Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

A beneficiation method and multi-metal technology, applied in flotation, solid separation and other directions, can solve the problems of high copper, lead and zinc mutual content, toxic chemicals, poor product quality, etc. Solve the effect of activation selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

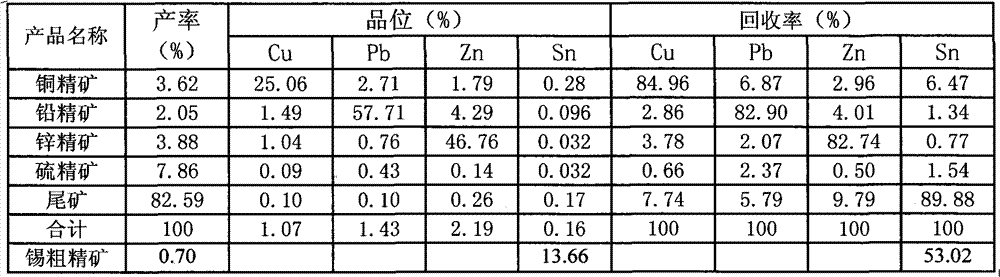

Embodiment 1

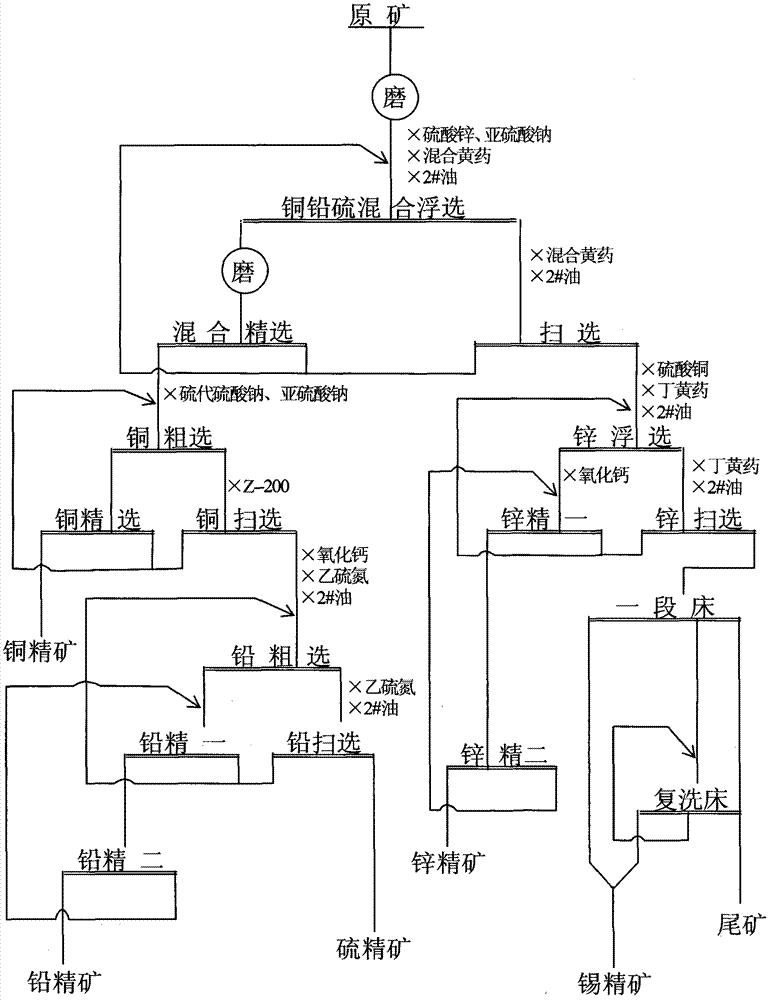

[0022] The combined beneficiation method of copper-lead-zinc-tin polymetallic sulfide ore consists of primary grinding of raw ore, mixed flotation of copper, lead and sulfur, secondary grinding and selection, separation of copper, lead and sulfur, lead flotation, and zinc flotation; In the mixed flotation, the beneficiation agent ethylene butyl mixed with xanthate is used as the collector of copper and lead minerals, and zinc sulfate and sodium sulfite are used as the inhibitor of zinc minerals; in the separation of copper, lead and sulfur, sodium sulfite and sodium thiosulfate are used as the lead and sulfur Mineral inhibitor, Z-200 is used as a collector for copper mineral sweeping. Calculated on the basis of 1 ton of raw ore, the first-stage grinding -200 mesh accounts for 70%, and the second-stage grinding -400 mesh accounts for 65%. The dosage is 40g, the dosage of zinc sulfate is 700g, and the dosage of sodium sulfite is 400g; the dosage of sodium sulfite in copper-lead-...

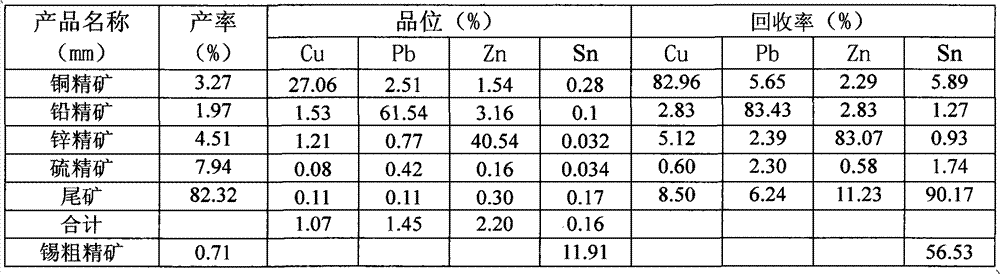

Embodiment 2

[0025] The combined beneficiation method of copper-lead-zinc-tin polymetallic sulfide ore consists of primary grinding of raw ore, mixed flotation of copper, lead and sulfur, secondary grinding and selection, separation of copper, lead and sulfur, lead flotation, and zinc flotation; In the mixed flotation, the beneficiation agent ethylene butyl mixed with xanthate is used as the collector of copper and lead minerals, and zinc sulfate and sodium sulfite are used as the inhibitor of zinc minerals; in the separation of copper, lead and sulfur, sodium sulfite and sodium thiosulfate are used as the lead and sulfur Mineral inhibitor, Z-200 is used as a collector for copper mineral sweeping. Calculated on the basis of 1 ton of raw ore, the first-stage grinding -200 mesh accounts for 65%, and the second-stage grinding -400 mesh accounts for 65%. The dosage is 40g, the dosage of zinc sulfate is 500g, and the dosage of sodium sulfite is 300g; the dosage of sodium sulfite in copper-lead-...

Embodiment 3

[0028] The combined beneficiation method of copper-lead-zinc-tin polymetallic sulfide ore is composed of primary grinding of raw ore, copper-lead-sulfur mixed flotation, secondary grinding and selection, copper-lead-sulfur separation, lead flotation, and zinc flotation; In the sulfur mixed flotation, the beneficiation agent ethyl butyl mixed with xanthate is used as the collector of copper and lead minerals, and zinc sulfate and sodium sulfite are used as inhibitors of zinc minerals; in the separation of copper, lead and sulfur, sodium sulfite and sodium thiosulfate are used as lead, Inhibitor of sulfur minerals, Z-200 is used as a collector for copper mineral sweeping. Calculated on the basis of 1 ton of raw ore, the first-stage grinding -200 mesh accounts for 75%, and the second-stage grinding is -400 mesh, accounting for 75%. The dosage is 30g, the dosage of zinc sulfate is 1000g, and the dosage of sodium sulfite is 700g; the dosage of sodium sulfite in copper-lead-sulfur s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com