Biological preparation capable of preventing and treating cruciferae club root and use thereof

A technology of cruciferous and biological preparations, applied in the field of microorganisms, can solve problems such as cruciferous clubroot that have not been seen yet, achieve remarkable control effects, increase production, and solve control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

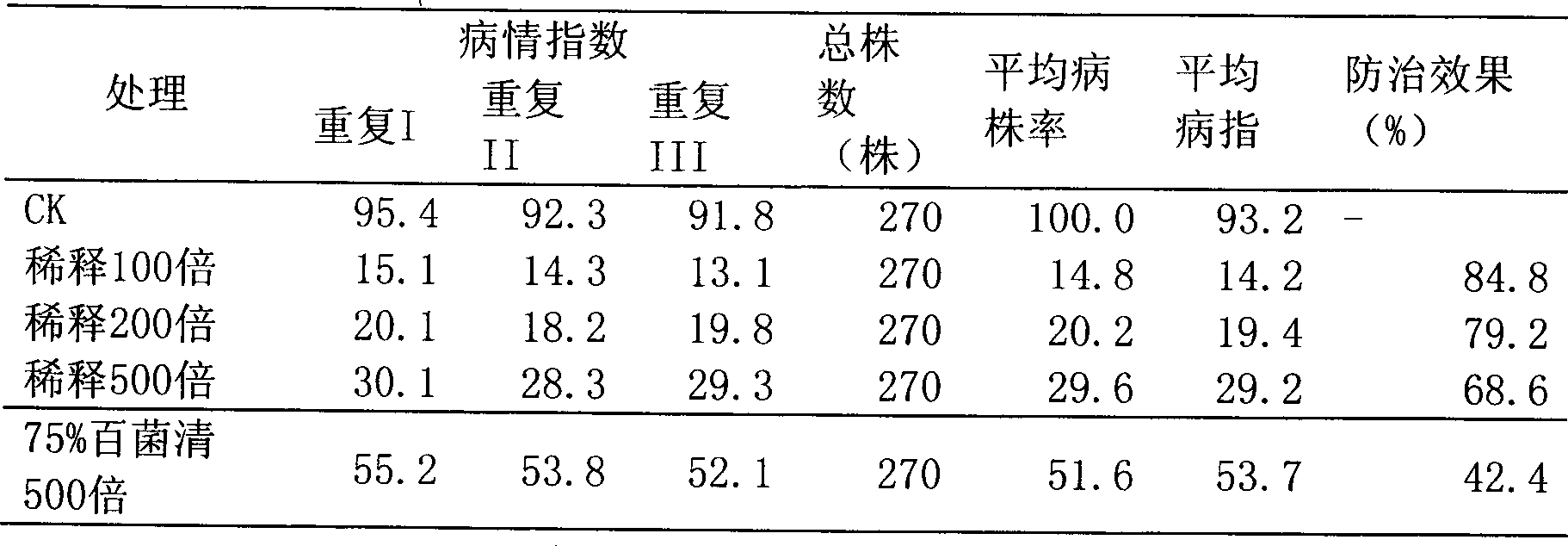

Image

Examples

Embodiment 1

[0067] Bacillus subtilis (Bacillus subtilis) XF-1 was transferred to a test tube slant medium, and the formula for test tube slant culture was: 1% tryptone, 0.5% yeast extract, 1% NaCl, 1.5% agar, pH7.0. Cultivate in an incubator at 30°C for 2 days to obtain test tube species.

[0068] Liquid fermentation medium formula: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O 0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0; inoculate the test tube into 500ml Erlenmeyer flask (200ml per bottle) liquid medium, at 30°C, the speed is 150rpm Cultivate on a shaker for 48 hours, and the resulting culture solution is the biological preparation of the present invention.

Embodiment 2

[0070]At first will obtain test tube seed (with embodiment one), test tube seed is inoculated in 500ml Erlenmeyer flask (every bottle adorns 200ml) liquid medium, medium formula is: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O 0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0. Cultivate at 30° C. for 48 hours on a shaker with a rotating speed of 180 rpm, and the obtained culture solution is the biological preparation of the present invention.

Embodiment 3

[0072] At first will obtain test tube seed (with embodiment one), test tube seed is inoculated in 500ml Erlenmeyer flask (every bottle adorns 200ml) liquid medium, medium formula is: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O 0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0. Cultivate at 30° C. for 48 hours on a shaker with a rotating speed of 200 rpm, transfer the obtained culture liquid to a fermenter for fermentation production, and obtain the fermented liquid which is the biological preparation of the present invention.

[0073] Production conditions in the fermenter:

[0074] Tank temperature: The temperature in the fermenter is controlled at 30°C to 37°C, measured by a thermometer inserted into the culture medium, and adjusted by passing cooling water or hot water into the interlayer.

[0075] Tank pressure: The tank pressure of the fermenter is controlled at 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com