamic acid derivatives (including salts thereof) such as monatin by converting a substituted α-keto acid of formula (1) into a glutamic acid derivative of formula (2) in the presence of an enzyme catalyzing conversion of the same

Owner:AJINOMOTO CO INC

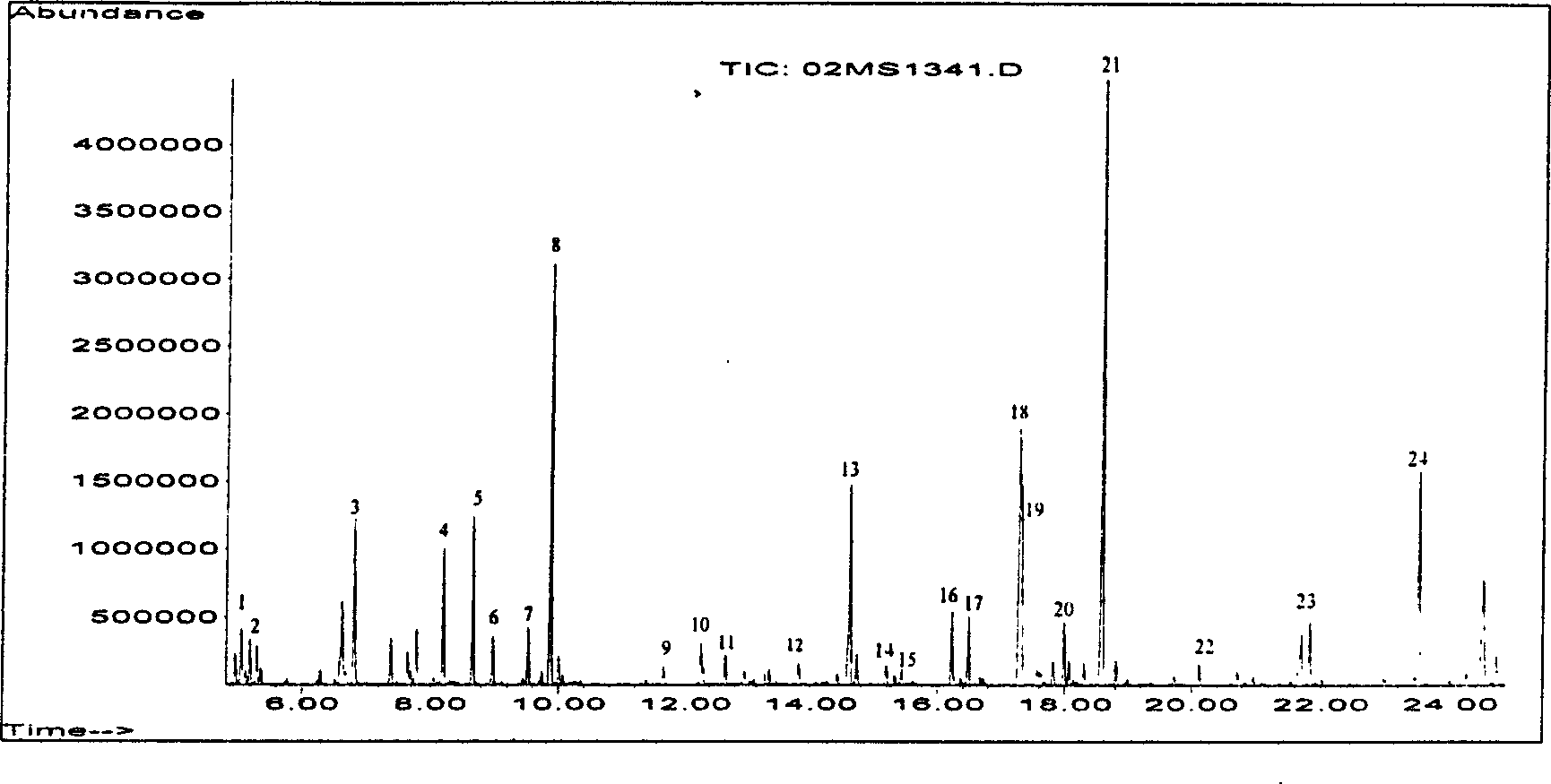

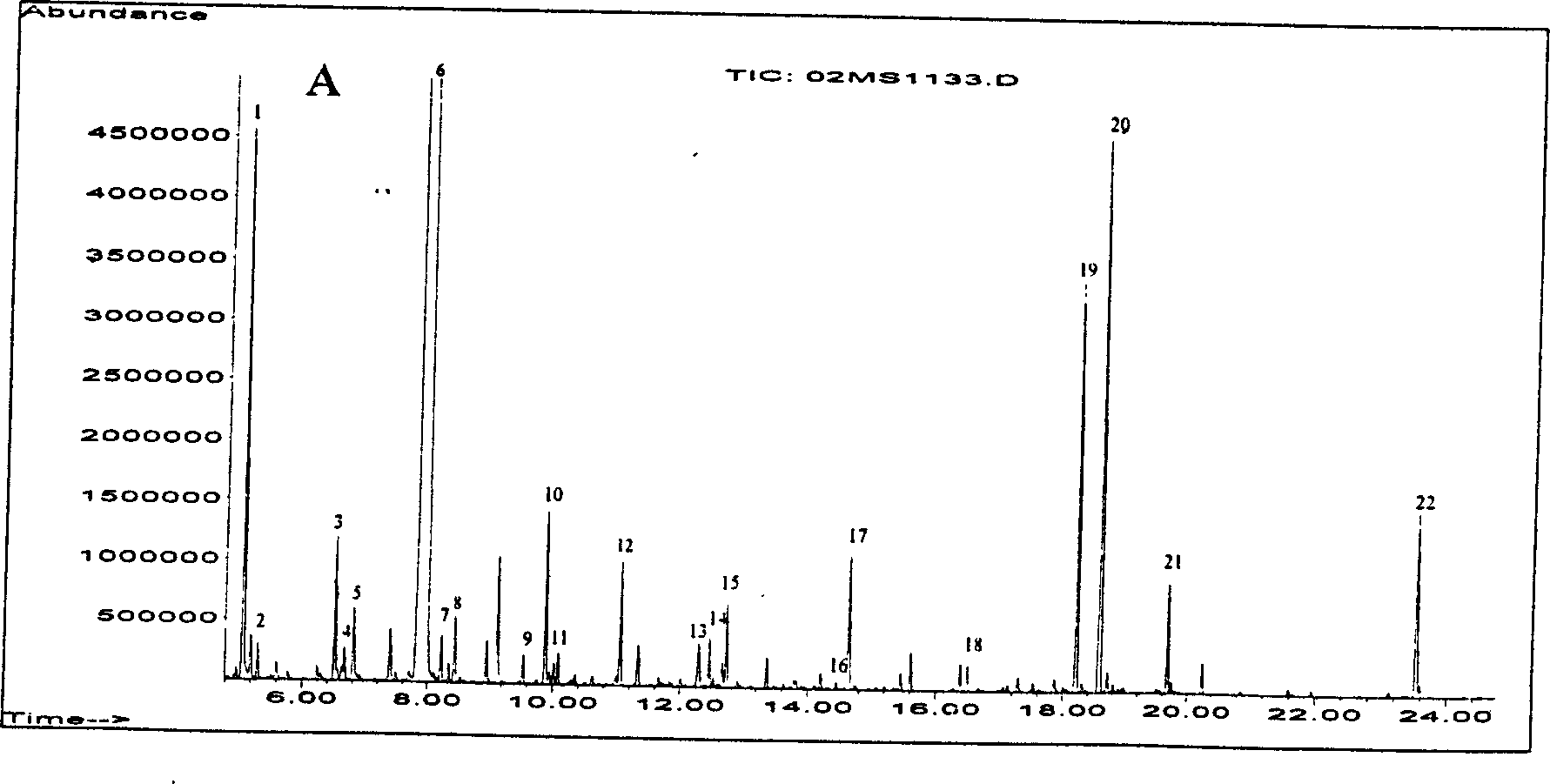

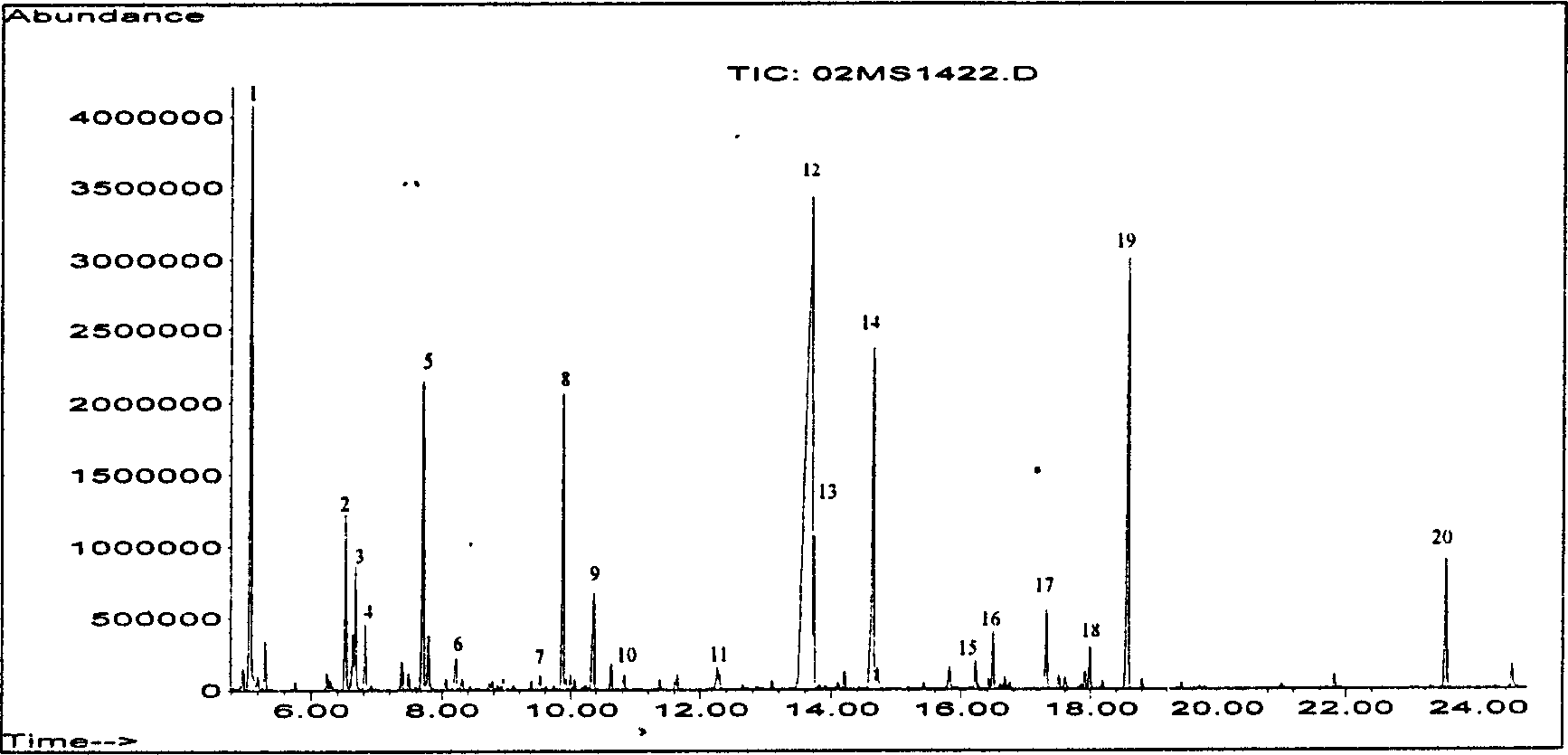

Method for detecting organic acid/amino acid metabolic product by filter paper shect gas chromatography-mass spectrum analysis

The present invention discloses filter paper sheet gas chromatography-mass spectrum analysis process of organic acid / amino acid metabolic product in urine. The process includes elution of urine collected with filter paper, oximation reaction, extraction, methyl silane derivation, and united detection with chromatographic instrument and mass spectrograph. The process of the present invention is superior in that the filter paper collection of urine favors remote analysis of genetic metabolic diseases; the oximation reaction processing favors alpha-ketonic acid detection for diagnosis of branched chain ketonic acid metabolic disorder; the extraction has high recovery rate of organic acid / amino acid metabolic product, high repeatability, less chromatographic impurity peaks and no pollution to chromatographic capillary column and mass spectrographic ion source; and the united detection is suitable for screening analysis of great amount of samples.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

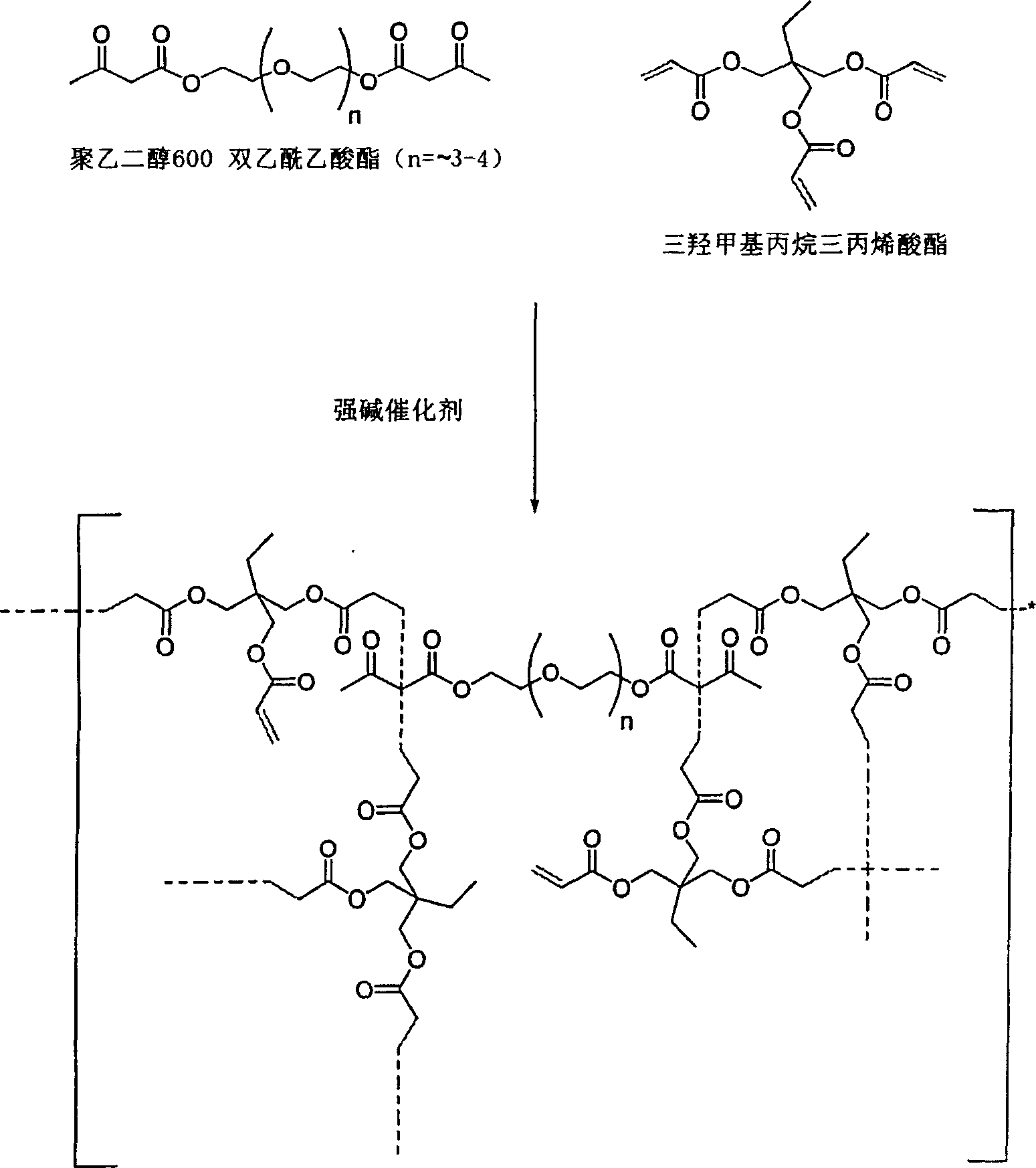

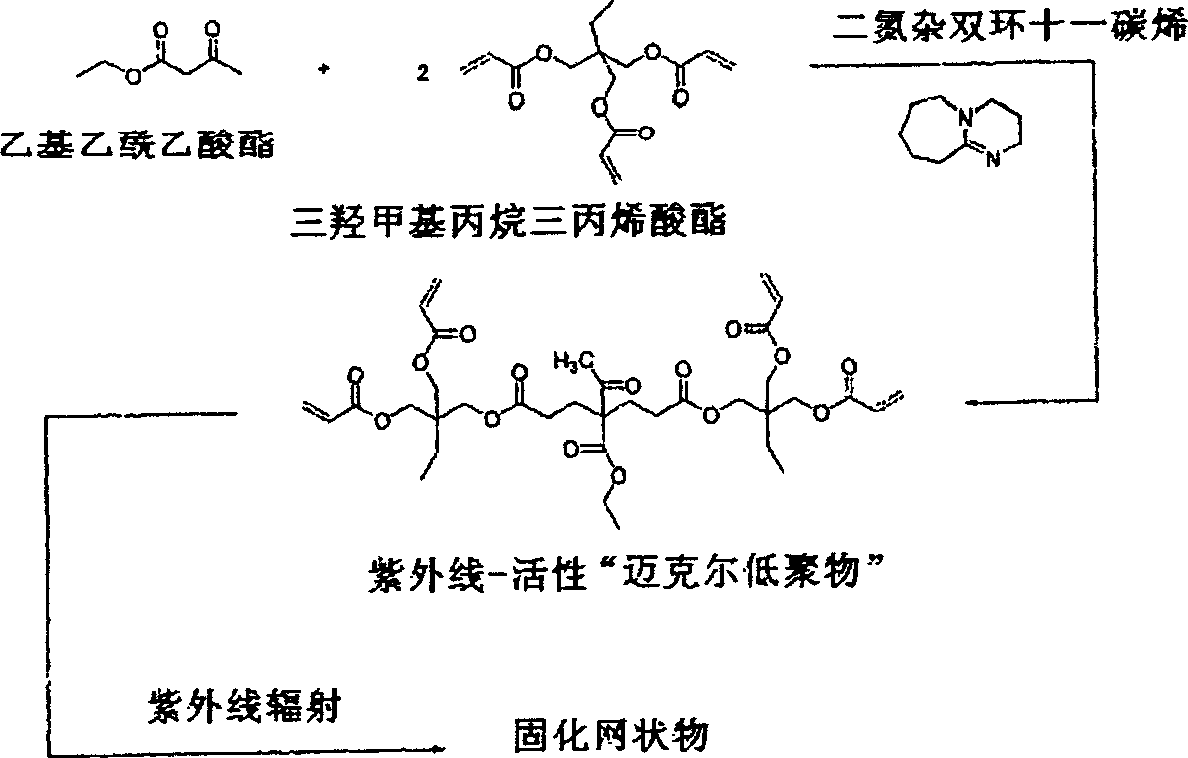

Dual cure reaction products of self-photoinitiating multifunctional acrylates with cycloaliphatic epoxy compounds

Owner:ASHLAND LICENSING & INTPROP LLC

Preparing method of 2-methoxy imino group 2-furan ammonium acetate

InactiveCN101538255AReduce spawn rateReduce unit consumptionOrganic chemistryFuranReaction temperature

The invention relates to a preparing method of 2-methoxy imino group 2-furan ammonium acetate which comprises the following steps: (1) sodium nitrite reacts with acetate furan to generate furan keto acid by oximation, rearrangement and hydrolysis; (2) the furan keto acid is extracted; (3) condensation reaction is carried out on the furan keto and methoxy ammonium hydrochloride to generate 2-imino group 2-furan acetic acid; (4) the 2-imino group 2-furan acetic acid is extracted; (5) ammonia is introduced for salt formation to generate the 2-methoxy imino group 2-furan ammonium acetate; wherein, solvent adopted in the furan keto extraction of step (2) is butyl acetate. Under the same condition, the dissolution loss of the ethyl acetate in water is four times larger than that of the butyl acetate. With the butyl acetate being adopted as the solvent, the unit consumption is lowered by 50 percent, and the production cost is lowered. Furthermore, 58-60 DEG C of the reaction temperature for oximation is adopted by the invention, the production rate of furoic acid is smaller than 1 percent, and the product yield is improved greatly.

Owner:ZHEJIANG TOP MEDICINE

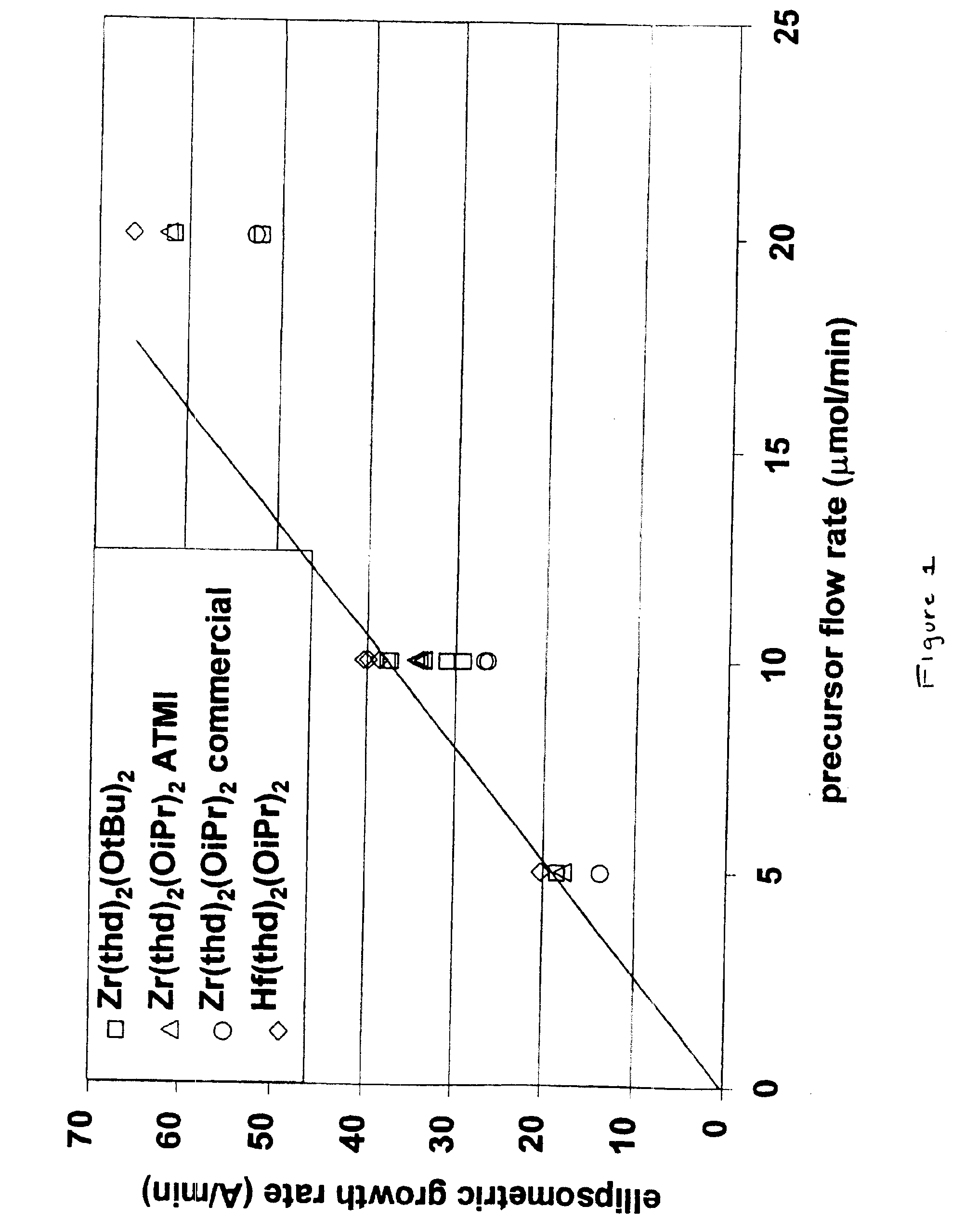

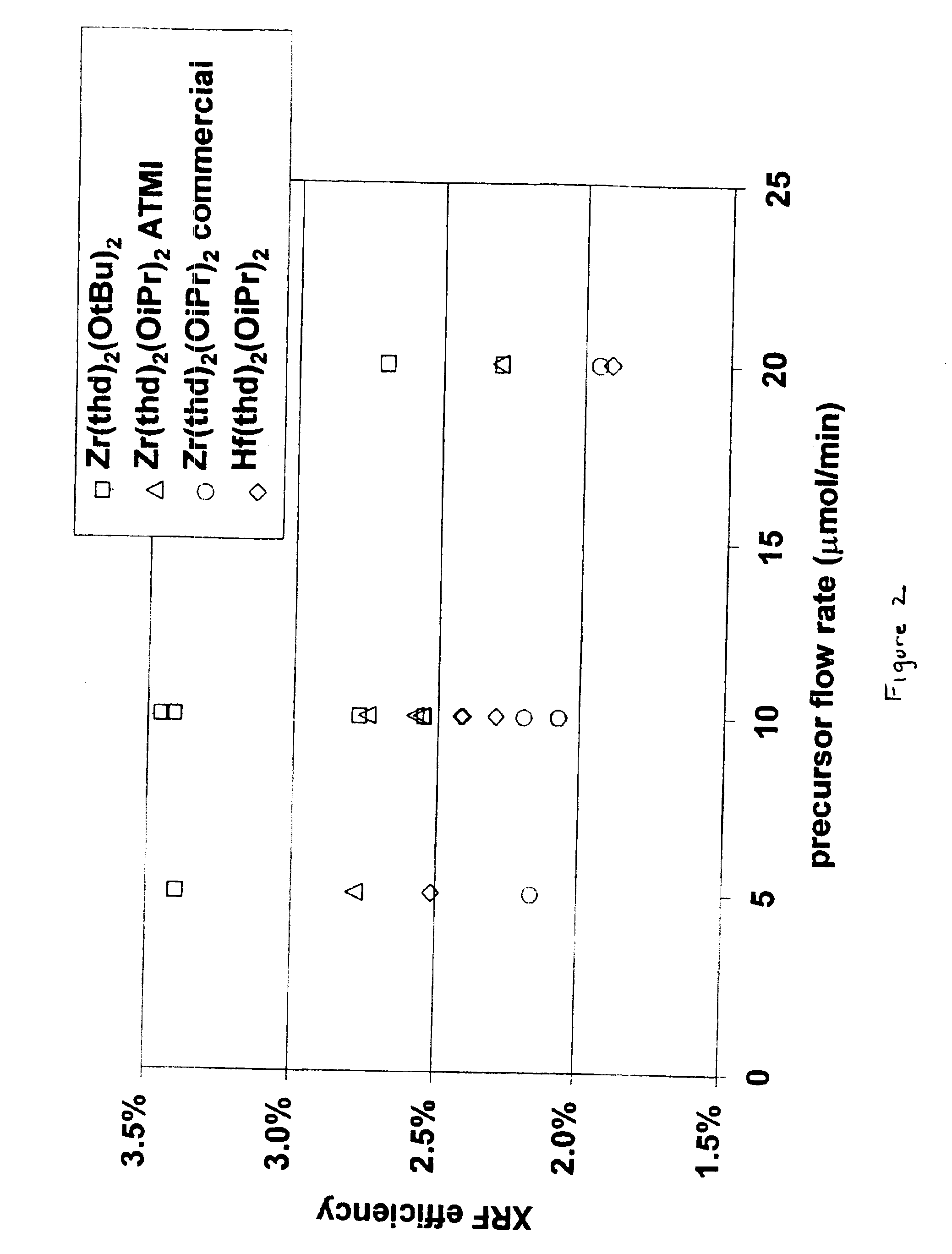

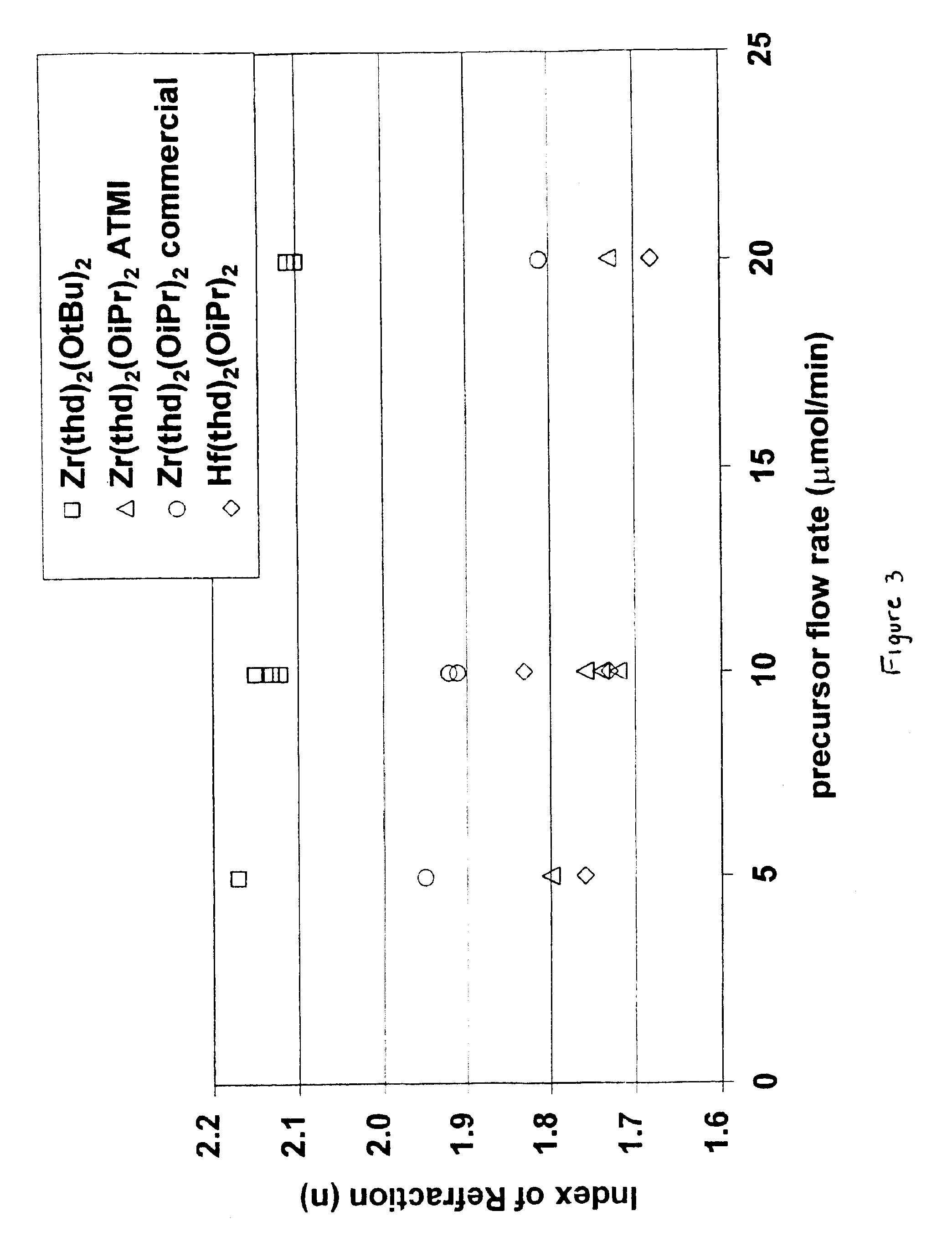

Source reagent compositions for CVD formation of high dielectric constant and ferroelectric metal oxide thin films and method of using same

InactiveUS7094284B2Improve thermal stabilityMinimizing reactionGroup 4/14 organic compounds without C-metal linkagesTitanium organic compoundsDielectricCyclic ether

Chemical vapor deposition (CVD) precursor compositions for forming metal oxide high dielectric constant (κ) thin films. The precursor composition in one embodiment comprises a metal precursor having a general formula M(β-diketonate)2(OR)2, wherein M is Hf, Zr or Ti, and R is t-butyl. The precursor composition may also comprise a solvent medium selected from the group consisting of ethers, glymes, tetraglymes, amines, polyamines, alcohols, glycols, aliphatic hydrocarbon solvents, aromatic hydrocarbon solvents, cyclic ethers, and compatible combinations of two or more of the foregoing.

Owner:ENTEGRIS INC

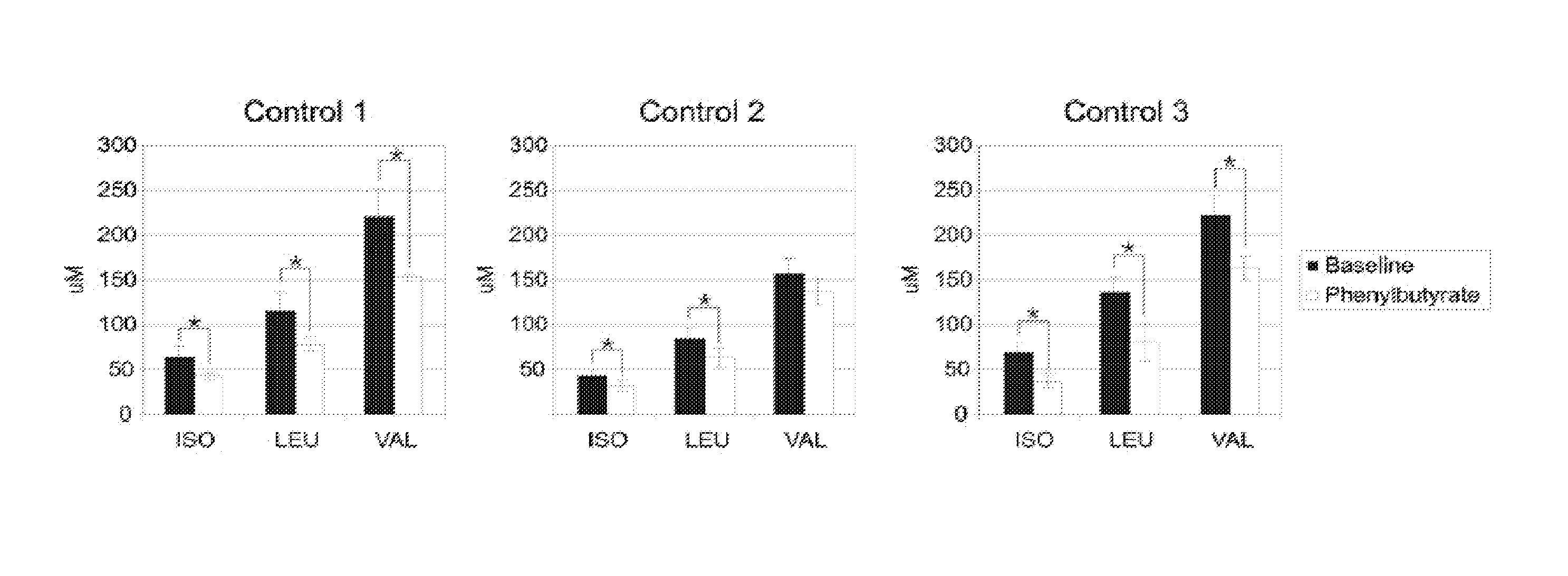

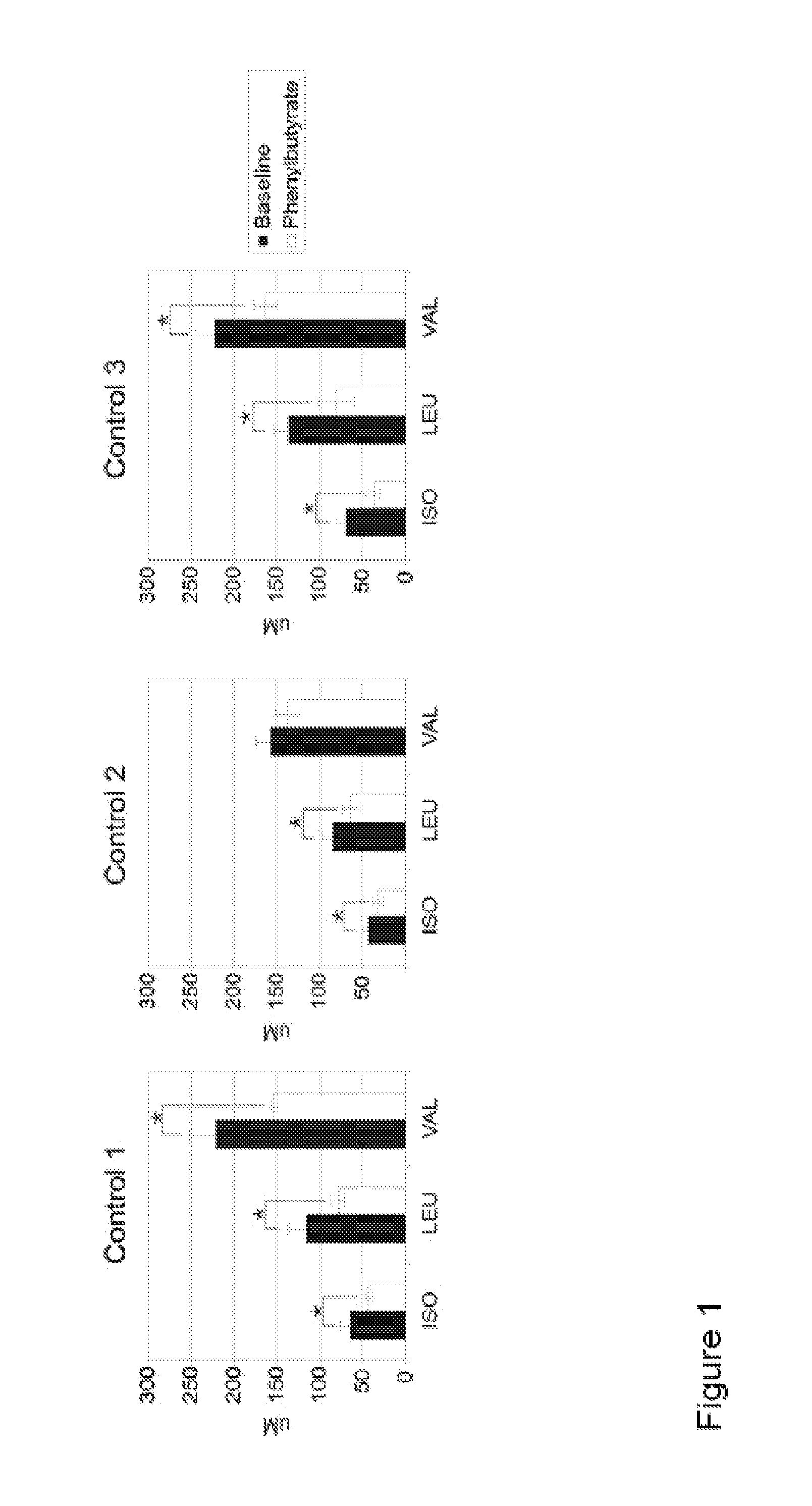

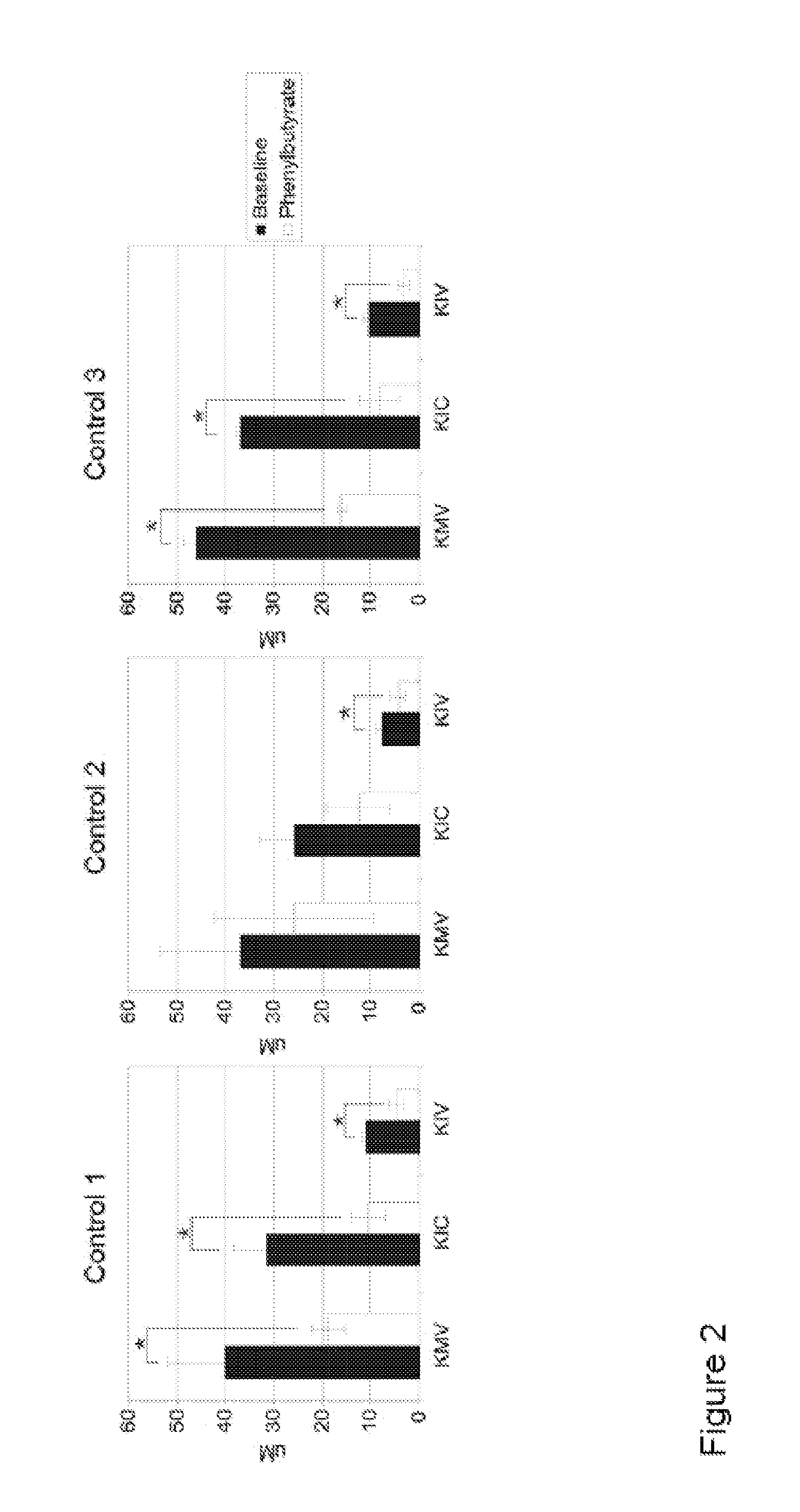

Methods of modulation of branched chain acids and uses thereof

ActiveUS9078865B2Reduce phosphorylationEffective amountMetabolism disorderAnhydride/acid/halide active ingredientsScavengerBlood plasma

Owner:BAYLOR COLLEGE OF MEDICINE

Volatile noble metal organometallic complexes

InactiveUS7112690B2Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIodideChelating ligands

Owner:NATIONAL TSING HUA UNIVERSITY +1

Enzymatic reactions in the presence of keto acids

Owner:ENTERIS BIOPHARMA

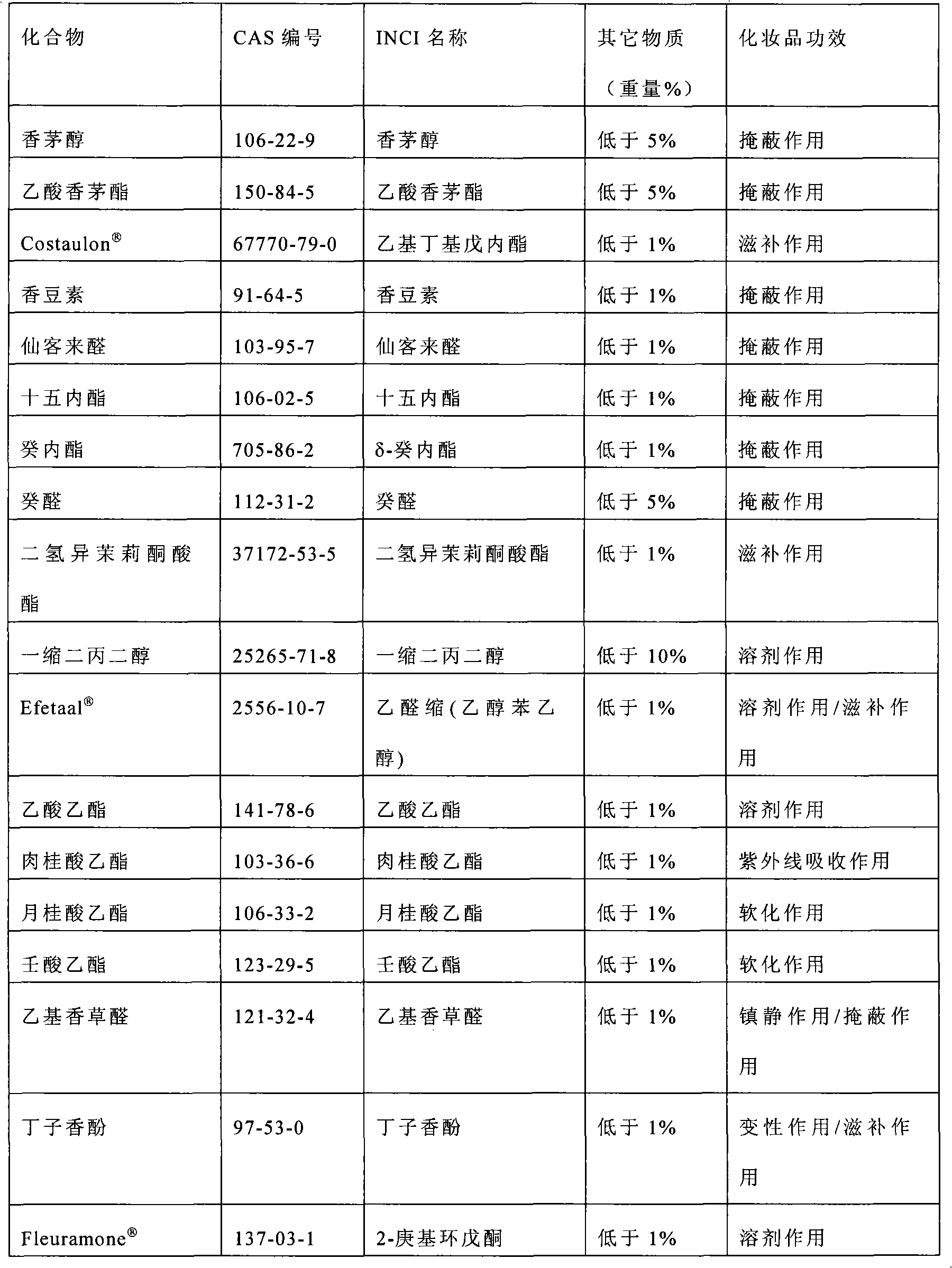

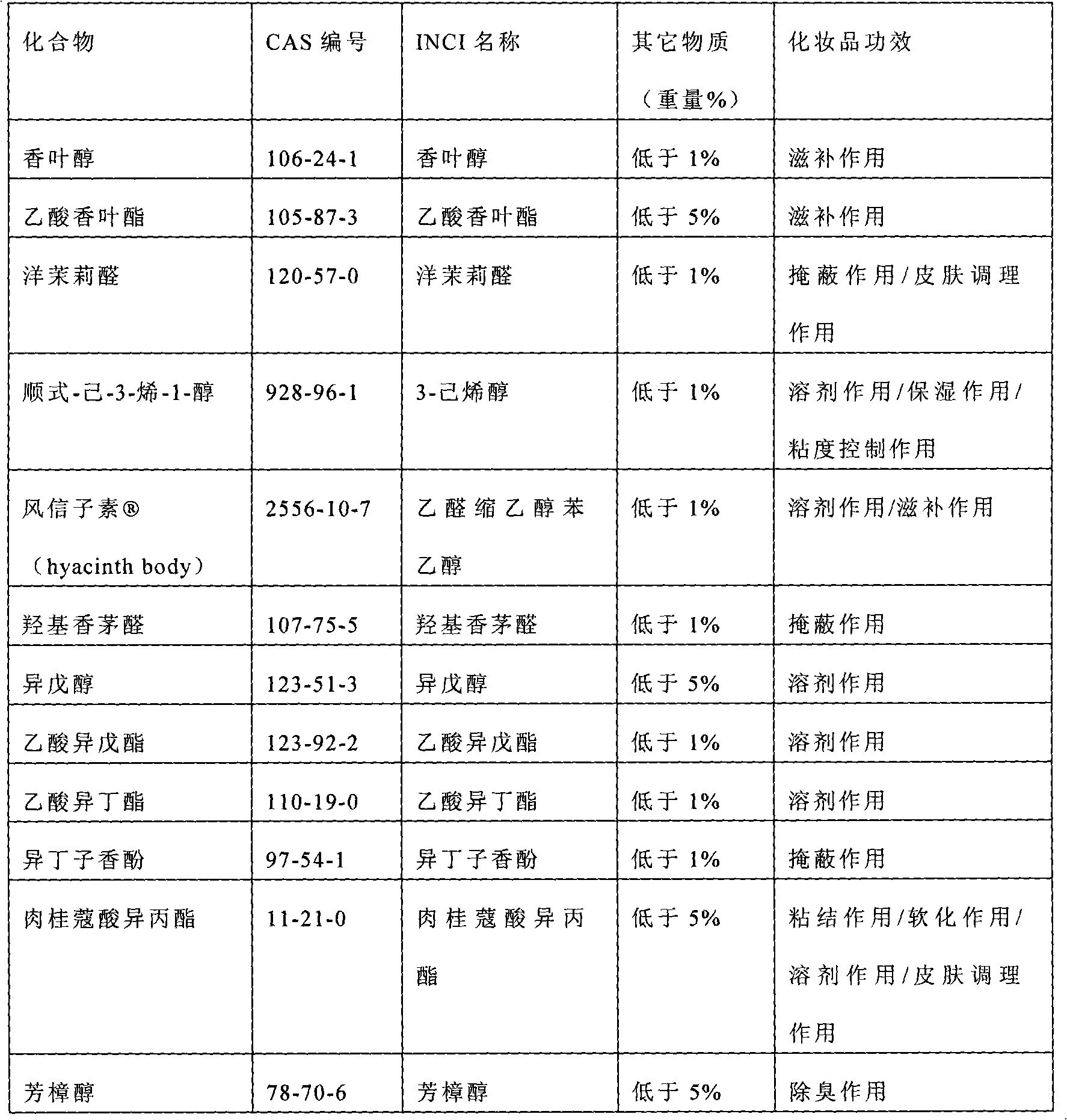

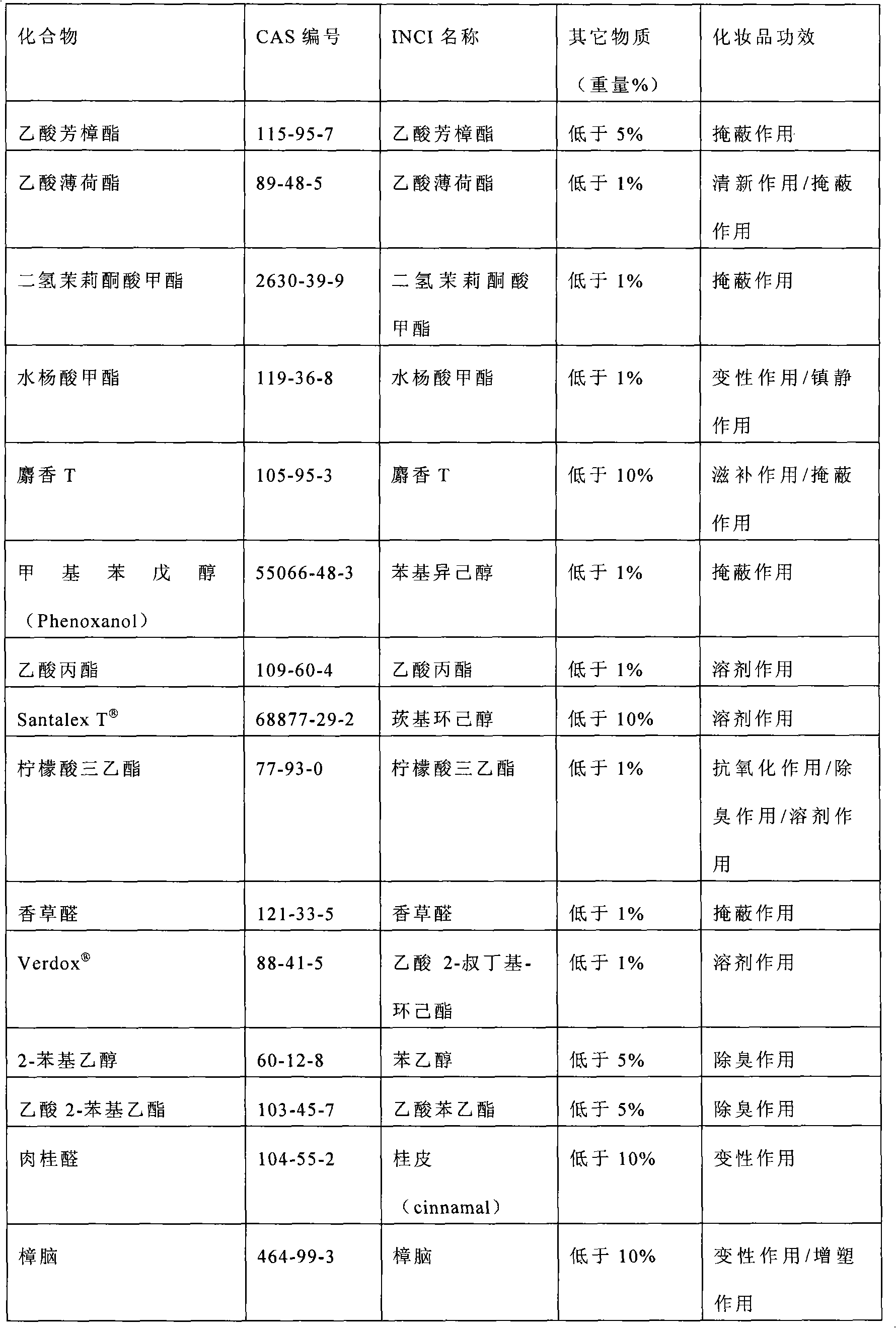

Preservative compositions

InactiveCN101254157AHave effectHas a cosmetic effectCosmetic preparationsHair cosmeticsEthyl cinnamateBenzaldehyde

Owner:TAKASAGO INTERNATIONAL CORPORATION

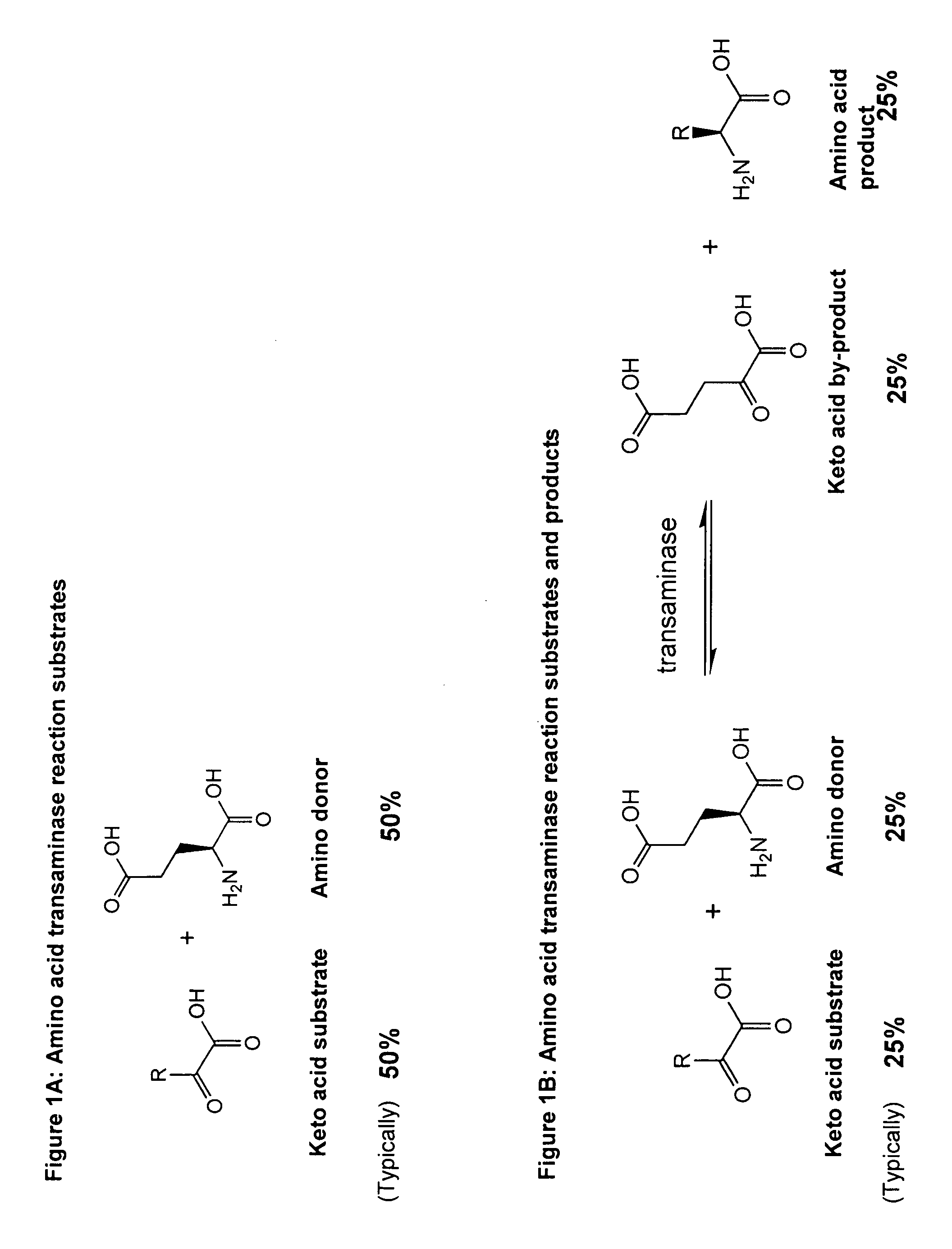

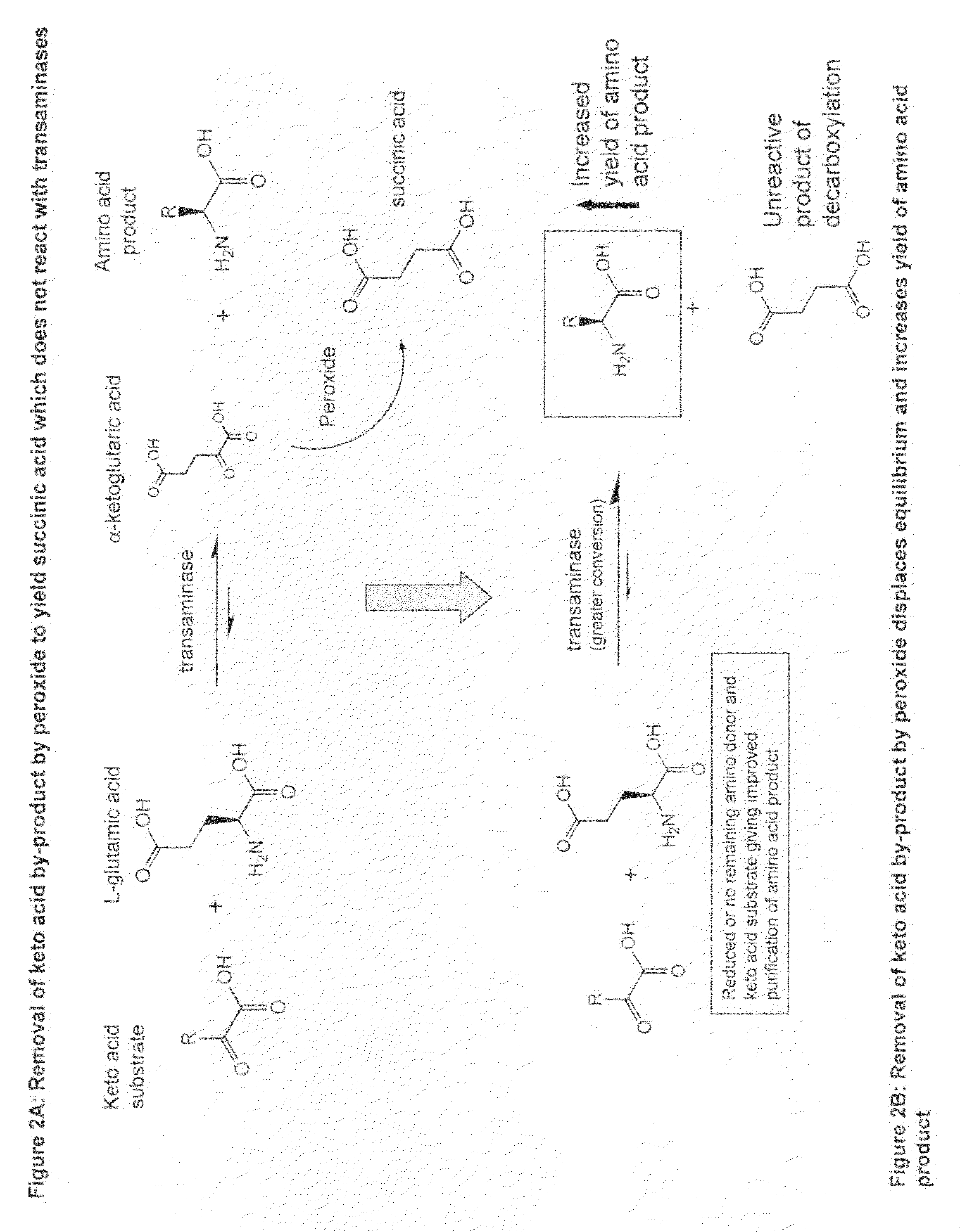

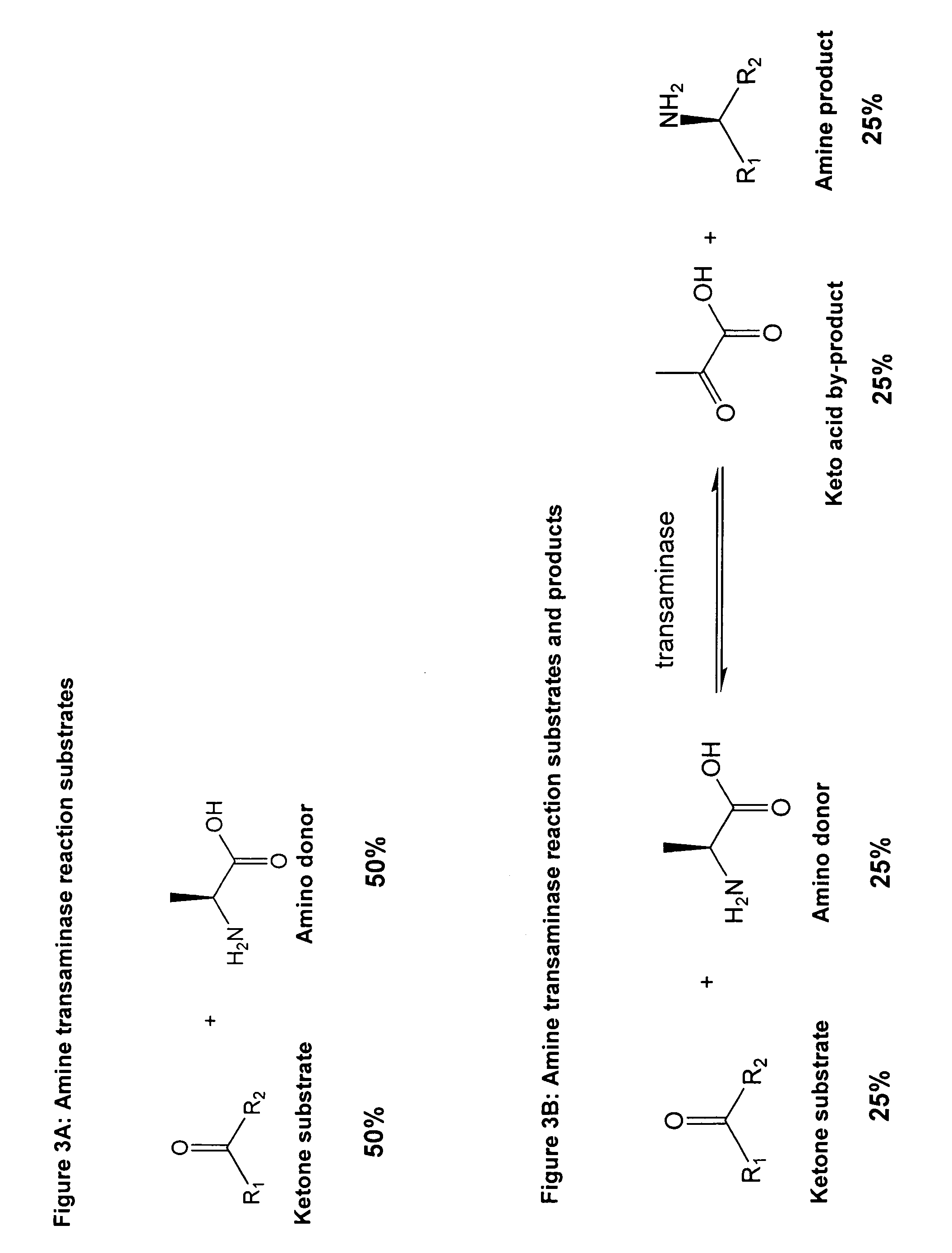

Method to increase the yield and improve purification of products from transaminase reactions

A process for producing high yields of enantioselective amino acids and chiral amines by reacting a keto acid or ketone and an amino acid donor in the presence of a transaminase biocatalyst to produce a keto acid by-product and an amino acid or amine product. Further reacting the keto acid by-product with a peroxide to increase the yield of additional amino acid or amine product.

Owner:RICHMOND CHEM CORP

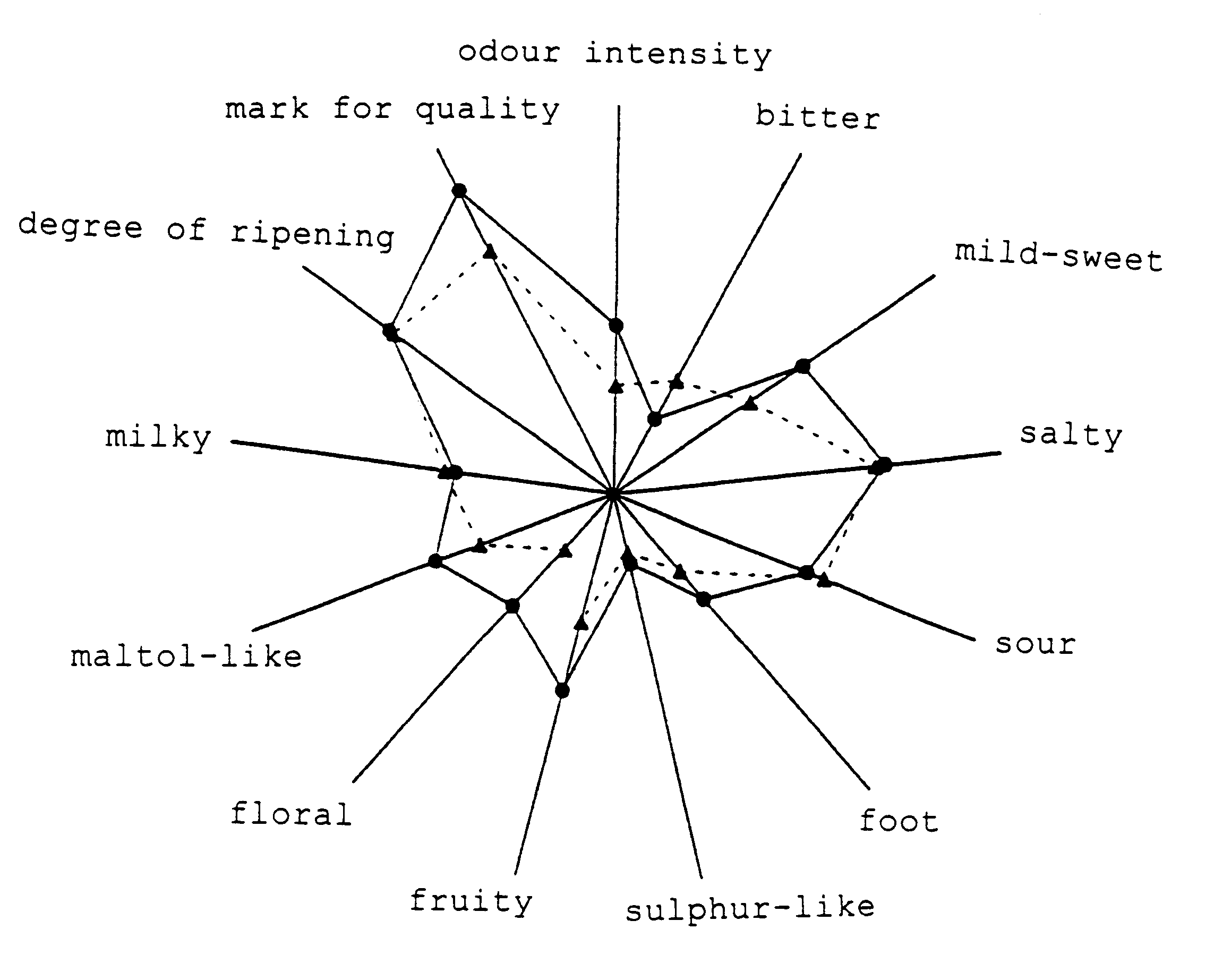

Use of keto acids to enhance the flavor of cheese products

Process for enhancing the flavour of a cheese or of a cheese-flavoured food product whose preparation comprises a maturation step in the presence of lactic acid bacteria, characterized in that a preparation additive comprising at least one keto acid chosen from the group consisting of alpha-ketoglutaric acid, alpha-ketoisocaproic acid ketoisovaleric acid and phenylpyruvic acid is used to increase the catabolism of the amino acids in the cheese or food product by the said bacteria.

Owner:INSTITUT NATIONAL DE LA RECHERCHE AGRONOMIQUE

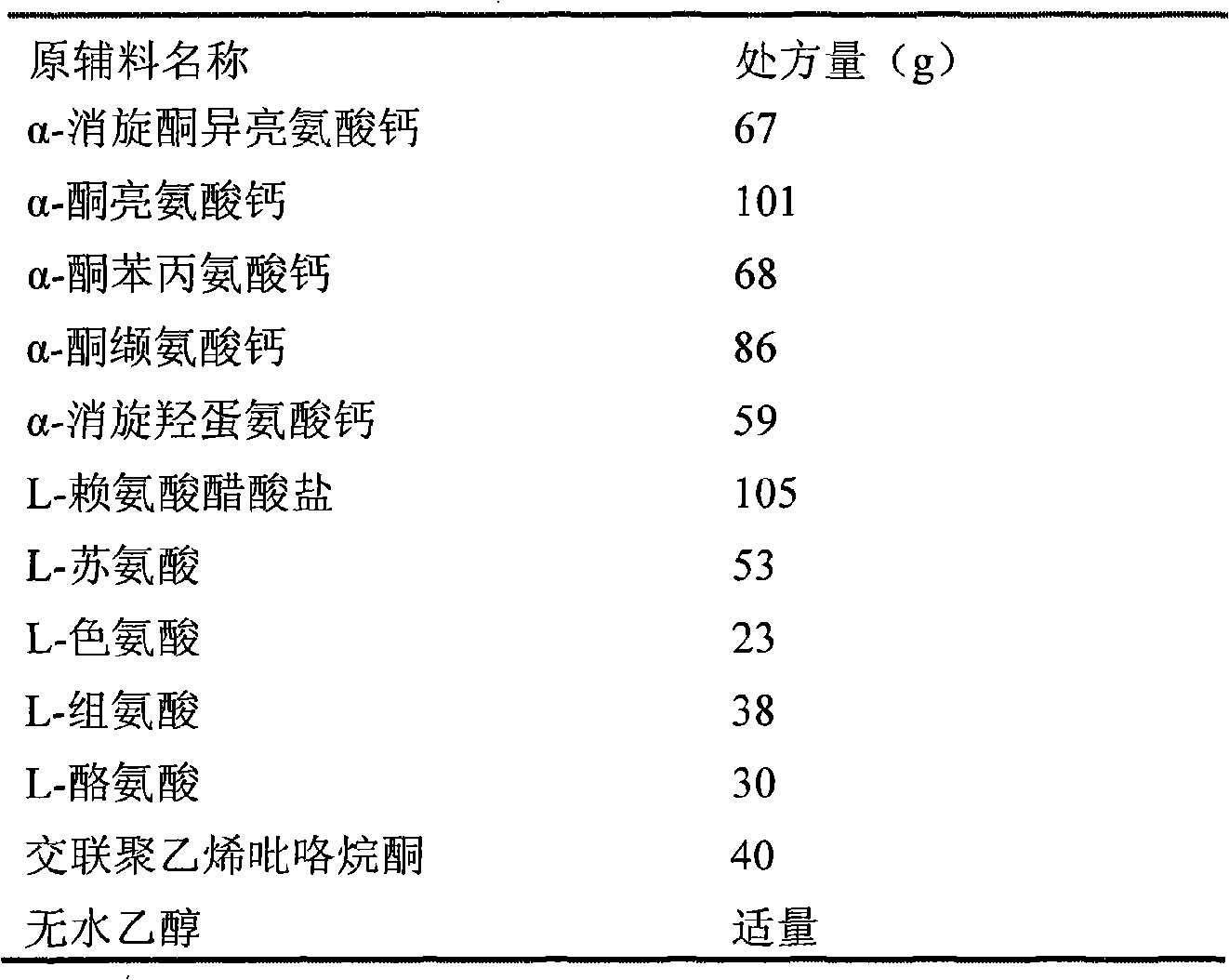

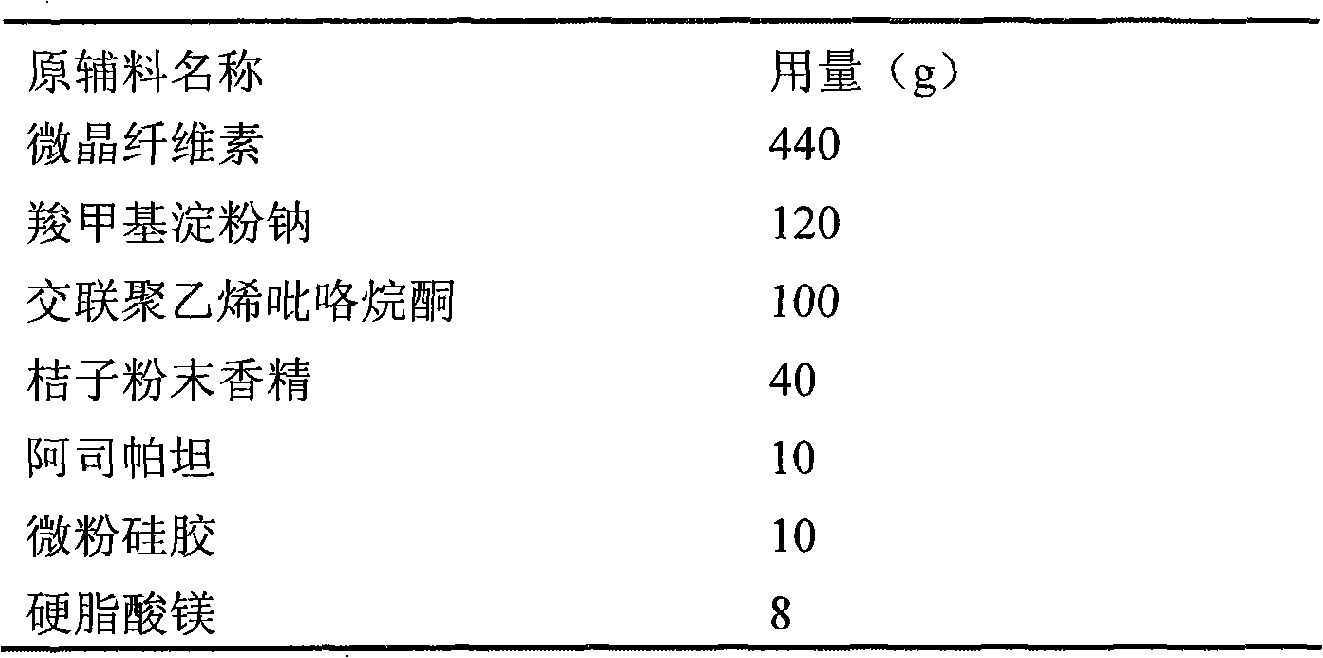

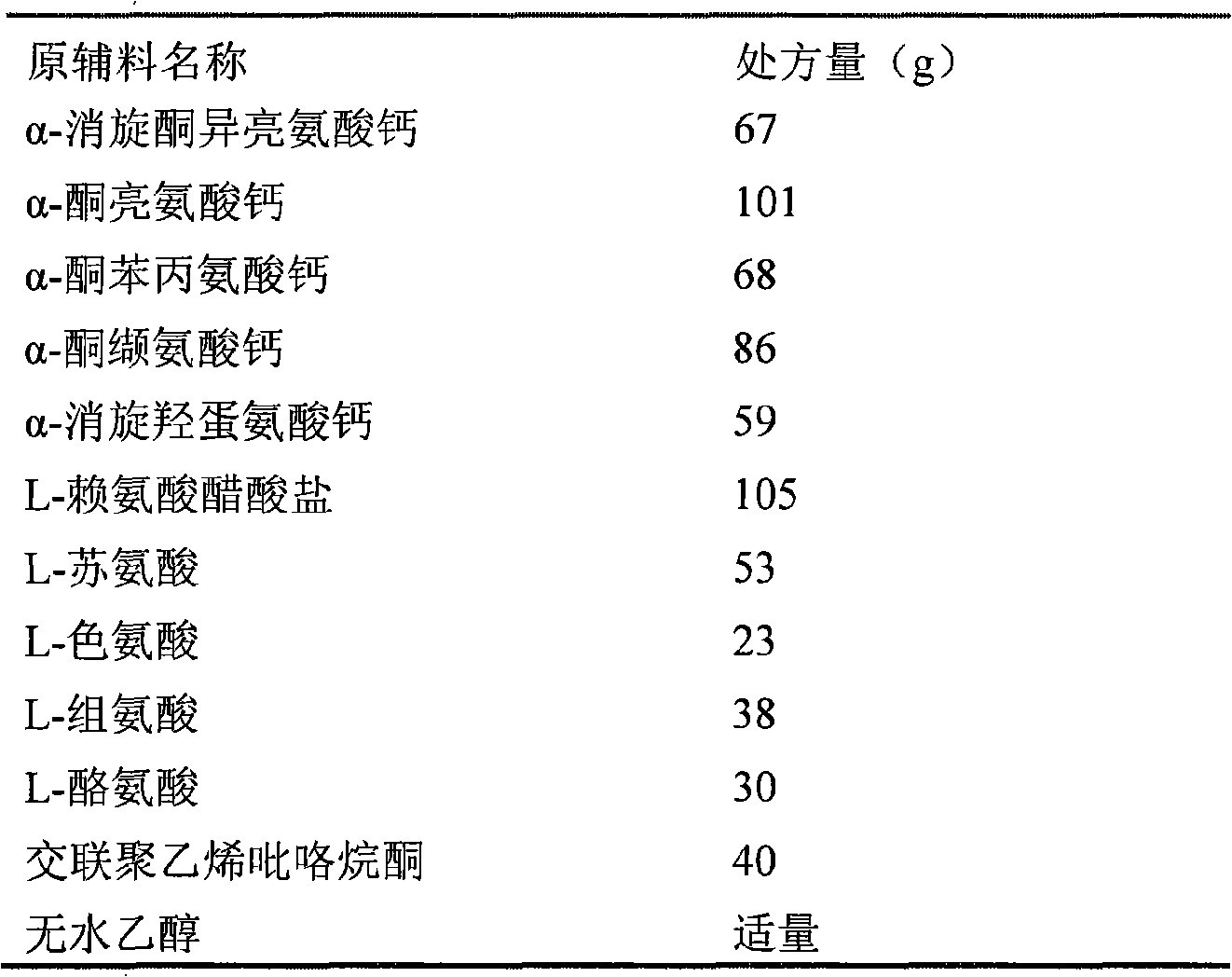

Compound alpha-keto acid dispersible tablet and preparation method thereof

InactiveCN101623271AOrganic active ingredientsMetabolism disorderProtein metabolism disorderAdjuvant

The invention discloses a compound alpha-keto acid dispersible tablet for treating chronic kidney diseases, containing four kinds of keto amino acid calcium, one kind of hydroxyamino acid calcium, five kinds of amino acid and pharmaceutically acceptable adjuvants. The tablet is mainly and clinically used for postponing renal failure process, correcting metabolic disturbance, coordinating with low-protein diet and preventing and treating damages caused by protein metabolism disorder because of chronic renal insufficiency.

Owner:佟兵 +2

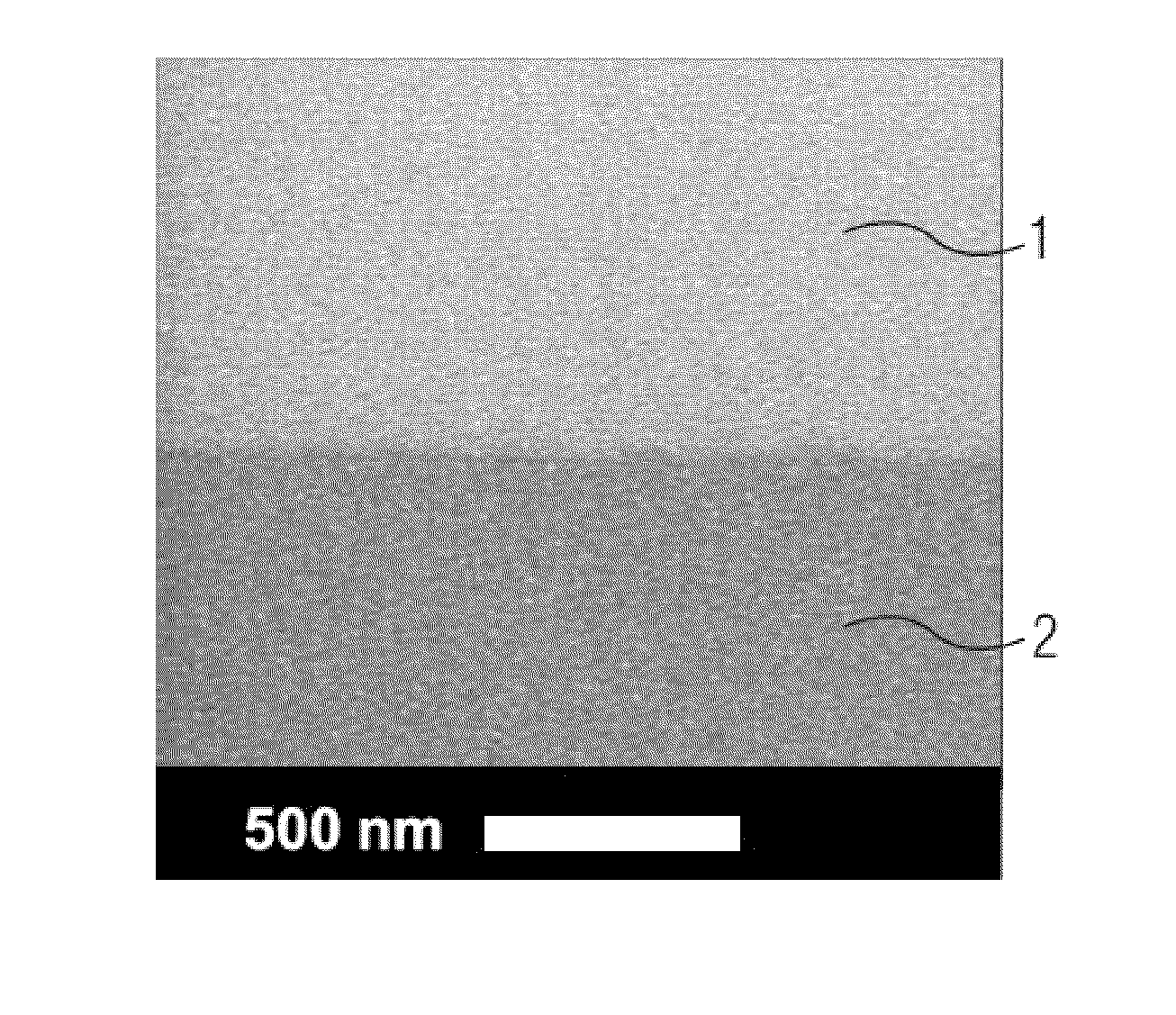

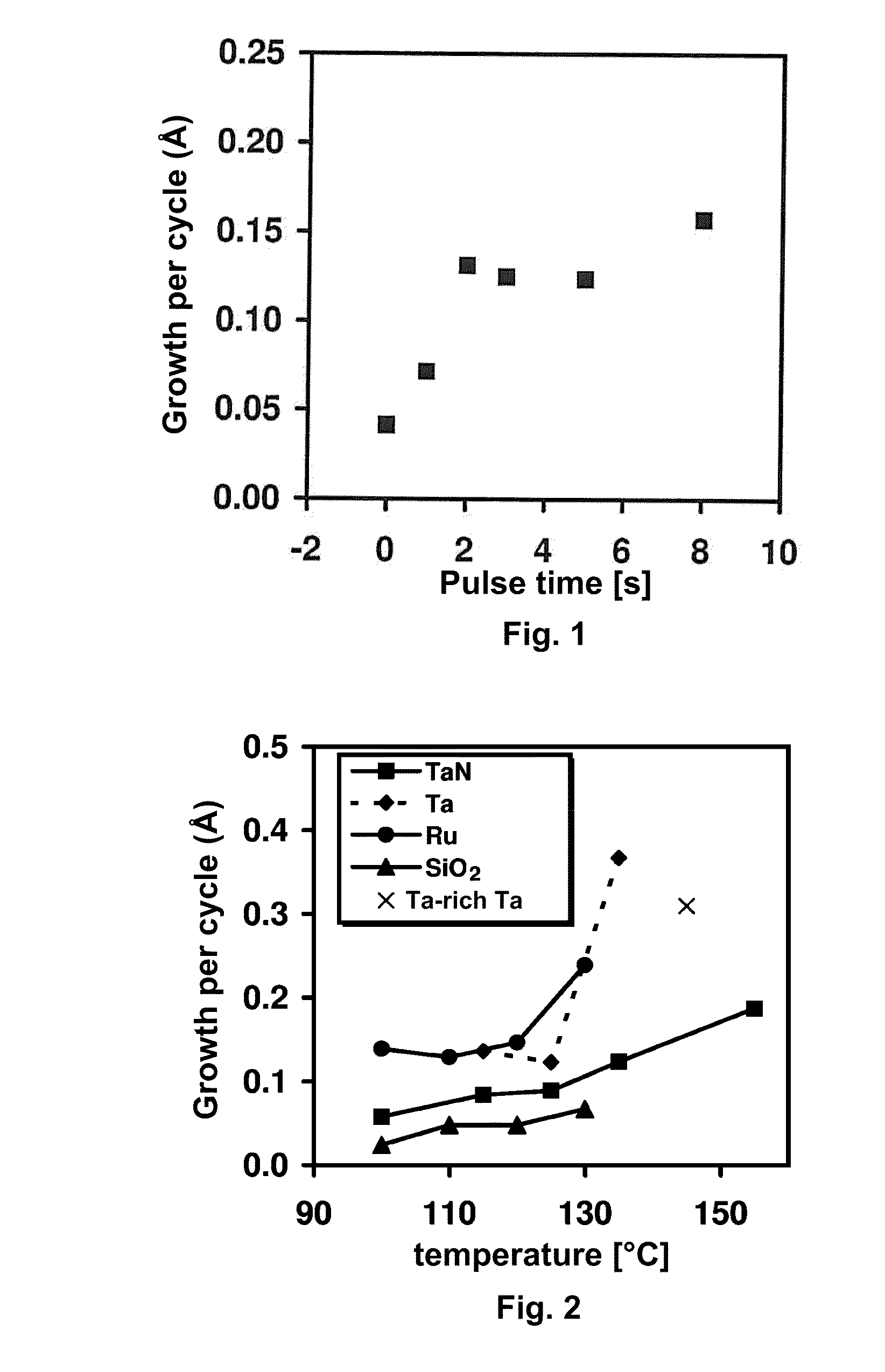

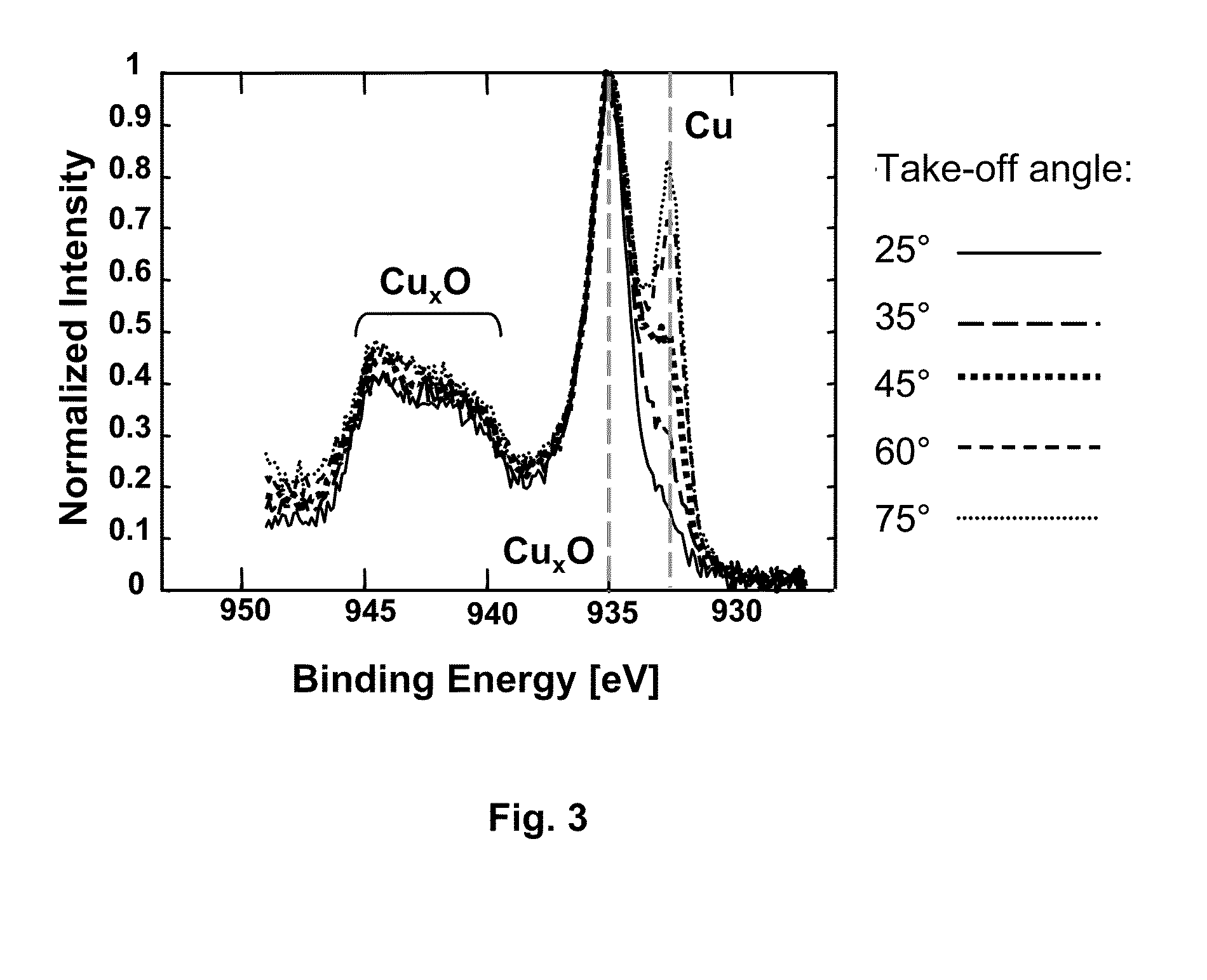

Substrate Having a Coating Comprising Copper and Method for the Production Thereof by Means of Atomic Layer Deposition

ActiveUS20100301478A1Overcome disadvantagesSimple methodGroup 1/11 element organic compoundsSemiconductor/solid-state device detailsCopperAtomic layer deposition

A method can be used for the production of a coated substrate. The coating contains copper. A copper precursor and a substrate are provided. The copper precursor is a copper(I) complex which contains no fluorine. A copper-containing layer is deposited by means of atomic layer deposition (ALD) at least on partial regions of the substrate surface by using the precursor. Optionally, a reduction step is performed in which a reducing agent acts on the substrate obtained in the layer deposition step. In various embodiments, the precursor is a complex of the formula L2Cu(X∩X) in which L are identical or different σ-donor-π acceptor ligands and / or identical or different σ,π-donor-π acceptor ligands and X∩X is a bidentate ligand which is selected from the group consisting of β-diketonates, β-ketoiminates, β-diiminates, amidinates, carboxylates and thiocarboxylates.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

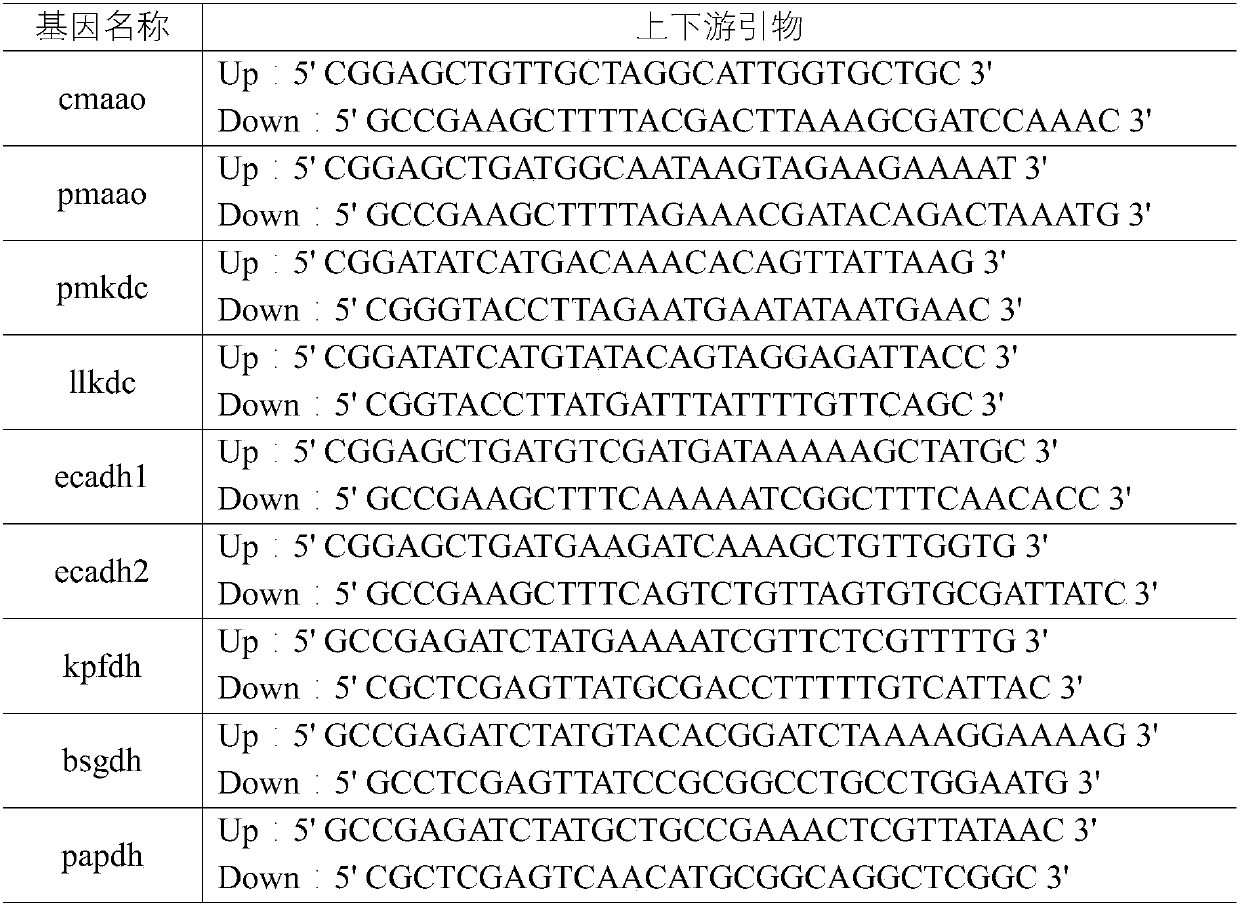

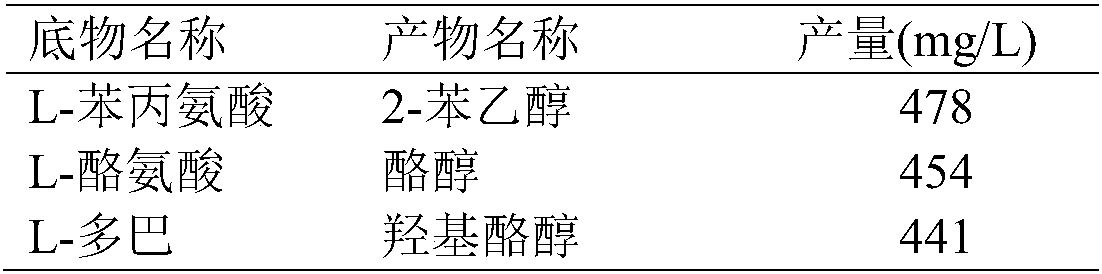

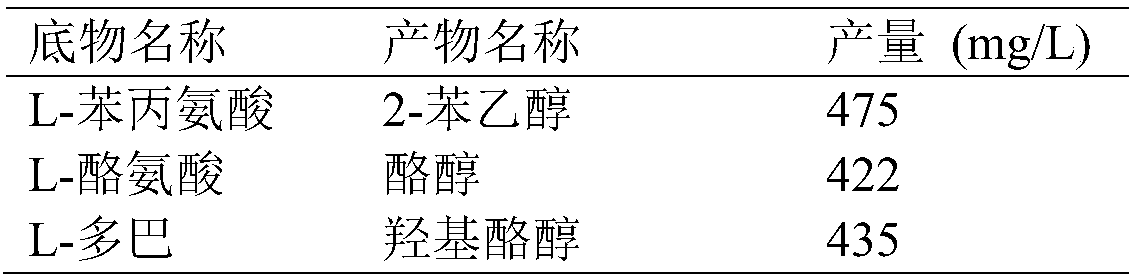

Engineering bacteria and application thereof

ActiveCN107586752APoor substrate specificityHigh activityBacteriaMicroorganism based processesEscherichia coliEnzyme Gene

The invention discloses escherichia coli gene engineering bacteria for four enzyme co-expression. The engineering bacteria is characterized by introducing an L-amino acid oxidase gene, an alpha-ketonic acid decarboxylase gene, an alcohol dehydrogenase gene, and an enzyme gene capable of reducing NAD(P) to NAD(P)H. The invention further discloses a construction method and application of recombinantescherichia coli. The engineering bacteria is applied to biological synthesis of phenylethyl alcohol compounds, has the characteristics of simple operation, low cost, high product synthetic efficiency, and high optical purity, and has bright industrial prospects.

Owner:HONGTAOSIM RES INST OF ANALYCAL SCI & TECH LTD CO

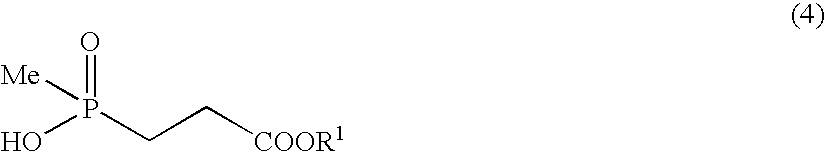

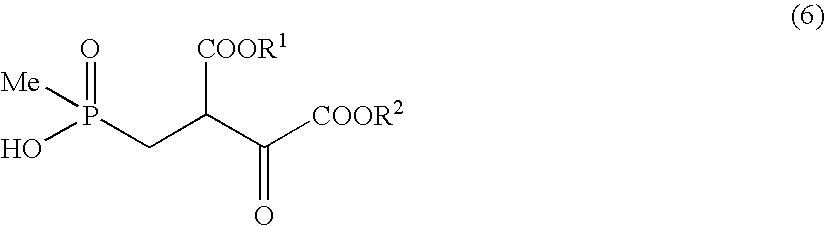

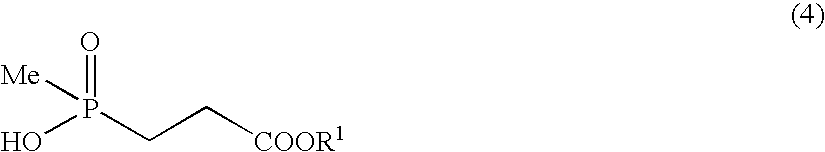

Method for producing phosphorus-containing α-keto acid

InactiveUS8017797B2Increase productionEfficient productionOrganic compound preparationGroup 5/15 element organic compoundsButyratePhosphinidene

A method for efficiently producing 4-(hydroxymethylphosphinyl)-2-oxobutanoic acid, useful as a production intermediate of herbicide L-AMPB. The method comprises using a compound represented by the below formula (4): (4) where R1 represents a C1-4 alkyl group, arylmethyl group, or substituted arylmethyl group.

Owner:MEIJI SEIKA KAISHA LTD

Synthetic method for aliphatic alpha-calcium picrolonate

A synthetic method for aliphatic alpha-calcium picrolonate comprises the following steps: 1. adding carbonyl group reactant in glycolylurea in the presence of catalytic accessory and water and heating, wherein the mol ration of the glycolylurea and the carbonyl group reactant is 1:1.2-1.4; the carbonyl group reactant is aldehyde compound or ketone compound; when aldehyde compound is adopted the catalytic accessory is potassium bicarbonate, and when ketone compound is adopted the catalytic accessory is ethanolamine; 2. cooling to the room temperature, regulating the pH valve to 7 and separating out the intermediate product; 3. filtering and washing the intermediate product; 4. stirring and refluxing the intermediate product and sodium hydroxide solution, wherein the mol ratio of the intermediate product and sodium hydroxide is 1:3-5; 5. regulating the pH value to 4-5, antiregulating the pH value to 7 with the sodium hydroxide solution, and evaporating to remove the moisture; 6. adding absolute methyl alcohol to extract for several times and filtering; 7. distilling to remove the methyl alcohol; and 8. adding de-ionized water and aqueous calcium chloride solution of equivalent amount and separating out alpha-calcium picrolonate. As massive subsidiary products are removed in the method, the calcium content in the prepared product can achieve the standard.

Owner:NANJING CHEM REAGENT

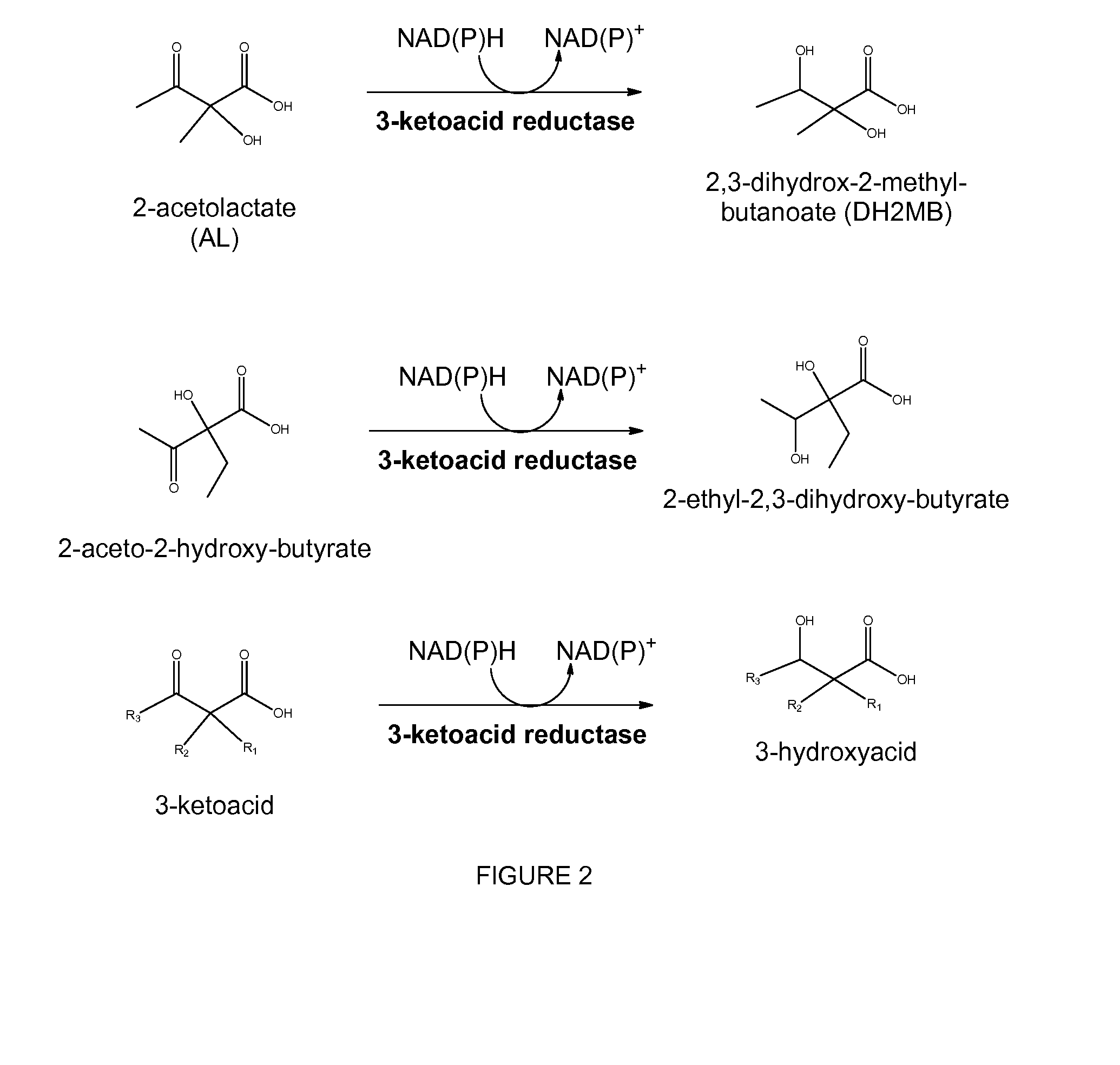

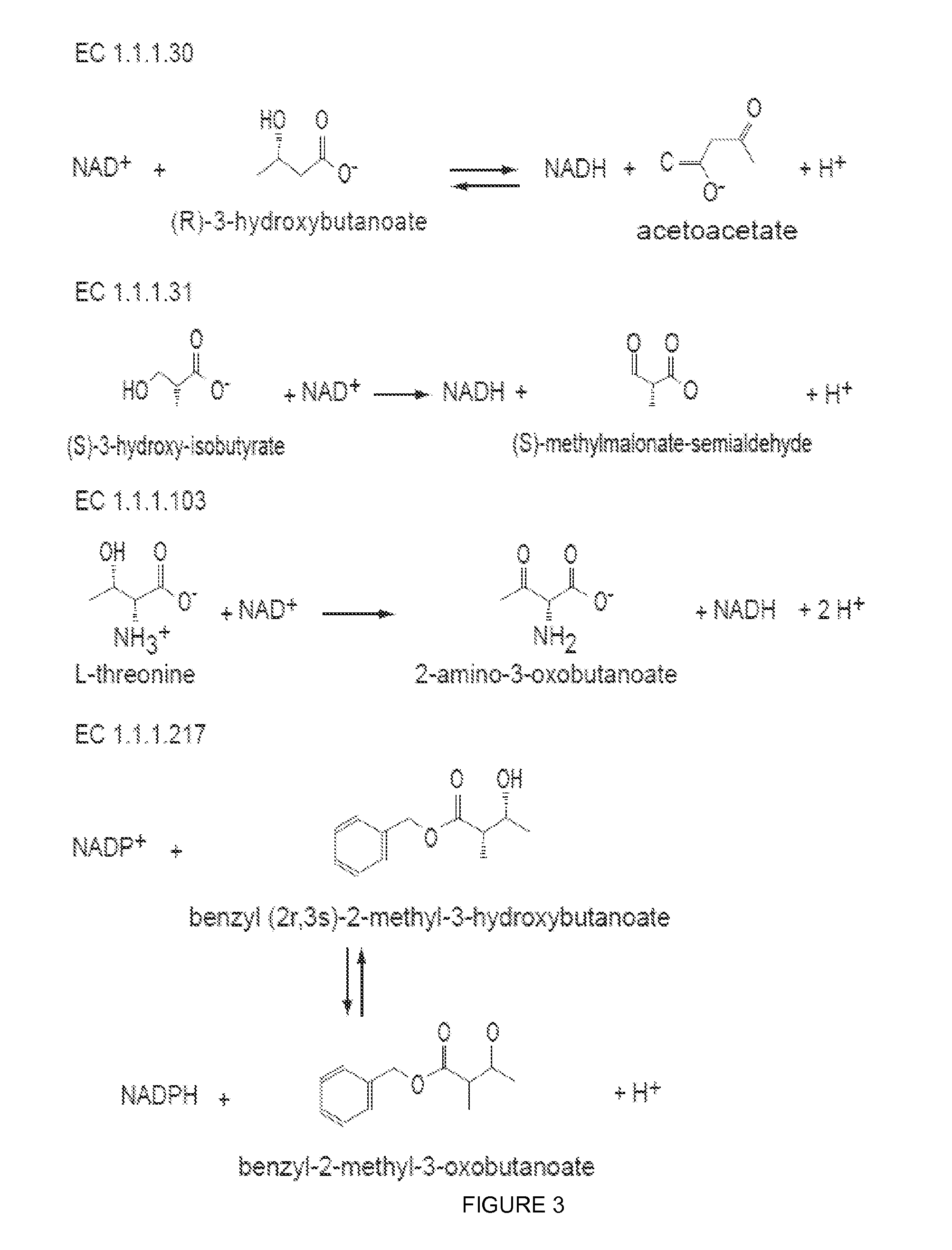

Reduced by-product accumulation for improved production of isobutanol

ActiveUS20110201073A1Catalytic efficiency be enhanceEnhance abilityFungiBiofuels2-HydroxybutyrateYeast

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

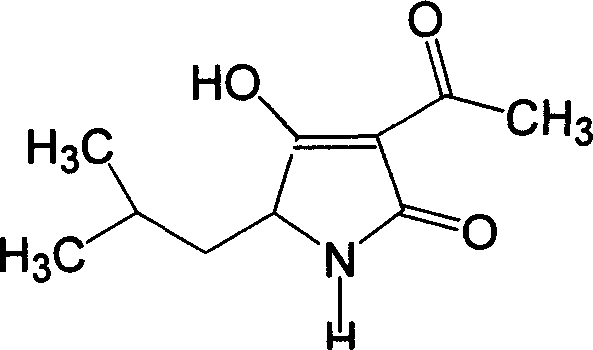

Synthesis of tenuazonic acid and iso-tenuazonic acid

InactiveCN1817859AProduction equipment requirements are simpleSimple and fast operationOrganic chemistryAlcoholTenuazonic acid

Synthesis of tenuazonic acid and isotenuazonic acid is carried out by taking amino acid as initial material, esterifying by alcohol, neutralizing by sodium alcoholate, acidylating by diketene, cyclizing and acidifying under the existence of sodium alcoholate to obtain final product. It is simple, safe and cheap, has more yield and better quality.

Owner:NANJING AGRICULTURAL UNIVERSITY

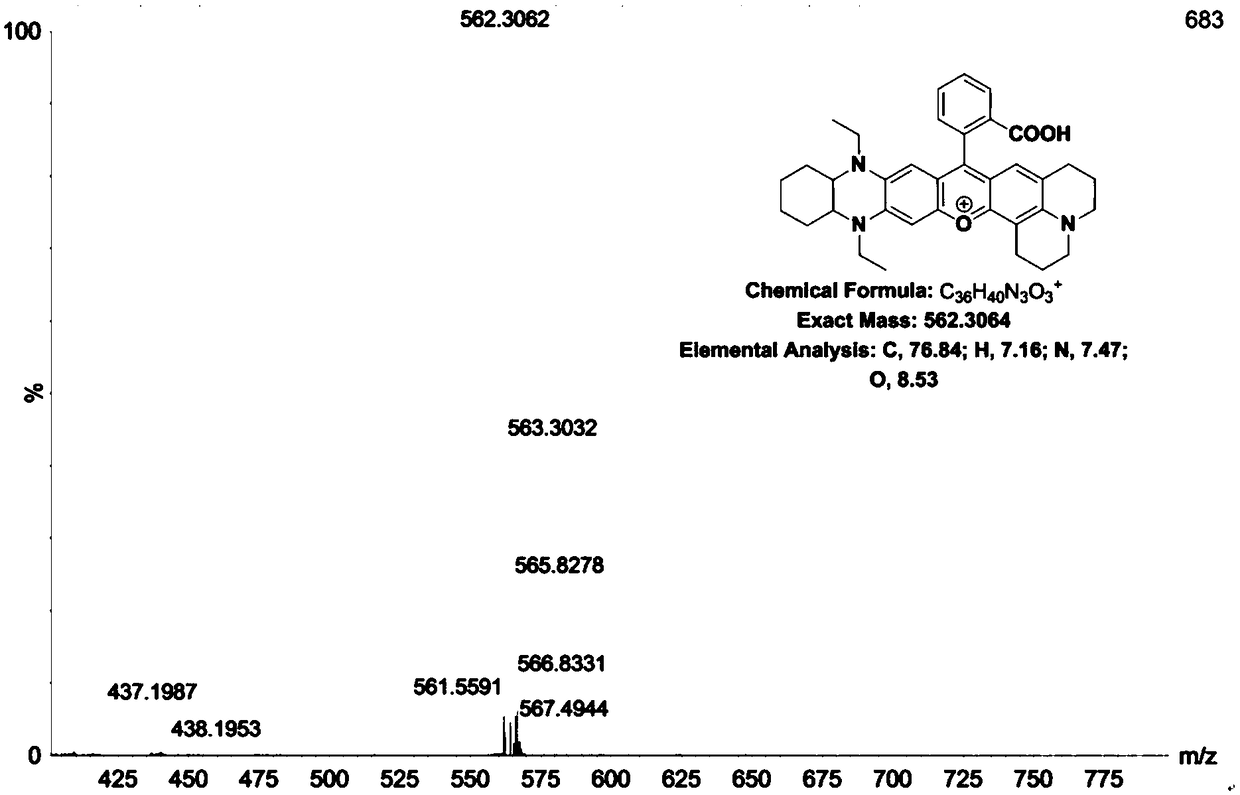

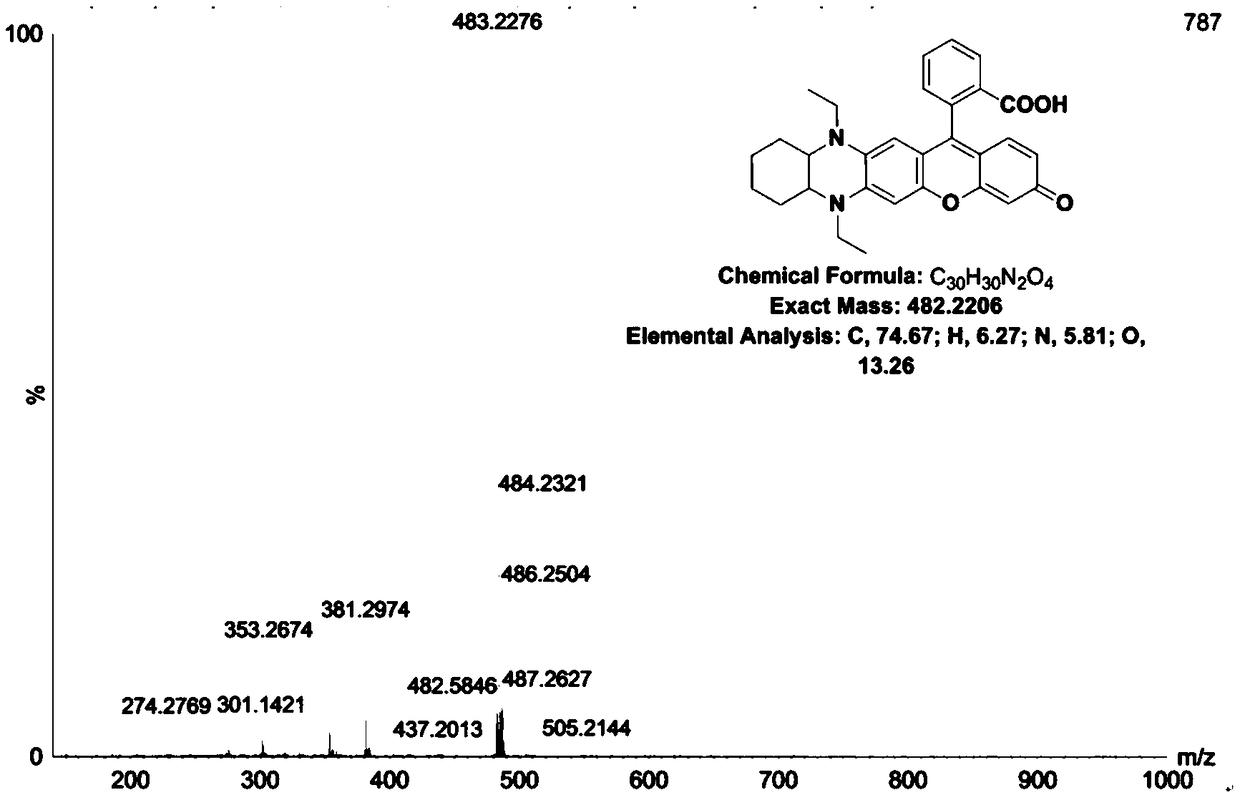

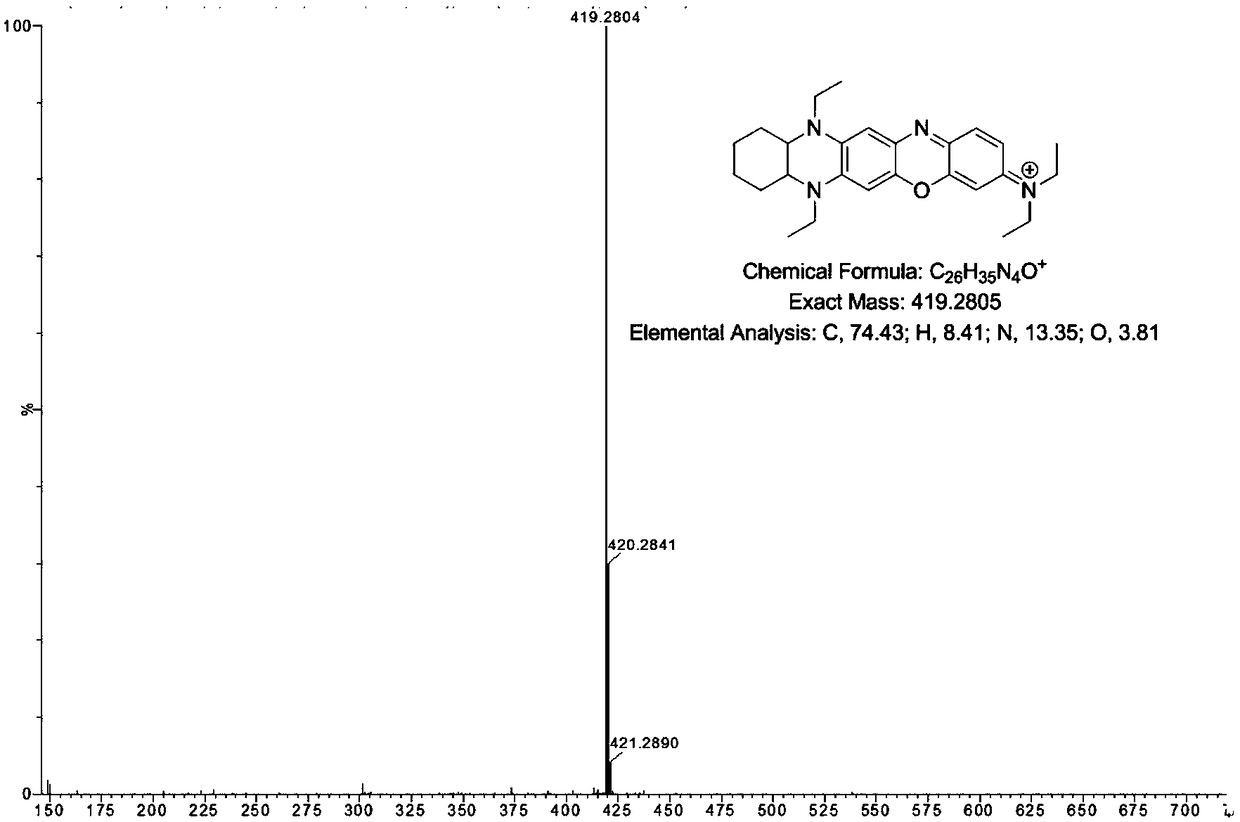

Fluorescent dye having phenazine condensed structure and synthesis method of same

ActiveCN108690032AHigh fluorescence quantum yieldGood light stabilitySilicon organic compoundsAzo dyesQuantum yieldSalicylaldehyde

The invention discloses a fluorescent dye having phenazine condensed structure, of which the structural formula is represented as one of the formulas (I) to (IV). The fluorescent dye having phenazinecondensed structure is prepared through steps of: reactions of cyclohexanedione condensation, sodium borohydride reduction, Vilsmeier formylation and the like are carried out to obtain an intermediatecompound; and then reactions with 4-subsituent amino-2-nitrosophenol, benzophenone acid, trans-4-subsituent amino-salicylaldehyde and the like compounds are carried out. Compared with classical fluorescent dyes (e.g. rhodamine, oxazine, squaric acid, anthocyanin dyes), the fluorescent dye in the invention has high photo-stability, is near-infrared in fluorescence emission wavelength of 635-829 nm, and has large Stokes shift capable of reaching 122 nm and high fluorescence quantum yield capable of reaching 0.43. The fluorescent dye can be applied to fields such as luminescent materials, bio-fluorescence probes, multicolor fluorescence imaging, etc.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com