Method and device for calcinating needle coke with rotary kiln

A rotary kiln and needle coke technology, which is applied in carbon preparation/purification, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of low content of coarse particles, affecting the quality of large-sized electrodes, etc., and improve the content of coarse particles. , the effect of strengthening the calcination effect and improving the actual yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the drawings and embodiments.

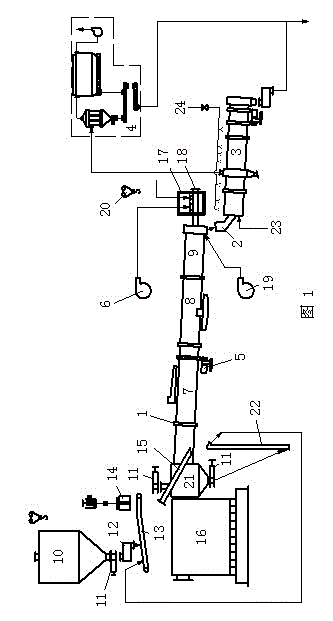

[0020] Example of the present invention: The principle of the method for calcining needle coke in a rotary kiln of the present invention is as follows figure 1 As shown, the method uses a rotary kiln to calcinate needle coke, which can avoid the severe thermal shock that occurs when the green coke enters the existing rotary bed calciner, and greatly reduces the brittleness of the calcined coke, thereby enabling modern large-scale The content of coarse particles in electrode production has increased. The rotary kiln is provided with a preheating section, a drying section and a combustion section in sequence from the feed port to the discharge port; it is beneficial to increase the calcination temperature and easier to control the heating rate of the materials in the kiln. The feed inlet of the rotary kiln adopts a variable diameter structure, which reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com