Cross-connection electrode for internal thermal serial graphitization furnace and production method thereof

A graphitization furnace and internal heat series connection technology, applied in electrical components, electric heating devices, heating by discharge, etc., can solve the problems of high cost of the jumper electrode, damage to the jumper electrode, unsatisfactory effect, etc., and achieve the flexural strength. The effect of improving, reducing resistivity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

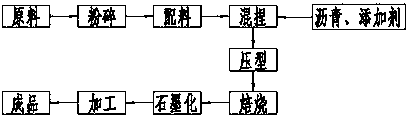

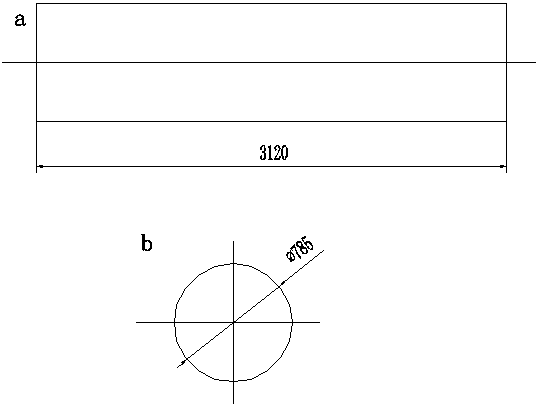

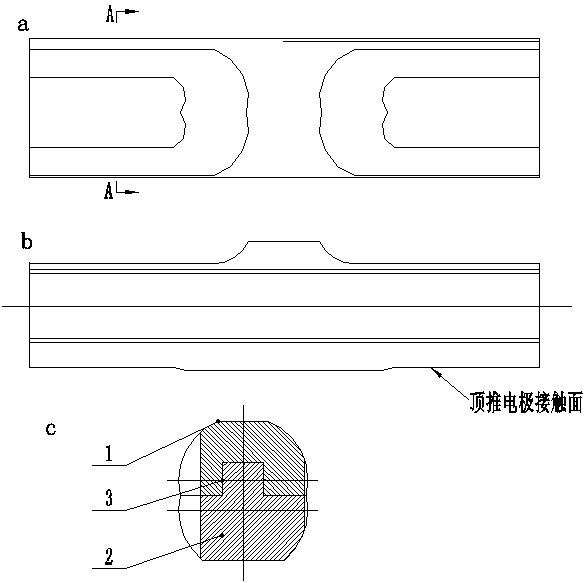

[0031] A jumper electrode for an internal thermal series graphitization furnace, including dry material composed of large-sized oil-based needle coke, medium-sized oil-based needle coke, and small-sized powder, as well as binders, additives, raw crushed and roasted crushed Components are made through crushing and screening, batching, kneading, molding, roasting, impregnating, graphitization, processing and assembling processes. 25% of needle coke, 40% of small particle size powder, binder accounts for 25% of the total weight of the dry material, stearic acid in the additive accounts for 0.5% of the total weight of the dry material, Fe in the additive 2 o 3 Powder accounts for 1% of the total weight of the dry material, raw crushed material accounts for 20% of the total weight of the dry material, and roasted crushed material accounts for 10% of the dry material; the binder is medium-temperature modified asphalt; the large-grained oil-based needle The particle size of the sha...

Embodiment 2

[0046] A jumper electrode for an internal thermal series graphitization furnace, including dry material composed of large-sized oil-based needle coke, medium-sized oil-based needle coke, and small-sized powder, as well as binders, additives, raw crushed and roasted crushed Components are made through crushing and screening, batching, kneading, molding, roasting, impregnating, graphitization, processing and assembling processes. Needle coke 25%, small particle size powder 40%, binder accounts for 30% of the total weight of the dry material, stearic acid in the additive accounts for 0.8% of the total weight of the dry material, Fe in the additive 2 o 3 Powder accounts for 0.5% of the total weight of the dry material, raw crushed material accounts for 10% of the total weight of the dry material, and roasted crushed material accounts for 5% of the dry material; the binder is medium-temperature modified asphalt; the large-grained oil-based needle The particle size of the shape co...

Embodiment 3

[0049] A jumper electrode for an internal thermal series graphitization furnace, including dry material composed of large-sized oil-based needle coke, medium-sized oil-based needle coke, and small-sized powder, as well as binders, additives, raw crushed and roasted crushed Components are made through crushing and screening, batching, kneading, molding, roasting, impregnating, graphitization, processing and assembling processes. Needle coke 25%, small particle size powder 40%, binder accounts for 28% of the total weight of the dry material, stearic acid in the additive accounts for 0.6% of the total weight of the dry material, raw powder accounts for 15% of the total weight of the dry material %; the binder is medium-temperature modified asphalt; the particle size of the large-size oil-based needle coke is 15-25mm, the particle size of the medium-size oil-based needle coke is 5-15mm, and the small-size powder is 200 Eye powder.

[0050] Concrete production process is with embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com