Manufacturing method of polyester-silk interwoven fabrics

A manufacturing method and fabric technology, applied in the field of fabric manufacturing, can solve problems such as poor color fastness, achieve the effect of soft cloth, full color, and improve poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Pretreatment stage - desizing

[0022] Polyacrylate (PMA)-based mixed pulp is often used in the weaving of polyester and nylon fabrics. In addition, the slurry also contains impurities such as oil agents and friction reducers, which affect the dyeing quality of the fabric. Therefore, the surface slurry and impurities must be removed to ensure The subsequent process is carried out. Desizing methods such as alkali desizing, oxidant desizing, hot water desizing and mechanical desizing are commonly used. Practice shows that after cold stacking and OS open-width desizing, better hand feeling and desizing effect can be obtained.

[0023] 1.1 Cold pile splitting

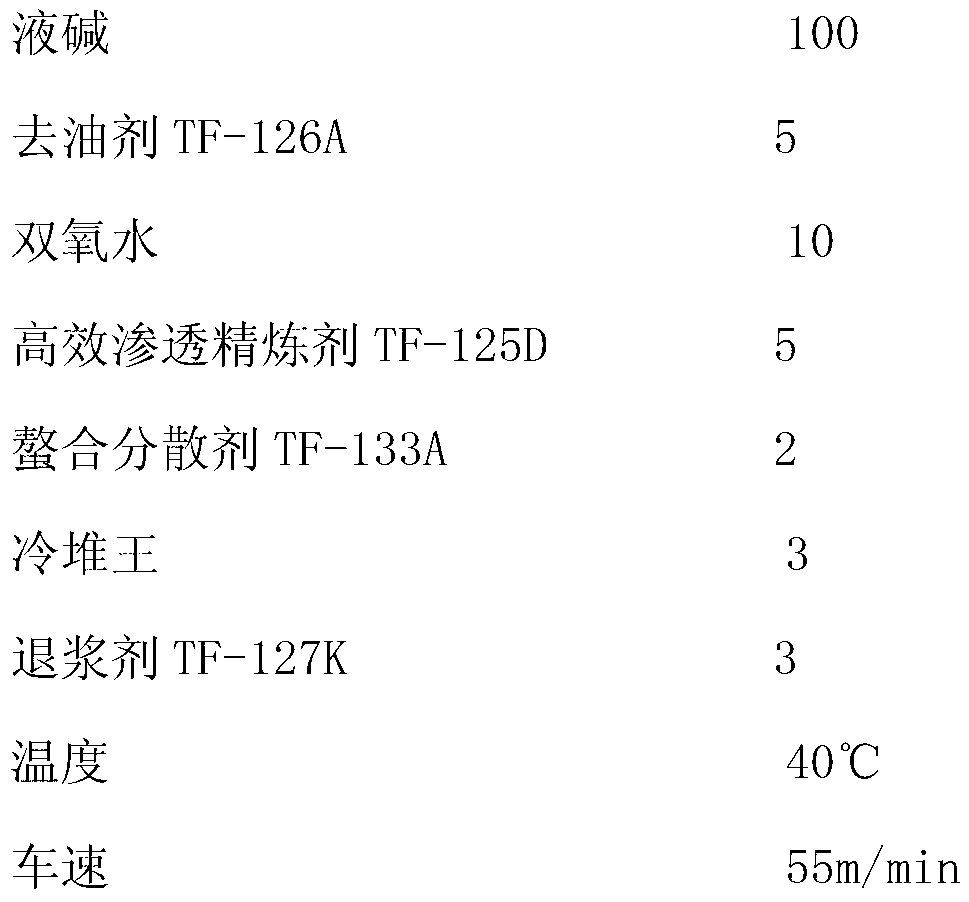

[0024] Process prescription (g / L) and conditions are as follows:

[0025]

[0026] In the above process, the chelating dispersant TF-133A can prevent equipment and fabrics from being stained, has the functions of scale inhibition and scale removal, and has good compatibility with desizing liquid. The degreasin...

Embodiment 2

[0034] Example 2: Dyeing stage

[0035] 2.1 Cylinder compounding and fiber opening

[0036] Process prescription (g / L) and conditions are as follows:

[0037]

[0038] Among them, ALBAFLUID (Abai Run) U can prevent cloth surface from being scratched. The purpose of cylinder compounding is to make the fabric fully shrink in the warp and weft direction in a relaxed state, to make the fibers in the twisted yarn fully bulky, to further remove the size and impurities on the fabric, and to further improve the hand feeling.

[0039] 2.2 Nylon filament color fixation

[0040] Process prescription (g / L) and conditions are as follows:

[0041] Acid color fixing agent CL-250TS 1.5

[0042] 60% glacial acetic acid 1

[0043] Fixing condition: 80℃×30min

[0044] Before dyeing, a color fixing operation is carried out, which can effectively protect the nylon yarn and wrap it up, preventing the nylon yarn from being polluted by disperse dyes, affecting the color fastness and nylon st...

Embodiment 3

[0068] Example 3 - stereotypes

[0069] In order to make the fabric width uniform, stable in size and shape, and to stably endow polyester fabric with special properties, it is necessary to carry out post-finishing process on the fabric.

[0070] Through padding post-finishing additives, advanced cool-touch finishing is adopted, providing a new high-quality wearing comfort. Adding a penetrating agent can improve the permeability of the fabric;

[0071] The polyester-nylon interwoven fabric ("polyester-nylon interlaced") of the present invention should maintain the slub style and feel soft and smooth, so the setting temperature is low, the wind speed of the fan is reduced, and a certain overfeed is applied.

[0072] Process prescription (g / L) and conditions are as follows:

[0073]

[0074] technical effect

[0075] The various performance indicators of the polyester-nylon interwoven fabric ("polyester-nylon interwoven") produced by the present invention have reached the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com