Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204results about How to "Reduce oxidation loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing nodulizing agent

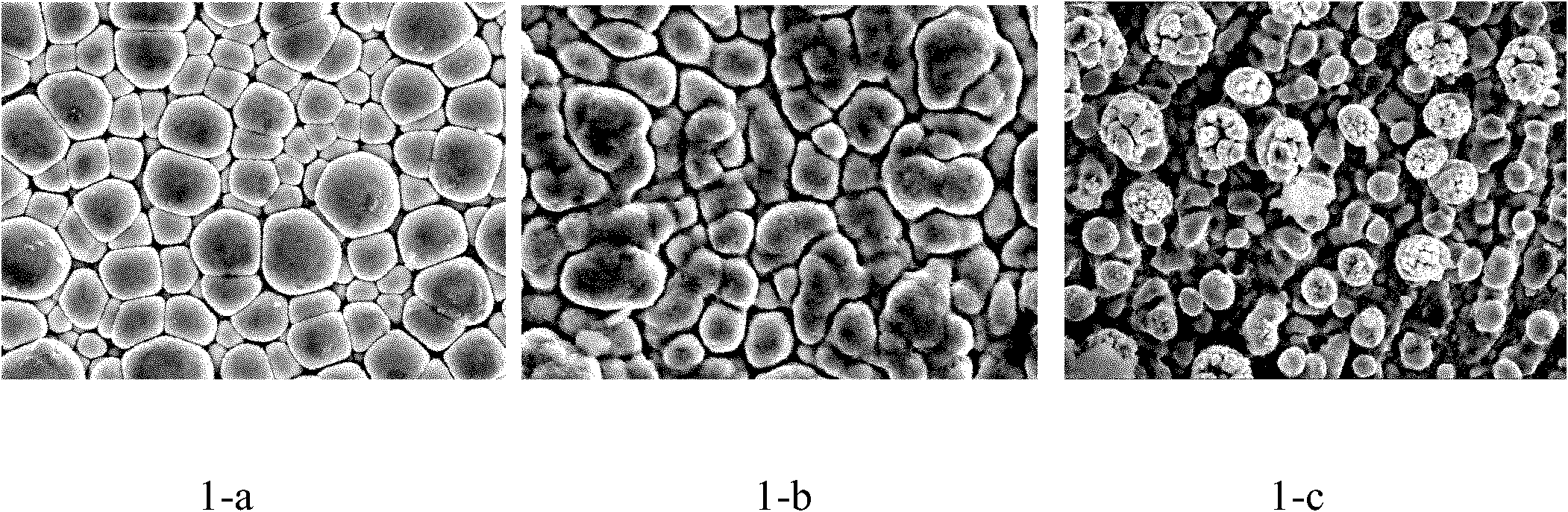

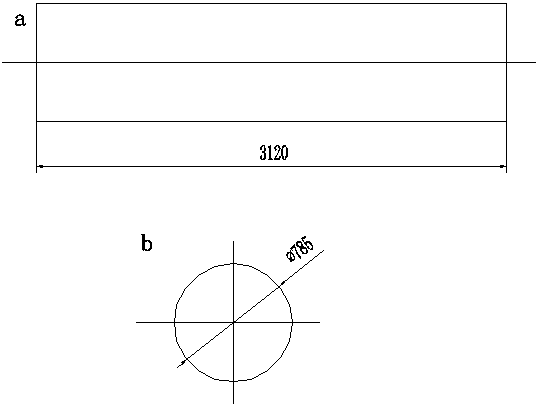

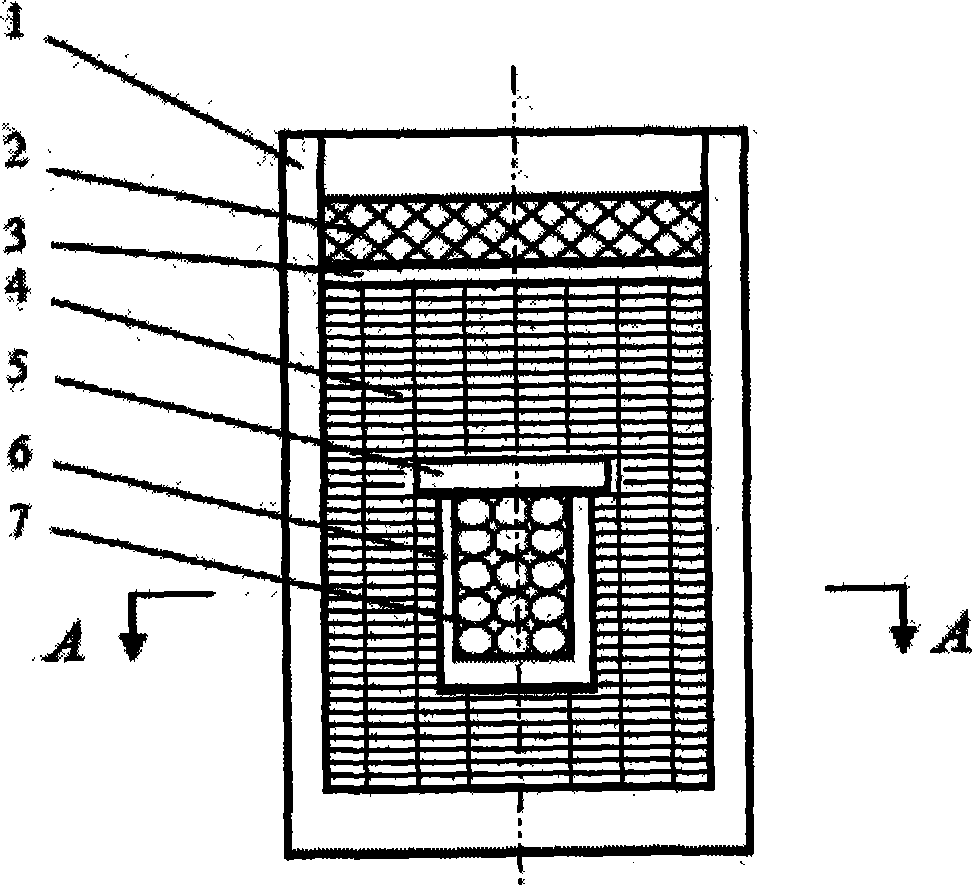

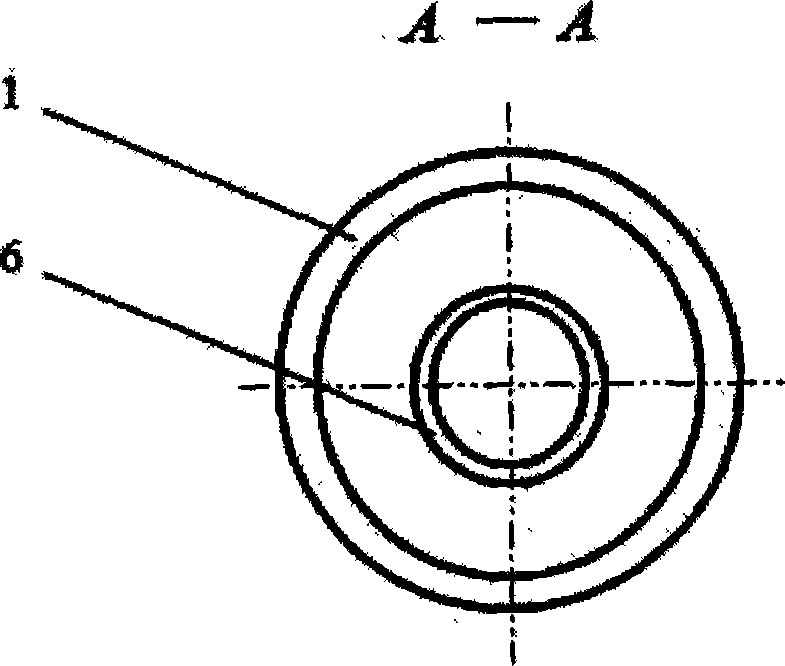

A manufacturing method of nodulizers with small chemical composition segregation and low oxidation loss is characterized in that the first part is an extruded magnesium treatment device which reacts under the condition of being filled with inert gases or carbon dioxide, thus effectively controlling the reaction time of the magnesium metal and superalloy liquid and conducing to the magnesium metal to form Mg2Si; the second part is a combined molten pool for pouring nodulizer alloy liquid; the combined molten pool and the pouring basin can ensure that the nodulizer alloy liquid rapidly fills the die cavity of the molten pool in a possibly short time and that the nodulizer alloy liquid of the pouring type die cavity can congeal at the same time. The alloy liquid is evenly cooled in a closed die cavity, thereby overcoming the oxidation and segregation of the upper surface of the nodulizer alloy liquid. The product quality is stable and the manufacturing cost is obviously lower than that of the nodulizer produced by the secondary smelting and remelting method. The method cancels the secondary smelting process of the nodulizers of rare earth-Mg-Si-Fe, achieves the purpose of energy-saving and environment protection and eliminates environmental pollution.

Owner:TIANJIN WANLU OF SCI & TECH +1

Melt treating method of high-vanadium high-speed steel roller material for various rolling machines

The invention discloses a melt processing method of high-speed steel rolls containing high vanadium used for various rolling mills. When molten steel in transportation, ferrovanadium granules are added with flowing, the addition amount of the ferrovanadium granules is 0.80-1.20 percent of total weight of the molten steel. Before the molten steel is poured over a pouring ladle, yttrium based rare earth magnesium alloy, nitriding ferrochrome, potassium salt and metal aluminum are added into the pouring ladle in advance; wherein, the addition amount of the yttrium based rare earth magnesium alloy is 0.30-0.80 percent of the weight of the molten steel, the addition amount of the nitriding ferrochrome is 0.20-0.50 percent of the weight of the molten steel, the addition amount of the potassium salt is 0.30-0.80 percent of the weight of the molten steel and the addition amount of the metal aluminum is 0.30-0.60 percent of the weight of the molten steel. When the temperature of the molten steel reaches between 1450-1480 DEG C, the molten steel in a centrifuge is directly cast into rollers; during the process of casting molten steel, the ferrovanadium granules and ferrotitanium granules with granule dimension between 5mm-8mm are added with flowing, wherein, the addition amount of the ferrovanadium granules and the ferrotitanium granules is respectively 0.30-0.80 percent and 0.40-1.00 percent of the total weight of the molten steel. The centrifugal casting high-speed steel rolls containing high vanadium of the invention has less segregation, no casting cracks, high rigidity and good abrasion resistance.

Owner:XI AN JIAOTONG UNIV

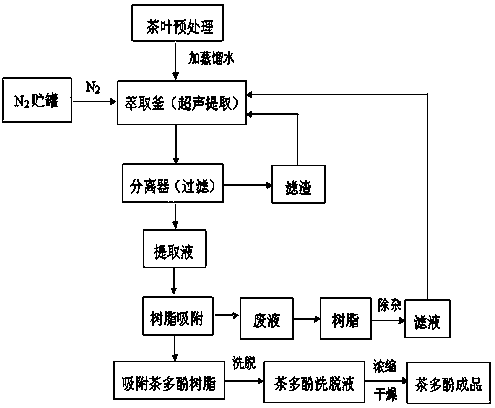

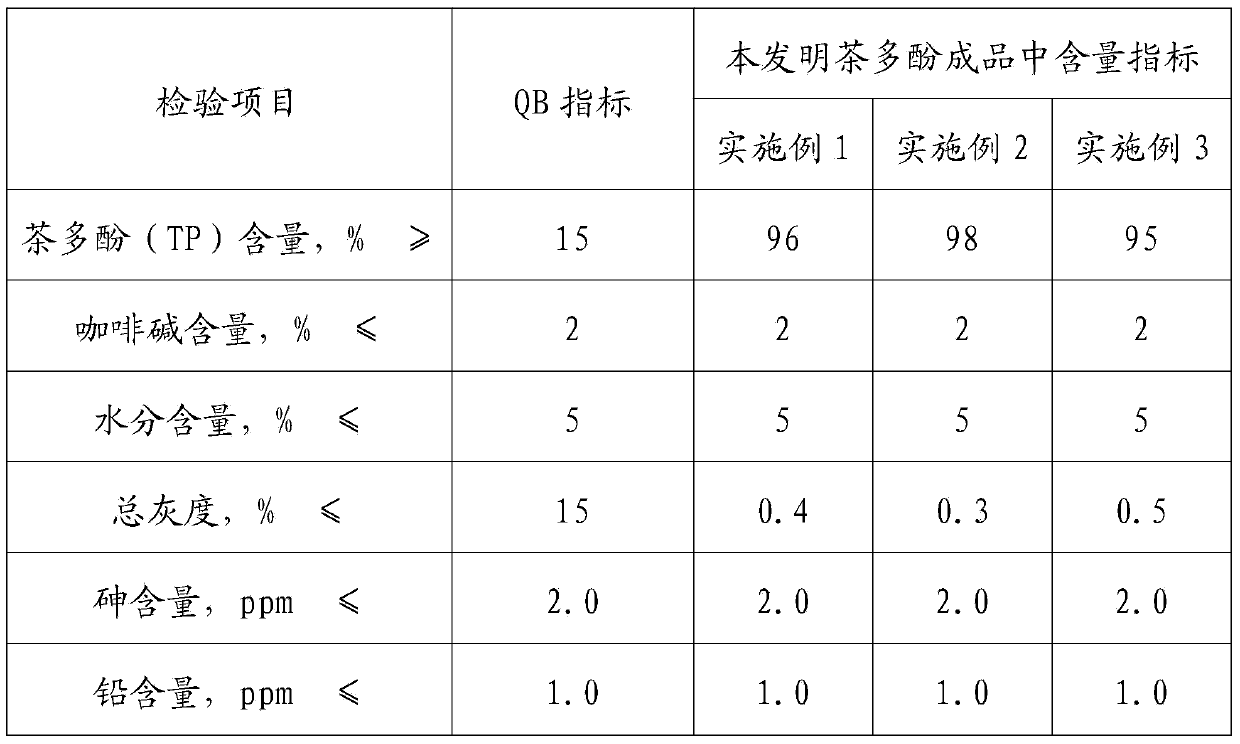

Preparation process for extracting green tea polyphenols from tea

InactiveCN103992359AIncrease the speed of diffusionHigh extraction rateOrganic chemistryGreen Tea PolyphenolsPhenolic content in tea

Belonging to the field of green tea polyphenol extraction processes, the invention discloses a preparation process for extracting green tea polyphenols from tea. The preparation process includes the following six steps: pretreatment of tea, nitrogen protection, ultrasonic extraction, separation and filtration, resin adsorption, concentration and drying. The process provided by the invention solves the problems of serious destruction of effective components, low product yield and purity, high production cost and pollution in existing green tea polyphenol extraction. The preparation method disclosed in the invention not only has the advantages of high recovery rate, time saving, high extraction rate and the like, but also avoids the use of toxic solvents, and is conducive to reducing energy consumption and lowering the production cost, thus having good industrial promotion value.

Owner:梁树钦

Method for drying apple pieces by nitrogen source low-oxygen heat pump

InactiveCN103444857AExtended storage timeLess nutrient lossFruits/vegetable preservation by irradiation/electric treatmentFood processingQuinoneVitamin C

The invention belongs to the field of drying of agricultural products, and particularly relates to a method for drying apple pieces by a nitrogen source low-oxygen heat pump. The method comprises the following steps of cutting applies into pieces after the apples are selected, peeled and seeded, performing color protection, shape fixation, blanching and draining, drying the apple pieces in a nitrogen source heat pump dryer, drying the apple pieces in a vacuum drying box, and sealing and storing the apple pieces. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, and the shortcomings of low drying efficiency and long drying time in the later drying period of heat pump drying are overcome; the apple pieces are subjected to heat pump drying and vacuum low-temperature drying after the color protection and blanching treatment, so that the problems of reduction of the gloss of the apple pieces and changes in colors are effectively solved; phenolic substances in the apples can be prevented from being oxidized to generate quinone, the oxidation loss of vitamin C can be reduced, the color and the texture of the apple pieces can be prevented from being damaged by an oxidation effect in a drying process, and dry products with natural colors can be obtained.

Owner:HENAN UNIV OF SCI & TECH

Method of non-vacuum melting and casting copper-chromium-zirconium alloy

The invention relates to a method for non-vacuum melting and casting a copper-chromium-zirconium alloy. The method comprises the steps of drying an oven, loading a copper-containing raw material and a covering agent in a hearth of a melting furnace, melting the copper-containing raw material into copper water; (2) pulverizing chromium metal powder into particles with the particle size of 3-5 mm, putting the particles in a fire-resistant container, sealing the container, pressing the fire-resistant container into the copper water to make the chromium metal particles completely released into the copper water, and keeping a temperature of the hearth at 1,300-1,400 DEG C; (3) wrapping a zirconium metal by a copper foil, pressing the zirconium metal wrapped by the copper foil in the copper water rapidly, keeping the temperature of the hearth at 1,250-1,350 DEG C for 5-10 minutes, shutting down the furnace and slagging off; and (4) adjusting the temperature of the hearth to 1,200-1,300 DEG C, transferring a melt in the melting furnace into a casting ladle, and casting the melt. The method provided by the invention is simple in operation and low in cost, has small oxidation loss of the chromium metal and the zirconium metal, and can be produced in large-scale.

Owner:北京新北铜铝业有限责任公司

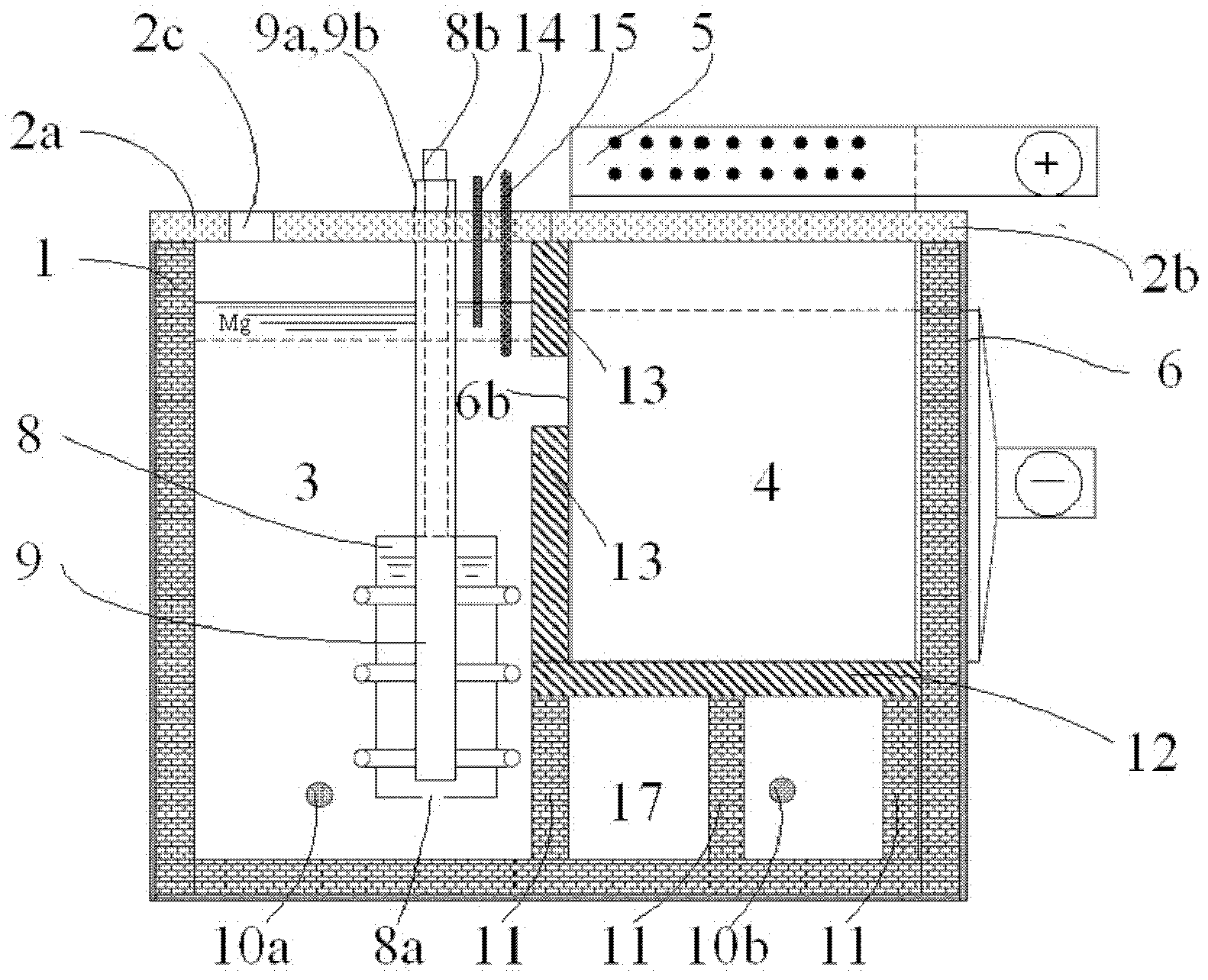

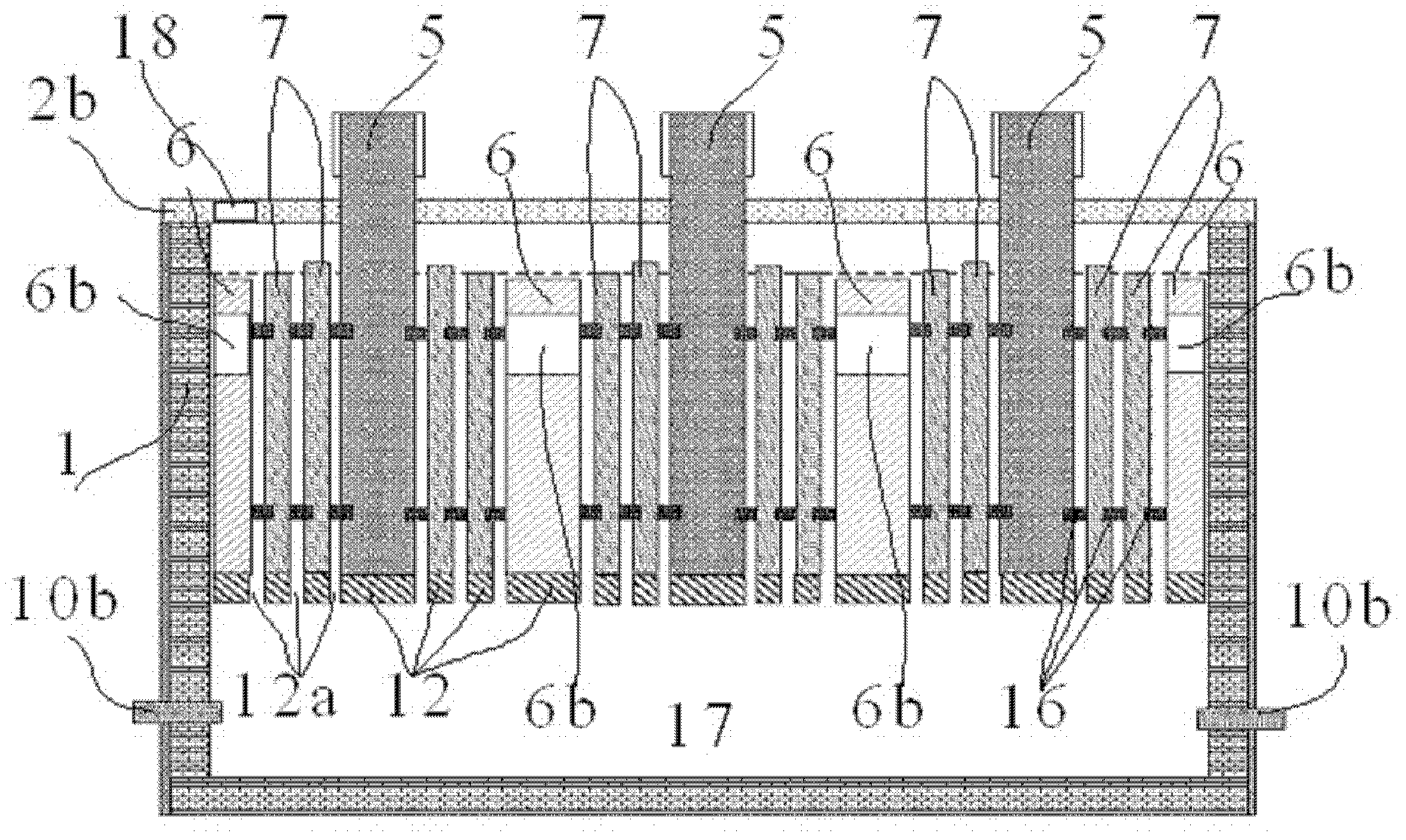

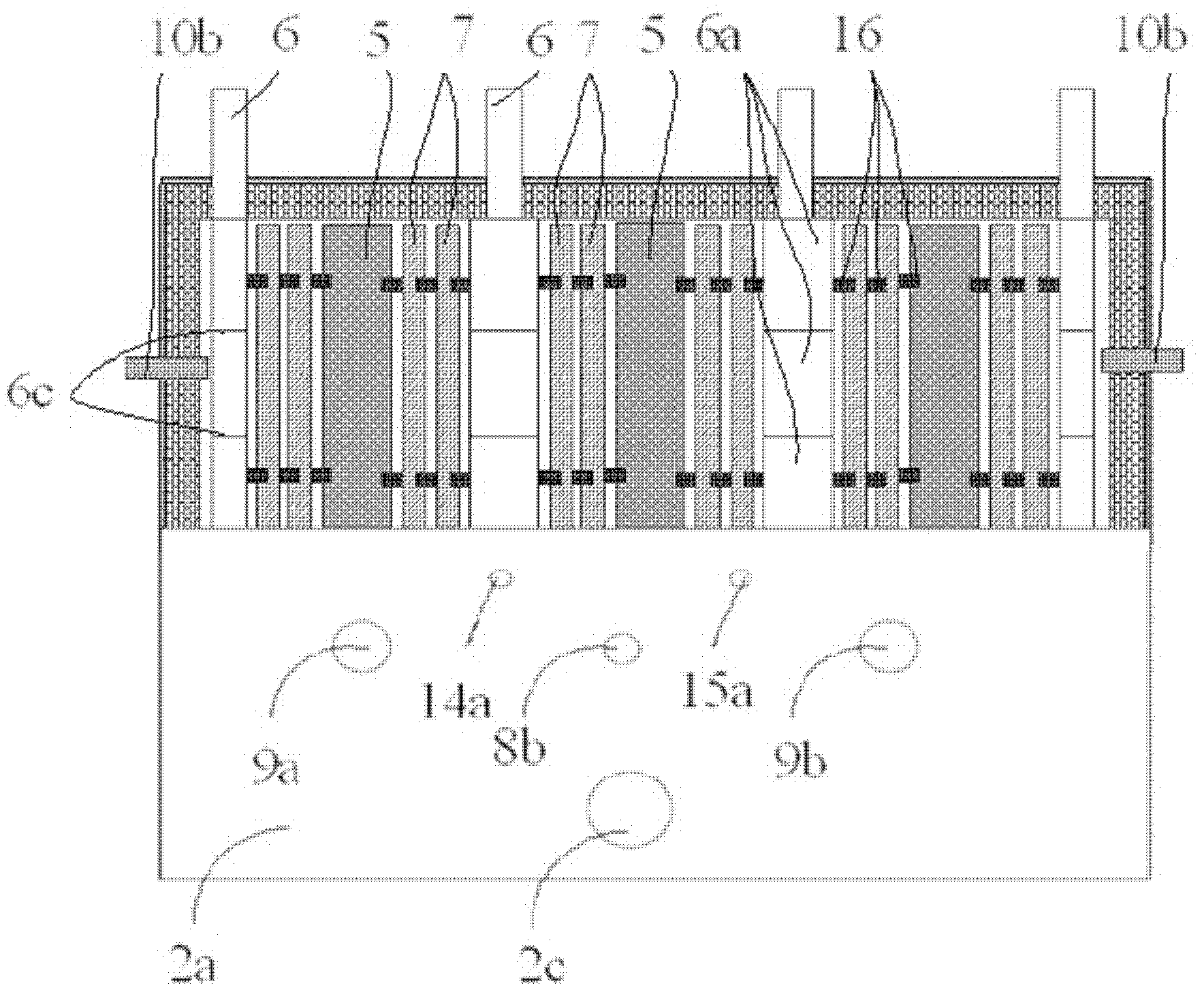

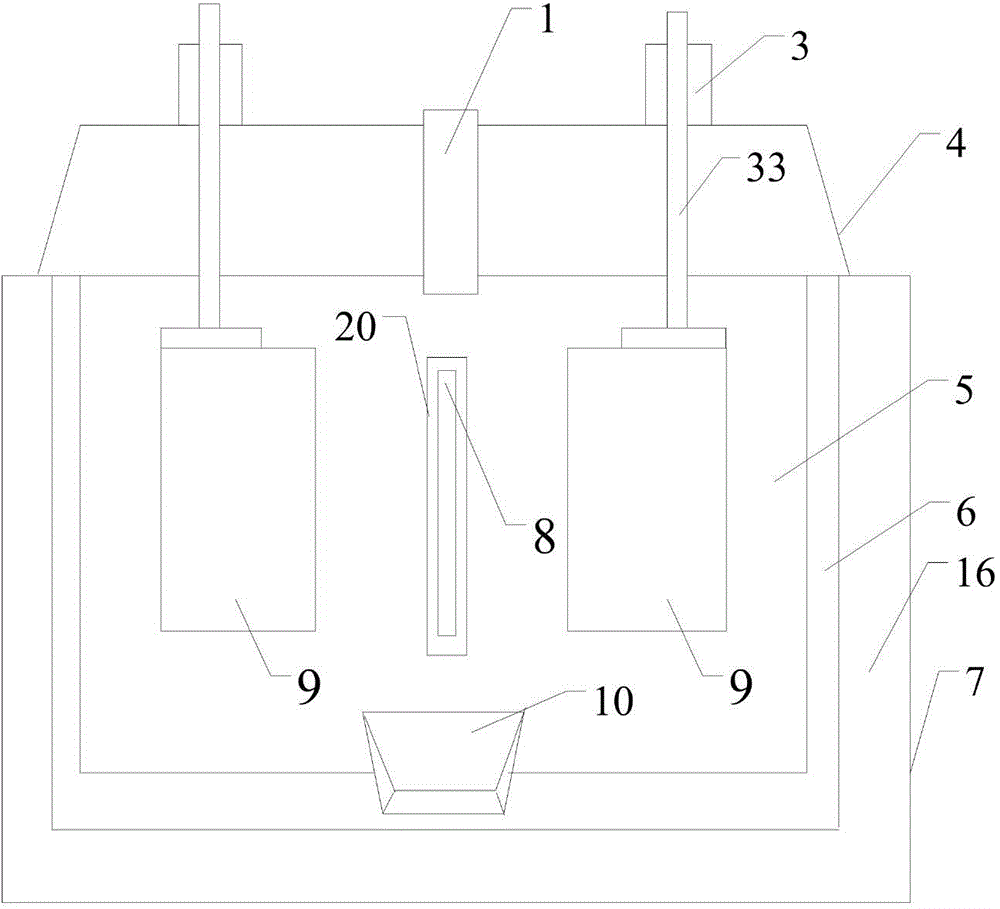

Device for generating metal magnesium by electrolyzing magnesium chloride

InactiveCN102534663AReduce oxidation lossReduce productionElectrolysis componentsTemperature controlElectrolysis

The invention relates to the field of magnesium chloride electrolysis and particularly discloses a device for generating metal magnesium by electrolyzing magnesium chloride. The device comprises a temperature control system, a liquid level control system and an electrolytic tank; a clapboard is arranged in the electrolytic tank to divide the upper part of the electrolytic tank into an electrolytic chamber and a magnesium collection chamber; a plurality of groups of carbon anodes and iron cathodes are installed in the electrolytic chamber; a plurality of bipolar electrodes are inserted between the anodes and the cathodes; a supporting plate is arranged at the lower part of the electrolytic chamber and is provided with an electrolyte circulation hole; a slag storage chamber is arranged below the supporting plate; and a sealing cover is arranged on the electrolytic chamber. The device of the invention has the beneficial effects that as the device for generating the metal magnesium by electrolyzing magnesium chloride does not need slag discharge operation, the labor intensity is greatly reduced, the working environment is improved, the oxidation loss of liquid magnesium and the generation quantity of magnesium oxide tank slag are reduced, and the productivity and the electrolysis efficiency of a single tank are improved.

Owner:QINGHAI NORMOON TECH

Low-metal-loss smelting method of copper alloy

The invention discloses a low-metal-loss smelting method of a copper alloy, which comprises the following steps: (1) adding all the raw materials except fusible and oxidable raw metals into a smelting furnace according to the components contained in the target alloy; after the raw materials are molten, introducing nitrogen or air into the smelting furnace, raising the pressure of the smelting furnace to 1-50 atm, and adding the low-melting raw metals into the smelting furnace; cooling the alloy melt, lowering the pressure of the hearth, and recovering valuable metals by using a micro reducing medium; using high-purity nitrogen, argon or carbon dioxide as a carrier gas, and adding a refining agent into the melt; introducing high-purity nitrogen or argon into the melt by using a rotary sprayer; adding a reducer-slag former mixture into the smelting furnace; and after removing all the furnace slag, adding a covering agent on the surface of the molten metal. The smelting method of the copper alloy can lower the metal loss, effectively remove impurity elements and gas inclusions in the alloy in the smelting process and enhance the refining effect.

Owner:XINJIANG UNIVERSITY +1

Method for performing continuous codeposition on Al-Mn alloy plating layer in molten salt system

InactiveCN102061490ASave heatReduce oxidation lossElectrolysis componentsRare-earth elementVoltage control

The invention relates to a method for performing continuous codeposition on an Al-Mn alloy plating layer in a molten salt system. A metal material (a steel plate) is used as a cathode and a pure aluminum material with the purity of over 99 percent is used as an anode. The method comprises the following steps of: adding a mixture of MnCl2, RClX, AlCl3, NaCl and KCl into an electrolytic bath; heating and melting; electrolyzing electrolytes, wherein R is a rare earth element, the electrolysis temperature is between 160 and 220 DEG C, the cathode-current density is controlled to be between 50 and 100 mA / cm<2>, and the bath voltage is controlled to be between 1.9 and 2.3V; stirring in the electrolytic bath, wherein the electroplating time is between 20 and 30 minutes; and plating for the second time and the third time after finishing plating for the first time, wherein the whole process is performed under the protection of argon. By the method, an Al-Mn plated alloy is directly obtained by one step through molten salt electrolysis and codeposition, and the appearance quality and the corrosion resistance of the plating layer after continuously plating under the environment can remain consistent basically.

Owner:淄博德丰化工有限公司

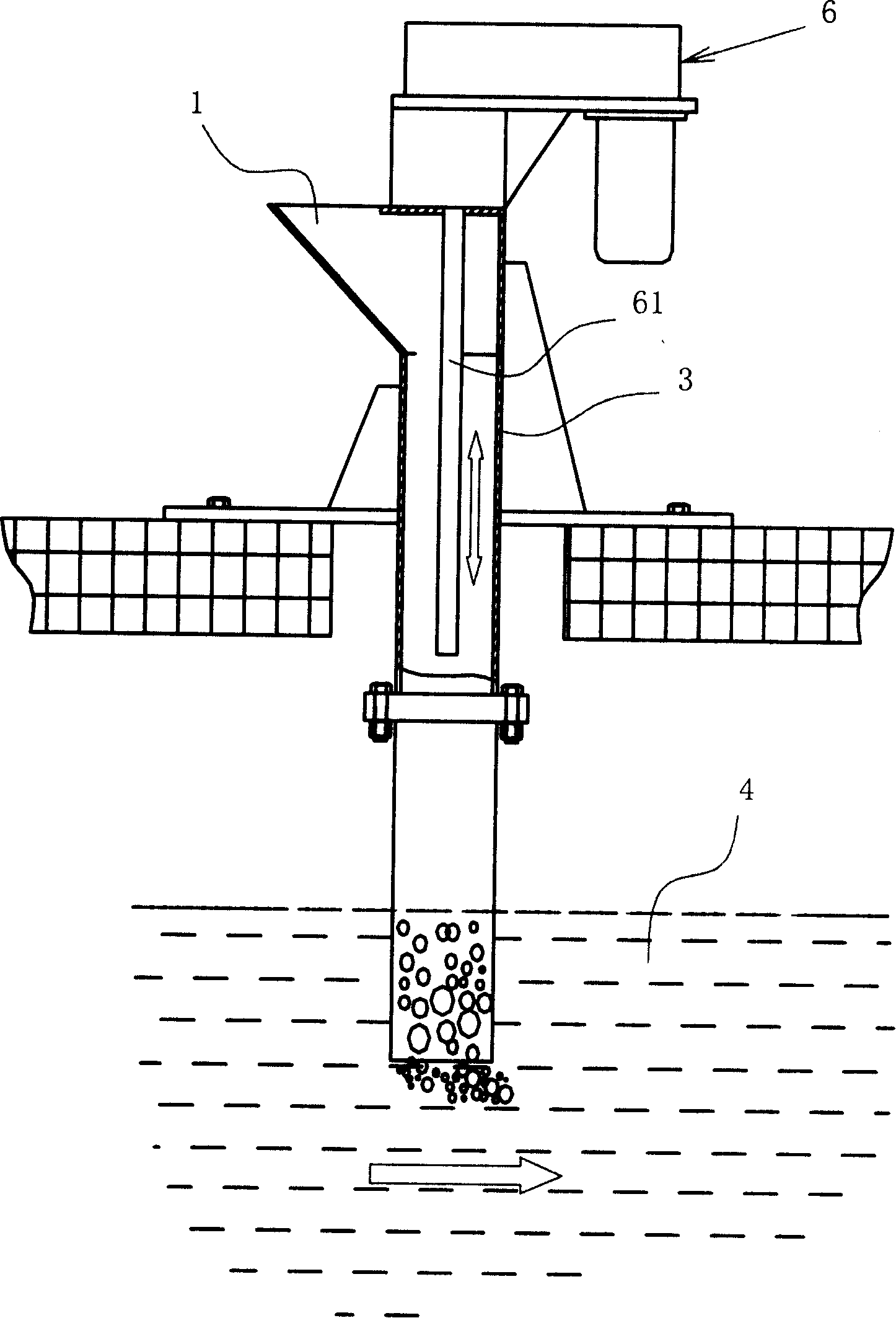

Waste aluminum recovery system

InactiveCN101235443AReduce oxidation lossImprove smelting yieldLighting and heating apparatusProcess efficiency improvementWaste managementSmelting

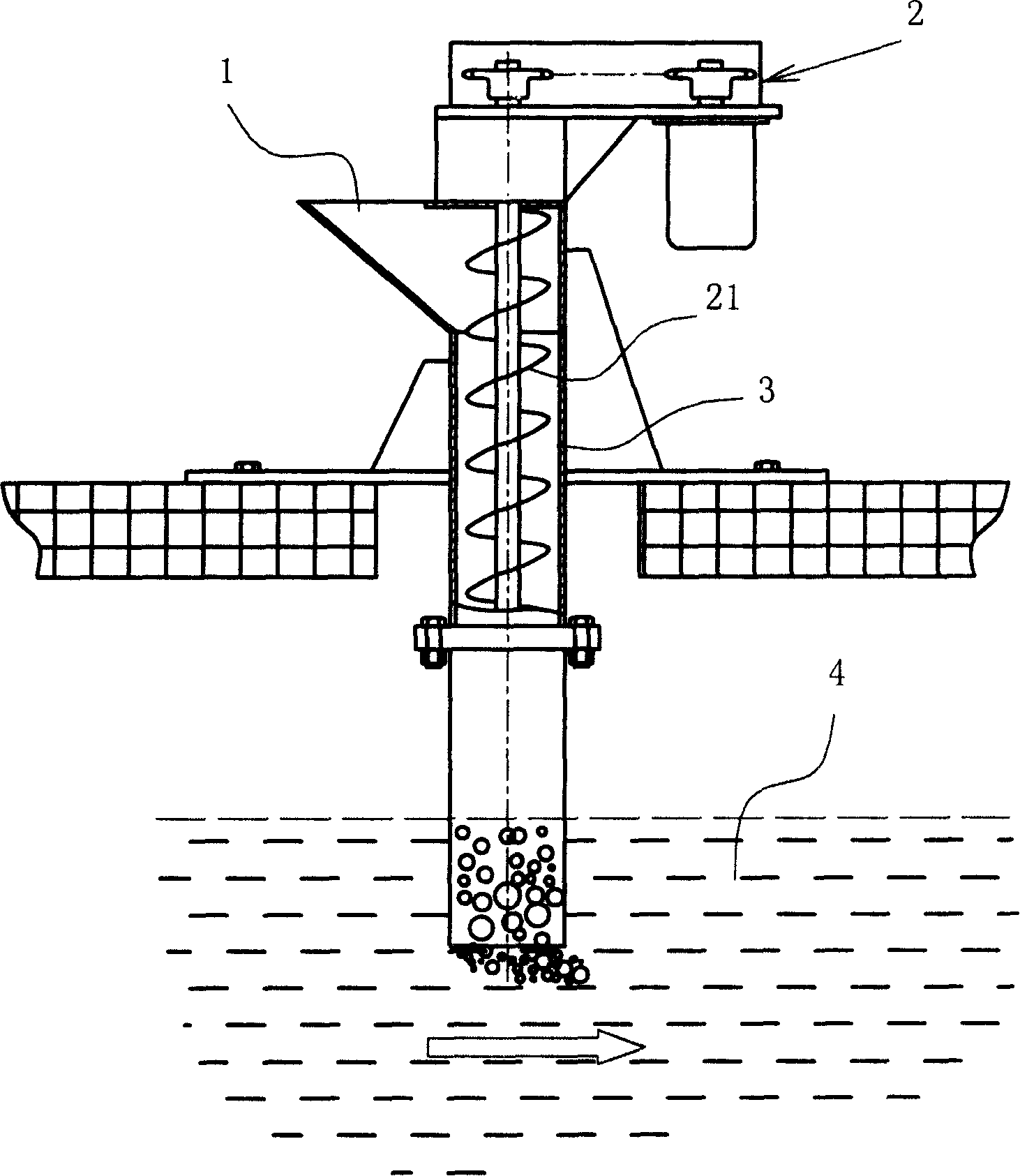

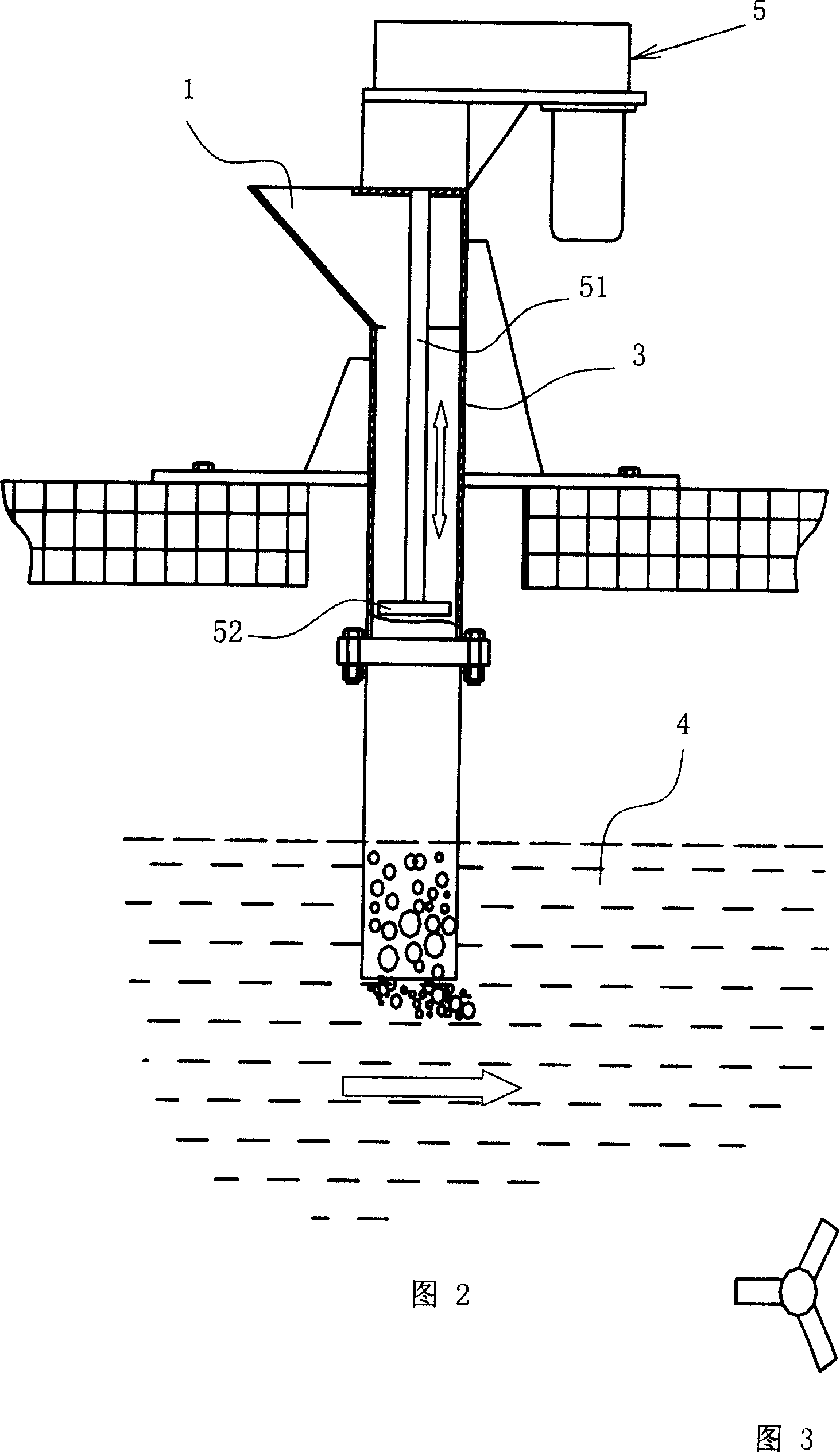

The invention relates to a system for recovering waste aluminum, which has simple structure, convenient use and maintenance, little waste and high actual yield, a feed delivery pipe (3) whose lower end is inserted into aluminum liquid (4) is arranged on a material feeding position of a smelting furnace, a material feeding port is arranged on the upper end of the feed delivery pipe, and a longitudinal material feeding component which is driven by machinery is arranged in the feed delivery pipe (3). The invention is suitable for smelting and recovering the waste aluminum.

Owner:HANGZHOU GAOQIAO MAGNETOELECTRIC EQUIP

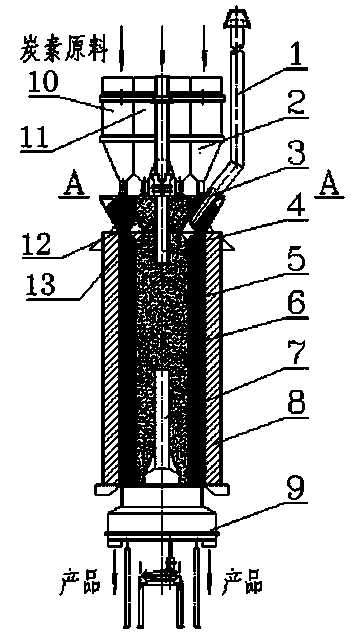

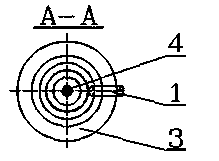

Vertical-type continuous graphitization furnace

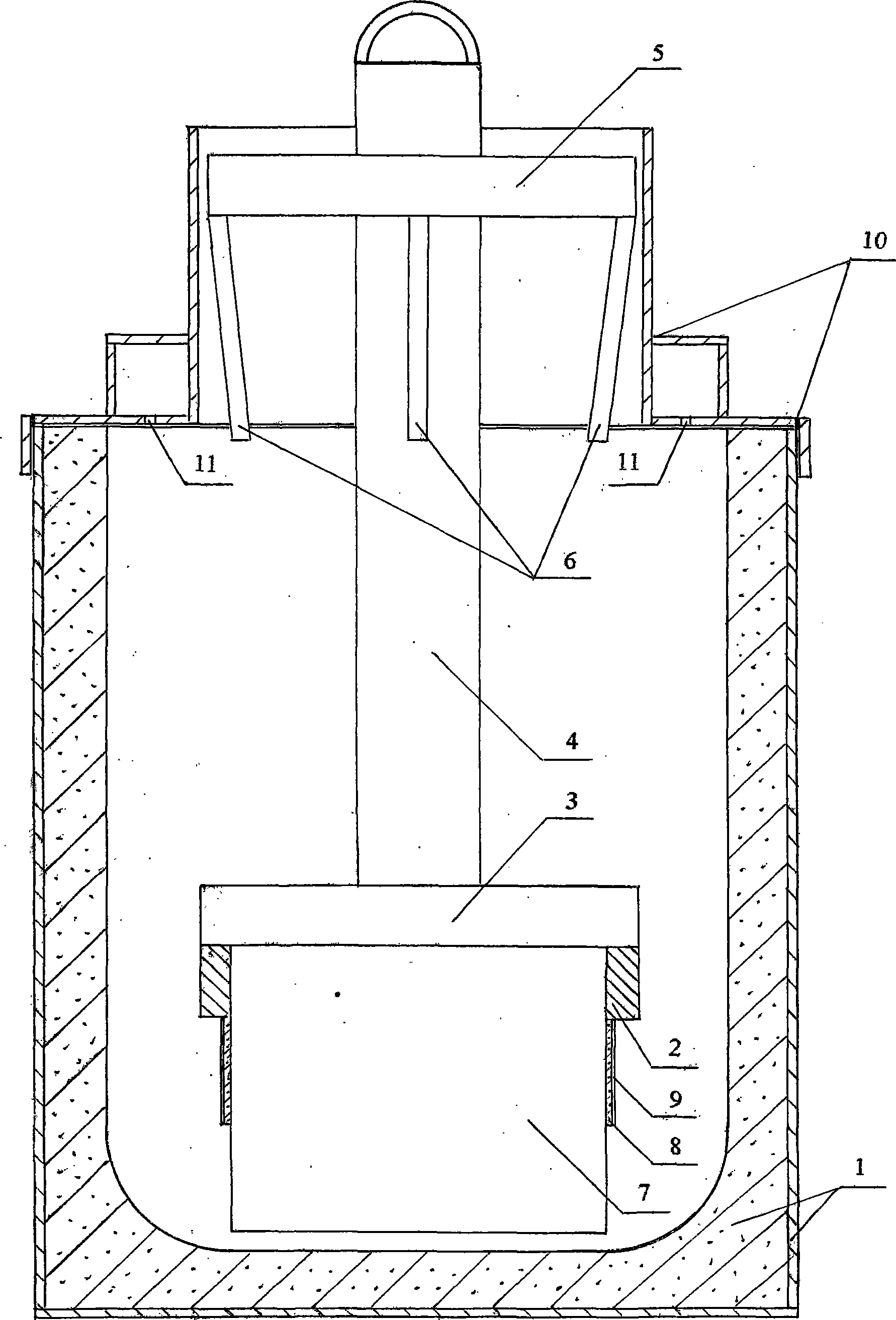

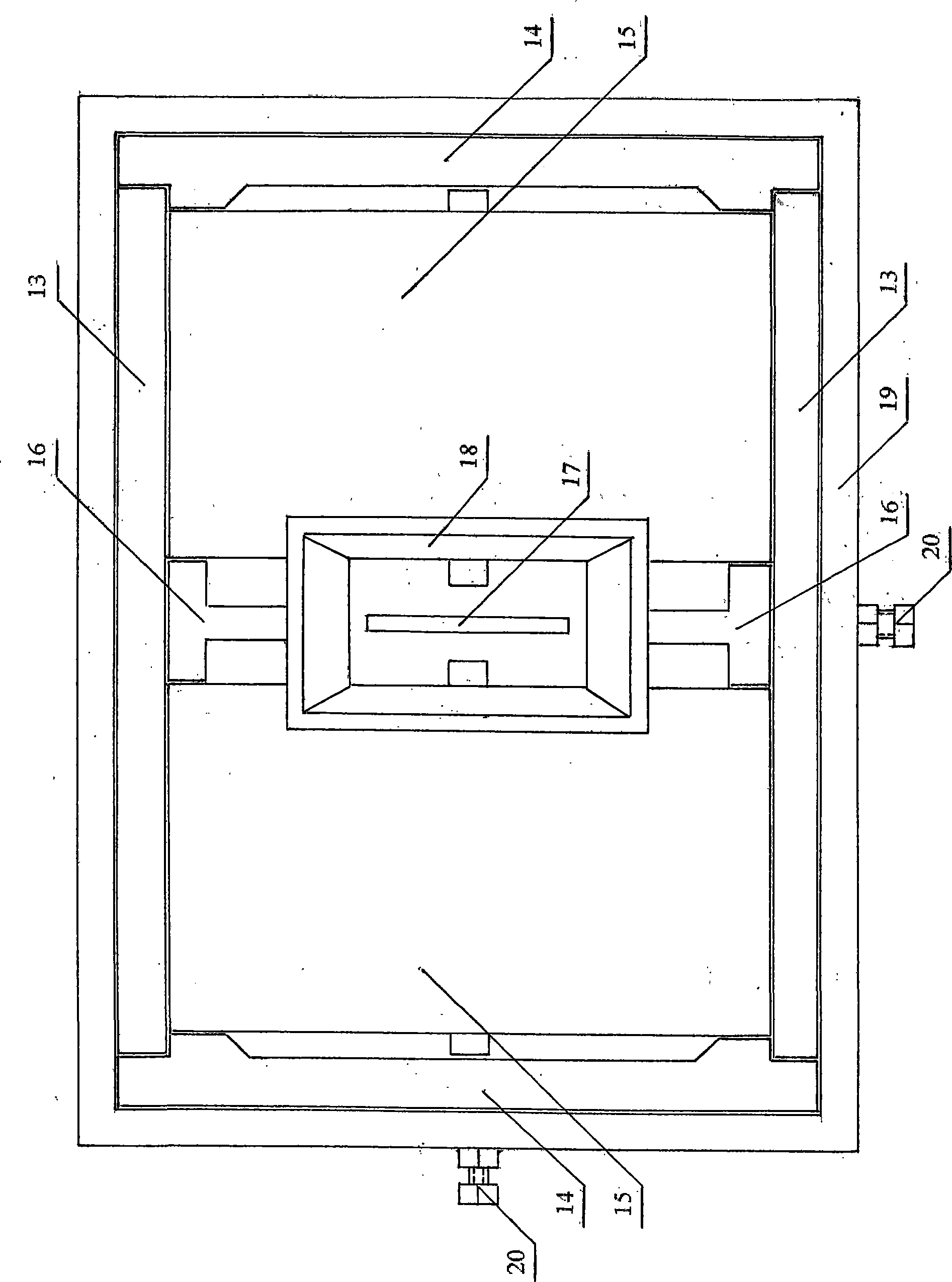

The invention discloses a vertical-type continuous graphitization furnace. A feeding tunnel (3) is arranged at the top of the furnace, and a storage bin (2) is arranged on the feeding tunnel (3); the storage bin (2) has a three-segment structure and specifically comprises a middle bin (11) and two side bins (10); the feeding tunnel (3) has a double-layer round structure and specifically has a combination structure of a tunnel inner cylinder and a tunnel outer cylinder; an annular gas exhaust channel (13) is formed at the bottom between the tunnel inner cylinder and the tunnel outer cylinder, and is connected with a gas exhaust pipe (1); an upper electrode (4) is arranged at the furnace top and at the center position of the feeding tunnel (3); a lower electrode (7) is arranged at the middle position at the lower segment of the furnace body; a coarse-particle material (5) is placed at the middle position of the furnace body, and a fine-particle material (6) is placed between a refractory-material inner liner (8) of the furnace and the coarse-particle material (5); a material discharging mechanism (9) is arranged at the bottom of the furnace body; and the annular gas exhaust channel is a triangular cavity, and the bottom employs a refractory castable (12).

Owner:GUIYANG AL-MG DESIGN & RES INST

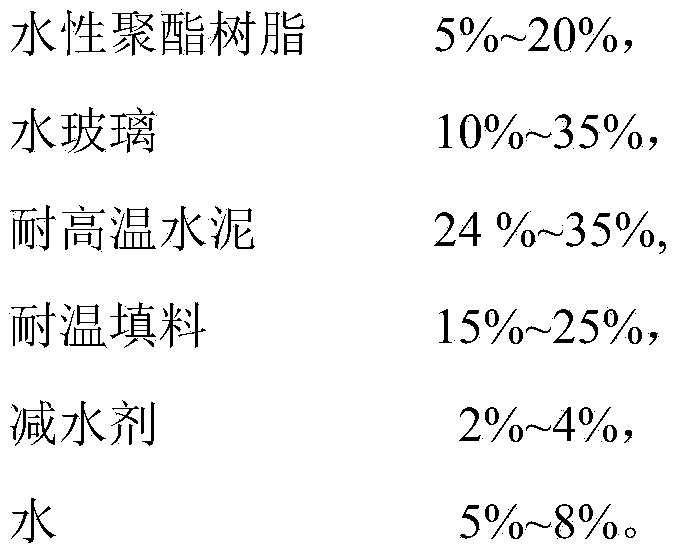

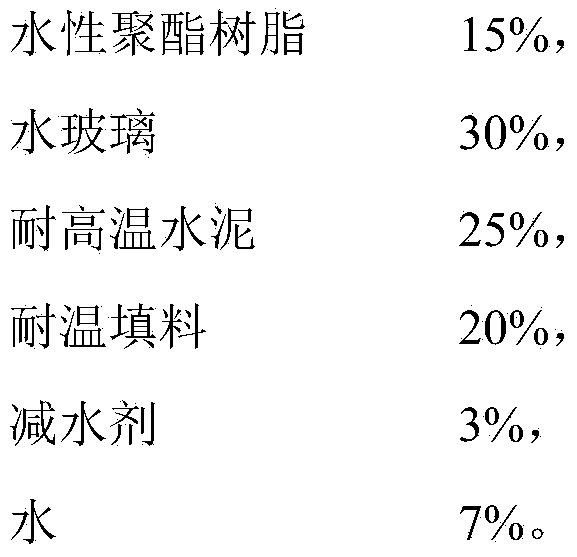

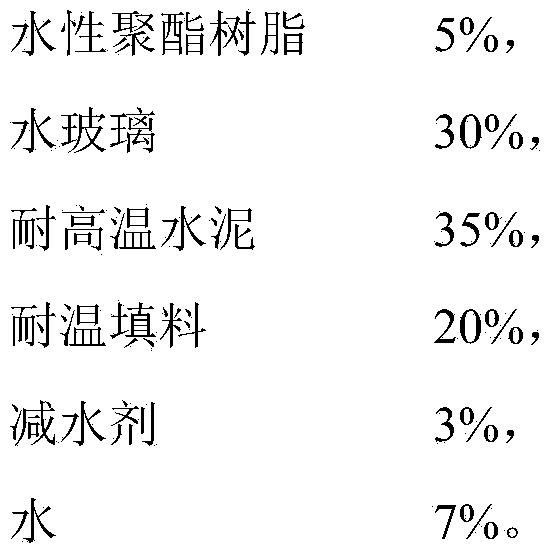

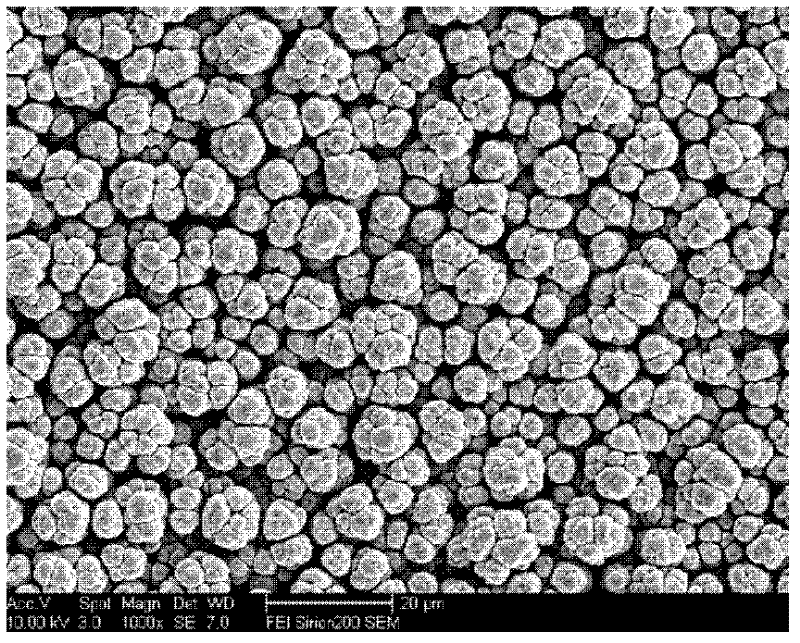

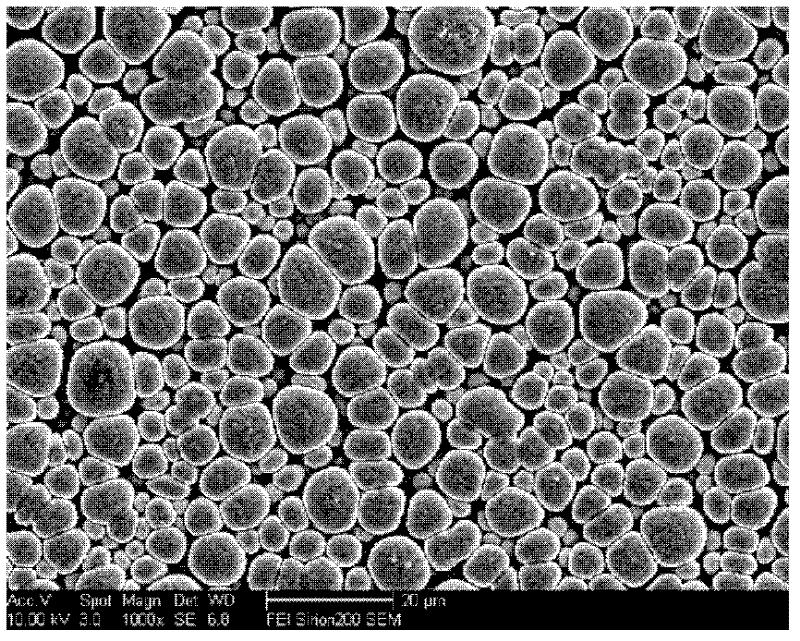

Protective coating for heat treatment of metals

InactiveCN103627302AImprove temperature resistanceReduce oxidation lossAnti-corrosive paintsPolyester coatingsPolyester resinWater reducer

The invention discloses a protective coating for heat treatment of metals. The coating comprises the following components in percentage by weight: 5-20% of waterborne polyester resin, 10-35% of water glass, 20-35% of high-temperature resistant cement, 15-25% of temperature resistant filler, 1-5% of a water reducer and 5-10% of water. The coating disclosed by the invention is good in temperature resistance, simple in preparation method and convenient to use and operate, the oxidation loss of a metal workpiece can be reduced, and the coating is easy to fall after heat treatment of metals.

Owner:JIANGSU UNIV OF SCI & TECH

Method for co-depositing Al-Mn alloy plating layer in ionic liquid system

The invention relates to an electroplating method, in particular to a method for co-depositing an Al-Mn alloy plating layer in an ionic liquid system. The method has the characteristics in that: a metal material is taken as a cathode and a pure aluminum material with the purity of more than 99 wt% is taken as an anode; a mixture of MnSO4, R3(SO4)3 and Al2O3 is added into an electrolytic cell, themixture is fused with [EMIM]HSO4 ionic liquid, and then the fused mixture is used as an electrolyte to carry out electrolysis. The method provided by the invention has the advantages that: the [EMIM]HSO4 ionic liquid is adopted as the electrolyte so that aluminum ions and manganese ions are electrolyzed and co-deposited on a cathode material to generate a uniform and dense Al-Mn alloy plating layer; the heat energy needed by generating the plating layer is low (the step of plating can be carried out at a temperature of 100 DEG C), the oxidization loss of an alloy metal is small, a zero-pollution emission is realized and the production cost is low, so that the method accords with a development tendency of the modern industrial production.

Owner:淄博鸿润新材料有限公司

A continuous casting billet hot delivery and hot charging process

The invention provides a continuous casting billet hot delivery and hot charging process and solves the problem that products in the prior art are not stable enough in performance. The quality of casting blanks is guaranteed while the effects of energy saving and environmental production are achieved, and meanwhile, the fuel consumption of a casting blank heating furnace is reduced and the output of the casting blank heating furnace is increased; the surface oxidation burning loss amount of casting blanks is reduced; the time for heating the casting blanks in the furnace is reduced and thus the surface oxidation burning loss amount of the casting blanks is reduced relatively; generally the burning loss amount of a cold charging furnace is 1.5%-2.0%, sometimes more than 2.5%; under the condition of a hot charging furnace, the burning loss amount can be reduced to 0.5%-0.7%, so that the yield of the casting blanks is increased.

Owner:张学一

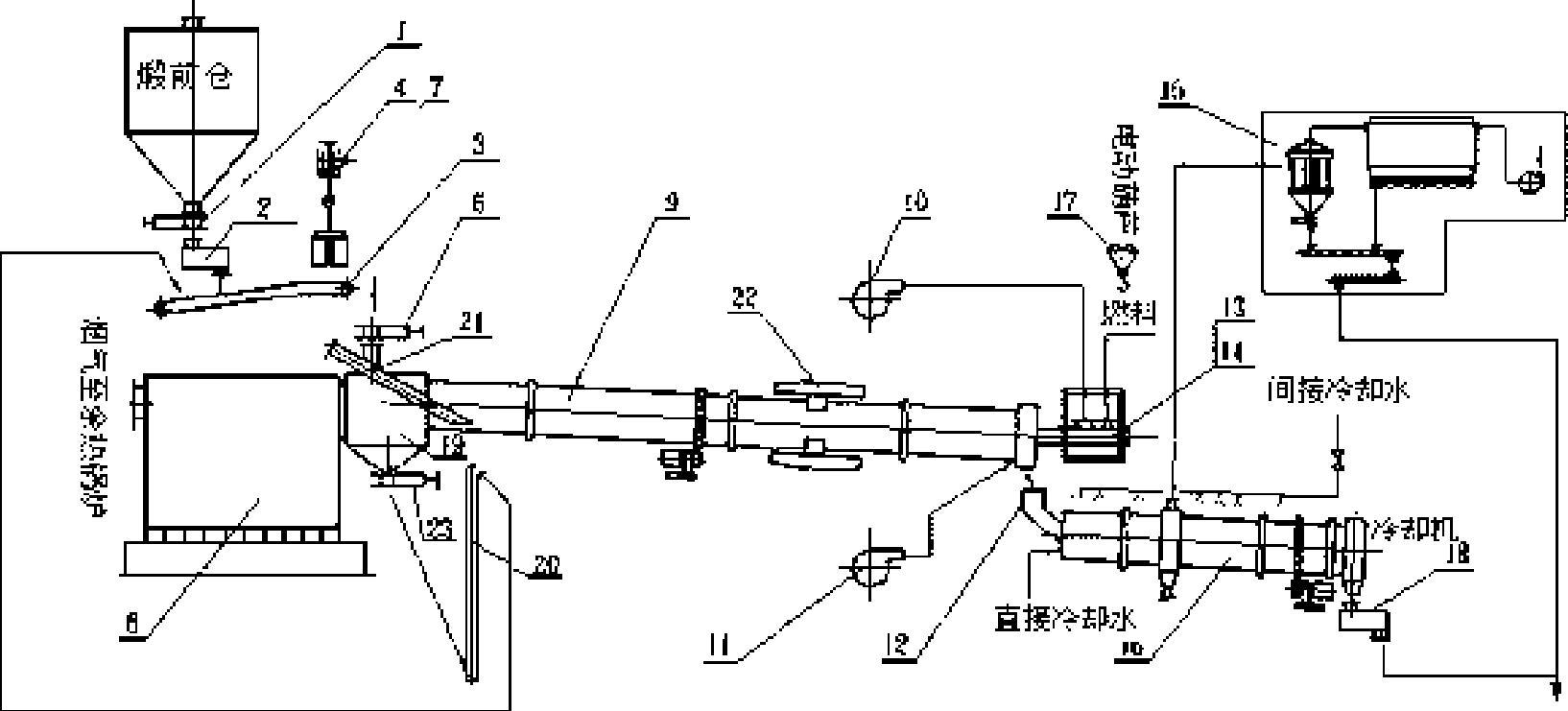

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

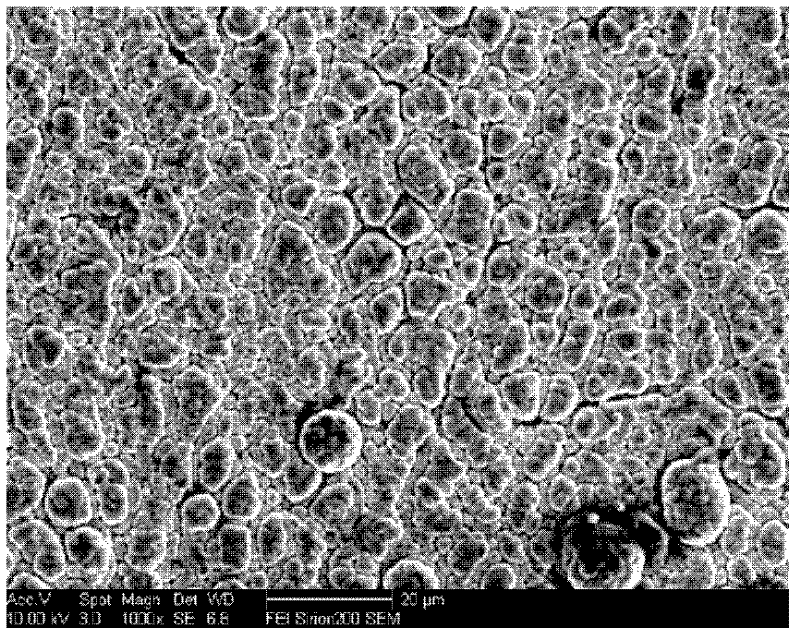

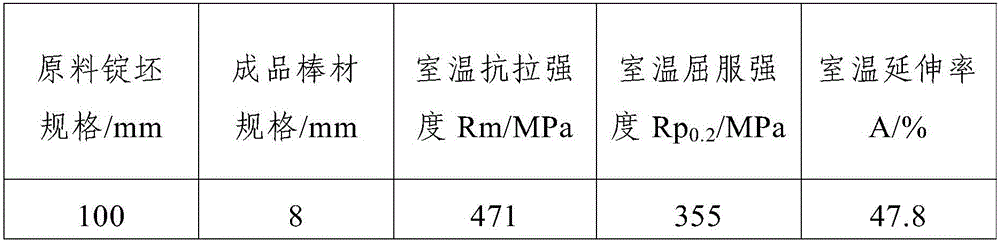

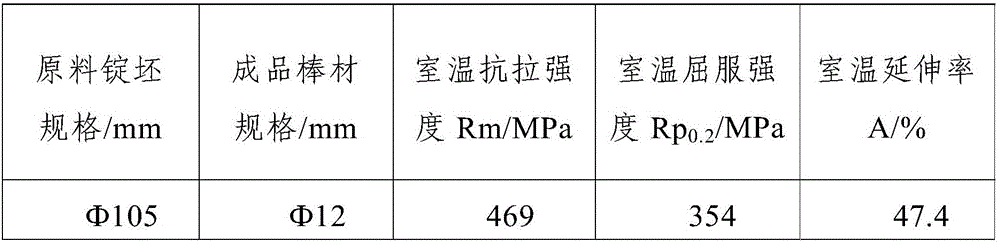

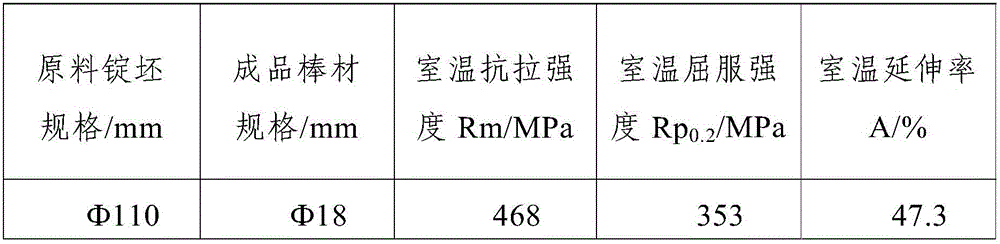

Processing method for small-size and high-strength niobium-hafnium alloy bar

The invention provides a processing method for a small-size and high-strength niobium-hafnium alloy bar. The processing method comprises the following steps that 1, a niobium-hafnium alloy ingot blank is sawn, and after being heated, the sawn niobium-hafnium alloy ingot blank is coated with an anti-oxidative protective lubricant; 2, the niobium-hafnium alloy ingot blank coated with the anti-oxidative protective lubricant is forged through upsetting and stretching to obtain a bar billet; 3, the bar billet is sequentially turned, ground and vacuum-annealed for the first time; 4, the vacuum-annealed bar billet is heated, the heated bar billet is coated with an anti-oxidative protective lubricant, and the bar billet coated with the anti-oxidative protective lubricant is formed through die forging to obtain a forging stock; 5, the forging stock is sequentially turned, ground and vacuum-annealed for the second time; 6, the vacuum-annealed forged stock is rolled with grooved rolls to obtain a small-size bar billet; and 7, the small-size bar billet is sequentially straightened, scalped, polished, pickled and annealed to obtain the small-size and high-strength niobium-hafnium alloy bar. The diameter of the section of the bar obtained according to the processing method is 8-20 mm, the room temperature tensile strength of the bar is up to above 465 MPa, the yield strength of the bar is up to above 350 MPa, the elongation of the bar is above 47%, and the grain structure of the bar is fine and uniform.

Owner:西安诺博尔稀贵金属材料股份有限公司

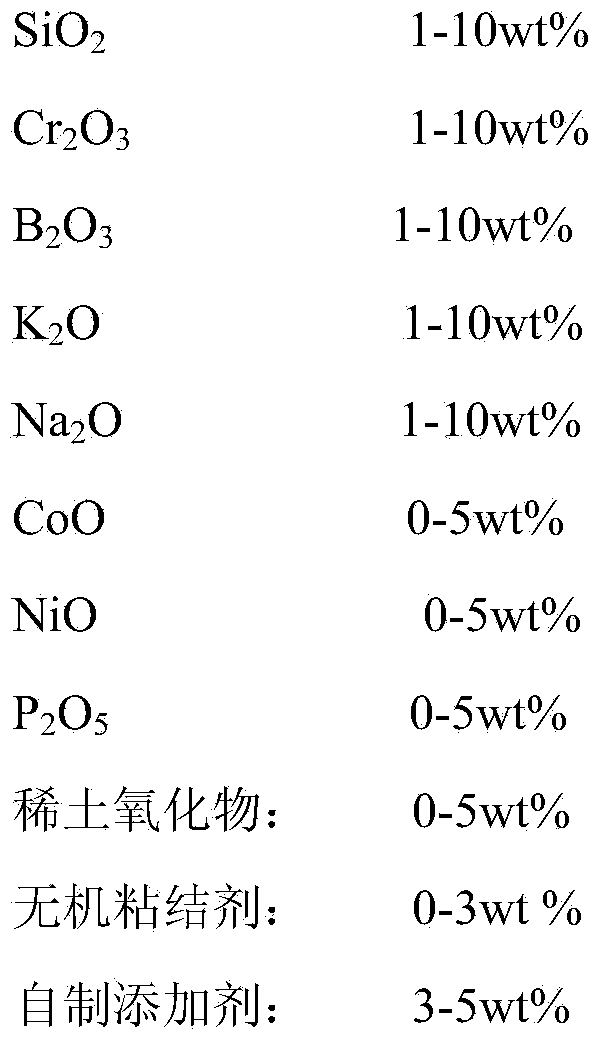

Water-based protective coating capable of adhering to high temperature billet and preparation method thereof

ActiveCN104109406AReduce heat dissipationReduce oxidation lossChemical industryCoatingsSteel qualityPromotion effect

The invention relates to a water-based protective coating capable of adhering to a high temperature billet and a preparation method thereof, and belongs to the field of metal high-temperature protection. The water-based protective coating comprises main powder, 0-3wt% of an inorganic binder and 3-5wt% of a self-made additive. The main powder is prepared from natural raw materials such as clay, magnesite, diatomite, magnetite and metallurgy tailings. The self-made additive is a sol system comprising a surfactant and a Zn-containing component. The powder is subjected to ball milling so that particle sizes are less than 300 meshes, density of the slurry is adjusted to 1.2-1.5g / cm<3> and density is decreased with spray-coating temperature increasing. The water-based protective coating is suitable for spray-coating a billet having a temperature less than 1200 DEG C and heated in a heating furnace for 1-10h. The preparation method can realize adjustment and control of billet trace element distribution, does not change billet surface physicochemical characteristics and reduces a burning loss by more than 60%. The preparation method has active promotion effects of saving energy and reducing consumption in the metallurgy industry, improving steel quality and improving core competitiveness of a steel enterprise.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for drying Hami melon slices by nitrogen source low oxygen heat pump

InactiveCN103416475AExtended storage timeLess nutrient lossFood processingFruits/vegetable preservation by heatingQuinoneVitamin C

The invention belongs to the field of agricultural product drying, and particularly relates to a method for drying Hami melon slices by a nitrogen source low oxygen heat pump. The method comprises the steps of selecting Hami melons, removing peels and pulp of the Hami melons, conducting slicing, conducting color protection and type fixing, blanching, draining, conducting drying in a nitrogen source heat pump drying machine, and conducting drying, sealing and storing in a vacuum drying box. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, the defects that in the drying later stage, the heat pump is low in drying efficiency and long in time required by drying are overcome, heat pump drying and vacuum low-temperature drying are carried out after color protection and blanching treatment, and therefore the problems that the brightness of the Hami melon slices is reduced, and the color is changed are solved. According to the method, phenolic substances in the Hami melon slices can be restrained from being oxidized to generate quinone, the oxidation loss of vitamin C is reduced, damage, caused by oxidation in the drying process, to the color and texture of the Hami melon slices can be avoided, and dried products with the natural color are obtained.

Owner:HENAN UNIV OF SCI & TECH

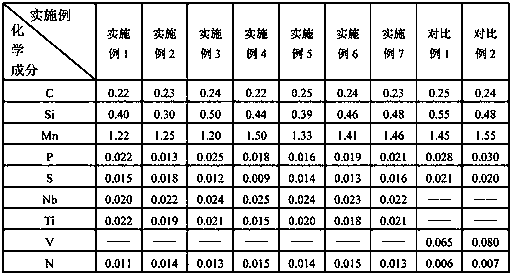

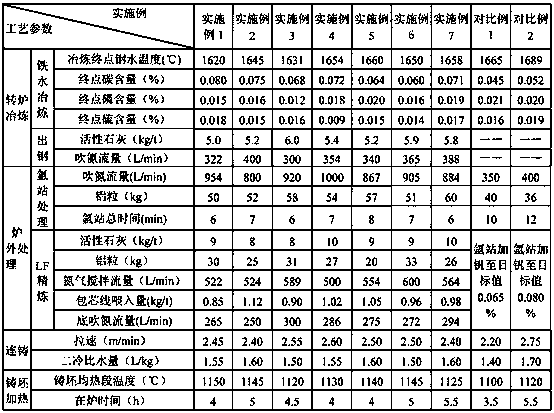

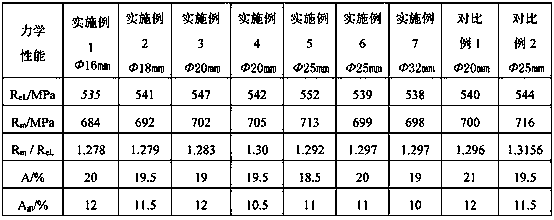

Niobium titanium microalloyed HRB500E screw-thread steel and preparation method thereof

The invention discloses a niobium titanium microalloyed HRB500E screw-thread steel and a preparation method thereof. The HRB500E screw-thread steel comprises the following chemical components of, in percentage by mass, 0.22% to 0.25% of C, 0.30% to 0.50% of Si, 1.2% to 1.5% of Mn, 0.020% to 0.025% of Nb, 0.015% to 0.022% of Ti, 0.011%-0.015% of N, less than or equal to 0.025% of P, less than or equal to 0.018% of S, and the balance Fe and inevitable impurities. The screw-thread steel is prepared through the metallurgy process of 150t combined blown converter smelting-LF refining-7 machine 7 strand billet continuous casting; and through the optimization of an alloy system, Nb + Ti composite microalloying replaces V microalloying, the alloying cost is obviously reduced, the metallurgy process is controllable, and the low-cost stable batch production of HRB500E is realized.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

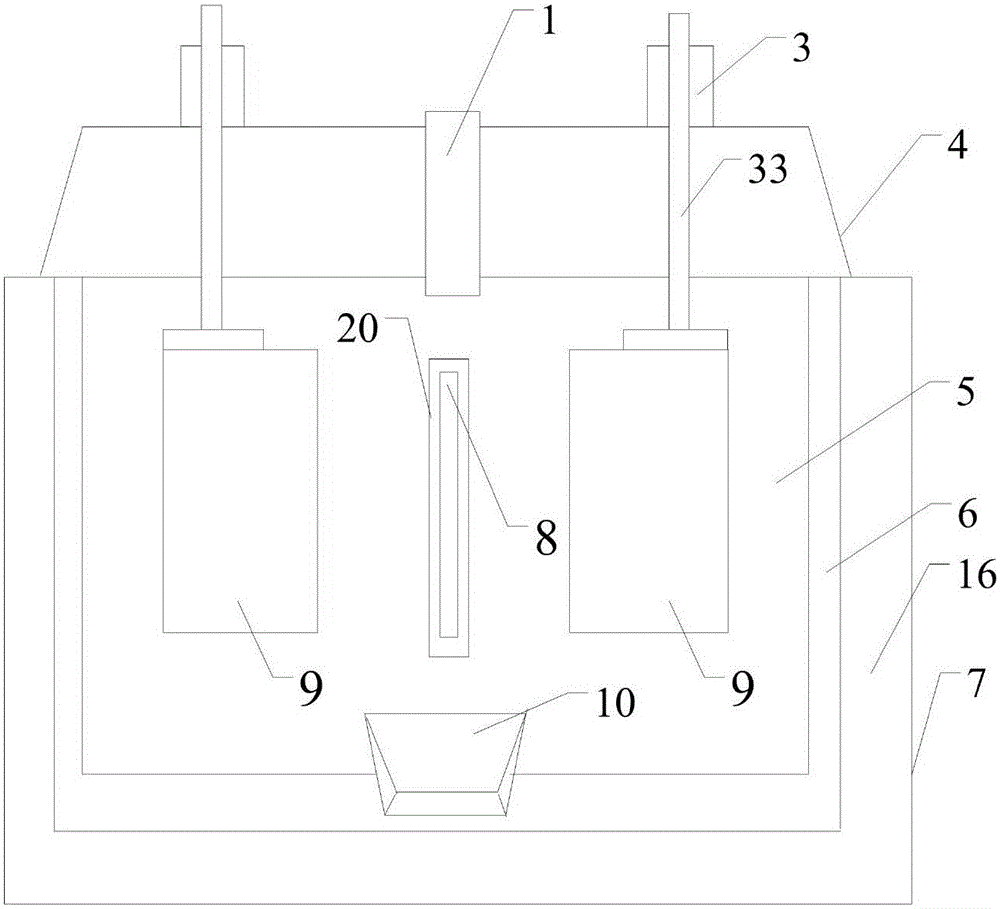

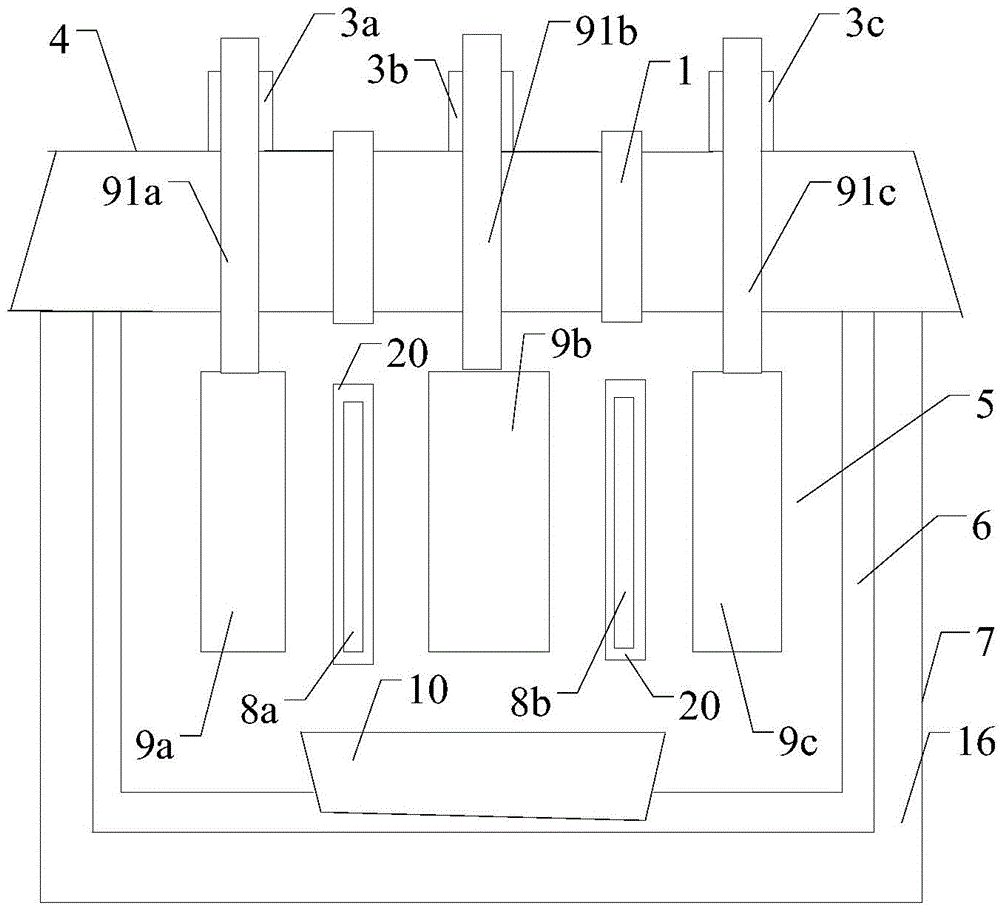

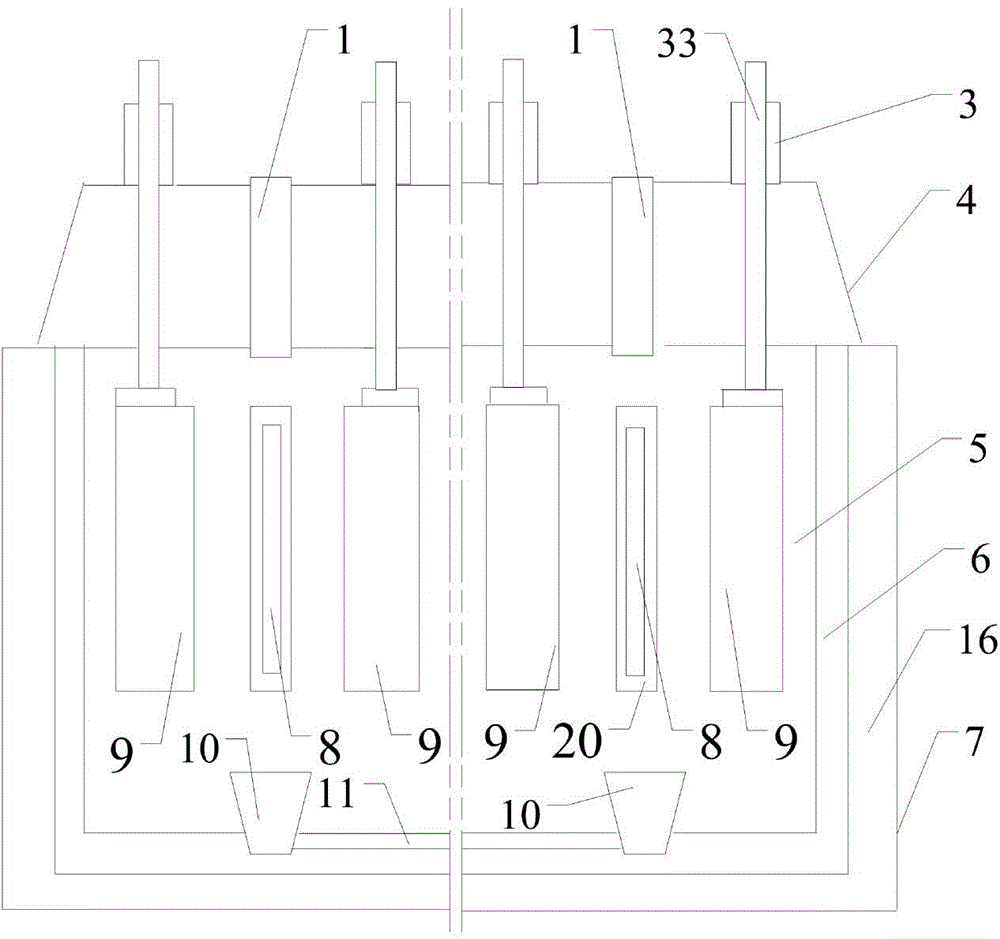

Electrolytic furnace

ActiveCN105088284AExtended service lifeReduce oxidation lossCellsElectrical resistance and conductanceSlag

The invention relates to an electrolytic furnace and belongs to the technical field of rare-earth metallurgical equipment and application of the rare-earth metallurgical equipment. The electrolytic furnace comprises an adjusting component (3), a sealing cover (4), a negative electrode (8), a positive electrode (9) and an impermeable insulating component (20). The negative electrode (8) and the positive electrode (9) are vertically distributed in parallel, and the positive electrode (9) can move to adjust the distance between the negative electrode and the position electrode. The electrolytic furnace has the beneficial effects that reaction gas is prone to escaping and easy to collect, products are easy to collect, slag generated in reaction is easy to clean, a product taking out component is easy to install, and the products are easy to take out; the service life of the negative electrode is long; a plurality of negative electrode and positive electrode sets can be arranged in the same electrolytic furnace to bring convenience to achieving large-scale and automatic production; energy is further saved, and clean production is achieved; and the negative electrode can be cooled by a cooling device to enhance the effect of preventing electrolyte from leaking, slow down oxidation loss of the negative electrode and reduce the resistance of the negative electrode.

Owner:QIANDONG RARE EARTH GRP

Method for preparing coix seed polysaccharide beverage

The invention relates to a method for preparing a coix seed polysaccharide beverage. The method comprises the steps of: crushing coix seeds and sieving to obtain coix seed powders; adding the coix seed powders to the distilled water and leaching to obtain a leaching solution; and centrifuging the leaching solution, taking out a supernatant, cooling, conducting enzymolysis, mixing, homogenizing, degassing, encapsulating and sterilizing to obtain functional beverage containing the coix seed polysaccharide. According to the preparation method, a water extraction is adopted to extract the coix seed polysaccharide, simultaneously starch is removed by enzymolysis and then mixing, homogenizing, degassing, encapsulating and sterilizing are conducted to obtain the functional beverage containing the coix seed polysaccharide, feed liquor can be mixed uniformly, thereby avoiding layering and precipitating, making the mouth feel tender and reducing the oxidation loss of the ingredients such as vitamins, aromas and pigments, etc. And meanwhile, under the condition that the intrinsic flavor of the coix seed is kept, the intrinsic bad odor and oil odor of the coix seed are covered.

Owner:TIANJIN UNIV OF SCI & TECH

Inorganic composite binders with high-temperature resistance

InactiveUS20120174828A1Improve relationshipNo corrosivity to the substrateFireproof paintsAntifouling/underwater paintsAluminium hydroxidePhosphate

In certain examples, this invention provides an inorganic composite binder with high-temperature resistance comprising 5-12% of aluminium hydroxide, 15-35% of phosphoric acid, 0.1-1% of rare earth oxide, 5-20% of silica sol, 1-15% of polyaluminium phosphate, 1-5% of borax, based on the total weight of said binder, and the rest being water, and a method for producing the same. The binder of the example can be used in temporary protective coating layer such as the high temperature coating and the high temperature antioxidation coating layer during the heat treatment of the metal workpiece, can make it possible to form an antioxidation coating layer immediately upon directly spraying the coating onto the substrate surface of the metal at high temperature of 400-1000° C., and can continuously keep its good bonding property under the high temperature environment in the heating furnace, thereby it is helpful to reduce the oxidation loss of the metal material in the heat treatment, and improve the surface quality of the metal material; also, the binder of the invention is usable in patching material for high temperature kiln or refractory material to enhance the material strength and lengthen its service life.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

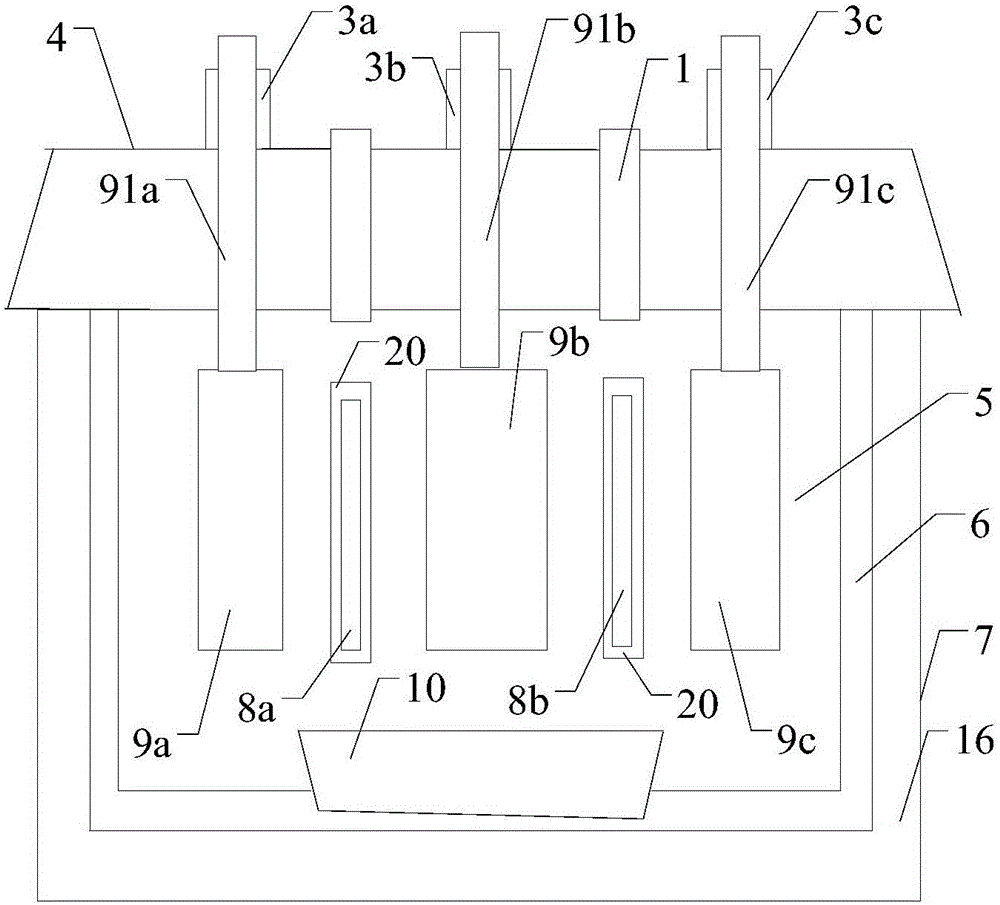

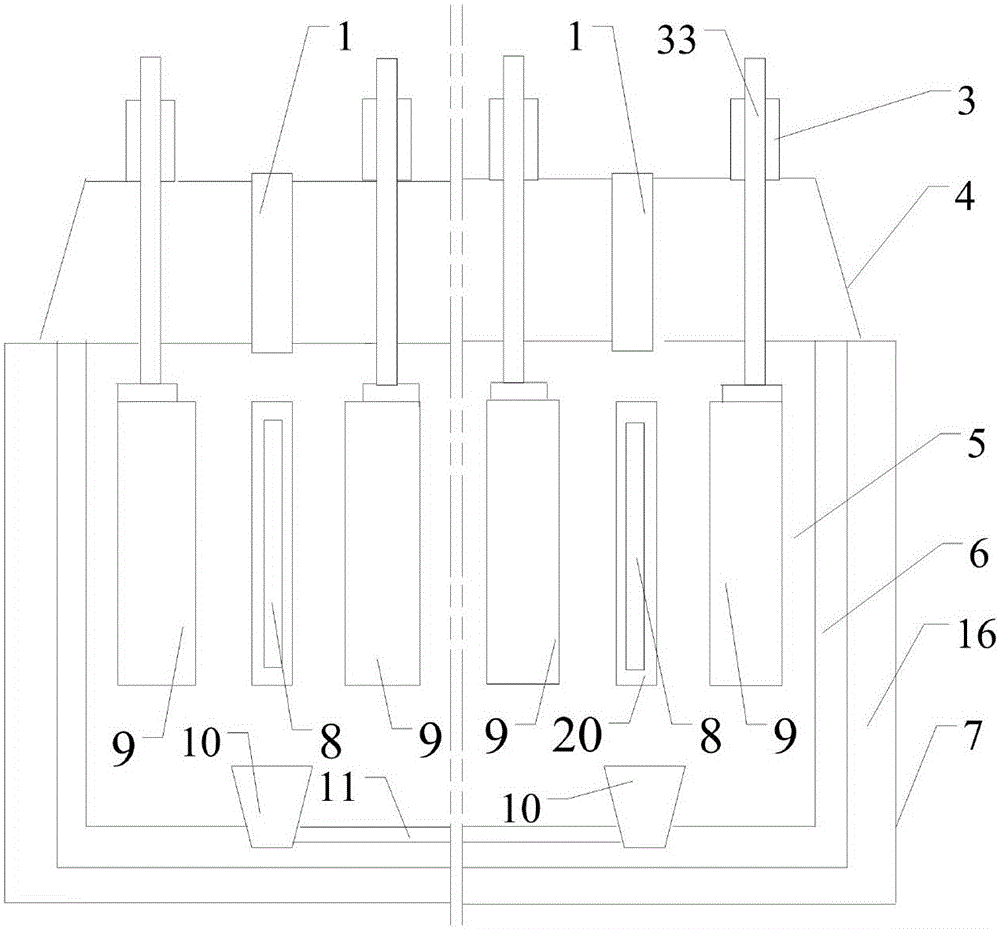

Electrolytic furnace group

An electrolytic furnace group and electrolytic method thereof belong to the field of rare earth metallurgical electrolysis equipment and use technologies thereof. The electrolytic furnace group includes a shared power supply (12) and at least two electrolytic furnaces. Each electrolytic furnace includes a cathode (8) and an anode (9), wherein the shared power supply (12) is connected to each electrolytic furnace in a manner that the positive pole of the shared power supply (12) is connected to the anode of a first electrolytic furnace, and then the anode of each electrolytic furnace is connected to the cathode of the one before the electrolytic furnace, and the cathode of the last one electrolytic furnace is connected to a negative pole of the shared power supply (12). In the shared power supply (12), a circuit for supplying power to the electrolytic furnaces is a main circuit. Each electrolytic furnace also includes an adjustment part (3) for controlling the anode (9) to move. The electrolytic furnace group is sensitive in control, is convenient to use, is high in energy utilization rate, is low in electricity consumption, and allows gas generated in electrolysis to be easy to escape. In the electrolytic furnace group, electricity unit consumption of a product is reduced while the number of operated electrolytic furnaces in the group is increased.

Owner:QIANDONG RARE EARTH GRP

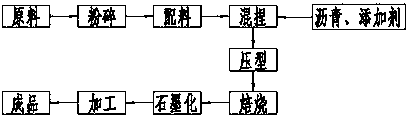

Cross-connection electrode for internal thermal serial graphitization furnace and production method thereof

InactiveCN108276000AIncrease the conductive areaImprove flexural strengthElectric discharge heatingCross connectionStearic acid

The invention provides a cross-connection electrode for an internal thermal serial graphitization furnace and a production method thereof. The cross-connection electrode is prepared from a dry material composed of large-grained petroleum based needle coke, medium-grained petroleum based needle coke and small-grained powder, a binding agent, additives, green ground components and roasted ground components through crushing, screening, mixing, kneading, shaping, roasting, dipping, graphitizing, processing and assembling, wherein the formula is as follows: the percentage of the large-grained petroleum based needle coke is 30-40%, the percentage of medium-grained petroleum based needle coke is 20-30%, the percentage of small-grained powder is 35-45%, the content of the binding agent is 25-30% of the total weight of the dry material, the content of the additive stearic acid is 0.5-0.8% of the total weight of the dry material, the content of the additive Fe2O3 is 0-1% of the total weight of the dry material, the content of the green ground components is 10-20% of the total weight of the dry material and the content of the roasted ground components is 0-10% of the total weight of the dry material; the binding agent is modified asphalt, and the grain size of the large-grained petroleum based needle coke is 15-25mm, the grain size of the medium-grained petroleum based needle coke is 5-15mm and the small-grained powder is 200-mesh powder.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

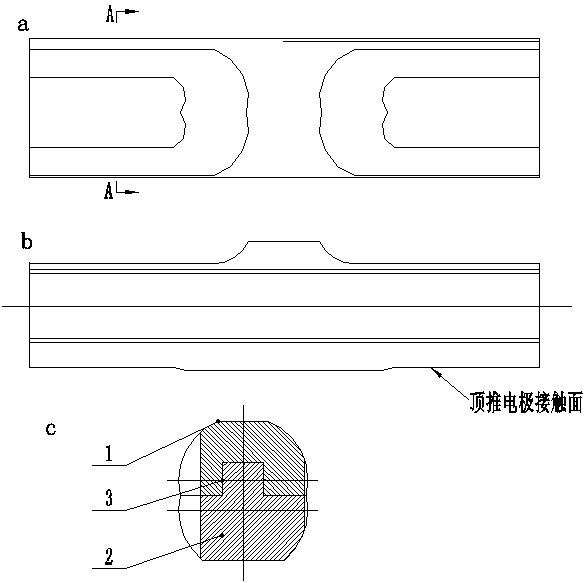

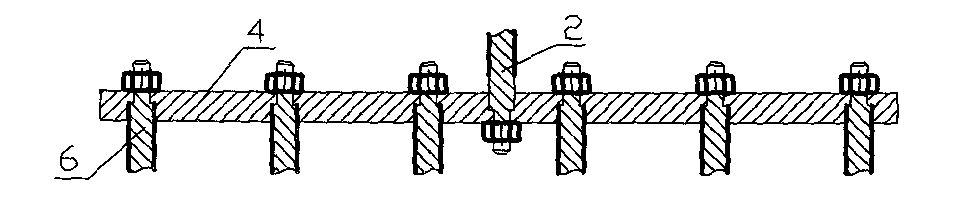

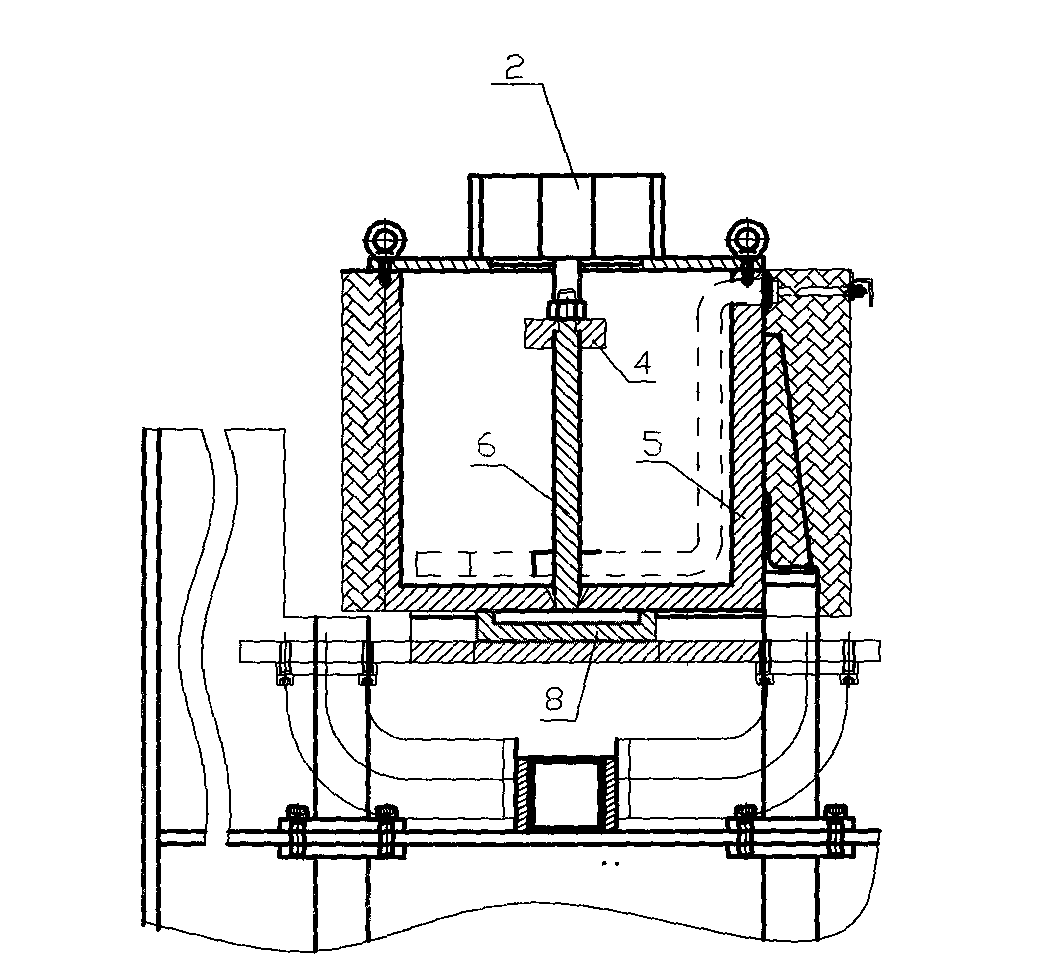

Method and special device for performing fusion welding on electrode lead plate of energy-saving environment-friendly type lead-acid battery

InactiveCN102581264AAvoid dripping accidentsReduce oxidation lossManufacturing technologyEngineering

The invention provides a method and a special device for performing fusion welding on an electrode lead plate of an energy-saving environment-friendly type lead-acid battery, relating to the manufacturing technology of lead-acid batteries. The method provided by the invention comprises the following steps: (1) heating and melting solid lead for being infused into a lead storage tank or a lead injection tank to melt the lead, and preheating a melting template; (2) shifting the melting template to tightly cling to the lead storage tank, driving plunger rods to raise through the action of a cylinder on the lead storage tank or the lead injection tank, infusing liquid lead into a rectangular groove of the melting template, and closing taper holes through the plunger rods; (3) shifting the melting template to a station for fusion welding, pushing a tooling box to lead the lower surface of the tooling box to stick on the upper surface of the melting template, and inserting a small rectangular relief block in the liquid lead inside the rectangular groove of the melting template for 2-10seconds; (4) cooling the melting template; and (5) separating a box body of the tooling box from the melting template and then taking out a product. The device provided by the invention consists of a lead melting furnace, the lead storage tank or the lead injection tank; an electric heating induction coil is fixed on the lead melting furnace; the lead storage tank is provided with an electric heating pipe, the taper holes, a cylinder piston rod and a linkage plate; and a liquid inlet pipe arranged on the side wall of the upper part of the lead storage tank is communicated with a liquid outlet pipe of the lead melting furnace. The method and the special device provided by the invention have the advantage that: little liquid lead is used so as to meet the energy-saving requirement during the process of lead injection.

Owner:FUAN GUANGYUAN ELECTROMECHANICAL

Anti-oxidation device and method for calcining and preparing new material

InactiveCN104069776APrevent material oxidationGuaranteed to proceed normallyHeat treatmentsCompound (substance)Crucible

The invention discloses an anti-oxidation device and method for calcining and preparing a new material, and belongs to the field of metallurgical chemical engineering equipment. The anti-oxidation device comprises a small crucible (6) with a small crucible cover (5) and a big crucible (1), wherein a to-be-calcined material (7) is held in the small crucible (6); the small crucible (6) is arranged inside the big crucible (1); the lower part of the big crucible (1) is filled with high temperature oxytropic powder (4) capable of completely embedding the small crucible (6); the upper part of the big crucible (1) is filled with a sealing layer used for sealing the big crucible (1). Through the simple and effective combination of the inner system and the outer system, the device not only prevents material oxidation, but also ensures normal conducting of the calcination chemical reaction, is convenient to operate, time-saving, safe and low in cost, and is extremely suitable for common teaching and experiment, as well as small and medium size industrial manufacture users who use the device infrequently or discontinuously.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of vitamin C hydrogen-enriched water and vitamin C hydrogen-enriched water prepared according to method

InactiveCN105776490AReductiveIncrease productivityWater/sewage treatment by substance additionVitamin CMetal

The invention discloses a preparation method of vitamin C hydrogen-enriched water. The preparation method comprises the following step: (a), adding magnesium and vitamin C into water, or adding the magnesium into water rich in vitamin C. The invention further discloses the corresponding vitamin C hydrogen-enriched water which includes magnesium ascorbate, vitamin C and hydrogen. The vitamin C hydrogen-enriched water and the preparation method thereof disclosed by the invention have the beneficial effects that the vitamin C presents weak acid in the water, and the vitamin C and magnesium metal are easily subjected to a reaction to generate hydrogen, so that the production efficiency is high, and the cost is low; besides, the vitamin C and the magnesium ascorbate as a product have certain reducibility, and the vitamin C, the magnesium ascorbate and the hydrogen dissolved in a solution have the synergistic reaction, so that the oxidation losses of dissolved hydrogen in a storage and transportation process are reduced, besides, micro magnesium elements can be complemented for human bodies, and the vitamin C hydrogen-enriched water is good to health.

Owner:翟海峰 +1

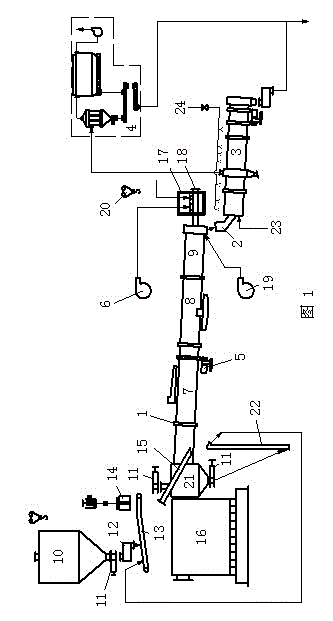

Method and device for calcinating needle coke with rotary kiln

InactiveCN102745664AReduce brittlenessAvoid severe thermal shockChemical industryCarbon preparation/purificationThermodynamicsElectric machine

The invention discloses a method and device for calcinating needle coke with a rotary kiln. The method makes use of a rotary kiln to calcinate needle coke, so that a violent thermal shock generated during green coke's entrance into existing rotary hearth calciners can be avoided, and the calcinated coke has greatly reduced brittleness, thus enhancing the content of coarse particles in modern large-specification electrode production. The device comprises a rotary kiln (1), the feed inlet of which is provided with a feeding device and an ash settling chamber. The discharge port of the rotary kiln is in connection with the feed inlet of a cooling machine (3) adopting dual cooling through an electric elephant trunk (2). The cooling machine is connected to a waste gas treatment system (4). The rotary kiln is driven to rotate by a variable frequency motor (5). The discharge port of the rotary kiln is provided with a double-frequency conversion blower (6). By employing the method and the device of the invention, the quality of calcinated coke can be improved, the investment can be reduced, the running rate can be high, automatic control is easy to realize, and the labor intensity of workers can be lowered.

Owner:GUIYANG AL-MG DESIGN & RES INST

Extraction method of phyllanthus emblica polyphenol

InactiveCN103768130AReduce oxidation lossPromote dissolutionPlant ingredientsChromatographic columnChemistry

The invention discloses an extraction method of phyllanthus emblica polyphenol. The extraction method comprises the following steps: removing stalks of obtained phyllanthus emblica fresh fruit, cleaning with deionized water, draining water, removing kernels, adding the phyllanthus emblica fresh fruit to a precooling acetone solution, pounding, homogenizing, carrying out magnetic force oscillation, centrifuging, taking supernatant, repeating the steps so as to extract precipitates for two to three times, combining supernatant, and recycling acetone, thus obtaining a total extracting solution; filtering the total extracting solution by using a pretreated hollow fibrous membrane; purifying a hollow fibrous membrane filtering medium by using a polyamide chromatographic column, collecting eluant, recycling alcohol, concentrating, and carrying out freeze drying, thus obtaining the phyllanthus emblica polyphenol. Compared with a conventional heat extraction method, the extraction method disclosed by the invention has the advantages that the extraction temperature is low, a technology is simple and easy to operate, the extraction effect is good, the extraction rate of the phyllanthus emblica polyphenol reaches above 95%, and the purity of the phyllanthus emblica polyphenol finished product reaches above 99%.

Owner:HEFEI KANGLING HEALTH TECH

Method for smelting base material of low phosphorous stainless steel by using low-grade limonite containing nickel-chromium

ActiveCN100532579CRich sourcesLow priceBlast furnace detailsManufacturing convertersHearthHigh pressure

Owner:前海索新发展科技(深圳)有限公司

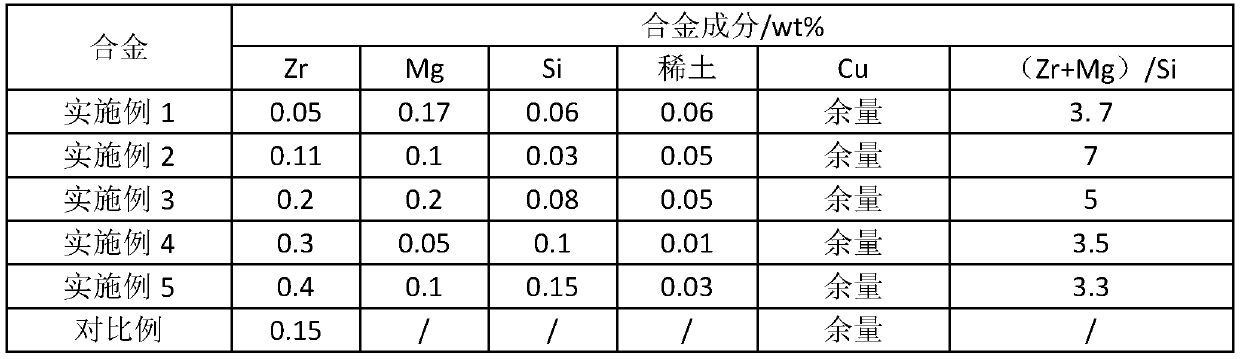

Copper-zirconium alloy for electronic component and preparation method of copper-zirconium alloy

The invention discloses a copper-zirconium alloy for an electronic component and a preparation method of the copper-zirconium alloy. The copper-zirconium alloy comprises the following alloy componentsincluding, by weight, 0.05%-0.4% of Zr, 0.05%-0.2% of Mg, 0.03%-0.15% of Si, 0.01%-0.06% of rare earth and the balance Cu and inevitable impurity elements. The invention further discloses the preparation method of the alloy. The preparation method comprises the steps of melting, alloying, casting, hot rolling, rough rolling, aging, finish rolling, stress relief annealing and finished product treatment. The copper-zirconium alloy has high strength, high conductivity and excellent bending processability under the influence of the comprehensive action of the added Mg, Si and rare earth elements,the preparation method of the alloy easily achieves engineering production and is low in cost, the tensile strength of a finished strip is not less than 560 MPa, the conductivity is not less than 80%IACS, and the product can be used for a tremendous-scale integrated circuit, a large-current electronic element and a heat dissipation component.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com