Copper-zinc separation beneficiation method

A beneficiation method, copper and zinc technology, applied in solid separation, flotation and other directions, can solve the problems of excessive copper content in zinc concentrate and high zinc content in copper concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

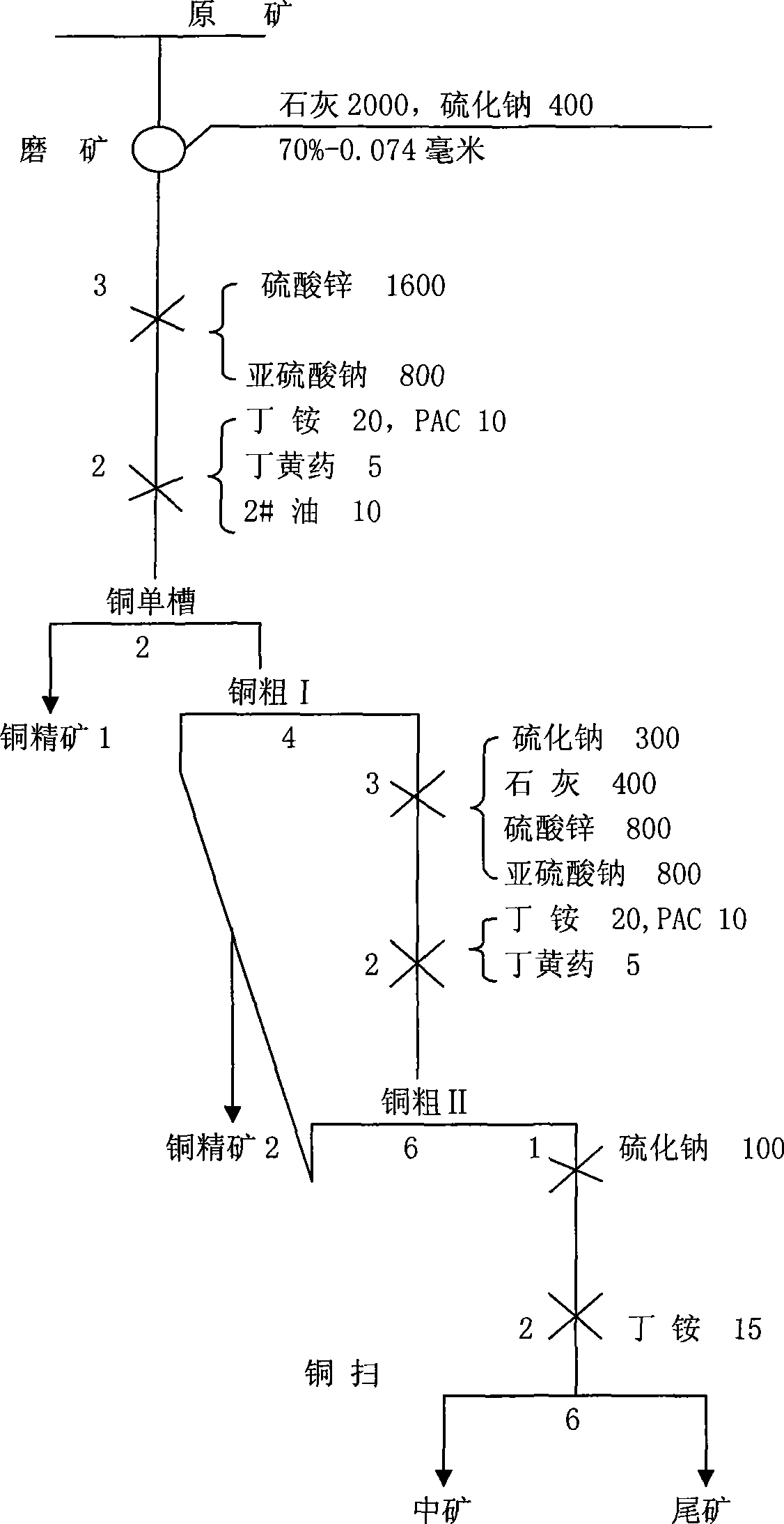

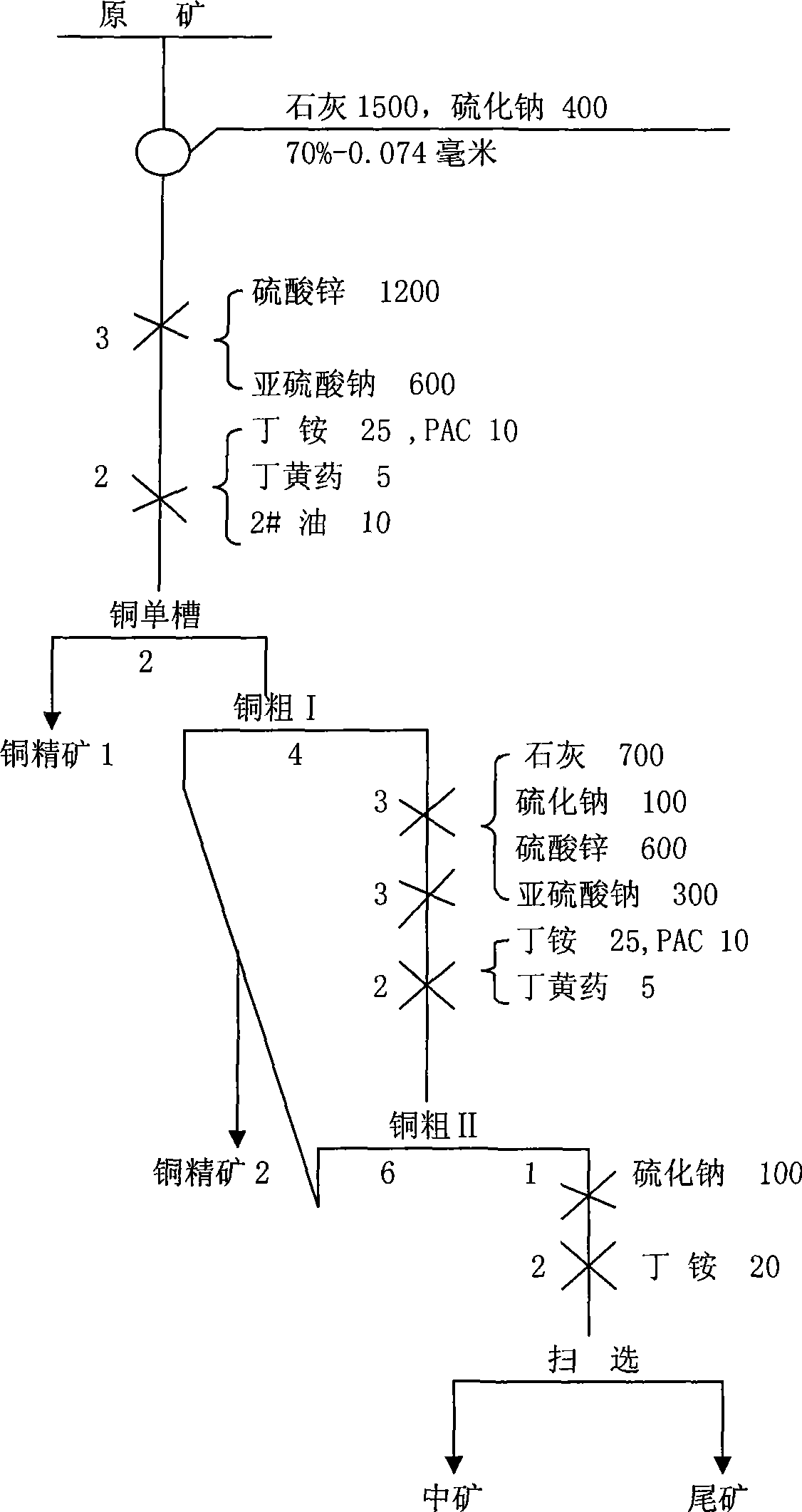

[0031] Example: figure 1 and figure 2 The dosage unit of the chemical in the ore is gram / ton. It can be seen from the study of the material composition that the copper, zinc and sulfur minerals in the ore are embedded in a relatively coarse particle size. Under the condition that the grinding particle size is 65-70%-0.074 mm, the chalcopyrite The monomer dissociation degree of zinc blende has reached 90%, and the monomer dissociation degree of sphalerite is also nearly 85%. Under this condition, copper, zinc and sulfur have already met the conditions for separation. The copper minerals are mainly chalcopyrite, and there are few secondary copper minerals. Except for sphalerite containing milky copper minerals, which is difficult to suppress, pure sphalerite is not activated by heavy metal ions, and its floatability is higher than that of copper. Minerals are poor, so it is necessary to make full use of the difference in their floatability, and it is reasonable to prefer coppe...

example A

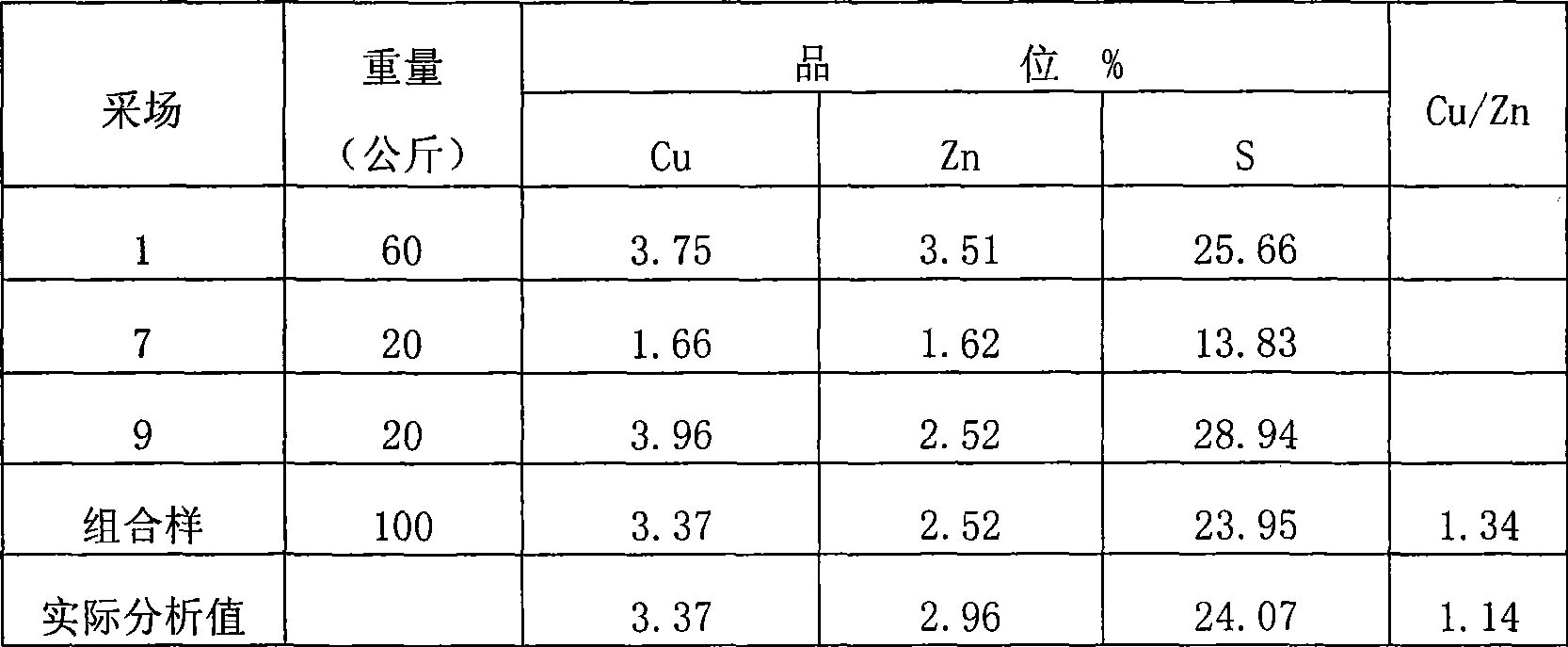

[0033] If the ratio of Cu / Zn is less than 1.5, it is called sample A, and the ore blending is shown in the table.

[0034]

example B

[0036] Those with Cu / Zn ratio less than 2.5 are called B samples, and the ore blending is shown in the table.

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com