Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Achieve economies of scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product supply chain optimization-based network community group buying system and implementation method thereof

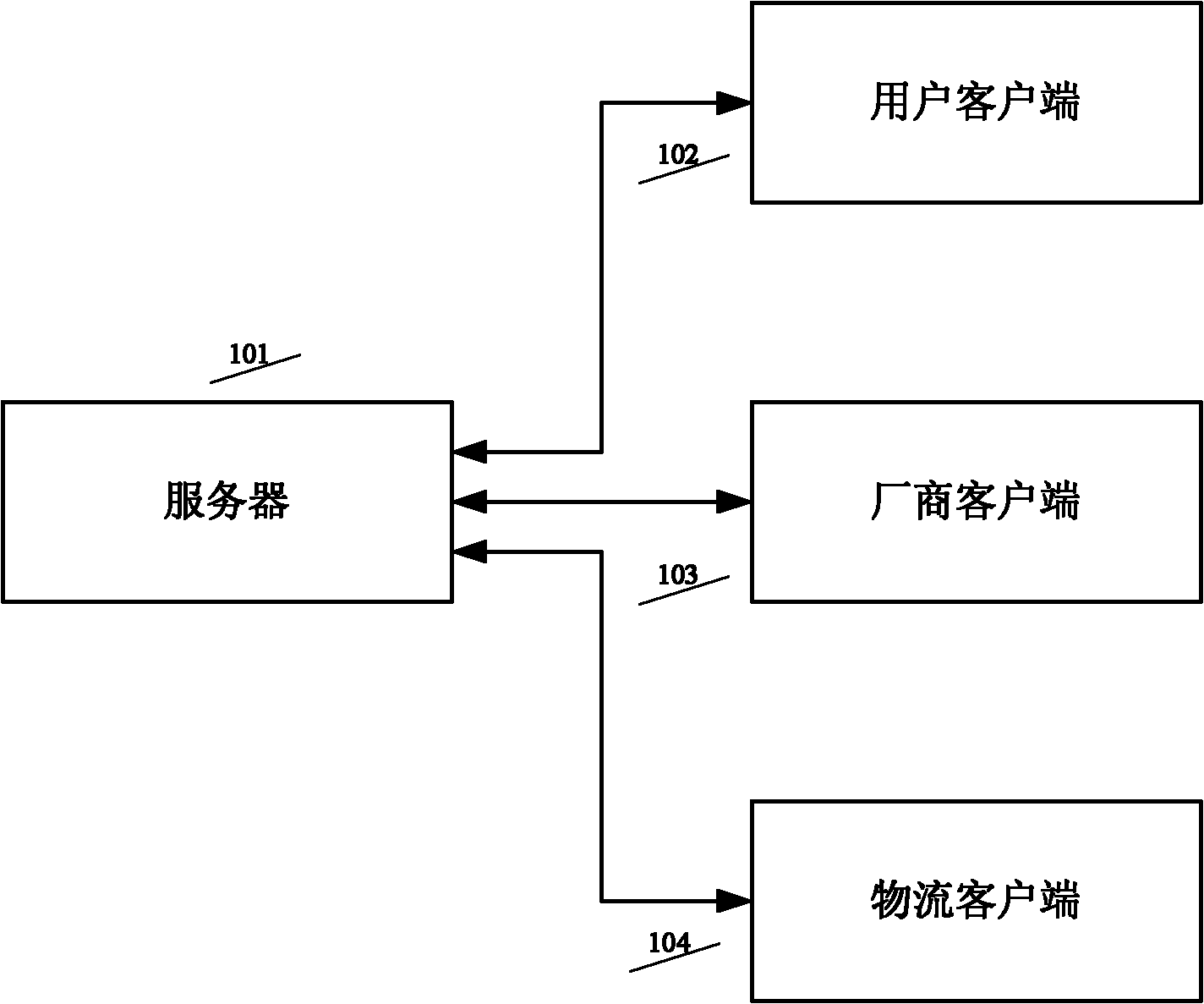

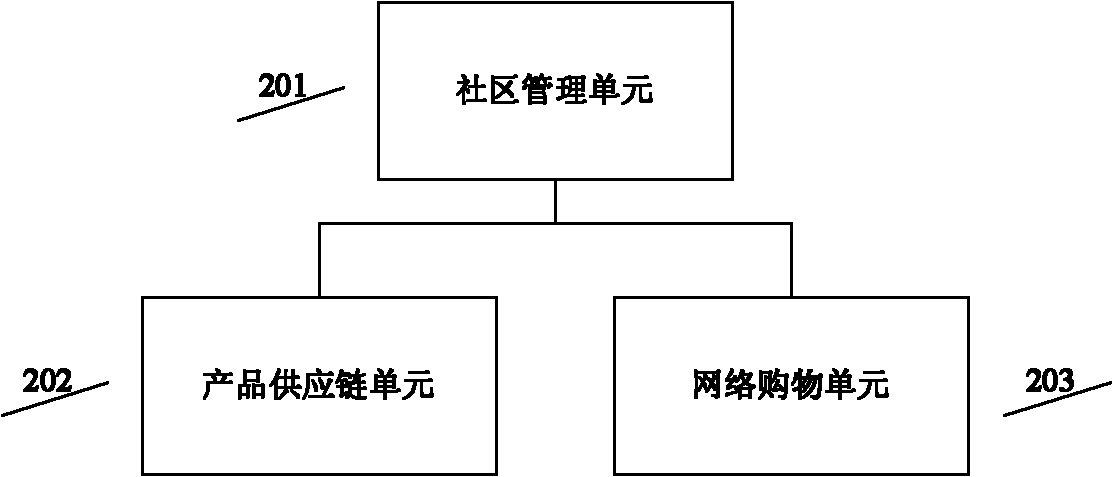

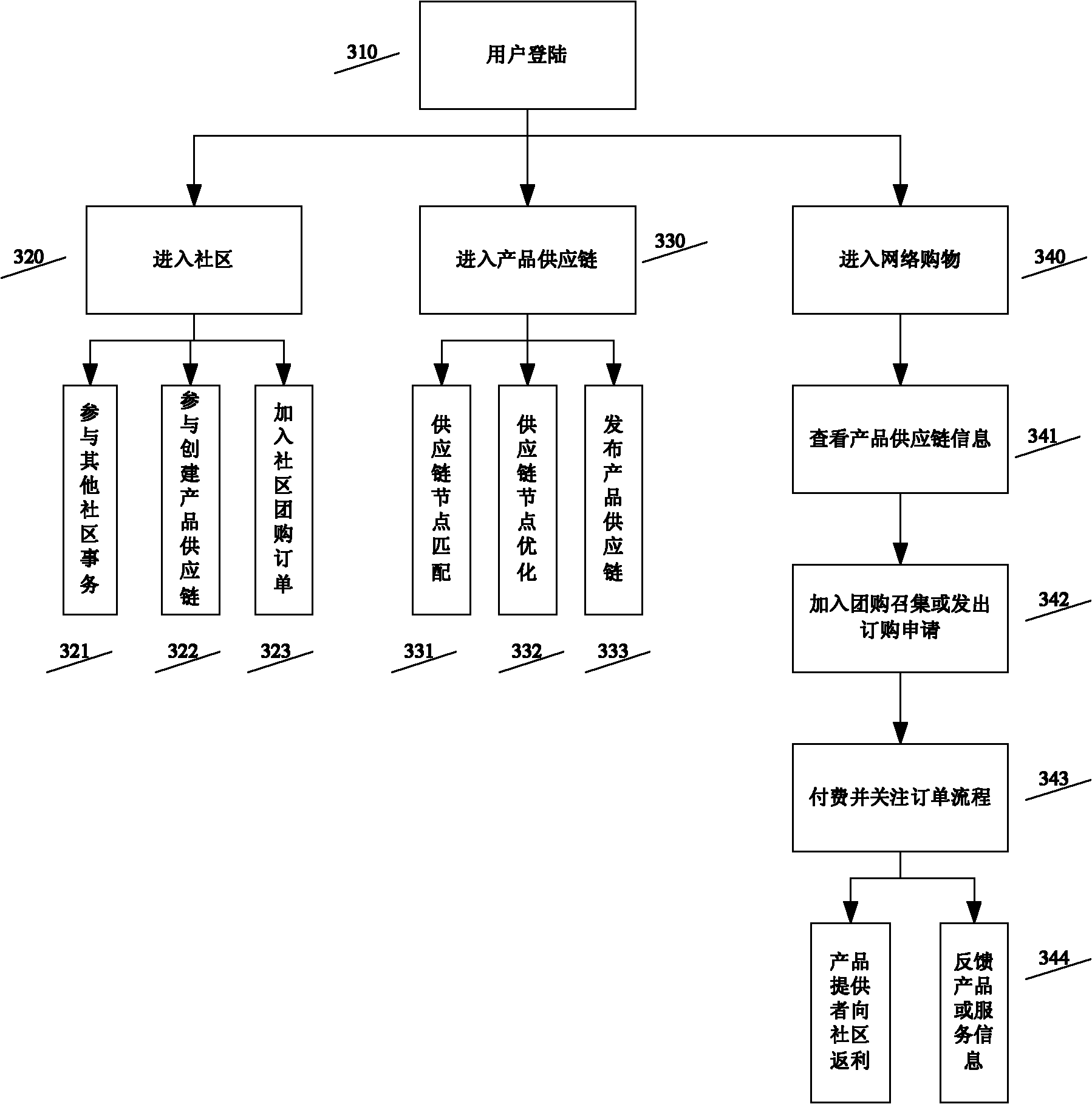

InactiveCN102214346ASafe Online ShoppingReduce product distribution costsCommerceGroup buyingMarketing channel

The invention discloses a product supply chain optimization-based network community group buying system and an implementation method thereof. The system comprises a community management unit, a supply chain management unit and a network shopping unit, wherein the community management unit is used for establishing and maintaining common consumer groups and initiating the establishment and the maintenance of product supply chains, group buying calling and on-line consulting related to the maintained product supply chains; the supply chain management unit is used for fuzzily matching the supply chains, optimizing the nodes of the supply chains, metering and inquiring; and the network shopping unit is used for buying all complete supply chains on line and establishing visual order process management for the nodes of the supply chains, which include buyers. By the system and the method, marketing channels can be established for more network products by the product supply chains, and the supply side and the demand side of the products can be quickly, directly and efficiently connected by a consumer intermediary, namely the community, so that the circulation cost of product providers is saved, and reliable and substantial product service can be provided for terminal consumers.

Owner:深圳市财富万方信息技术有限公司

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjusting the temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

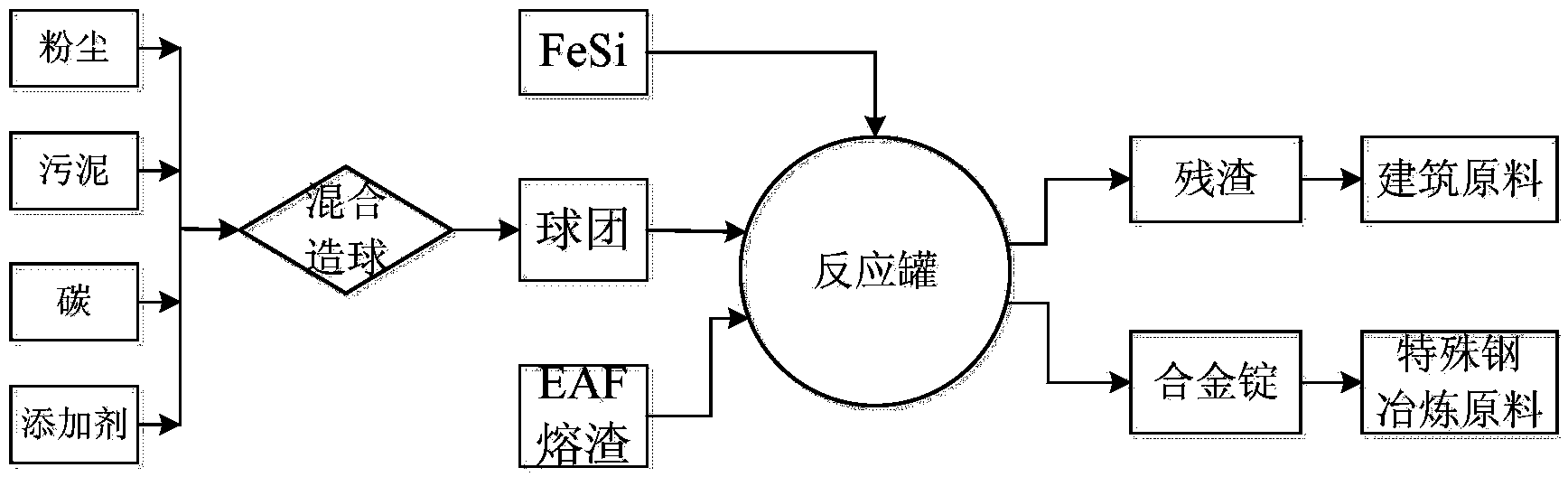

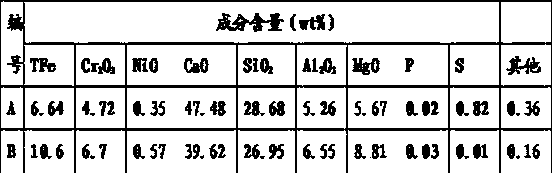

Method of melting stainless steel dust, slag and Cr-containing sludge

The invention belongs to the field of industrial waste recycling and particularly relates to a method of melting stainless steel dust, slag and Cr-containing sludge. The method comprises the steps of drying the stainless steel dust and Cr-containing sludge generated in a stainless steel production process; then, uniformly mixing with a reducer and an additive to prepare self-reductive pellets; adding the obtained pellets into a reaction tank filled with EAF (Effective Attenuation Factor) slag; controlling the temperature of the reaction tank at 1400-1600 DEG C, and adding silicon iron powder into the reaction furnace in the period, wherein the whole treatment process lasts for 40-60 minutes. The method has the advantages of simple and short technical flow, environment protection and energy saving, high metal yield, scale benefit and the like.

Owner:UNIV OF SCI & TECH BEIJING

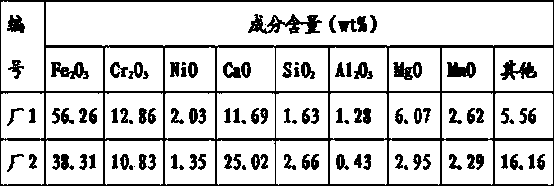

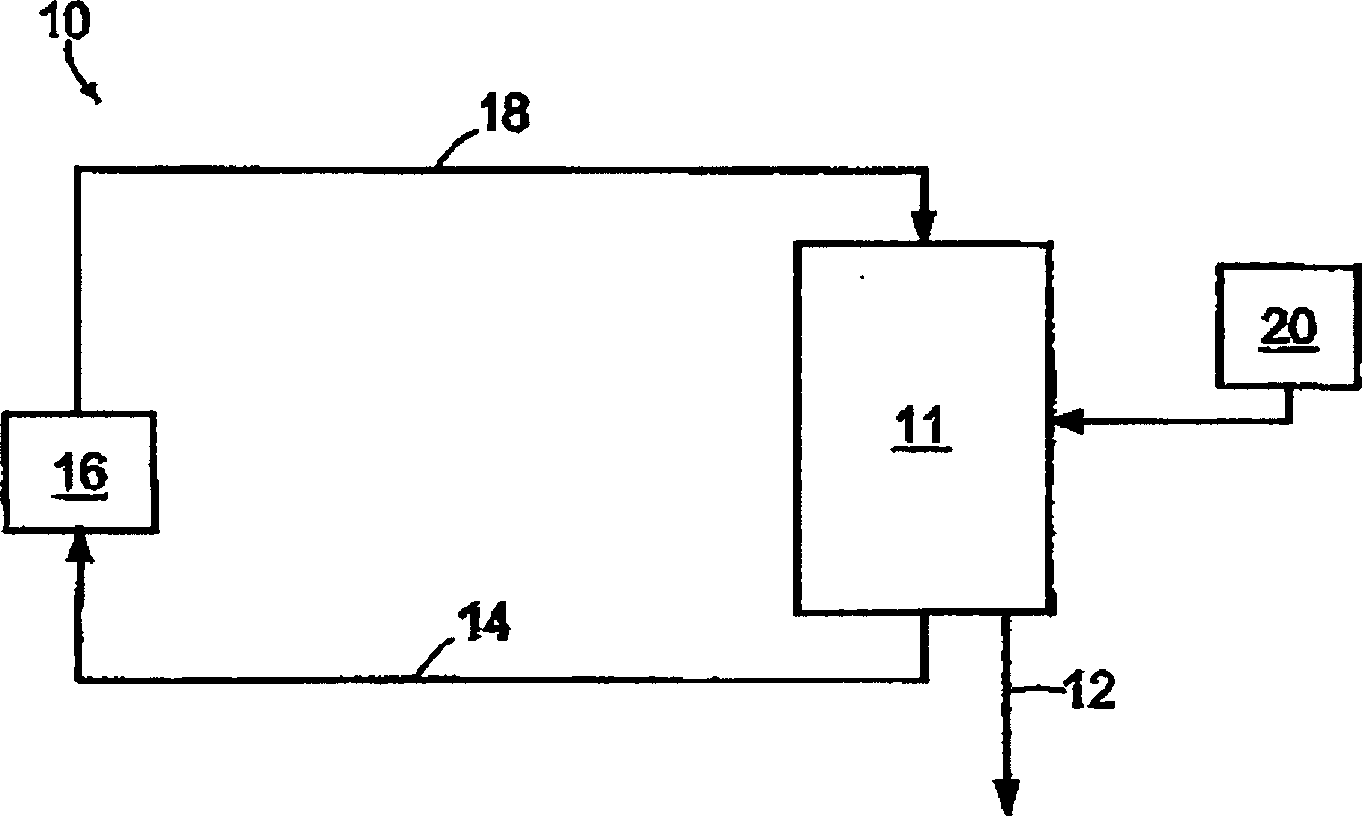

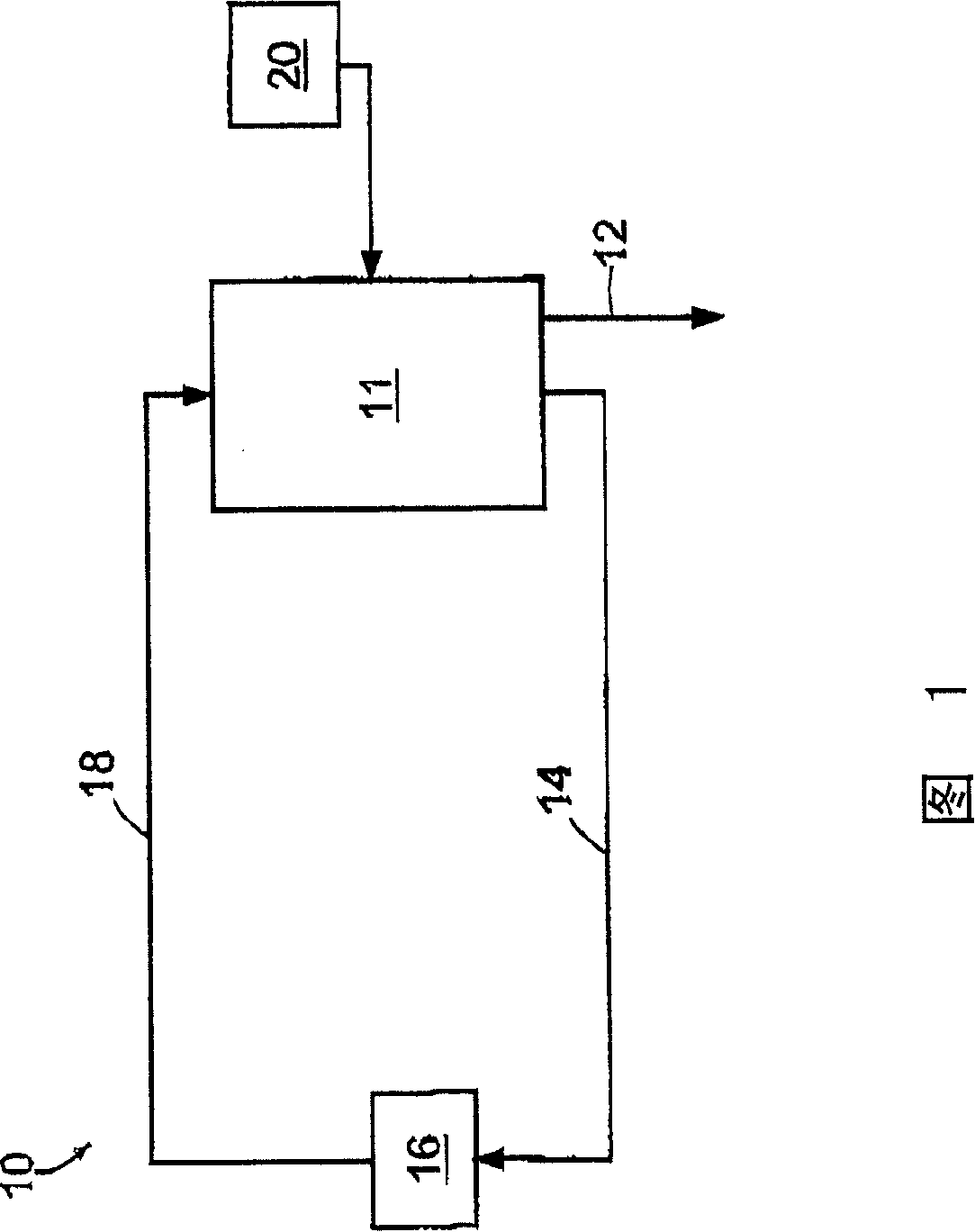

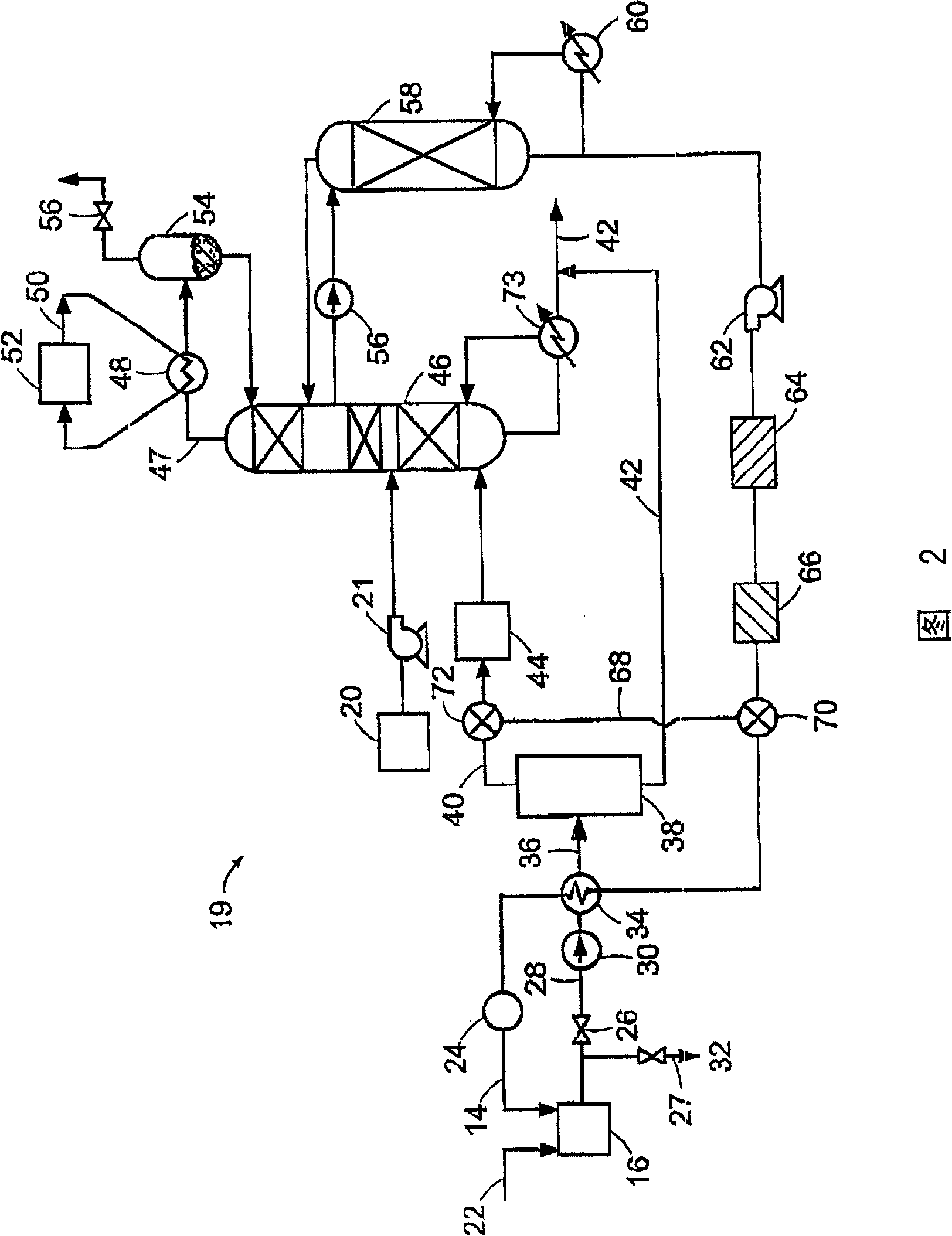

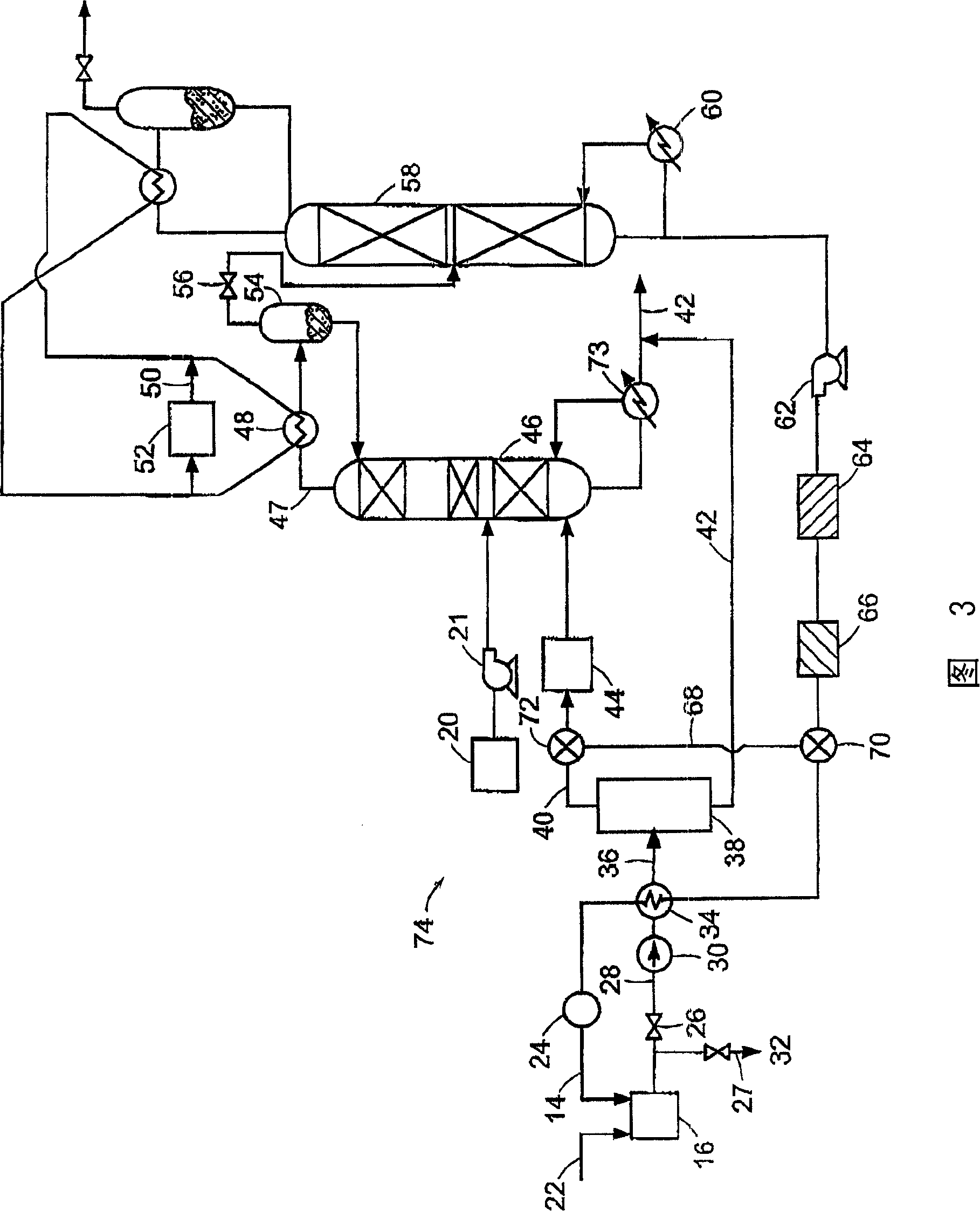

Recycle for supercritical carbon dioxide

InactiveCN1604882ALow costReduce complexitySolidificationPressurized chemical processImpuritySupercritical carbon dioxide

A method and a system for supplying a carbon dioxide fluid feed from a carbon dioxide purifying means to one or more applications. The feed is combined with contaminants at the applications to form an effluent, and at least one effluent is returned to the purifying means for recycling the carbon dioxide. Carbon dioxide from a carbon dioxide source is combined with the carbon dioxide of the system so that the purity of the carbon dioxide from the source is upgraded prior to the applications.

Owner:PRAXAIR TECH INC

Manufacturing method of encoder wire harness

InactiveCN108110583AAvoid double entryReduce manufacturing costContact member assembly/disassemblyConnection formation by deformationManufacturing cost reductionElectric current flow

The present invention discloses a manufacturing method of an encoder wire harness. The wire harness comprises wires, a connector, terminals, external materials and other parts. The wires are configured to carry a current to convey signals and provide electric power; the connector and the terminals are crimped with the wires according to a standard and then are locked in a hole groove of the connector, a male connector and a female connector are abutted to make communication between wire harnesses and of a loop from the wire harnesses to a terminal; and devices for manufacturing the wire harnesses comprise a winding inserter, a crimper and a peeling machine. The manufacturing method of the encoder wire harness can accurately reflect a multiple-layer material list of a manufacturing mode after optimization through creation, and can reduce the manufacturing cost; and general sub modules are determined to reduce manufacturing, stock and wasting cost. Therefore, the manufacturing method ofthe encoder wire harness can achieve scale economy, can avoid repeated waste, can avoid repeated record of data, can shorten error correction and verification time, and can ensure figure continuity ina process from a wire harness design environment to a manufacturing process.

Owner:SUZHOU RENWEIFENG SOFTWARE TECH

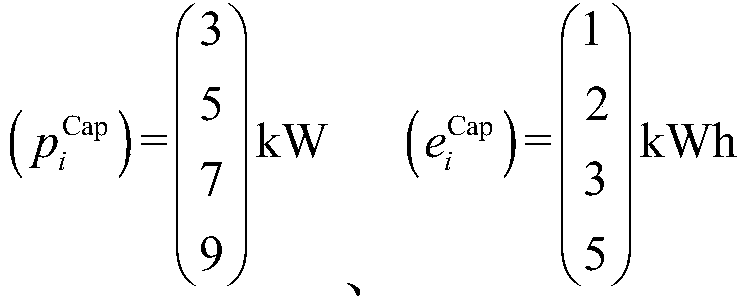

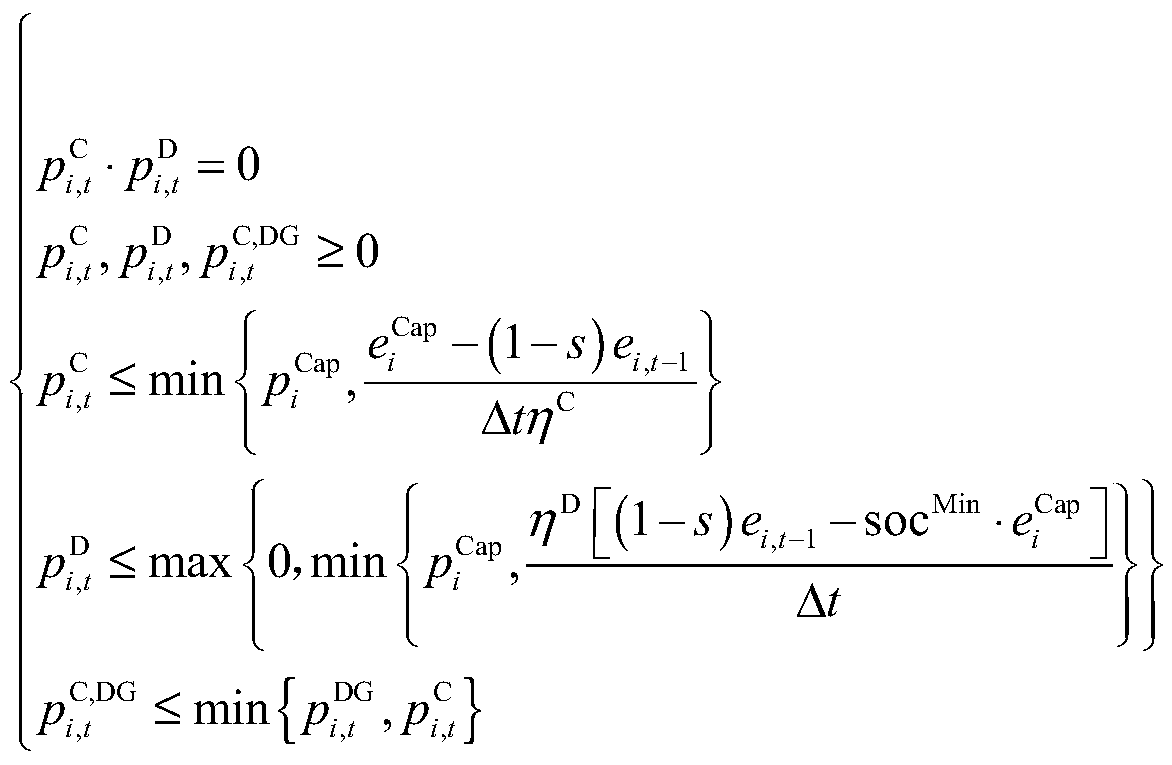

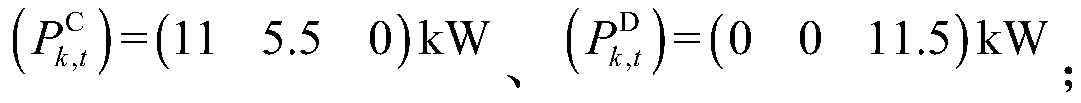

Centralized cloud energy storage system, transaction settlement method thereof, storage medium and terminal

PendingCN110335171AMeet needsNo maintenanceAc network load balancingBuying/selling/leasing transactionsService provisionPower grid

The invention belongs to the technical field of power grid energy storage, and specifically relates to a centralized cloud energy storage system, a transaction settlement method thereof, a storage medium and a terminal. The centralized cloud energy storage system comprises a centralized energy storage facility which is invested and operated by a cloud energy storage service provider, massive distributed users, a power network and a user energy management system, wherein the power network and the user energy management system are used for connecting the centralized energy storage facility and the massive distributed users; a user sends charging and discharging requests to the cloud energy storage service provider through the user energy management system; and the cloud energy storage service provider issues charging and discharging instructions to the centralized cloud energy storage system. The transaction settlement method comprises the steps that a cloud energy storage service provider provides a cloud energy storage service for a user, and the user sends a request to the cloud energy storage service provider; the cloud energy storage service provider issues charging power and discharging power instructions to the centralized energy storage facility; and settlement of the operation cost is carried out between the cloud energy storage service provider and the user and the power grid. The storage medium and the mobile terminal are used for realizing the transaction settlement method.

Owner:TSINGHUA UNIV

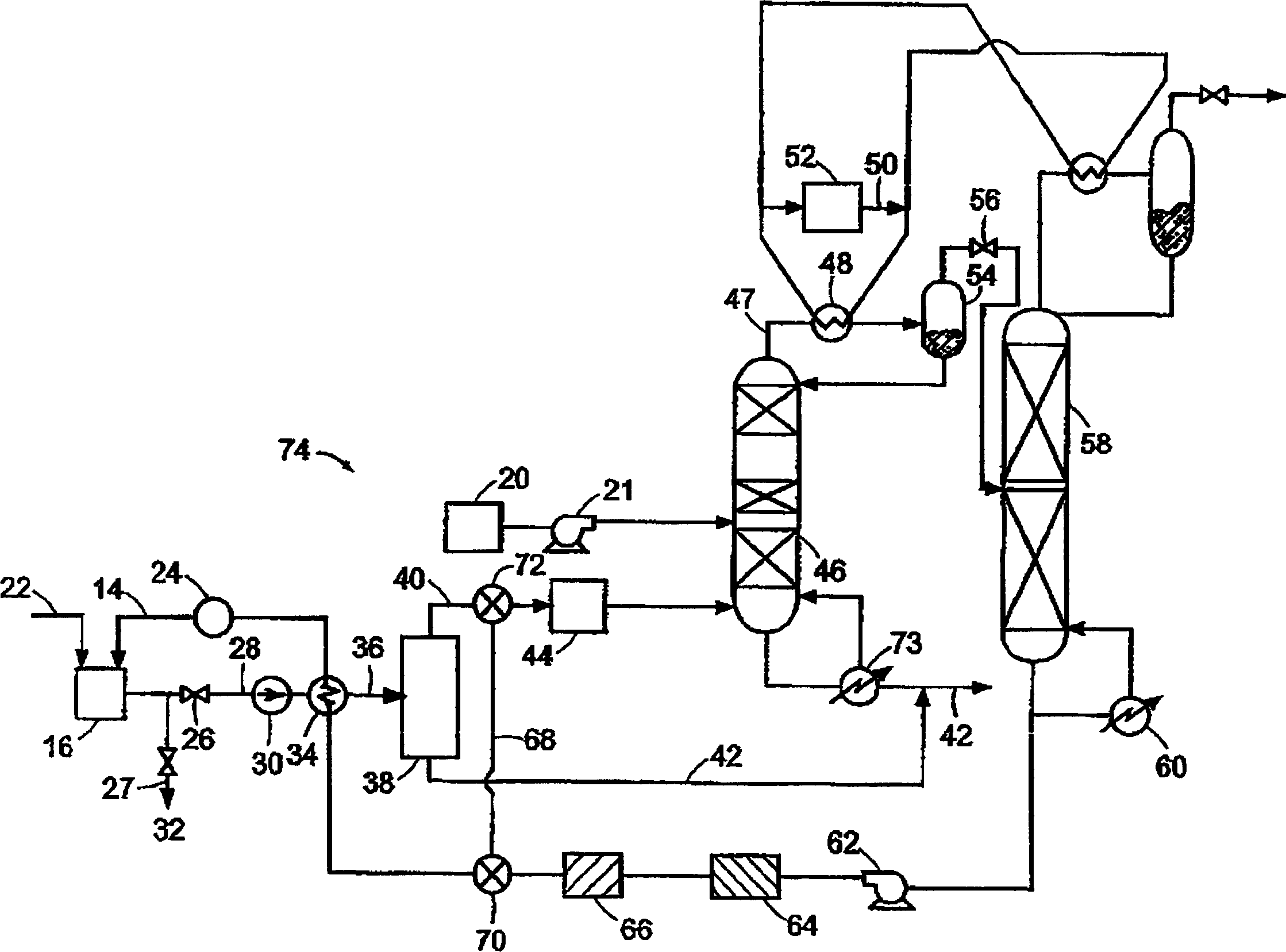

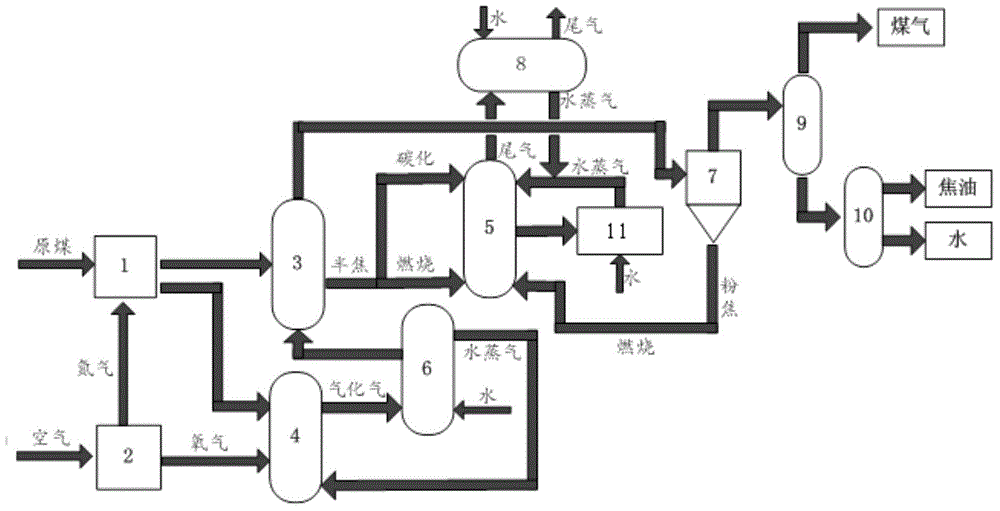

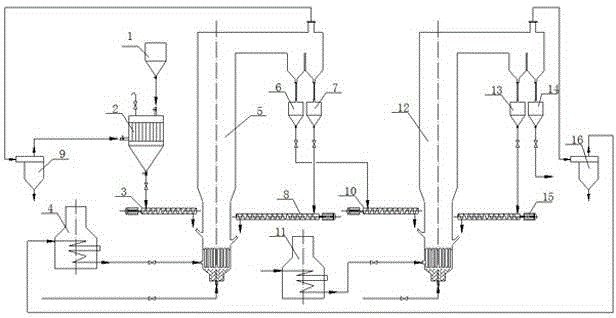

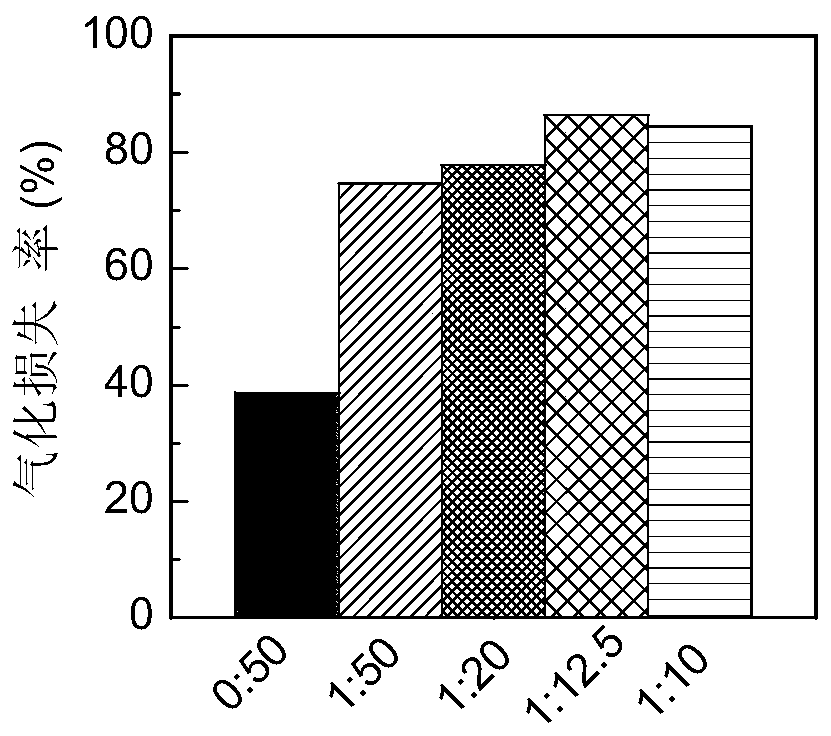

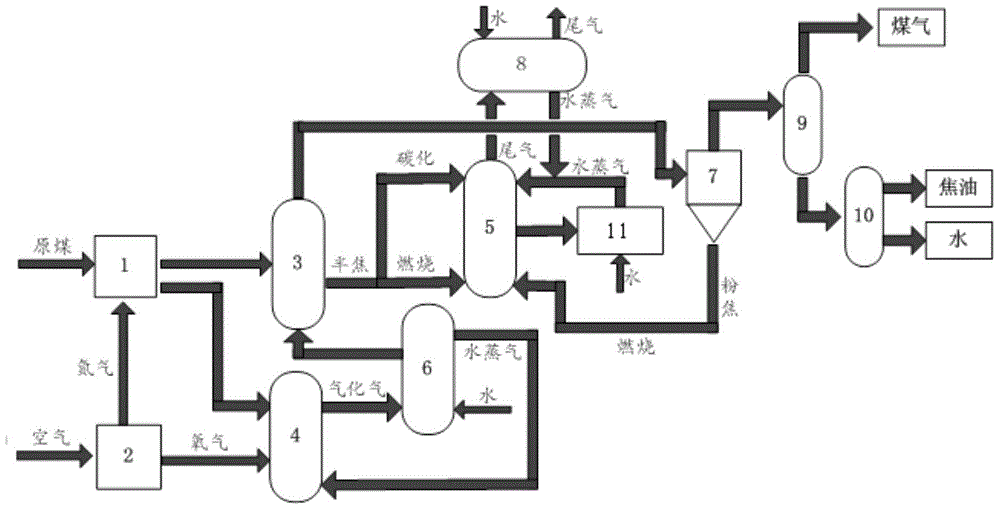

System and process for producing active carbon by virtue of coal gasification and pyrolysis

ActiveCN104357092ASolve the use problemSimple and fast operationCarbon compoundsDirect heating destructive distillationHeat carrierWater vapor

The invention discloses a system and process for producing active carbon by virtue of coal gasification and pyrolysis, and provides a coal base poly-generation process technology. The main body part of the system comprises three process units for coal pyrolysis, coal gasification and active carbon preparation as well as a first steam generator and a second steam generator, wherein the high-temperature gasification gas generated by the coal gasification unit is sequentially used as a heat carrier for the first steam generator and the coal pyrolysis unit, and the carbocoal generated by the coal pyrolysis unit is used as a carbon source for the active carbon preparation unit and a fuel for a main body heat source; and the first steam generator provides steam as a gasification agent (or oxidant) for the coal gasification unit, the steam generated by the second steam generator serves as part of an activator of the active carbon preparation unit, and the high-temperature tail gas generated by the active carbon preparation unit serves as a heat source of the second steam generator. By adopting the system and the process disclosed by the invention, the problem that the conventional pyrolysis process cannot effectively use pyrolysis carbocoal is solved, and a co-production technical route of three coal base products including active carbon, coal gas and tar is realized.

Owner:SHAANXI COAL & CHEM TECH INST

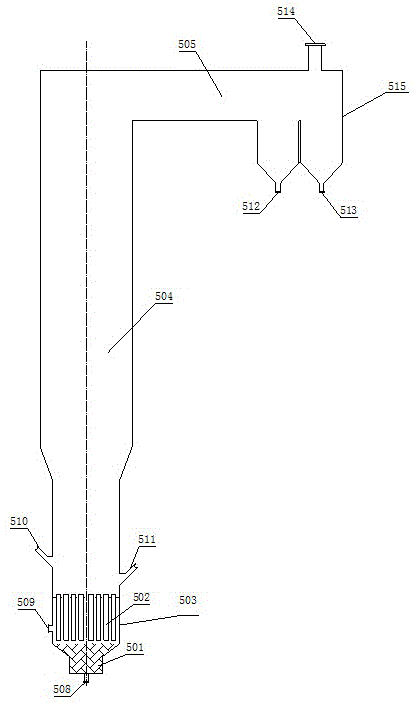

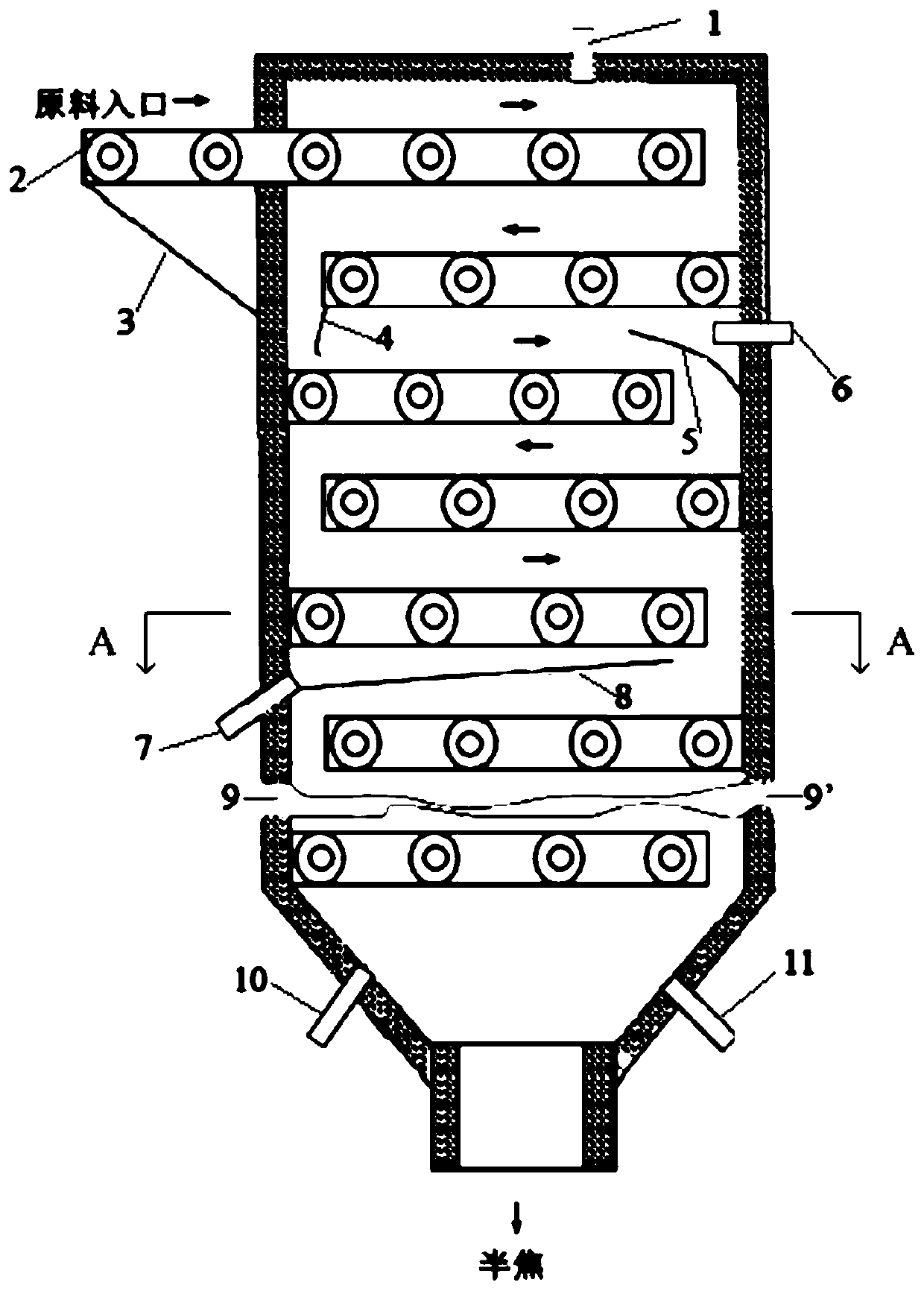

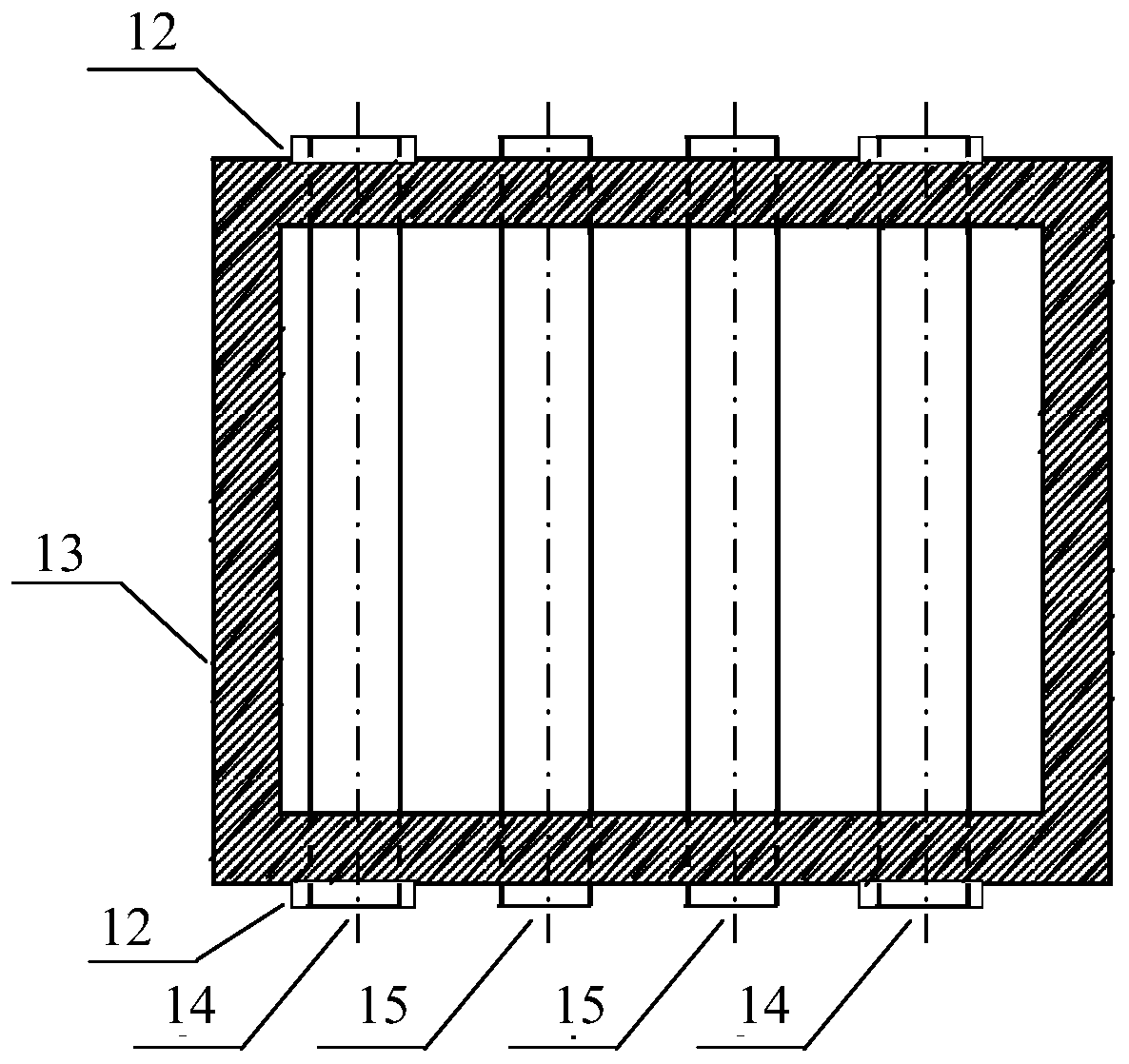

Drying-pyrolysis integrated vertical furnace

ActiveCN107227165AImprove heat utilizationBroaden the effective particle size rangeSpecial form destructive distillationHeat carrierBiomass

The invention discloses a drying-pyrolysis integrated vertical furnace. According to the vertical furnace, a 3-30 section three-dimensional space inner baffled (in the shape of continuous S) operation conveyor belt is used as a material conveying device, high-temperature gas (or high temperature flue gas) is used as a gas heat carrier for multiple-step staggered countercurrent-type heat exchange with material coal or biomass, and drying, low temperature pyrolysis and medium-high temperature pyrolysis of the material coal or biomass are realized from top to bottom step by step through bottom-to-top temperature gradient of the gas heat carrier. The vertical furnace has a wide material particle size application range, realizes drying-pyrolysis integration of the material coal or biomass in the same furnace, effectively uses flue gas produced by material coal or biomass pyrolysis to cool hot semicoke at the outlet of the vertical furnace or to adjust and control the temperature of the gas heat carrier, improves a thermal energy utilization rate of the vertical furnace, has a simple design, can be flexibly and simply operated, realizes a low investment cost and is easy to industrialize.

Owner:NORTHWEST UNIV

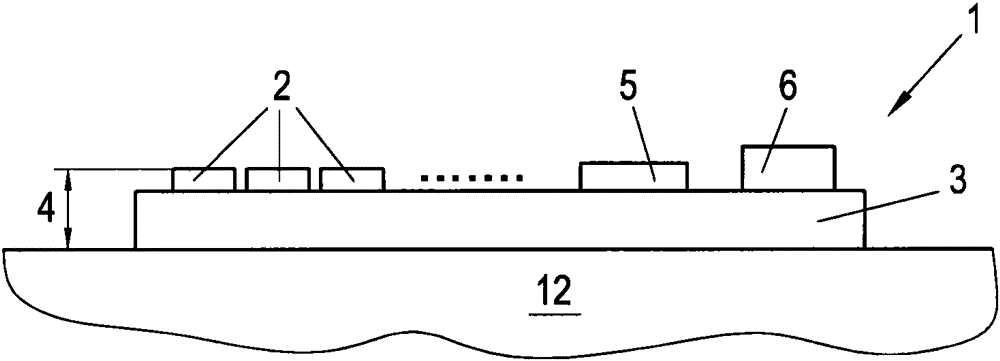

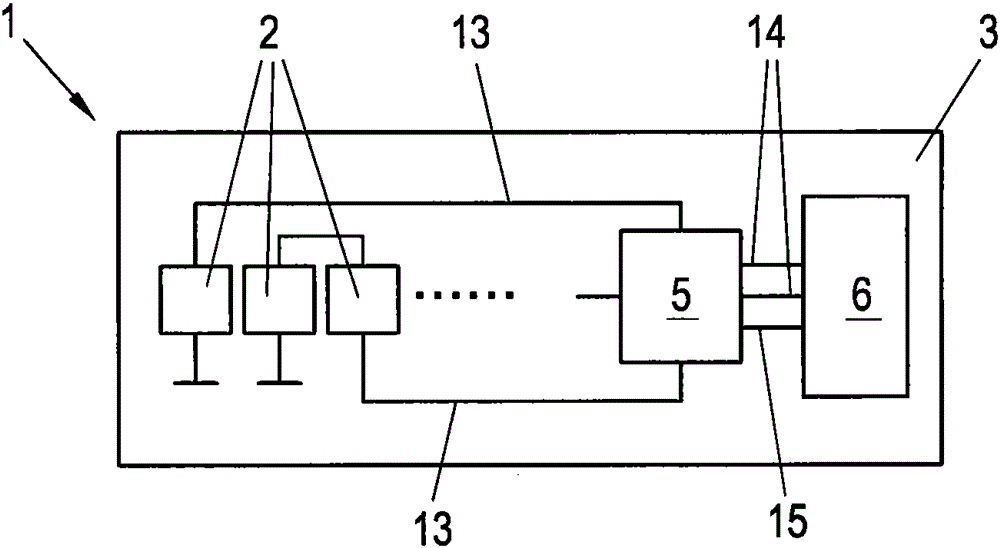

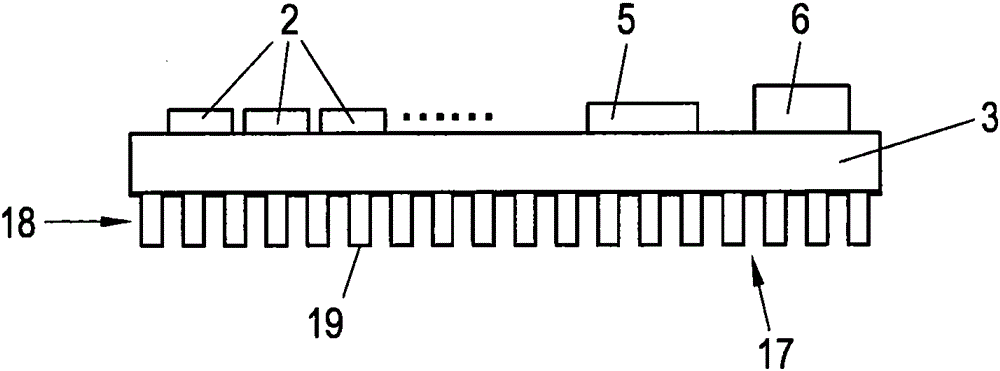

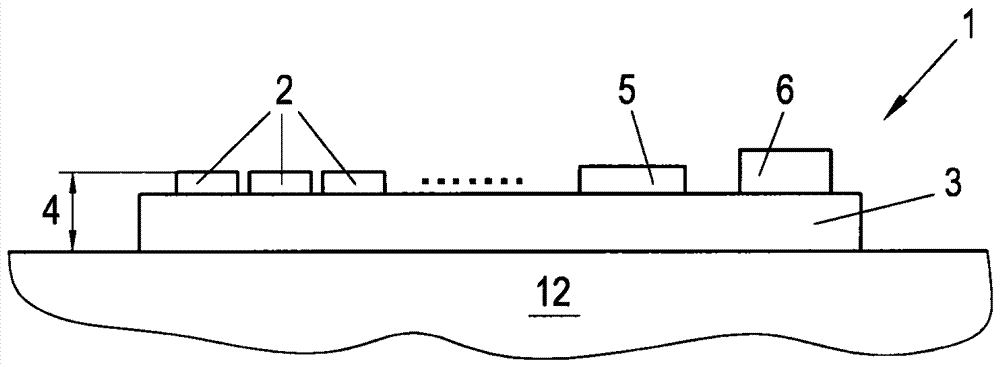

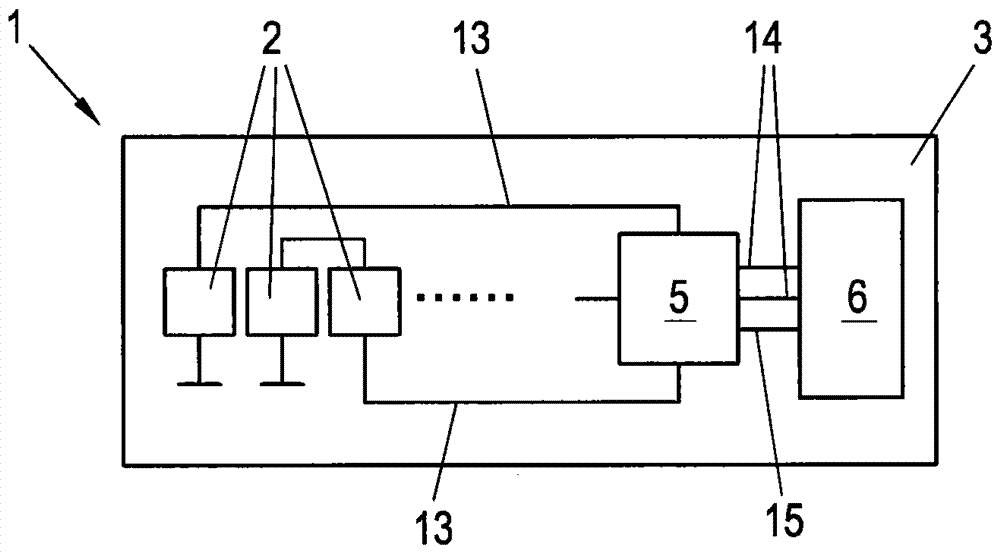

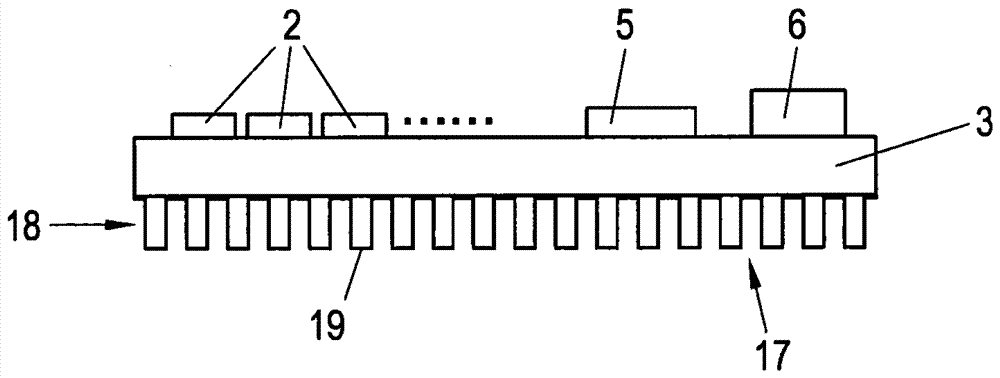

Light source and method for producing the light source

ActiveCN105103655AEasy to integrateReduce weightVehicle headlampsElectrical apparatusSurface mountingBuck converter

The invention relates to a light source (1) and a method for producing said light source, for integration in a headlight having a circuit board (3), on which at least one light diode (LED) (2) and a converter unit (5) for supplying power to the LED (2) are arranged, wherein the converter unit (5) and the at least one LED (2) are designed as surface-mounted components (surface-mounted device, SMD) and the converter unit (5) has one or a plurality of buck converters.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

MW (megawatt) grade cogeneration fuel cell power station

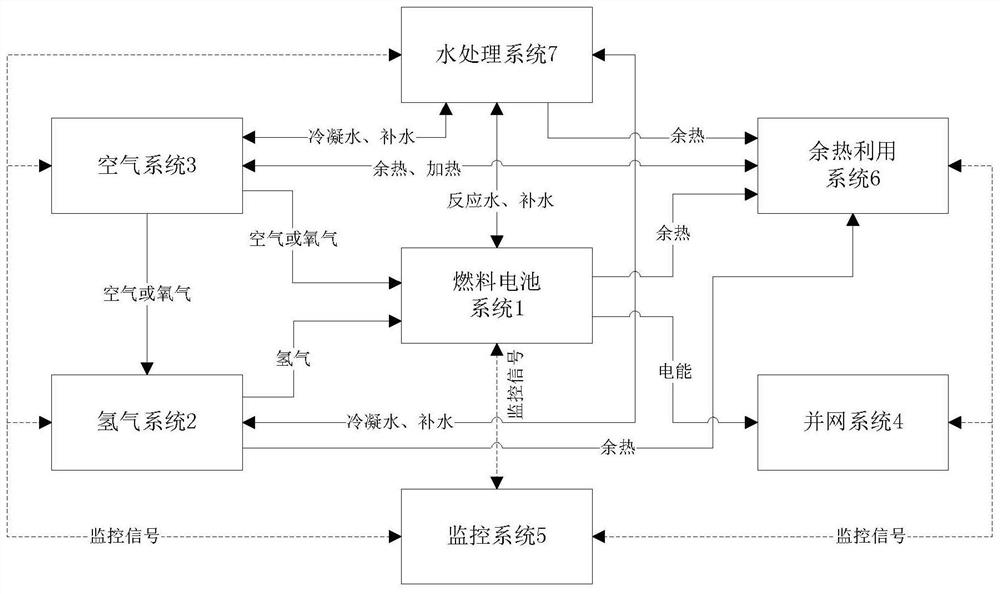

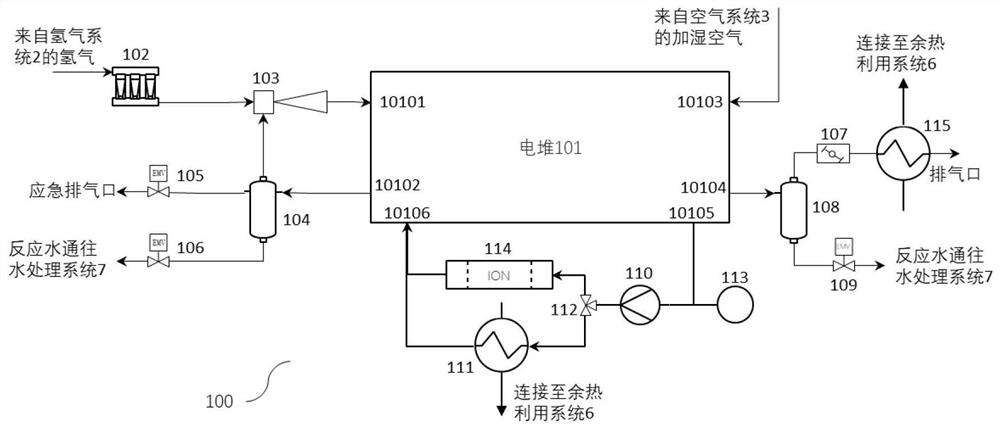

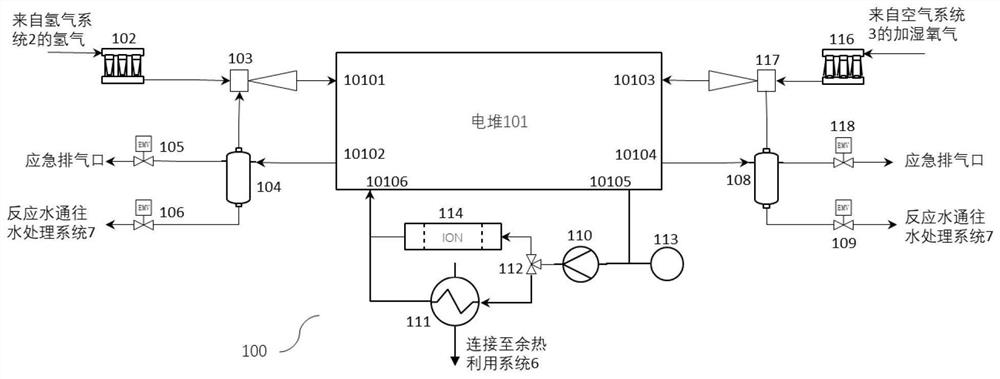

ActiveCN113889648AAchieve economies of scaleReduce the cost of using hydrogenDc network circuit arrangementsReactant parameters controlCogenerationEngineering

The invention provides an MW-level combined heat and power fuel cell power station, which comprises a fuel cell system, a hydrogen system, an air system, a grid-connected system and a monitoring system, and is characterized in that the hydrogen system adopts a reforming hydrogen production technology and provides high-purity hydrogen for the fuel cell system; the air system provides air or oxygen for the fuel cell system and the hydrogen system; the grid-connected system is used for transmitting electric energy to a power grid, and the monitoring system is used for monitoring and controlling operation parameters of the power station. The power station further comprises a waste heat utilization system used for recycling waste heat generated by the fuel cell system, the air system and the hydrogen system, providing a heating function for the air system and the hydrogen system and providing hot water for a hot water user. The water treatment system is used for recycling condensate water or reaction water and providing deionized water for the fuel cell system, the hydrogen system, the air system and the waste heat utilization system. The process flow is optimized, the energy utilization rate is increased, and zero water consumption can be realized during operation.

Owner:SHANGHAI MICROPOWERS +2

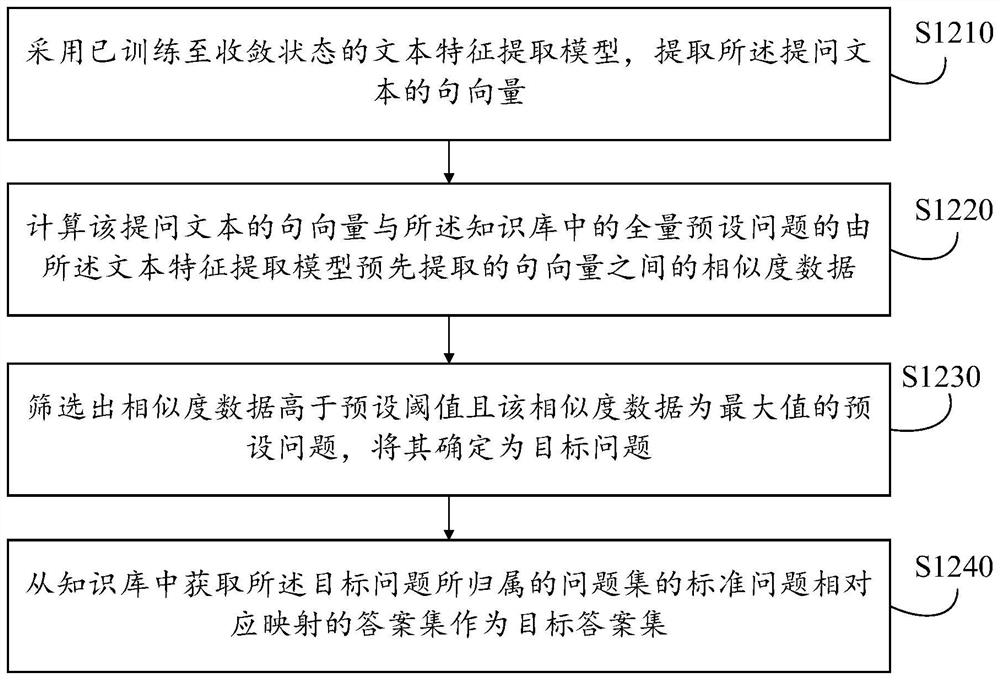

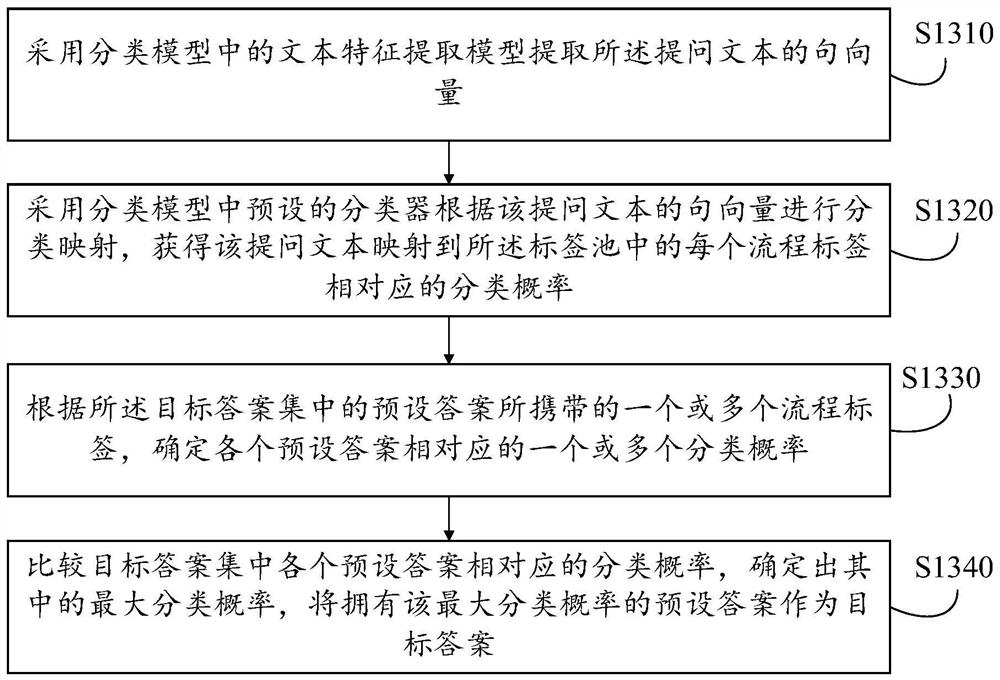

Intelligent customer service automatic answering method and device, equipment, medium and product

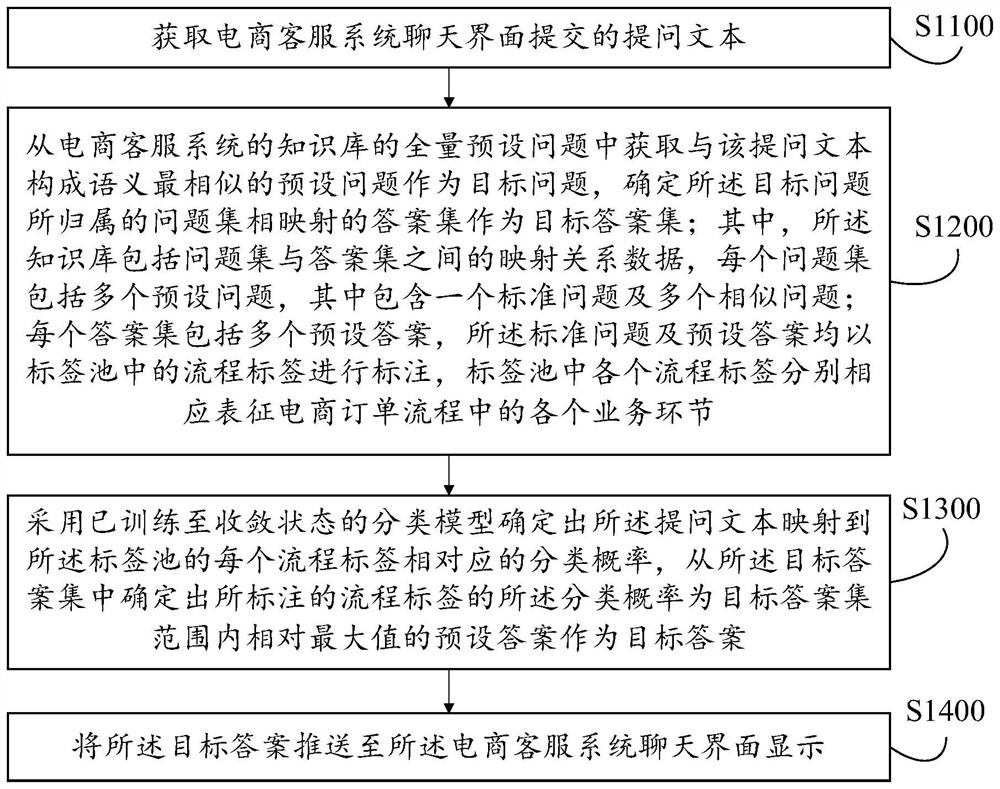

PendingCN114428845AHigh precisionAct as a sorting referenceBuying/selling/leasing transactionsKnowledge representationEngineeringData mining

The invention discloses an intelligent customer service automatic answering method and device, equipment, a medium and a product. The method comprises the following steps: acquiring a question text submitted by a chat interface of an e-commerce customer service system; obtaining a preset question with the most similar semantic composition with the question text from a knowledge base of an e-commerce customer service system as a target question, and determining an answer set mapped with a question set to which the target question belongs as a target answer set; standard questions in the question set and preset answers in the answer set are labeled with process labels in a label pool, and each process label in the label pool correspondingly represents each business link in the e-commerce order process; a classification model is adopted to determine a classification probability corresponding to mapping of the question text to each process label, and a preset answer with the classification probability of the process label being a relatively maximum value is determined from the target answer set to serve as a target answer; and pushing the target answer to the chat interface for display. According to the invention, the response accuracy of the e-commerce customer service system can be improved.

Owner:GUANGZHOU HUADUO NETWORK TECH

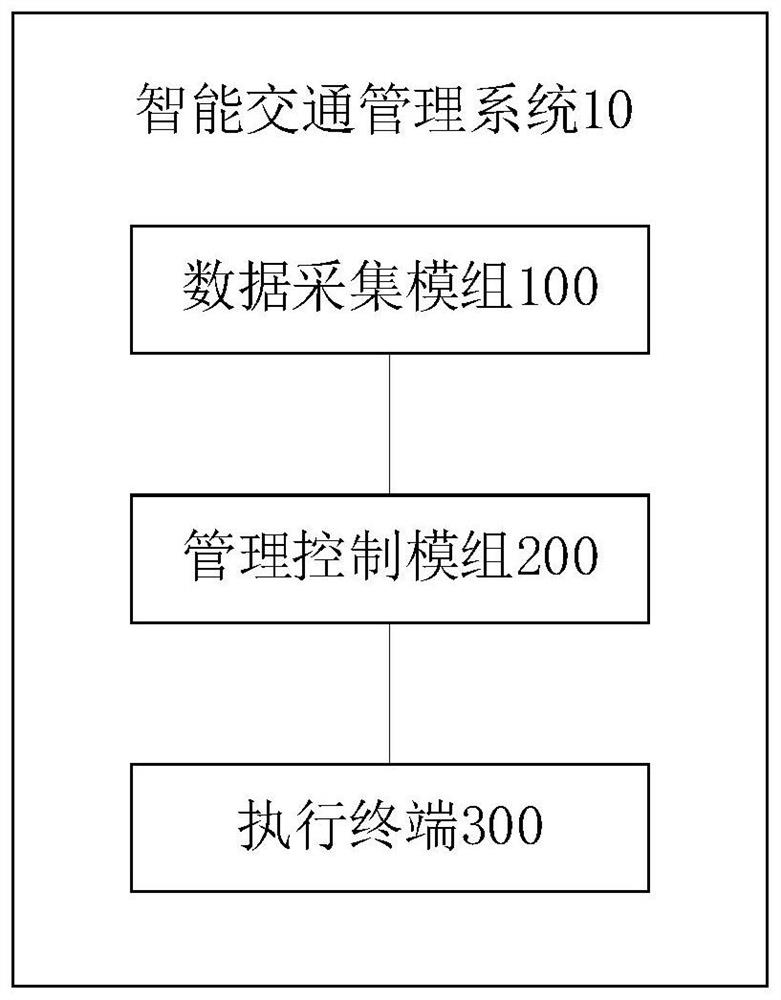

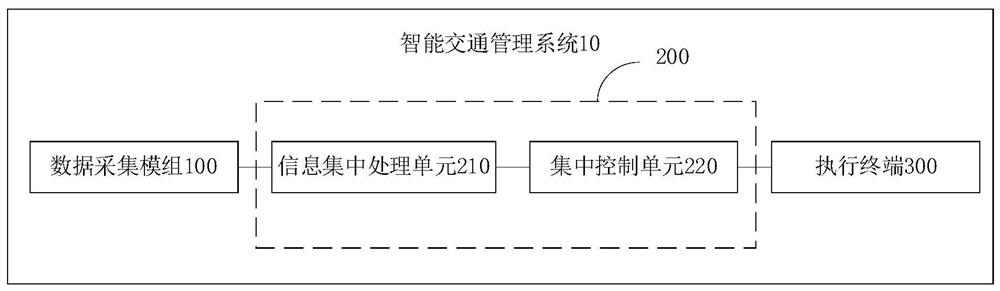

Intelligent traffic management system

PendingCN112489459ARealize on-site commandImprove targetingArrangements for variable traffic instructionsDetection of traffic movementTraffic networkData acquisition

The invention provides an intelligent traffic management system, and relates to the technical field of road traffic. The system comprises a data acquisition module, a management control module and anexecution terminal; the data acquisition module is connected with the management control module; the execution terminal is connected with the management control module; the data acquisition module isused for acquiring road condition data on a road; the management control module is used for receiving the road condition data and generating a control instruction according to the road condition data;and the execution terminal is used for executing corresponding operation according to the control instruction. In the implementation process, after the data acquisition module acquires the road condition data, the data acquisition module sends the road condition data to the management control module, and the management control module analyzes and processes the road condition data and generates the corresponding control instruction, so that the execution terminal can perform corresponding operation according to the control instruction. All the modules are integrated together to form an intelligent traffic network, the requirements of modern traffic can be effectively met, and the development of the intelligent traffic industry is powerfully promoted.

Owner:SHAOGUAN COLLEGE

Efficient sectional turtle culture breeding facility and method

PendingCN110692596AQuality improvementTake advantage ofClimate change adaptationPisciculture and aquariaShrimpZoology

The invention discloses an efficient sectional turtle culture breeding facility and method and belongs to the field of turtle breeding. The breeding facility comprises a big pond and further comprisesa small pond temperature-holding area, a big pond dyke is built around the big pond, an annular ditch is built on the inner side of the big pond dyke, the small pond temperature-holding area is provided with a light-pervious temperature-holding shed, a plurality of oxygen supply pumps, a waterway passage and a cage door device, and the cage door device comprises a gate and a cage door. The breeding method includes that an ecological three-dimensional breeding mode is adopted, and turtles eat live shrimps and are not fed with animal or vegetative processed feed, thereby being less prone to being infected with diseases; fishes eat dung of the turtles and remains of the shrimps to form a three-dimensional microcirculation system which is imitated wild breeding, and bred turtles are high in nutritional value. The efficient sectional turtle culture breeding facility has the advantage that shrimp seeds and turtles are fed separately; a small pond is provided with a temperature holding device, so that the shrimp seeds are prevented from being frozen to death.

Owner:宁波市明凤渔业有限公司

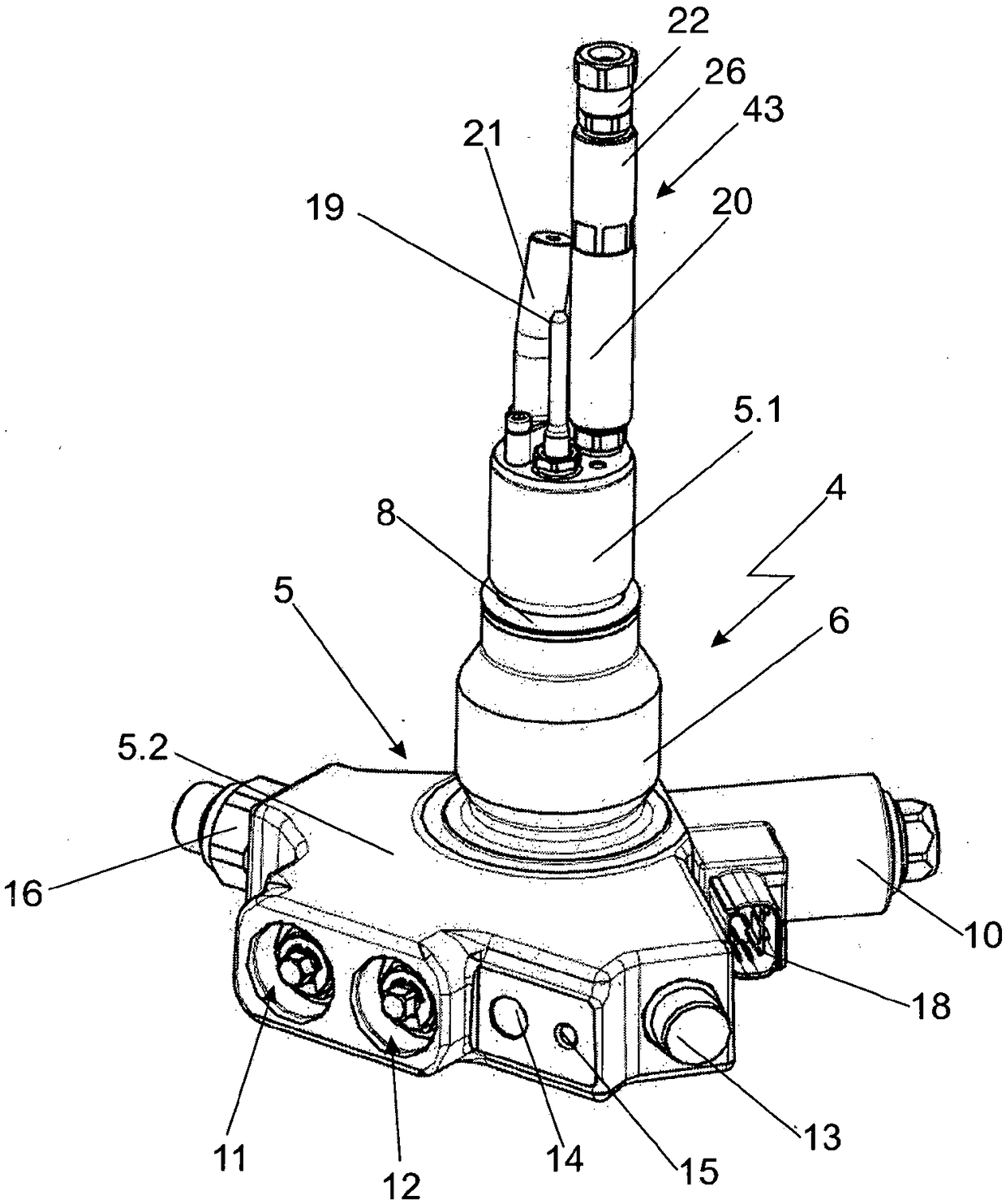

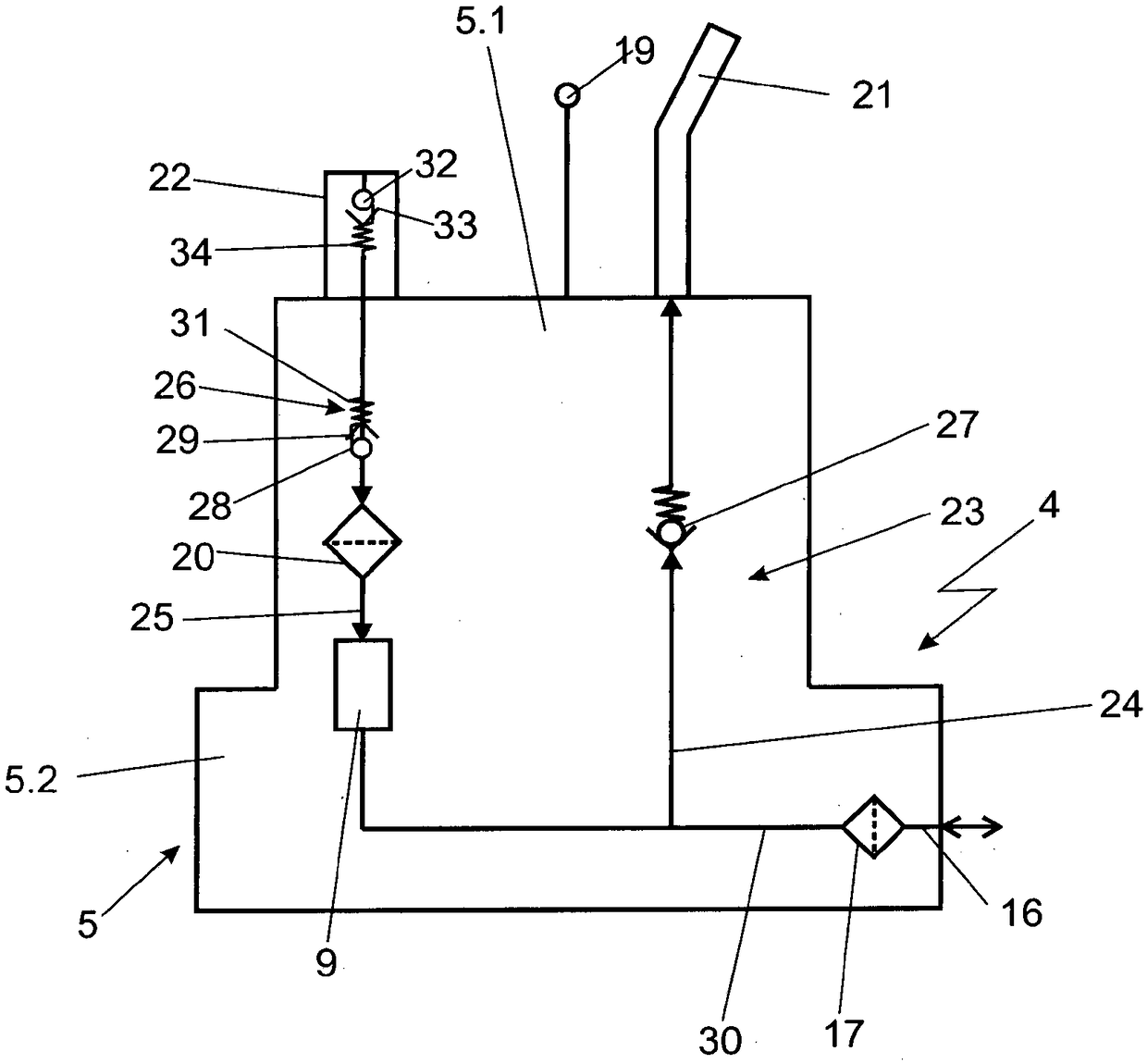

Tank valve

ActiveCN109416151AAutomatically block dischargeLow costVessel mounting detailsVessel geometry/arrangement/sizeEngineeringCheck valve

Owner:CELLCENTRIC GMBH & CO KG

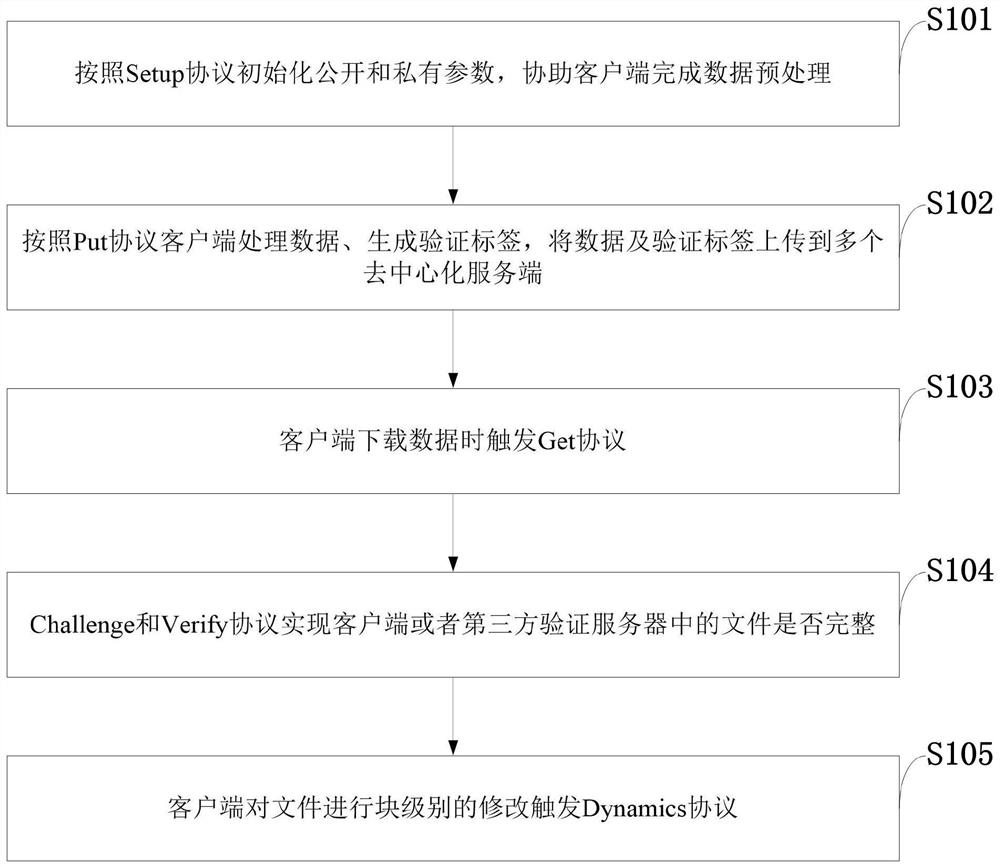

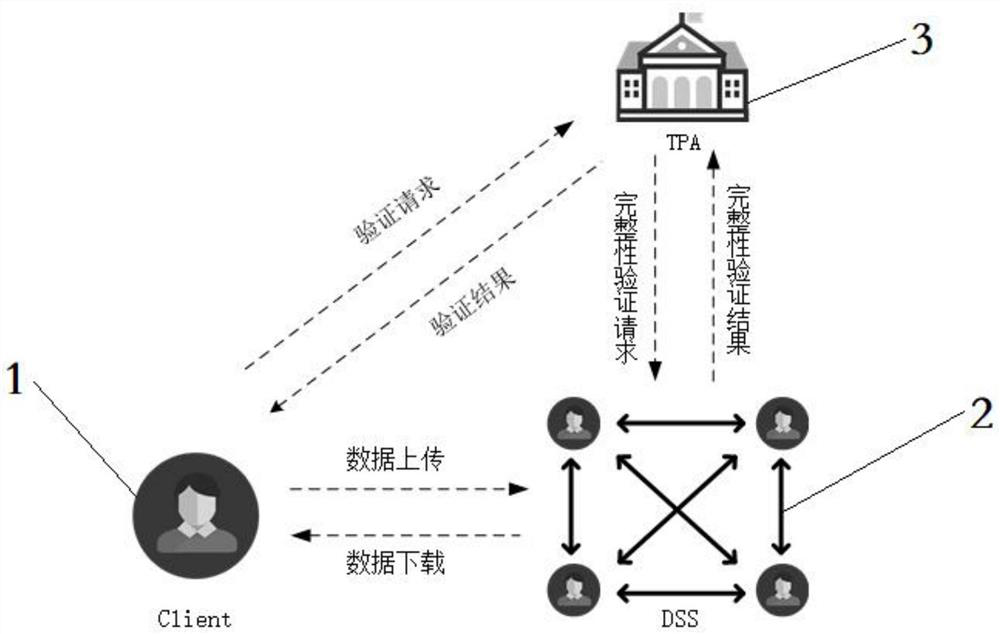

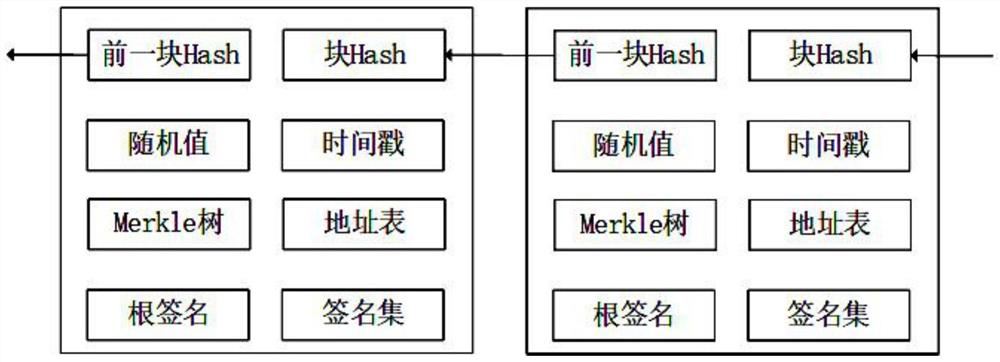

Decentralized storage method and system supporting data dynamic and public integrity auditing

PendingCN114499865AImprove download speedLow maintenanceKey distribution for secure communicationUser identity/authority verificationThird partyStorage security

The invention belongs to the technical field of decentralized storage security, and discloses a decentralized storage method and system supporting data dynamic and public integrity auditing, and the method comprises the steps: initializing user public and private parameters according to a Setup protocol, and carrying out the preprocessing of user data according to an erasure code; processing the data by the client according to a Put protocol, generating a verification tag, and uploading the data and the verification tag to a plurality of decentralized servers; when a user wants to download data, a Get protocol is triggered; when a user wants to verify the integrity of outsourcing data, triggering a Challenge protocol and a Verify protocol; and when the user wants to update the outsourcing data, triggering the Dynamics protocol. According to the method, a user or a third party is supported to perform integrity auditing on user data, malicious verification between the third party and the server side is effectively prevented by utilizing the block chain in the verification stage, and the verification efficiency is improved; and a user is supported to carry out block-level dynamic updating operation on the data.

Owner:XIDIAN UNIV

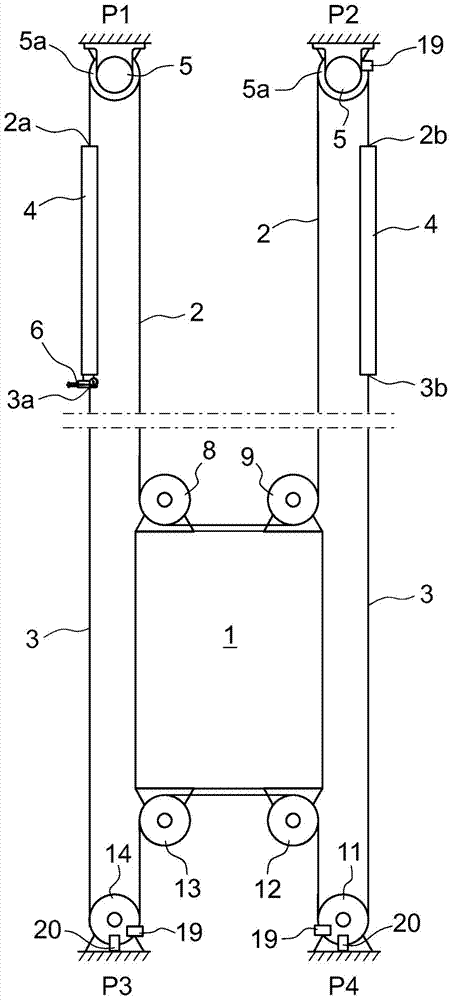

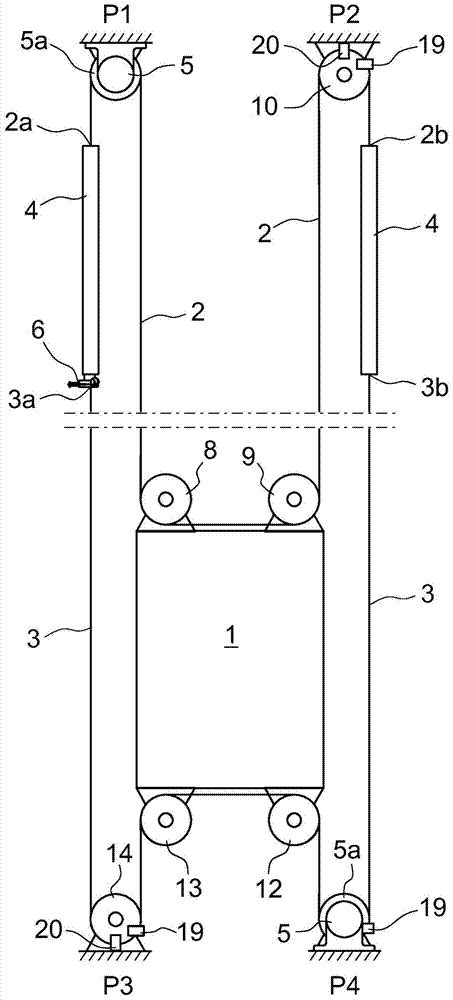

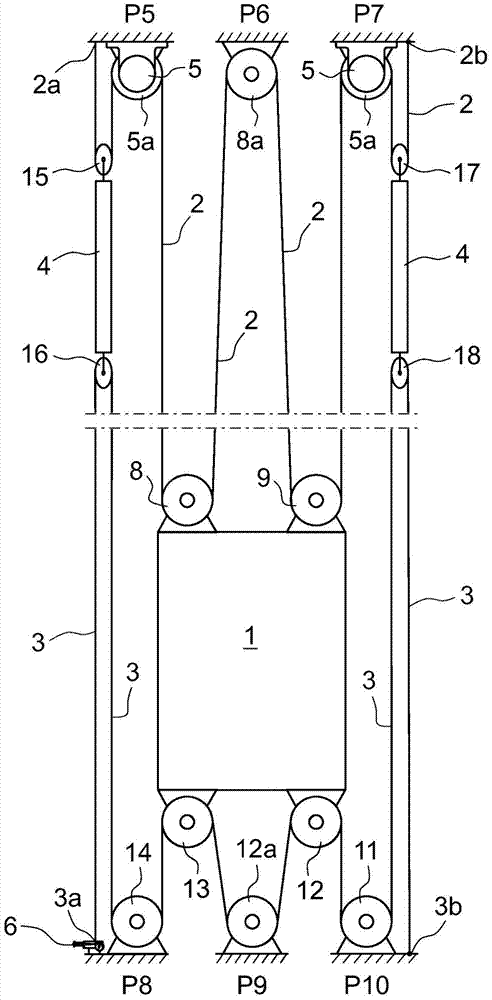

device for reducing the displacement of an elevator car caused by load changes

ActiveCN105358465BImprove energy consumptionImprove controllabilityElevatorsBuilding liftsPulleyAutomotive engineering

An arrangement for reducing the displacement of an elevator car caused by a change in loading includes at least an elevator car configured to move up and down in an elevator hoistway and one or more counterweights, and also at least one rope element above the elevator car and at least one rope element below the elevator car and at least one pretensioner of the rope elements. The elevator car and counterweight are configured to be supported and moved via the rope elements and the pretensioner and rope pulleys, of which rope pulleys the first part are diverting pulleys, and the second part are traction sheaves. The arrangement additionally includes at least two hoisting machines. In the arrangement is a mechanism configured to lock at least two rope pulleys to be non-rotating at least during loading of the elevator car.

Owner:KONE CORP

Light source and method for manufacturing same

ActiveCN105103655BEasy to integrateReduce weightVehicle headlampsElectrical apparatusSurface mountingBuck converter

The invention relates to a light source (1) for integration in a headlamp with a circuit board (3) on which at least one light-emitting diode (LED) is arranged and a method for producing said light source ) (2) and a converter unit (5) for powering said LED (2), wherein said converter unit (5) and said at least one LED (2) are implemented as surface mount devices (surface -mounted device, SMD) and the converter unit (5) has one or more buck converters.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

Method for manufacturing a series of at least one first and one second heat exchangers

PendingCN111089502AAchieve economies of scaleSpacing meansLiquefactionEngineeringMechanical engineering

In a method for producing a series of at least a first and a second plate and fin heat exchanger, each having at least one fluid distribution tank capping at least some of the openings of the matrix unit and which is connected to a pipe, the tank is partitioned into several compartments using at least one partition, so as to distribute the number of openings assigned to a first fluid and to a second fluid, the partition being designed to divide the said tank into several compartments which are each connected to a pipe for the passage of the first fluid or of the second fluid and which each communicate with a number of openings that varies according to the configuration adopted by the at least one partition, for the exchanger of the series.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Circulating air bed device for modification of titanium concentrate

ActiveCN103145182BIncrease productivityShorten the production cycleEnergy inputTitanium dioxideRaw materialOre concentrate

The invention discloses a circulating airflow bed device for continuous production of titanium concentrate modification, which comprises an airflow bed reactor, a titanium concentrate feeding system, a gas inlet system, a waste heat utilization system and a discharge system. The airflow bed The reactor includes an entrained-bed reactor for oxidation roasting and an entrained-bed reactor for reducing roasting. The entrained-bed reactor includes a gas flow distribution section, a gas-solid reaction section, an airflow sorting section and a discharge section, and is provided with a gas inlet, modified There are inert gas inlet, ilmenite concentrate inlet, return material inlet, tail gas outlet and material outlet, and the material outlet includes a large specific gravity material outlet and a small specific gravity material outlet. The device has low requirements on the particle size of raw materials, strong adaptability of raw materials, sufficient and rapid response, high production efficiency, short production cycle, low energy consumption, simple operation and good modification effect.

Owner:YIBIN TIANYUAN GRP CO LTD +1

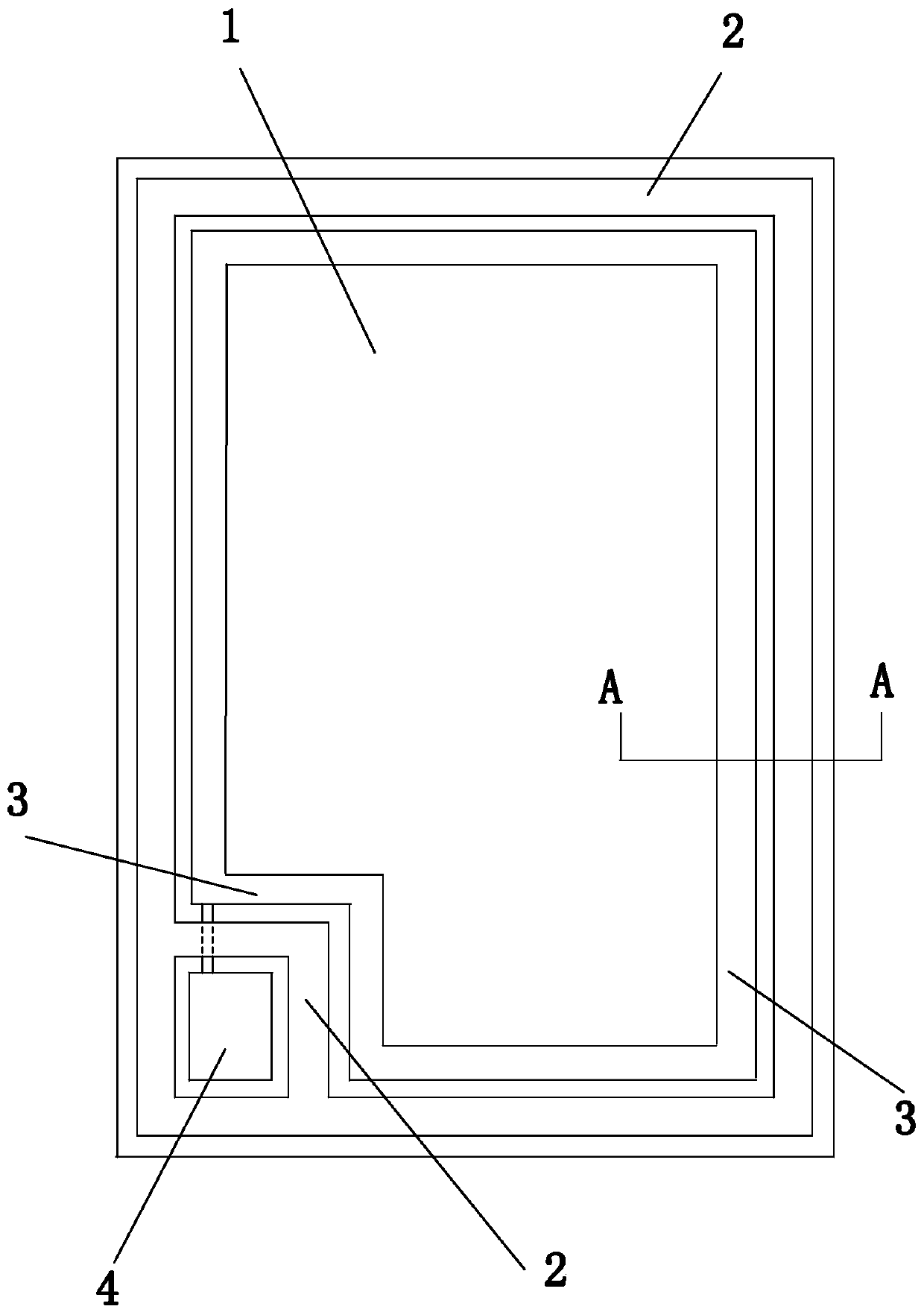

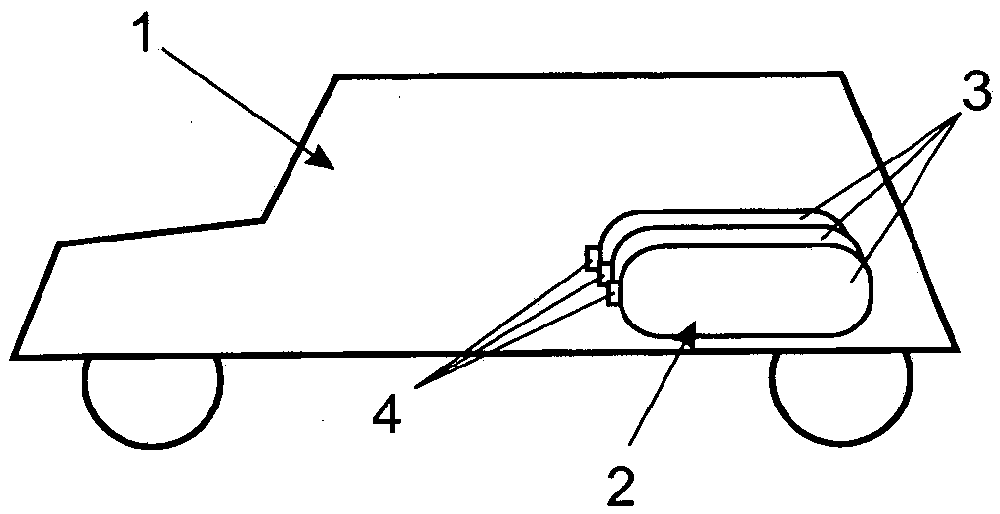

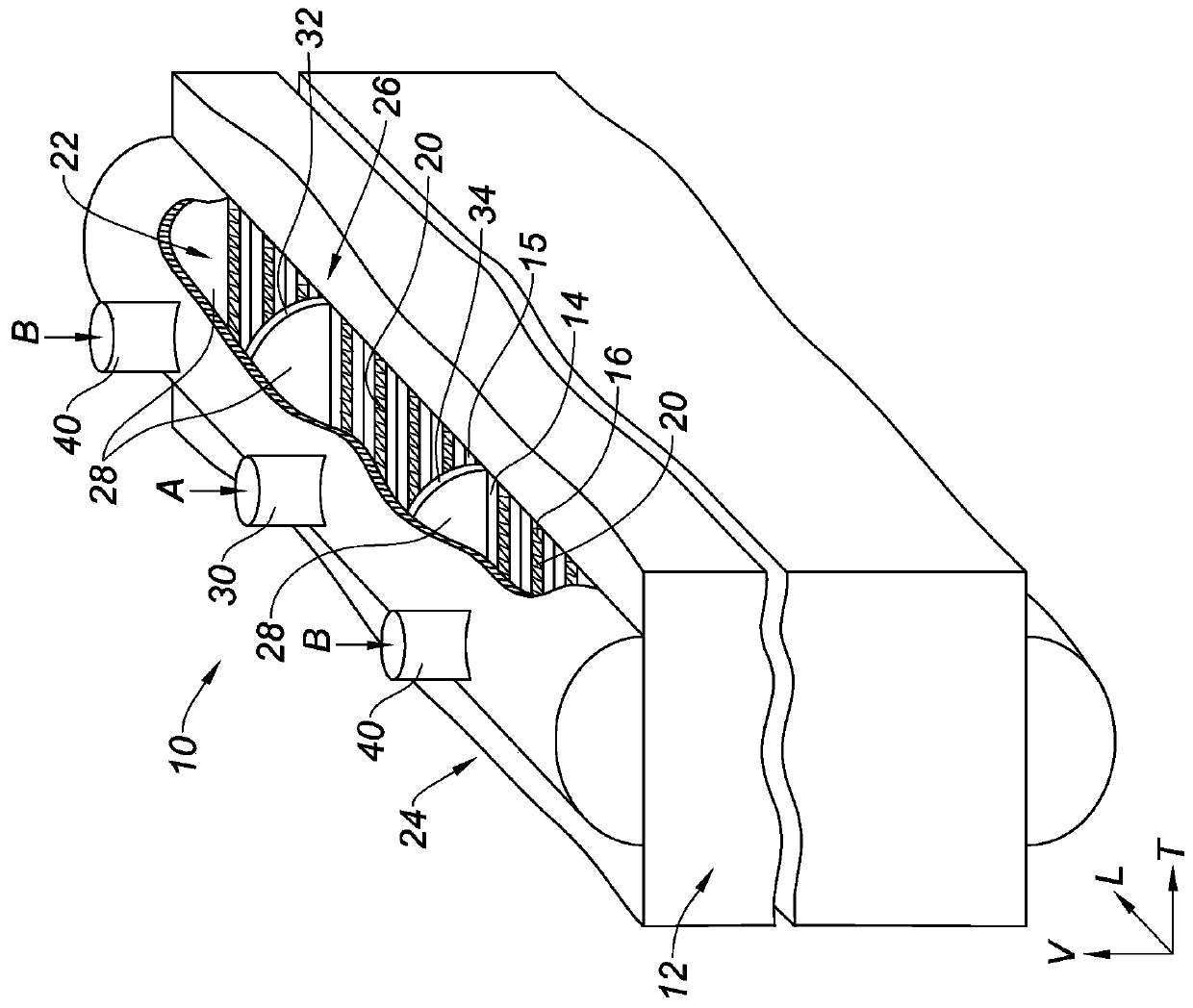

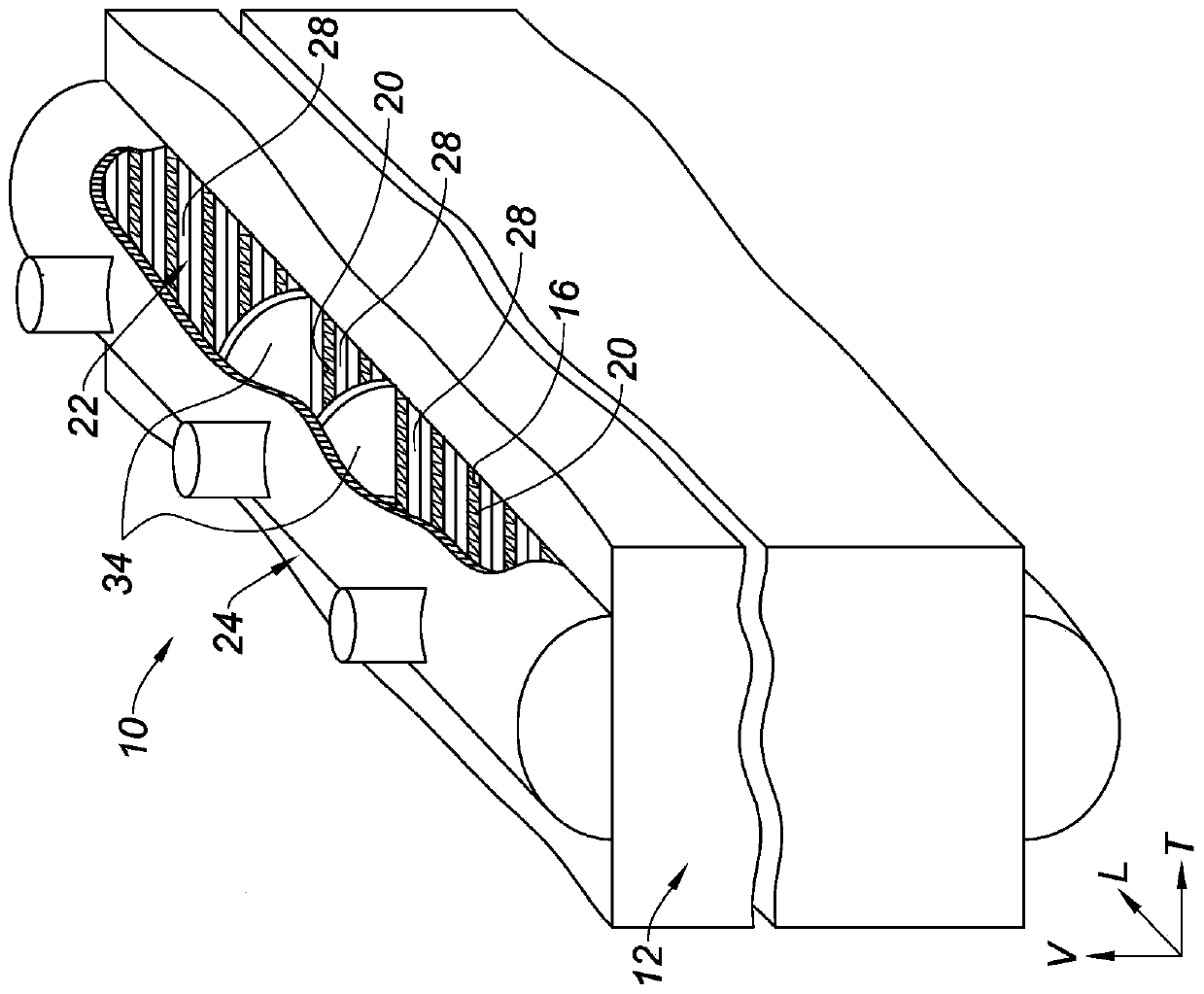

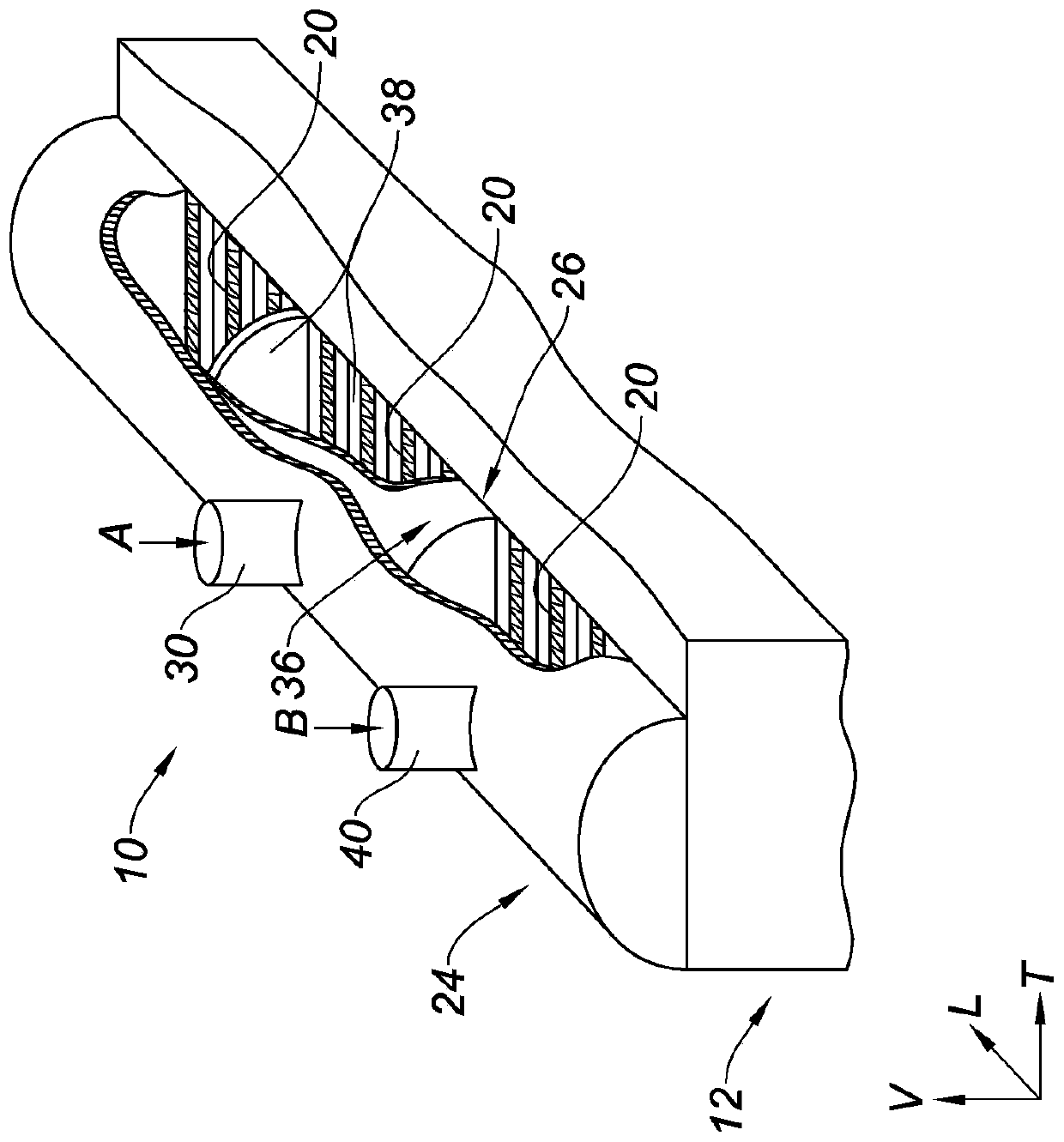

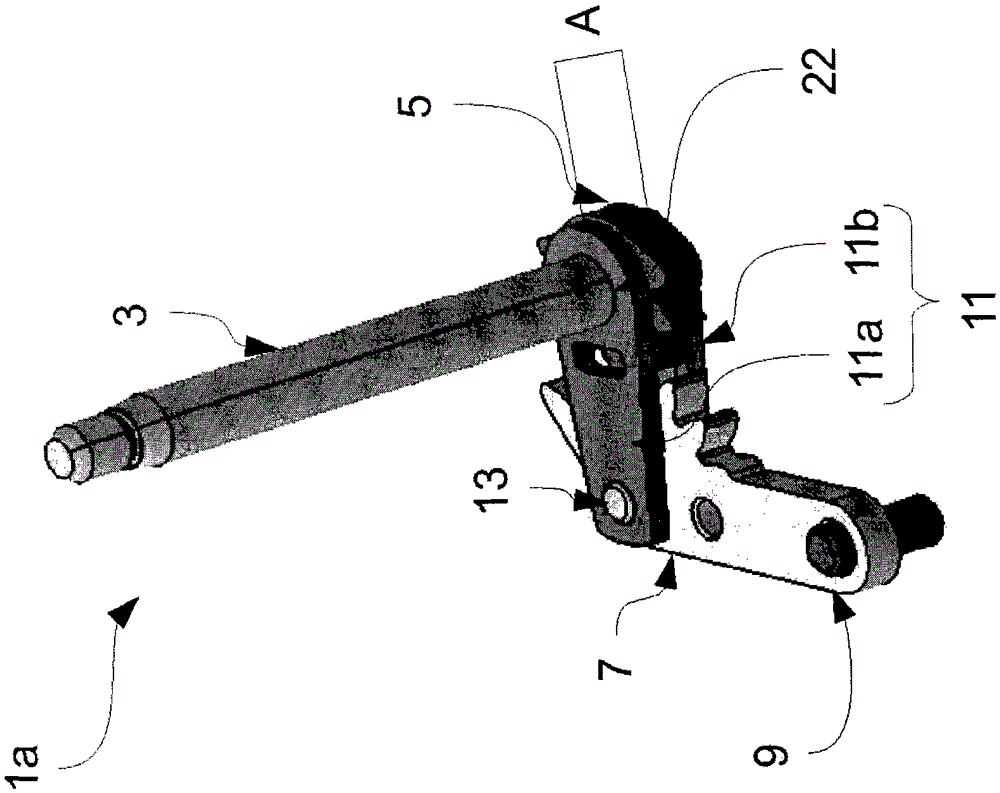

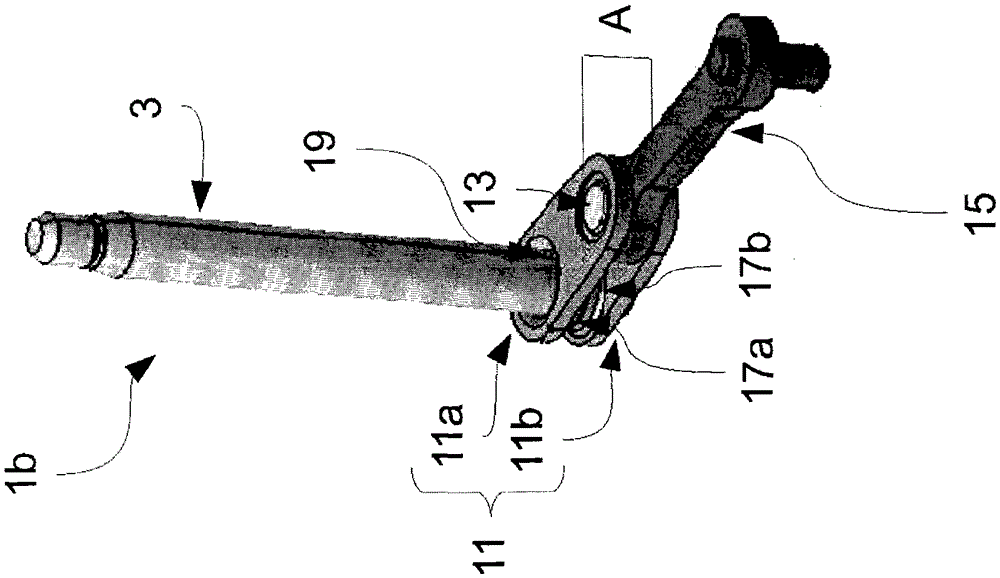

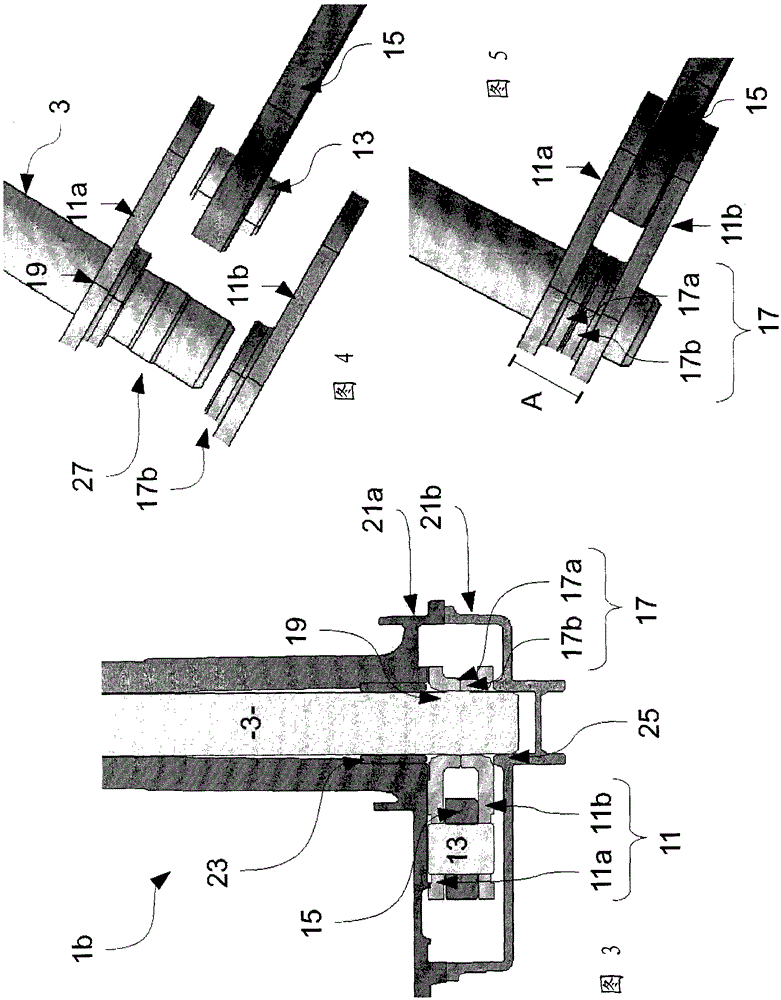

Wiper arm linkage system

ActiveCN103101513BSimplify Supply Chain LogisticsAchieve economies of scaleWindowsVehicle cleaningEngineeringTranslatory motion

The invention relates to a wiper arm coupling system (1b) for converting a rotational movement of a shaft (3) into a translational movement of a connecting rod (15), said coupling system (1b) comprising a coupling system accommodating gear meshes ( 1a) the housing (21), the crank (11) formed by two half-cranks (11a, 11b) engaged with the shaft (3), the pivot (13) at the end of said crank (11), Link (15) articulated to said pivot (13), characterized in that said crank (11) comprises a spacer (17) located between said half-cranks (11a, 11b) when abutting against Spacers (17) are placed with half-cranks (11a, 11b) spaced at least around said shaft (3) in accordance with the thickness (A) of the gear mesh coupling system (1a), so that said housing (21) At least around the shaft (3) is formed a sliding bearing bringing the two half-cranks (11a, 11b) into sliding contact.

Owner:VALEO SYST DESSUYAGE

Recycle for supercritical carbon dioxide

InactiveCN100383074CLow costReduce complexitySolidificationPressurized chemical processSupercritical carbon dioxideEffluent

A method and a system for supplying a carbon dioxide fluid feed from a carbon dioxide purifying means to one or more applications. The feed is combined with contaminants at the applications to form an effluent, and at least one effluent is returned to the purifying means for recycling the carbon dioxide. Carbon dioxide from a carbon dioxide source is combined with the carbon dioxide of the system so that the purity of the carbon dioxide from the source is upgraded prior to the applications.

Owner:PRAXAIR TECH INC

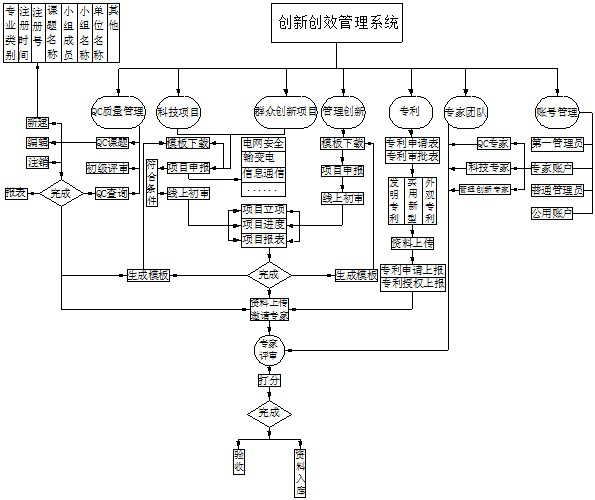

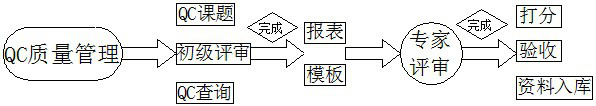

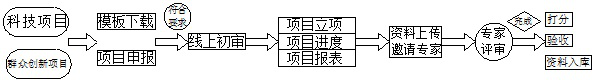

Innovation and creation efficiency management system

PendingCN113642981AImprove coordinationAchieve economies of scaleDatabase management systemsOffice automationNetwork architectureServer

The invention relates to an innovation and creation efficiency management system, which comprises QC quality management, science and technology projects, mass innovation projects, management innovation, patents, expert teams and account management, and is characterized in that the system comprises the QC quality management, the science and technology projects, the mass innovation projects, the management innovation, the patents, the expert teams and the account management; and the account management comprises a first administrator, an expert account, a common administrator and a public account, and the system is divided into three parts of three information centers, a data server and a department unit based on network architecture design, wherein the information center comprises a database server, an application server, a disk array and an authentication server. The data server comprises a backup subsystem. The system has the advantages that centralized management is achieved, benefit maximization is achieved, safe creation is guaranteed, the turnover speed of innovation projects is increased, and efficiency is improved.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN

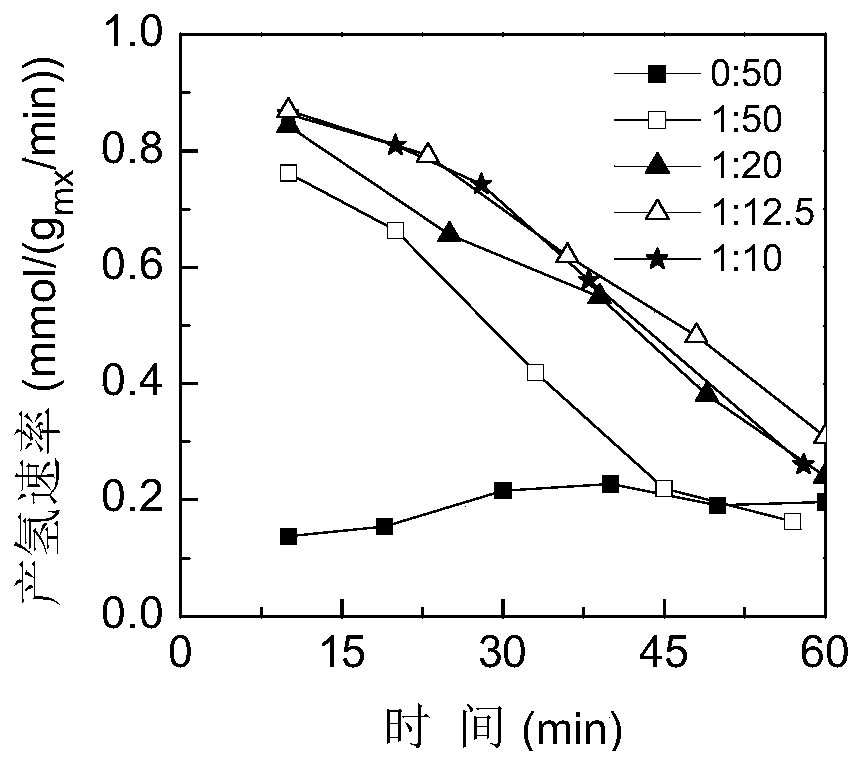

A method for preparing porous carbon-supported metal catalysts by gasification of coal or biomass

ActiveCN107649134BPromote gasification reactionRealize in-situ loadingHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPorous carbon

A method for preparing porous carbon-supported metal catalysts by gasification of coal or biomass. The coal or biomass raw materials are ground to obtain carbon-based raw material particles; the precursor of the main component of the catalyst and the carbon-based raw material particles are evenly mixed, and then Preheat treatment to form a semi-coke supported metal oxide; use the semi-coke supported metal oxide as a material for the gasification reaction, and perform the gasification reaction in the reactor; place the residue after the reaction in step three under inert gas protection The reaction mixture was cooled to below 100°C to obtain a porous carbon-supported metal catalyst. The products of the medium-temperature gasification reaction of coal or biomass are hydrogen-rich gas, porous carbon, and metal oxides, which can promote the catalytic gasification of coal or biomass. In order to control the catalyst preparation process, a new process technology was developed in which metal catalysts are supported on porous carbon in situ and can be reduced in situ.

Owner:NORTHWEST UNIV

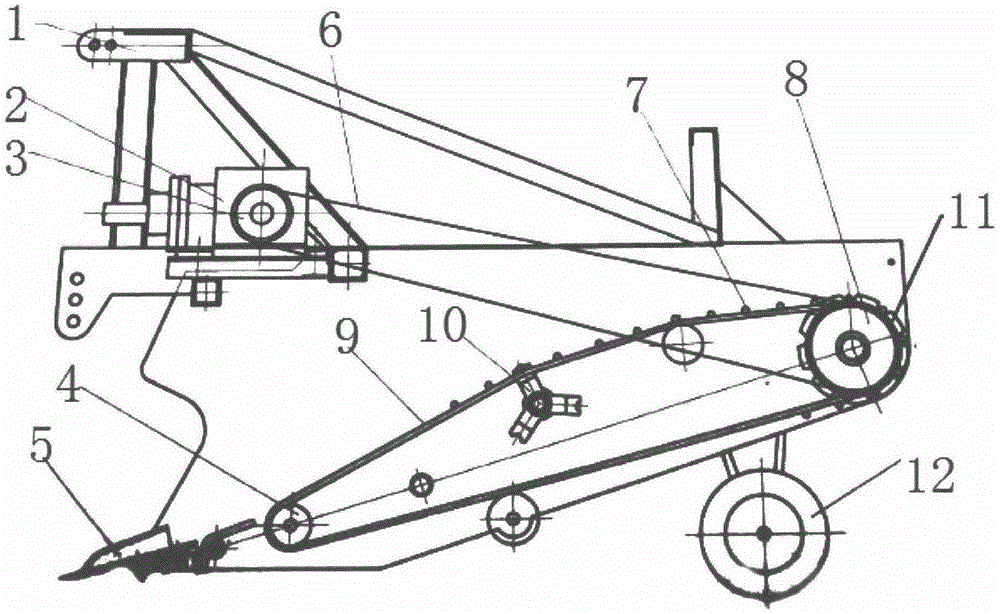

Cassava combine

The invention discloses a cassava combine which comprises a frame, a gear transmission box, a driving chain wheel, a conveying screen driven wheel, a shovel, a chain, a screen grid bars, a driven chain wheel, conveying screens, a bucket pulley, a conveying screen driving wheel and a depth limiter wheel. The gear transmission box is disposed on the frame, the driving chain wheel is disposed inside the gear transmission box and is connected with the driven chain wheel through the chain, the driven chain wheel and the conveying screen driving wheel are coaxial, the conveying screen driving wheel is connected with the conveying screen driven wheel through the conveying screens, the screen grid bars are disposed on the conveying screen, the bucket pulley is disposed between the conveying screens, and the shovel and the depth limiter wheel are disposed in the front and rear of the bottom of the frame, respectively. The cassava combine is friendly to the harvest, may be lower in power consumption and higher in machine utilization, is high in digging rate and low in breakage rate and may provide economies of scale.

Owner:南宁市鼎天机械制造有限公司

A drying-pyrolysis integrated vertical furnace

ActiveCN107227165BImprove heat utilizationBroaden the effective particle size rangeSpecial form destructive distillationHeat carrierThermodynamics

A drying-pyrolysis integrated vertical furnace, which uses a baffled (similar to a continuous S-shaped) conveyor belt operating in a three-dimensional space of 3 to 30 sections as a material conveying device. The vertical furnace uses high-temperature gas (or High-temperature flue gas) as a gas heat carrier and the material coal or biomass are exchanged in multiple staggered countercurrents to achieve heat exchange. The bottom-to-top temperature gradient of the gas heat carrier is used to gradually realize the drying and low-temperature heat of the material coal or biomass from top to bottom. decomposition and medium- to high-temperature pyrolysis. This vertical furnace has a wide range of material particle sizes. It can realize the integration of drying and pyrolysis of coal or biomass in the same furnace, and can effectively use the flue gas generated by pyrolysis of coal or biomass to cool the outlet of the vertical furnace. The hot semi-coke can be used to regulate the temperature of the gas heat carrier, thereby improving the thermal energy utilization of the vertical furnace. It has simple design, flexible and simple operation, low investment cost and is easy for industrial application.

Owner:NORTHWEST UNIV

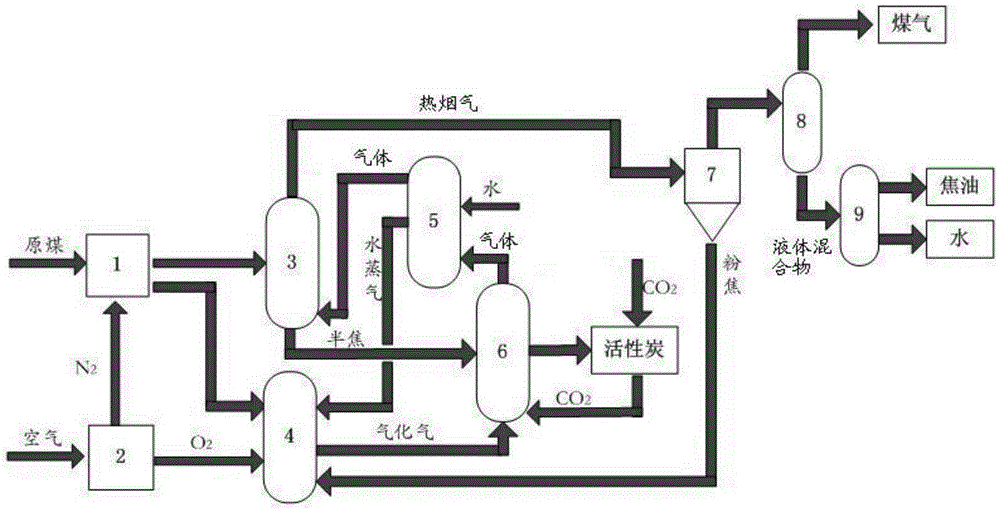

Coal gasification, pyrolysis combined production activated carbon system and process

ActiveCN104357092BSolve the use problemSimple and fast operationCarbon compoundsDirect heating destructive distillationHeat carrierWater vapor

The invention discloses a system and process for producing active carbon by virtue of coal gasification and pyrolysis, and provides a coal base poly-generation process technology. The main body part of the system comprises three process units for coal pyrolysis, coal gasification and active carbon preparation as well as a first steam generator and a second steam generator, wherein the high-temperature gasification gas generated by the coal gasification unit is sequentially used as a heat carrier for the first steam generator and the coal pyrolysis unit, and the carbocoal generated by the coal pyrolysis unit is used as a carbon source for the active carbon preparation unit and a fuel for a main body heat source; and the first steam generator provides steam as a gasification agent (or oxidant) for the coal gasification unit, the steam generated by the second steam generator serves as part of an activator of the active carbon preparation unit, and the high-temperature tail gas generated by the active carbon preparation unit serves as a heat source of the second steam generator. By adopting the system and the process disclosed by the invention, the problem that the conventional pyrolysis process cannot effectively use pyrolysis carbocoal is solved, and a co-production technical route of three coal base products including active carbon, coal gas and tar is realized.

Owner:SHAANXI COAL & CHEM TECH INST

A system and method for coal pyrolysis combined production of activated carbon

The invention discloses a system and a method for the joint production of activated carbon by virtue of coal pyrolysis. The main part of the system comprises a vapor generator and three process units, namely a coal pyrolysis unit, a coal gasification unit and a pyrolysis semicoke carbonization unit. High-temperature gasified gas produced by the coal gasification unit sequentially serves as heat source carriers of the pyrolysis semicoke carbonization unit, the vapor generator and the coal pyrolysis unit, thereby realizing the gradient utilization of the sensible heat of the high-temperature gasified gas; hot semicoke generated by the coal pyrolysis unit is converted into activated carbon on the spot by the pyrolysis semicoke carbonization unit, thereby realizing the utilization of the sensible heat of the hot semicoke; water vapor provided by the vapor generator to the coal gasification unit servers as a gasifying agent or an oxidizing agent. According to the system, the technical route of poly-generation of coal gas, tar and activated carbon is realized; the system is simple in design, high in energy utilization rate, strong in practicability and is convenient for industrial application.

Owner:SHAANXI COAL & CHEM TECH INST

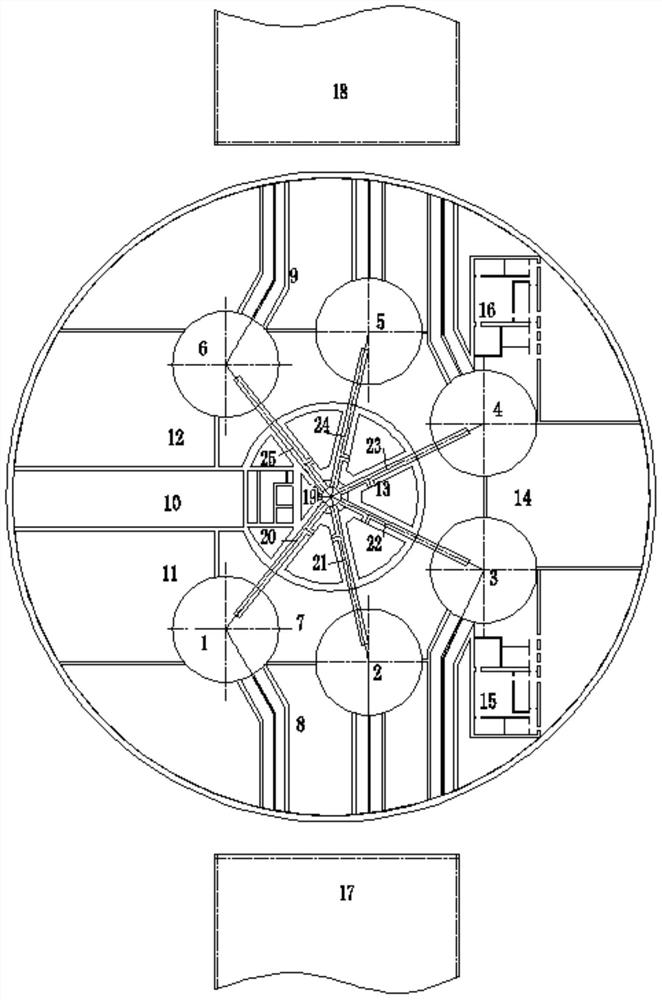

A layout structure of a multi-reactor nuclear power plant

ActiveCN106024081BSimple operating systemImprove seismic performanceNuclear energy generationNuclear plant auxillary equipmentNuclear engineeringNuclear power

Owner:CHINA NUCLEAR POWER ENG CO LTD

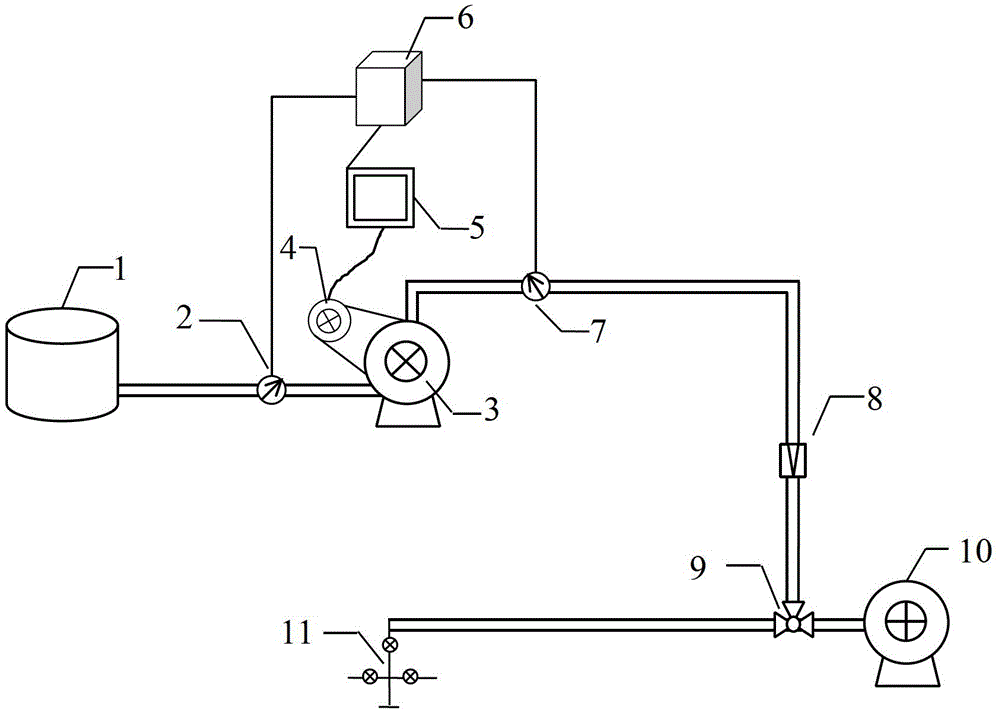

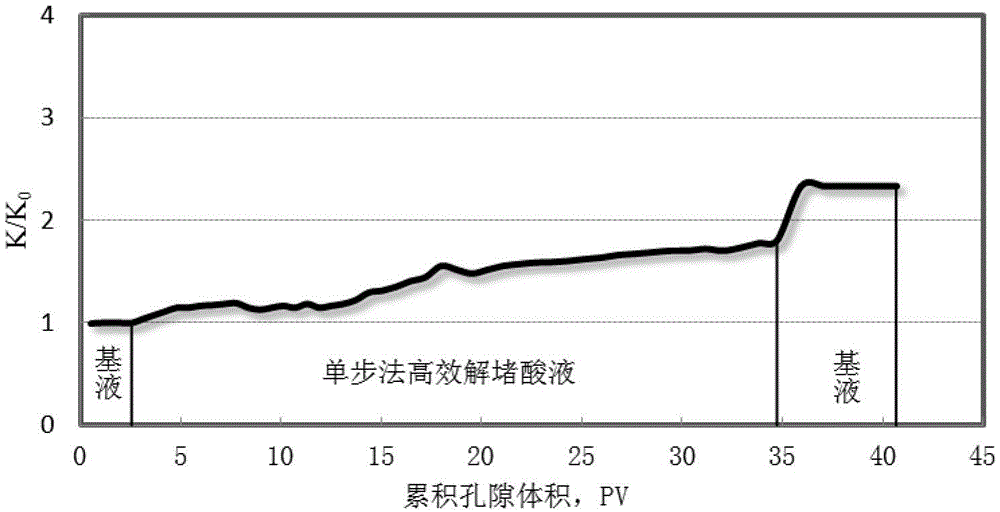

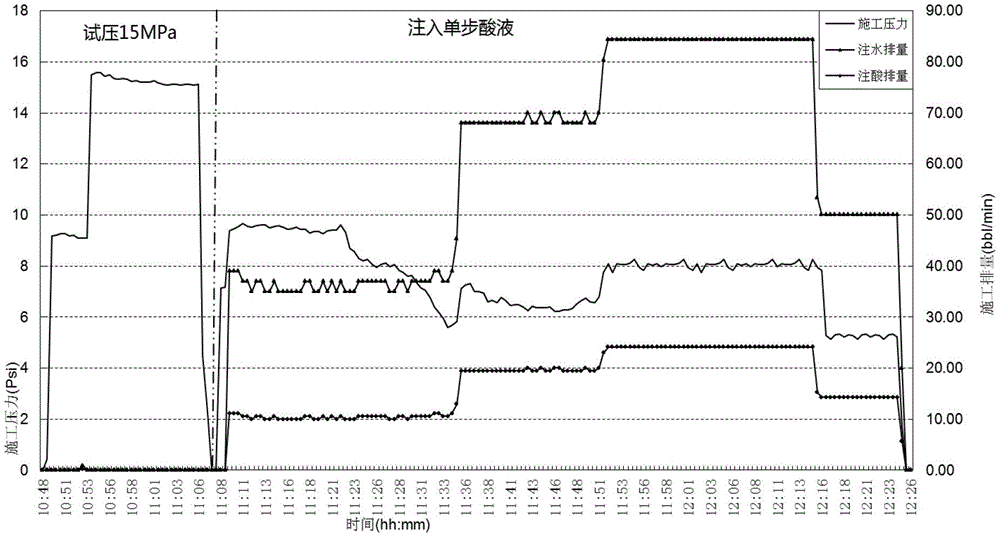

Offshore oilfield water injection well online one-step-process acidification technology

ActiveCN102828734BConfiguration labor intensity is reducedShorten construction timeFluid removalDrilling compositionAcetic acidHydrogen fluoride

Owner:SOUTHWEST PETROLEUM UNIV +1

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjustingthe temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com