System and process for producing active carbon by virtue of coal gasification and pyrolysis

A joint production and coal gasification technology, applied in the field of coal chemical industry, can solve the problems of ineffective use of pyrolysis semi-coke, etc., and achieve the effect of realizing light weight, improving heat energy utilization rate and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

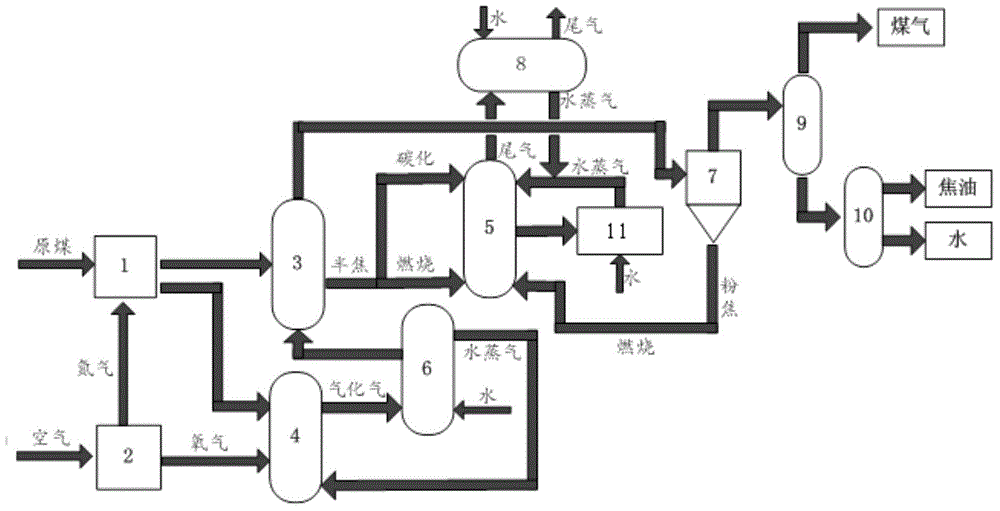

[0038] combine figure 1 , the coal gasification, pyrolysis joint production activated carbon system and process route of the present invention are described in detail as follows:

[0039] The coal gasification and pyrolysis joint production activated carbon process technology proposed by the present invention mainly includes three process units of coal gasification 4, coal pyrolysis 3 and activated carbon preparation 5, using high-temperature gasification gas produced by coal gasification as the heat carrier of coal pyrolysis , the semi-coke produced by coal pyrolysis is used as the carbon source for the preparation of activated carbon and the fuel for the main heat source to solve the utilization problem of coal pyrolysis semi-coke on the spot, thus providing a coal-based polygeneration process technology.

[0040] Coal gasification and pyrolysis joint production activated carbon system, including coal preparation system 1, air separation unit 2, coal pyrolysis unit 3, coal g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com