Surface frame tenon

A frame tenon and surface frame technology, applied to the surface frame tenon. It can solve the problems of high labor cost and achieve the effect of simple assembly, easy disassembly and transportation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

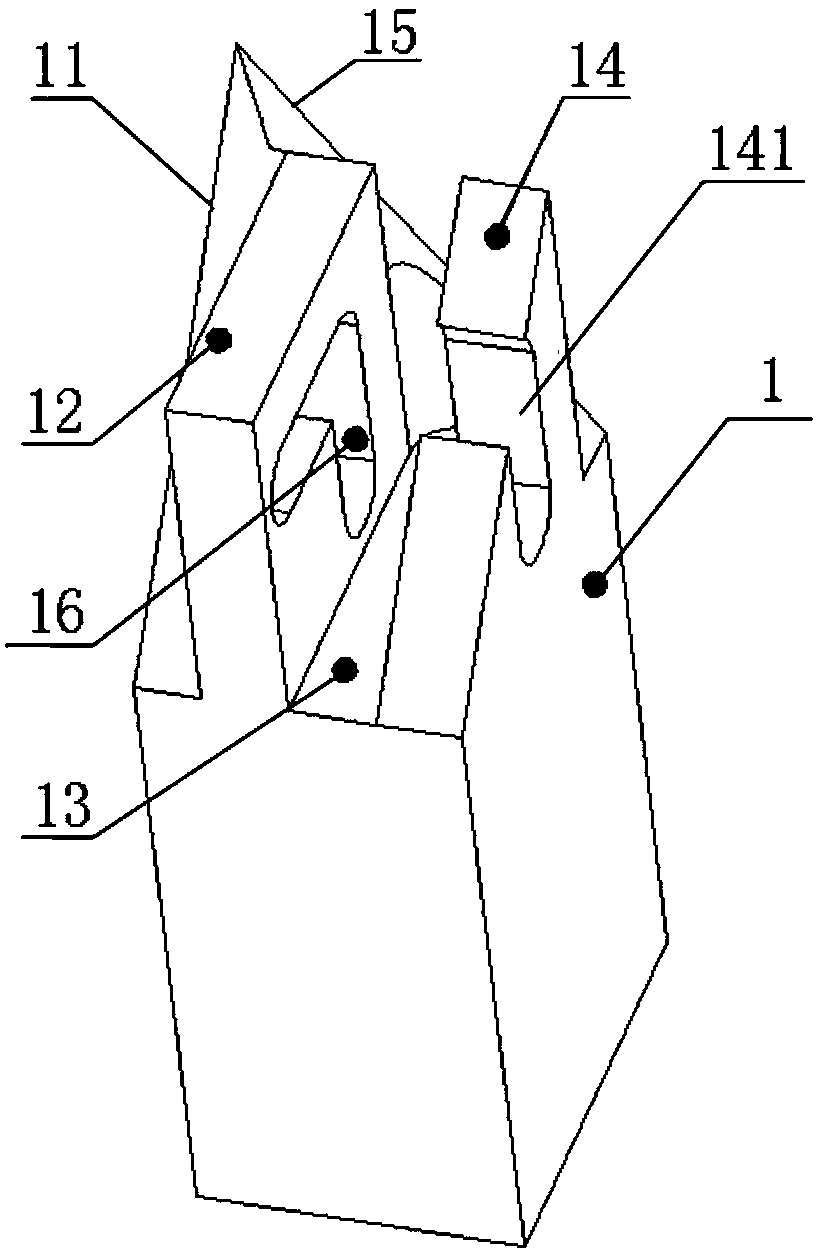

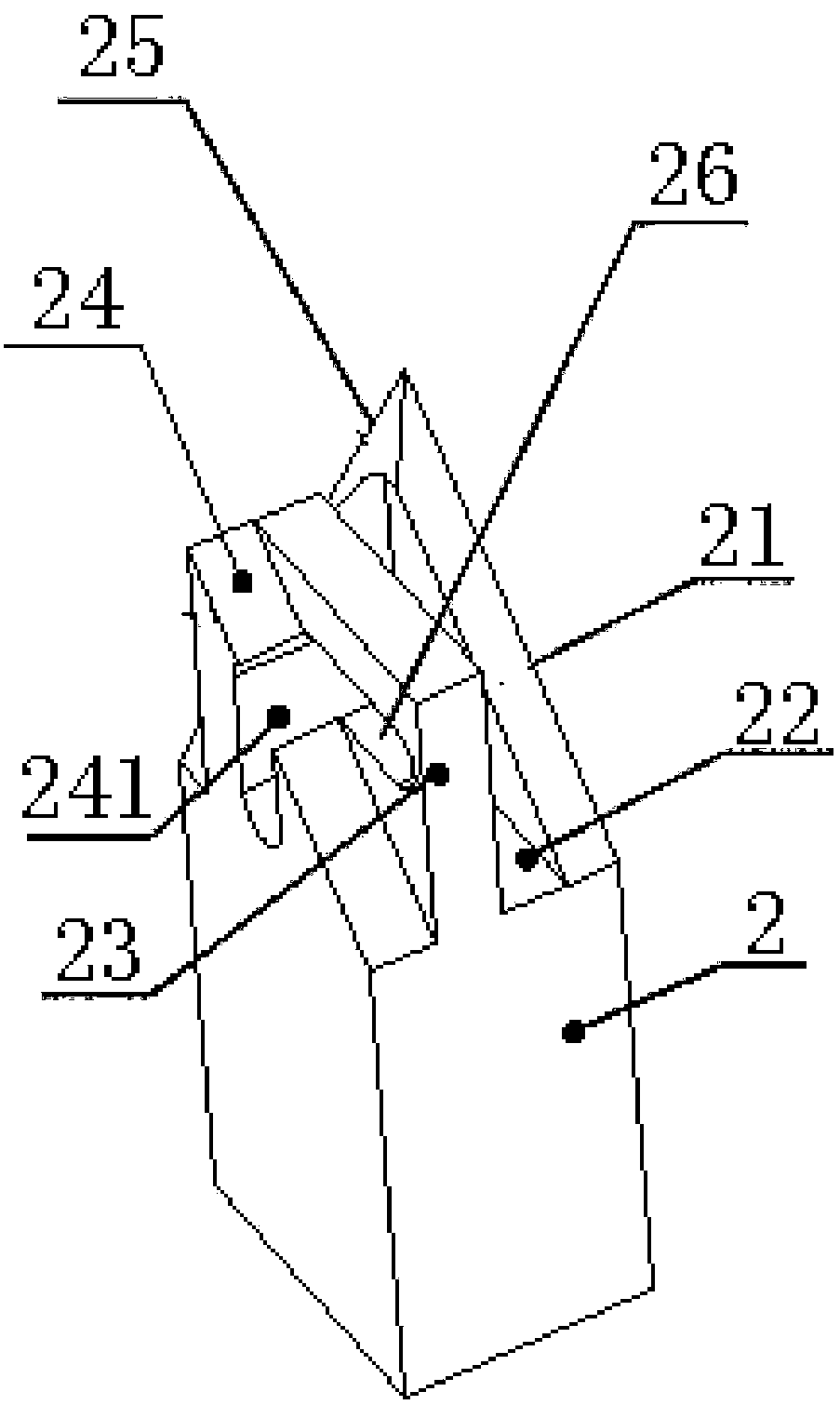

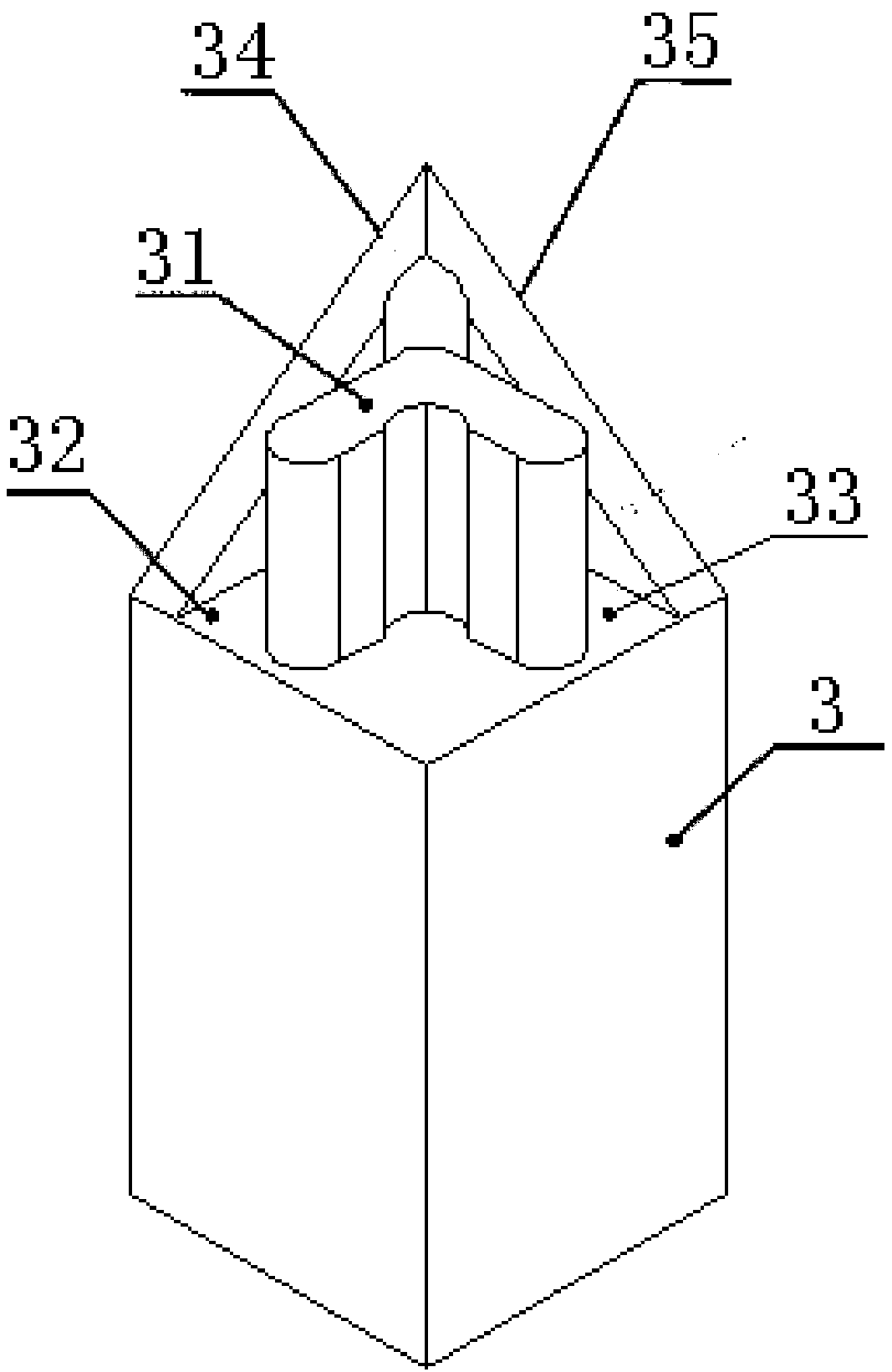

[0033] Embodiment one: see Figure 1-5 As shown, a surface frame tenon includes a first surface frame tenon 1, a second surface frame tenon 2 and a third surface frame tenon 3, and the two of the three are perpendicular to each other and assembled through the tenon head and the tenon groove. One side frame tenon 1, the second side frame tenon 2, and the third side frame tenon 3 respectively include the outer edge surface part and the inner tenon head part, the first side frame tenon 1, the second side frame tenon 2, and the third side frame tenon 3 There are two hypotenuses on the outer edge surface of the top respectively, and the six hypotenuses are overlapped in pairs, and the combined corners after the assembly of the first frame tenon 1, the second frame tenon 2, and the third frame tenon 3 are divided into six 45 ° angle; in the inner tenon part, the first socket 16 is provided on the first tenon 12 of the first surface frame tenon 1, and the second tenon 23 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com