Tank valve

A storage tank and valve body technology, which is applied in the application field of storage tank valves, can solve the problems of high manufacturing cost, reforming drilling tools, increasing storage tank valve configuration time and manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

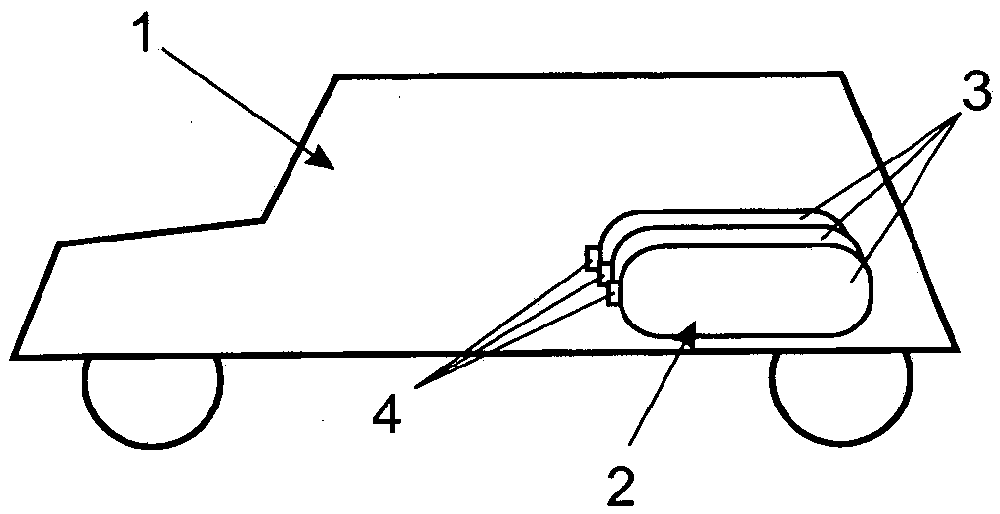

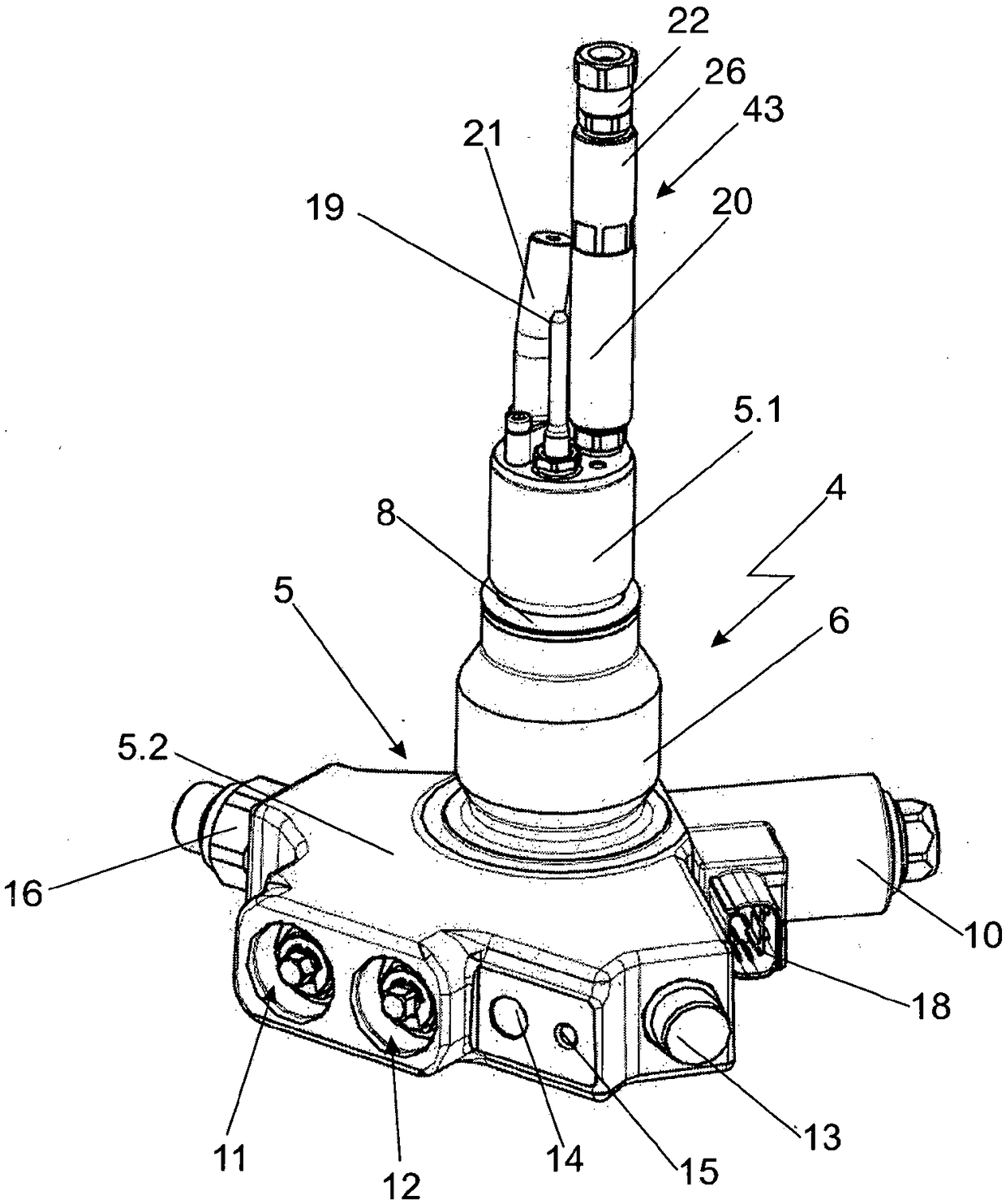

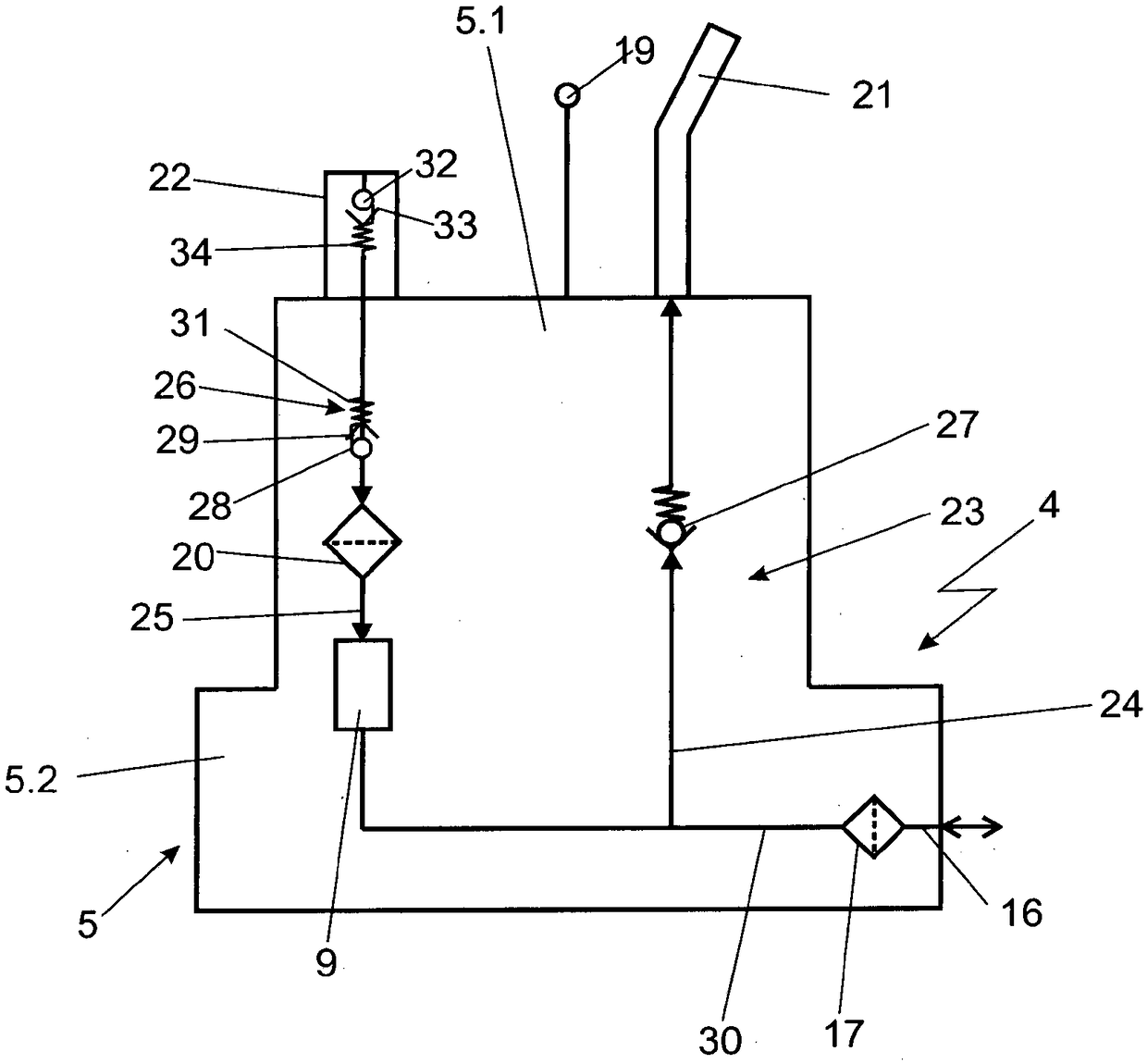

[0030] figure 1 The vehicle 1 is shown purely by way of example. This vehicle is powered by gaseous fuels such as compressed natural gas or compressed hydrogen. For this purpose, the fuel can be converted into power for the drive in the internal combustion engine or, especially when hydrogen is used, preferably also in the fuel cell system. In order to store compressed gas, there is a storage device designated as a whole with 2 in the vehicle 1 . This storage device consists of several individual compressed gas containers 3 each having a tank valve 4 . The storage tank valve 4 is also called On-Tank-Valve, or OTV for short. Therein, the individual compressed gas containers 3 together with their storage tank valves 4 can be connected to one another, for example in a manner known from the aforementioned prior art, via common pipes in order to be able to use the gas from the storage device 2 in the vehicle. The nominal pressure of such a compressed gas container 3 with storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com