Protective coating for heat treatment of metals

A technology for metal heat treatment and protective coatings, applied in anti-corrosion coatings, polyester coatings, coatings, etc., to achieve the effects of good temperature resistance, reduced oxidation loss, and convenient use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

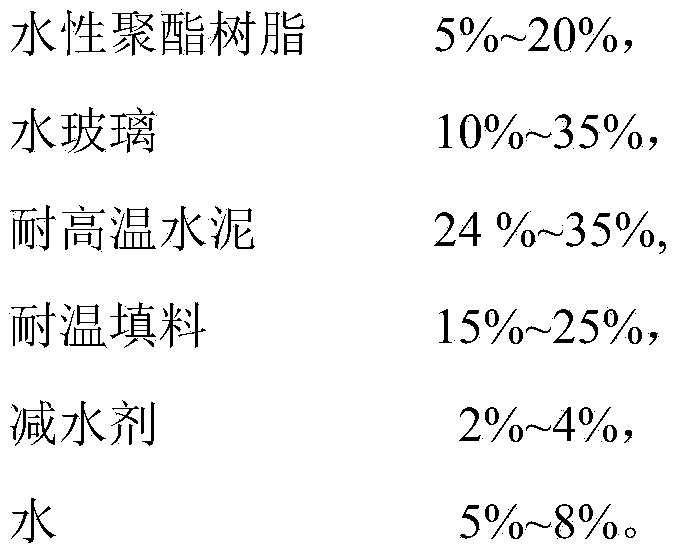

Embodiment 1

[0022] 1. Content formula according to mass percentage

[0023]

[0024] 2. Preparation method

[0025] The coating of the present invention is obtained by mixing the water-based polyester resin, water glass, high-temperature resistant cement, temperature-resistant filler and water reducer evenly, and then packaging.

[0026] 3. Performance indicators

[0027] After testing, the coating has no scale or corrosion after 12 hours at 800°C, the coating automatically falls off after metal heat treatment, the coating has no cracking bubbles, and the coating adhesion is 0.7MPa.

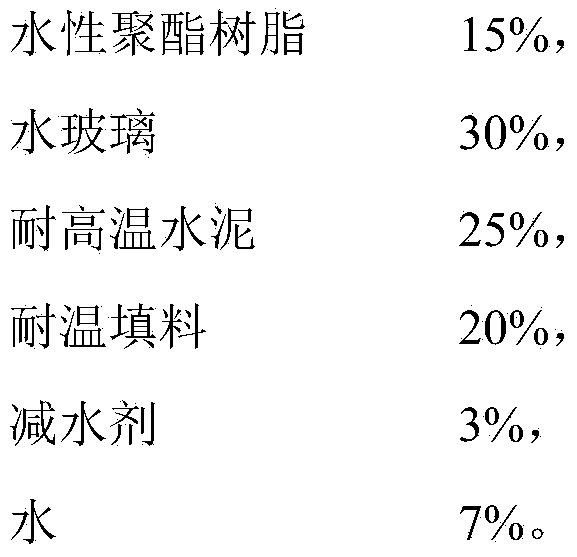

Embodiment 2

[0029] 1. Content formula according to mass percentage

[0030]

[0031] Two, preparation method is the same as embodiment 1.

[0032] 3. Performance indicators

[0033] After testing, the coating has no scale or corrosion after 12 hours at 860°C, the coating automatically falls off after metal heat treatment, the coating has no cracking bubbles, and the coating adhesion is 0.5MPa.

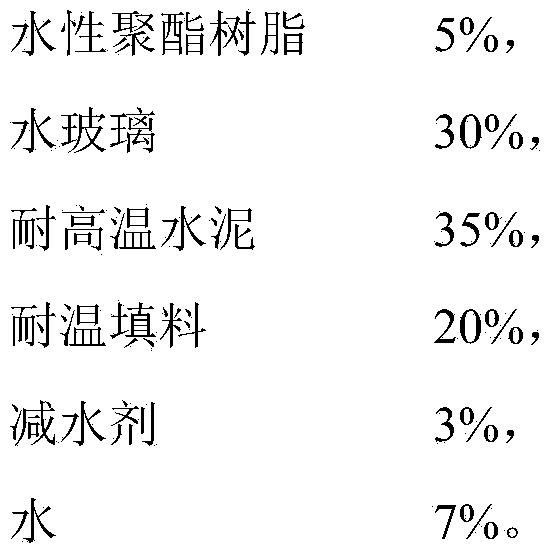

Embodiment 3

[0035] 1. Content formula according to mass percentage

[0036]

[0037] Two, preparation method is the same as embodiment 1.

[0038] 3. Performance indicators

[0039] After testing, the coating has no scale or corrosion after 12 hours at 900°C, the coating automatically falls off after metal heat treatment, the coating has no cracking bubbles, and the coating adhesion is 0.78MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com