Beneficiation method for low-grade mixed copper ore containing molybdenum

A beneficiation method and copper ore technology, applied in the beneficiation field of molybdenum-containing low-grade mixed copper ore, can solve problems such as tailings pipeline and bubble generator blockage, and achieve improved concentrate grade, recovery rate, and chemical dosage The effect of reducing and stabilizing the foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

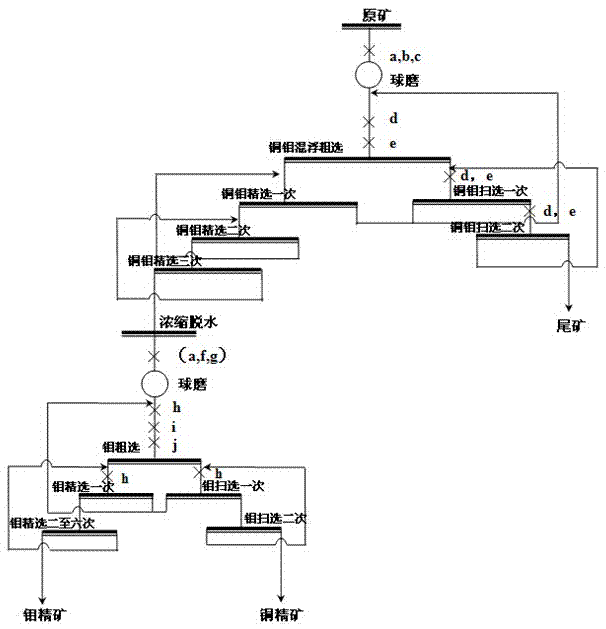

Image

Examples

Embodiment 1

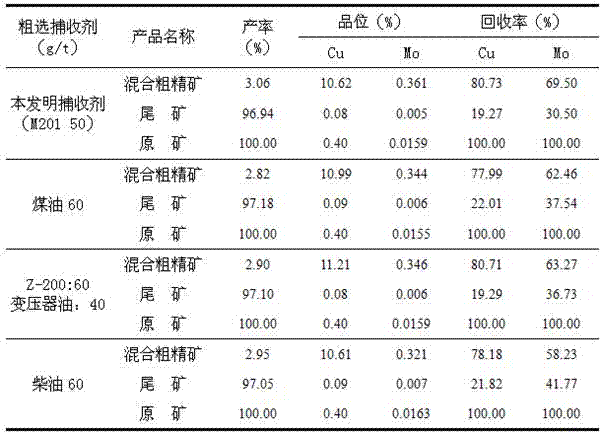

[0028] A low-grade copper-molybdenum ore in Nimu County, Tibet, which contains 0.40% Cu, 0.016% Mo, and 15.00% copper oxide. It is a typical low-grade mixed copper ore containing molybdenum.

[0029] Raw ore grinding: After crushing, the raw ore and water are added to the ball mill in a ratio of 1:1 for grinding, and lime (a) 300g / t, sodium sulfide (b) 300g / t, Ammonium sulfate (c) 200g / t (based on the dry weight of the original ore, the same below), the grinding fineness of the grinding product is -74μm accounting for 70%; copper-molybdenum mixed floatation roughing: the pH value of the slurry is 9 Under the conditions of, add 100g / t of collector butyl xanthate (d) and 50g / t of collector foaming agent M201(e) for copper-molybdenum mixed roughing, and the obtained copper-molybdenum mixed crude concentrate enters copper-molybdenum In the beneficiation operation, the rough dressing tailings enter the copper-molybdenum sweeping operation; the copper-molybdenum mixed flotation sweeps ...

Embodiment 2

[0042] A low-grade copper-molybdenum ore in Inner Mongolia contains 0.425% Cu, 0.022% Mo, and 10.21% copper oxide. The copper phase analysis shows that the copper in the ore mainly exists in the form of copper sulfide, and some copper exists in the form of oxides. The ore is a low-grade mixed copper ore. The phase analysis of molybdenum showed that the molybdenum in the ore mainly exists in the form of molybdenum sulfide.

[0043] Raw ore grinding: The crushed raw ore and water are added to the ball mill at a ratio of 1:1 for grinding, and lime (a) 150g / t, sodium sulfide (b) 200g / t, Ammonium sulfate (c) 100g / t, the grinding fineness of the grinding product is -74μm, accounting for 70%; copper-molybdenum mixed flotation roughing operation: under the condition that the pH value of the slurry is 8-9, add the collector D The amount of base xanthate (d) is 60g / t and the amount of collecting foaming agent M201(e) is 30g / t for copper-molybdenum mixed roughing. The obtained copper-molyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com