Method for flotation and separation of copper molybdenum sulphide bulk concentrates

A technology of mixing concentrate and copper-molybdenum sulfide, applied in flotation, solid separation, etc., can solve problems such as difficulty in copper-molybdenum separation, achieve the effects of reducing mineral processing costs, reducing pollution, and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

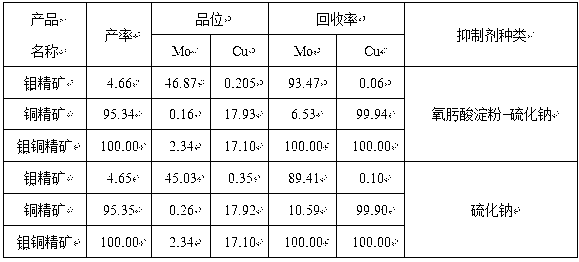

[0023] A copper sulfide molybdenum flotation mixed concentrate has a copper grade of 17.10% and a molybdenum grade of 2.34%. The monomer dissociation degree of molybdenum mineral is 97%.

[0024] Copper-molybdenum flotation mixed concentrate is adjusted to a pulp concentration of 33%, and water glass 500g / t, hydroxamic acid starch 160g / t, sodium sulfide 700g / t, kerosene 30g / t are added in turn ,2 # Oil 20g / t is fed to the ore, and molybdenum roughing is carried out to obtain rough molybdenum concentrate and roughing tailings, and the roughing tailings are added with kerosene and 2 # oil for scavenging, scavenging 1 kerosene and 2 # The amount of oil added is 15g / t for ore and 10 g / t for ore, and the second kerosene and 2 # The amount of oil added is 10g / t for ore and 8g / t for ore to obtain scavenging concentrate and scavenging tailings, and the scavenging tailings are copper concentrates.

[0025] Molybdenum rough concentrate is added with copper mineral inhibitor hydroxam...

Embodiment 2

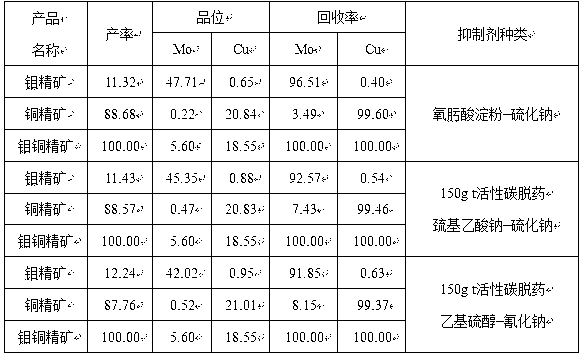

[0032] A copper sulfide molybdenum flotation mixed concentrate has a copper grade of 18.55% and a molybdenum grade of 5.60%. The copper minerals are mainly chalcopyrite, bornite and blue chalcocite, and the molybdenum minerals are mainly molybdenite. 84%-44μm, the monomer dissociation degree of copper mineral and molybdenum mineral is 96%.

[0033] Copper-molybdenum mixed concentrate is slurried to a pulp concentration of 30%, followed by adding water glass 600g / t to ore, high-efficiency copper sulfide mineral inhibitor hydroxamic acid starch 120g / t to ore, sodium sulfide 680 g / t to ore, kerosene 50g / t to ore, 2 # Oil 20g / t is fed to the ore, and molybdenum roughing is carried out to obtain rough molybdenum concentrate and roughing tailings, and the roughing tailings are added with kerosene and 2 # oil for scavenging, scavenging 1 kerosene and 2 # The amount of oil added is 25g / t for ore and 10 g / t for ore, and the second kerosene and 2 # The amount of oil added is 15g / t fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com