Method for synthesizing xanthate

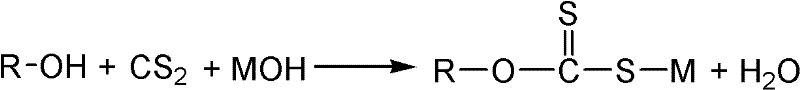

A synthesis method and technology of xanthate, applied in the direction of organic chemistry, etc., can solve the problems of incomplete xanthate reaction, low purity and yield of xanthate products, save raw materials, efficient reaction, eliminate combustion, and reduce volatilization loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] The preparation of embodiment 2 sodium isobutyl xanthate

[0030] 46.13 parts of purity are 99% carbon disulfide and 14.98 parts of purity are 99% isobutanol to add in the reactor (the ratio of the amount of substance of alcohol and carbon disulfide is n (alcohol): n (carbon disulfide)=1: 3), in Cool the mixture to about 15°C under stirring, then add 3 parts, 3 parts and 2.34 parts of flaky sodium hydroxide (96% purity) into the reactor in 3 times, and stir for 10 minutes after each addition About, control the temperature when adding the alkali to be 15°C-30°C, after adding caustic alkali, stir and react at 25°C for 2 hours, and the reaction ends. The excess carbon disulfide solvent is recovered by step-by-step distillation under normal pressure and then under reduced pressure to obtain the desired sodium isobutyl xanthate product. Analysis showed that the purity of sodium isobutyl xanthate was 88.9%, and the product yield based on isobutanol was 95.4%.

Embodiment 3

[0031] The preparation of embodiment 3 sodium isobutyl xanthate

[0032] Add 46.13 parts of carbon disulfide with a purity of 99% and 8.34 parts of granular sodium hydroxide (with a purity of 96%) into the reactor, and cool the mixture to about 15°C under stirring, and then use it under stirring at 15°C to 30°C 14.98 parts of purity is 99% isobutanol (the ratio of the amount of substance of alcohol and carbon disulfide is n (alcohol): n (carbon disulfide)=1: 3) to reactor dropwise, dropwise and keep reaction temperature is 25 ℃, The reaction was stirred for 4 hours, and the reaction was completed. The excess carbon disulfide solvent is recovered by step-by-step distillation under normal pressure and then under reduced pressure to obtain the desired sodium isobutyl xanthate product. Analysis showed that the purity of sodium isobutyl xanthate was 89.2%, and the product yield based on isobutanol was 96.8%.

Embodiment 4

[0033] The preparation of embodiment 4 sodium isobutyl xanthate

[0034] 46.13 parts of carbon disulfide in embodiment 2 are used as 61.50 parts of carbon disulfide (the ratio of the amount of substance of alcohol and carbon disulfide is n (alcohol): n (carbon disulfide)=1: 4), granular sodium hydroxide (purity is 96%) Use instead flake sodium hydroxide, other conditions remain unchanged, the purity of sodium isobutyl xanthate in the sodium isobutyl xanthate product obtained is 88.4%, and the product yield based on isobutanol is 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com