Method for producing sawdust xanthogenate using sawdust and for treating heavy metal waste water using it

A xanthate and heavy metal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high manufacturing cost, achieve low cost, high purification efficiency, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

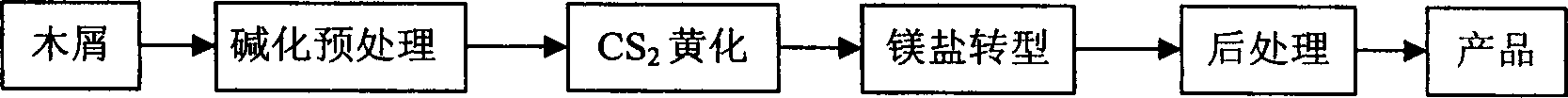

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Effect of Alkalinization Concentration on Properties of Sawdust Xanthate

[0040] Take 3g of wood chips, alkalize them with sodium hydroxide solutions with mass concentrations of 10%, 15%, 20%, 25%, and 30%, and add 1.5ml of CS 2 , and reacted for 2 hours at 30°C. The copper ion wastewater with an initial concentration of 25.0 mg / L was treated with synthetic wood chip xanthate, stirred and reacted for 30 minutes, and the concentration of copper ions after the reaction was measured. The measured removal rates of copper ions are: 96.5%, 97.4%, 98.3%, 95.6% and 95%.

Embodiment 2

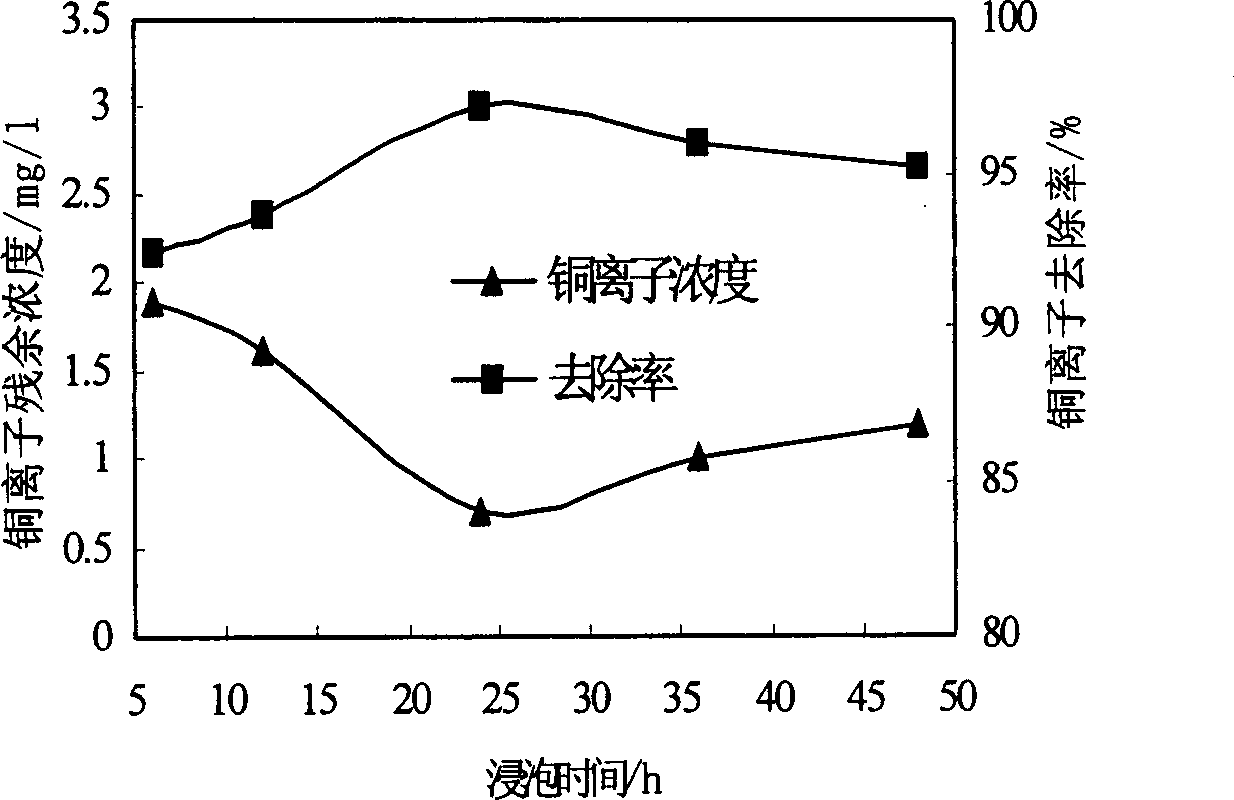

[0041] Example 2: Effect of alkalization time on properties of wood chip xanthate

[0042] Take 3g sawdust, in alkali concentration 20%, CS 2 The addition amount is 1.0ml, the yellowing reaction temperature is 30°C, and the yellowing reaction time is 2 hours. The alkalization time is 6, 12, 24, 36, and 48 minutes, and the initial concentration of the synthetic wood chip xanthate is 25.00 mg / For the copper ion solution of L, the removal rates of copper ions are respectively: 92.4%, 93.6%, 97.2%, 96.0%, 95.2%.

Embodiment 3

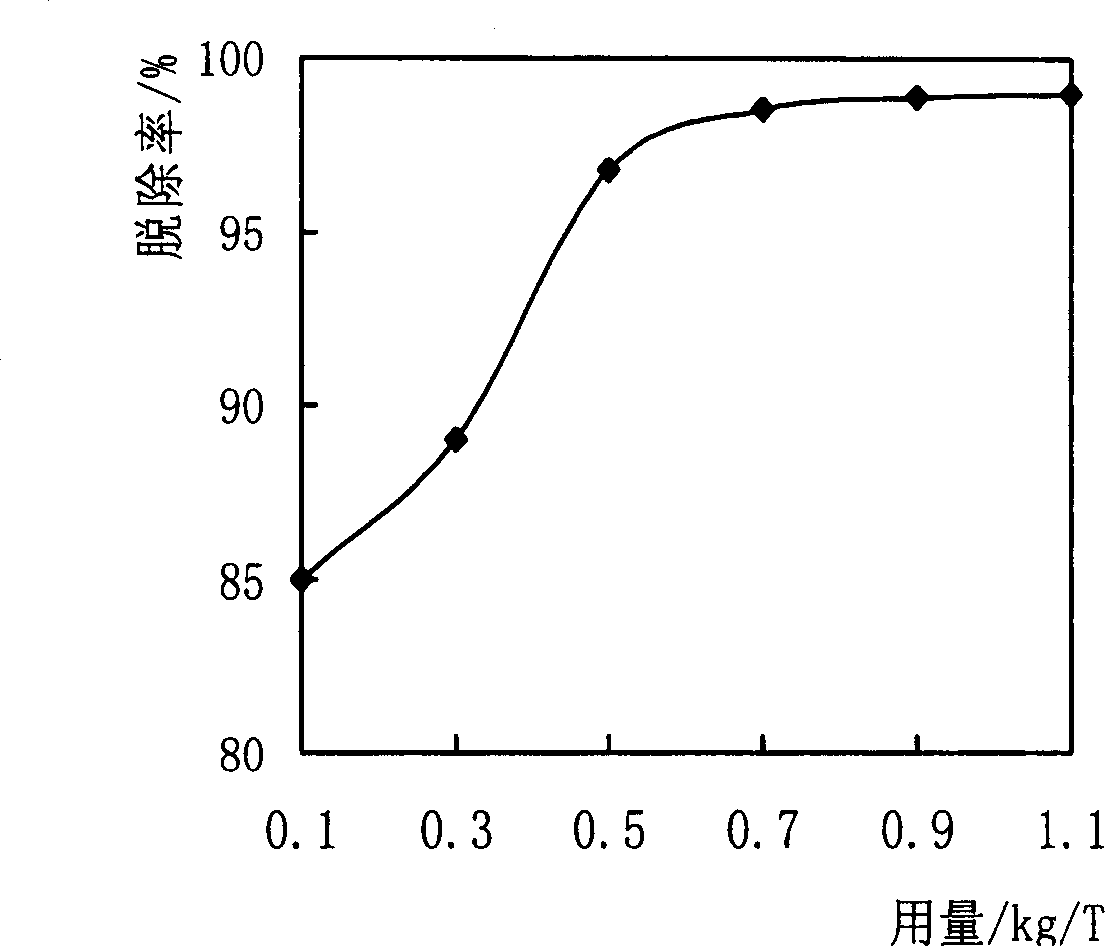

[0043] Example 3: CS 2 Effects of dosage on properties of wood chip xanthate

[0044] Take 3g of sawdust, soak it for 24h under the condition of 20% alkali concentration, and react it for 2.0 hours under the condition of 30℃, CS 2 The dosages are: 0.1667, 0.3333, 0.5000, 0.6667, 0.8333ml / g, and the prepared SCX respectively treats the initial concentration C 0 = 25.0mg / L copper ion solution, the removal rates of heavy metal ions after treatment are: 99.3%, 99.39%, 99.86%, 99.35%, 99.27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com