Recycle for supercritical carbon dioxide

A carbon dioxide and catalytic oxidation technology, applied in liquefaction, inorganic chemistry, carbon compounds, etc., can solve the problems that economic feasibility cannot be completely relied on, and no system or method is pointed out, so as to reduce cost and complexity, reduce production cost, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

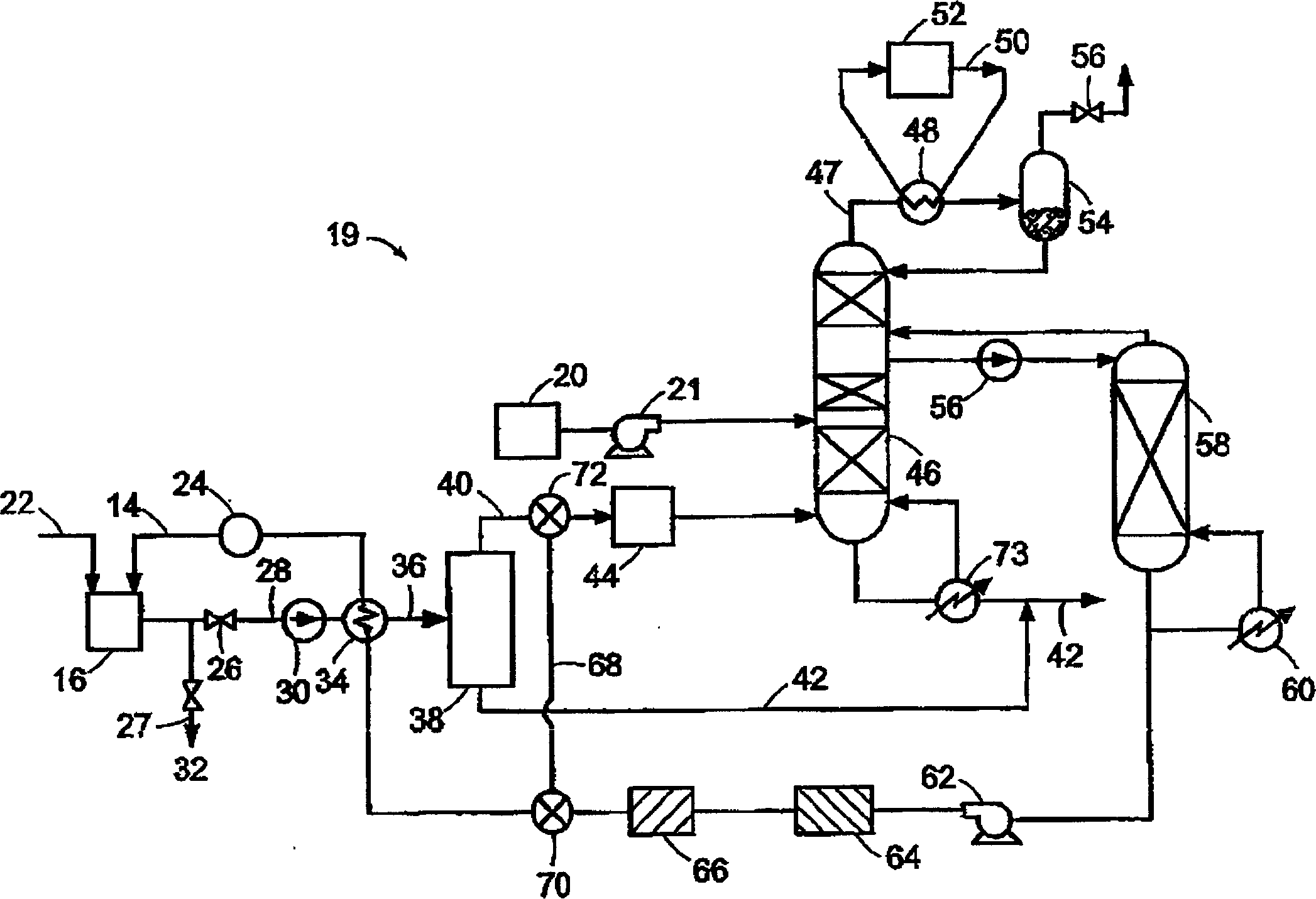

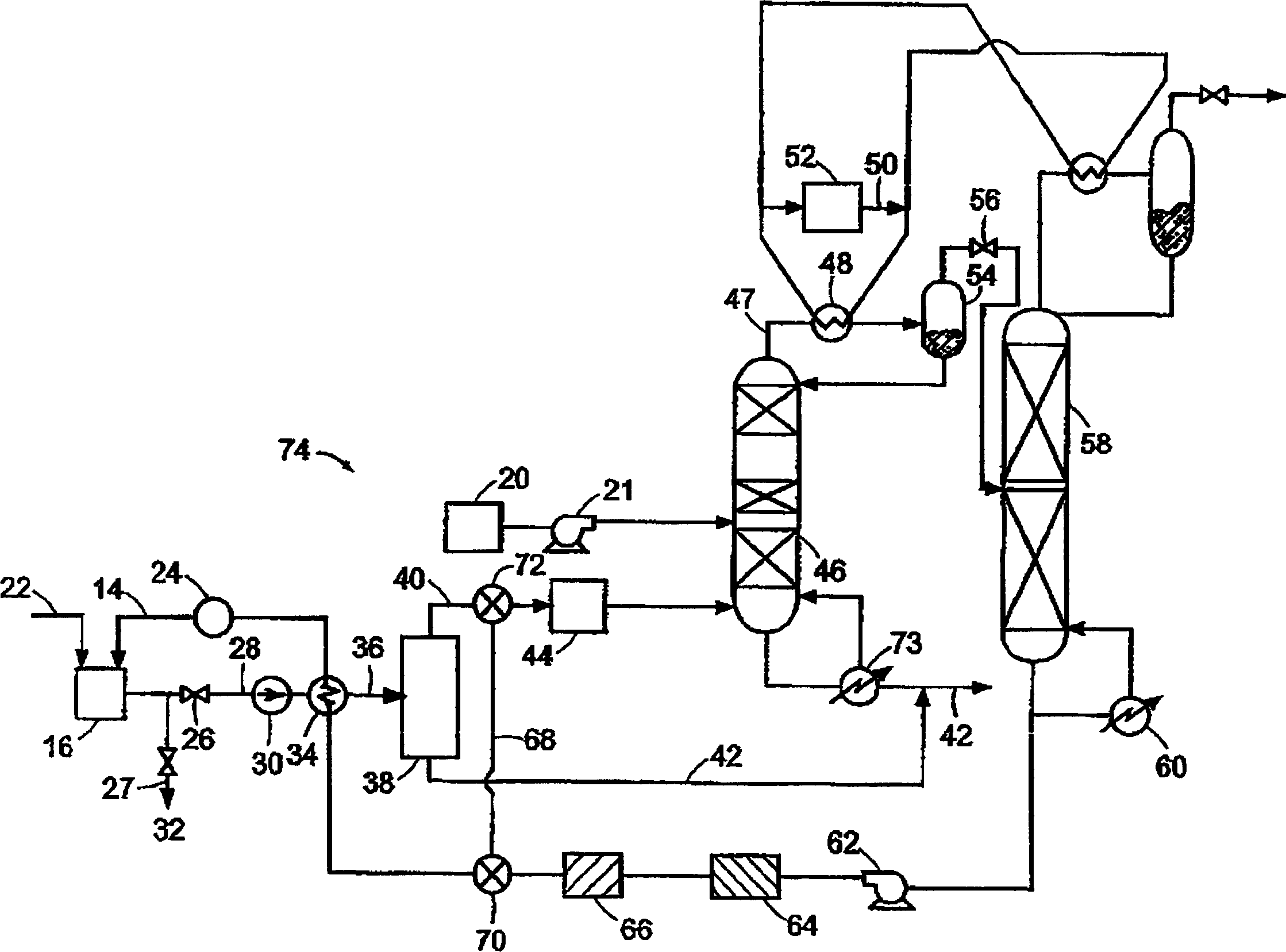

[0048] Table 1 gives the corresponding Figure 4 Values for the flow conditions and compositions of the individual material streams of the process shown. In this example, the expanded stream undergoes phase separation at reduced temperature in vessel 38 and is warmed to ambient temperature before entering first distillation column 46 . Impurities considered should include oxygen, nitrogen, methane (introduced with the added liquid), water, hexane, propylene carbonate, acetone and ethyl acetate. For these impurities, reactor 44 and heat exchanger 80 between columns 46 and 58 are not required. Furthermore, condensers 48 and 82 are preferably operated in the same unit.

[0049] The energy flows are listed in Table 2. The cooling power can be estimated based on the usage of the ammonia refrigeration loop. It can be assumed that this loop can power the reboilers 41 and 44 and that the cold water for condensing the high pressure ammonia vapor in the refrigeration loop is avail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com