Method for manufacturing a series of at least one first and one second heat exchangers

一种制造方法、换热器的技术,应用在换热器外壳、间接换热器、换热器类型等方向,能够解决制造所需时间长、制造所需时间不能缩短、高成本等问题,达到减少制造所需时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

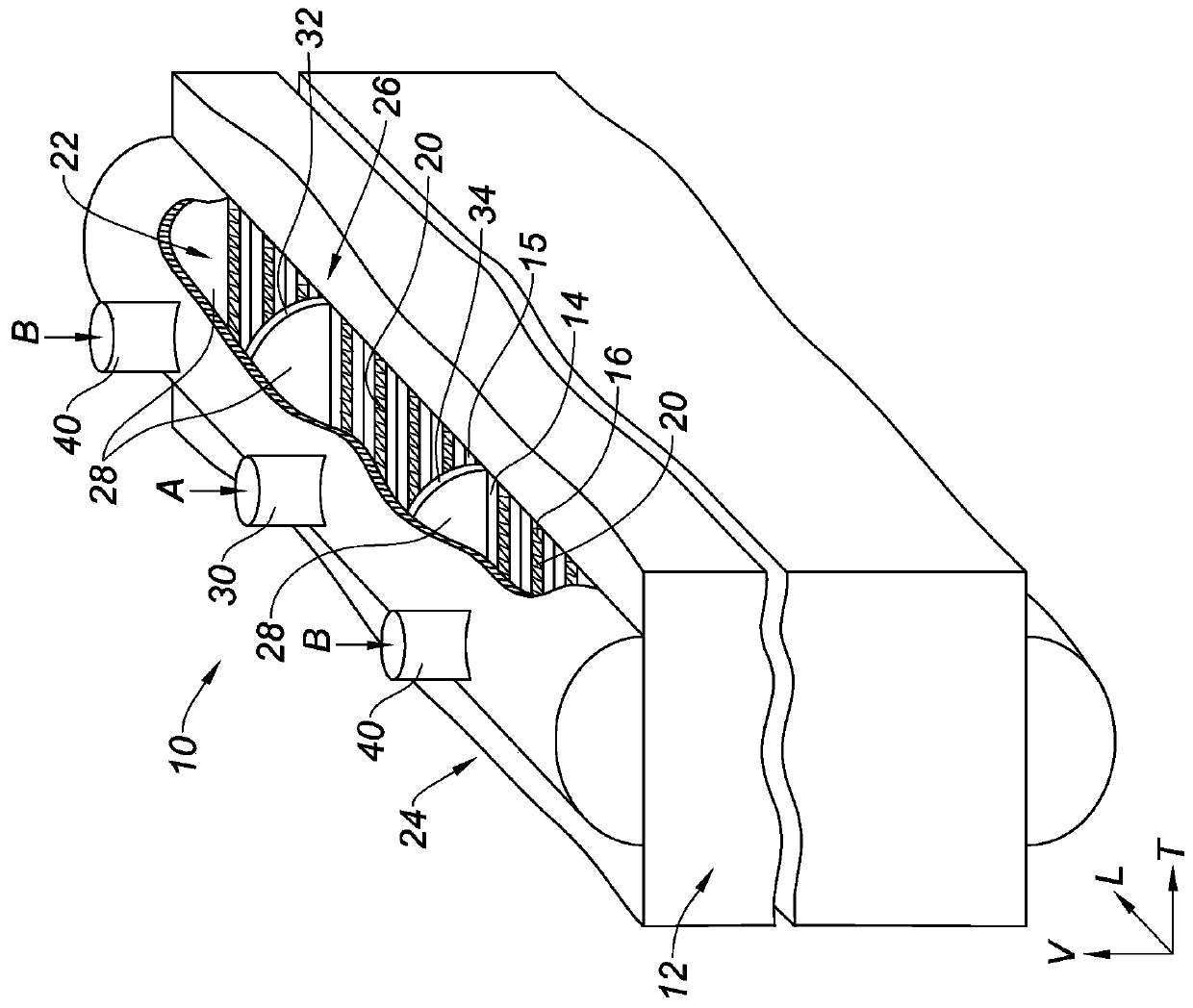

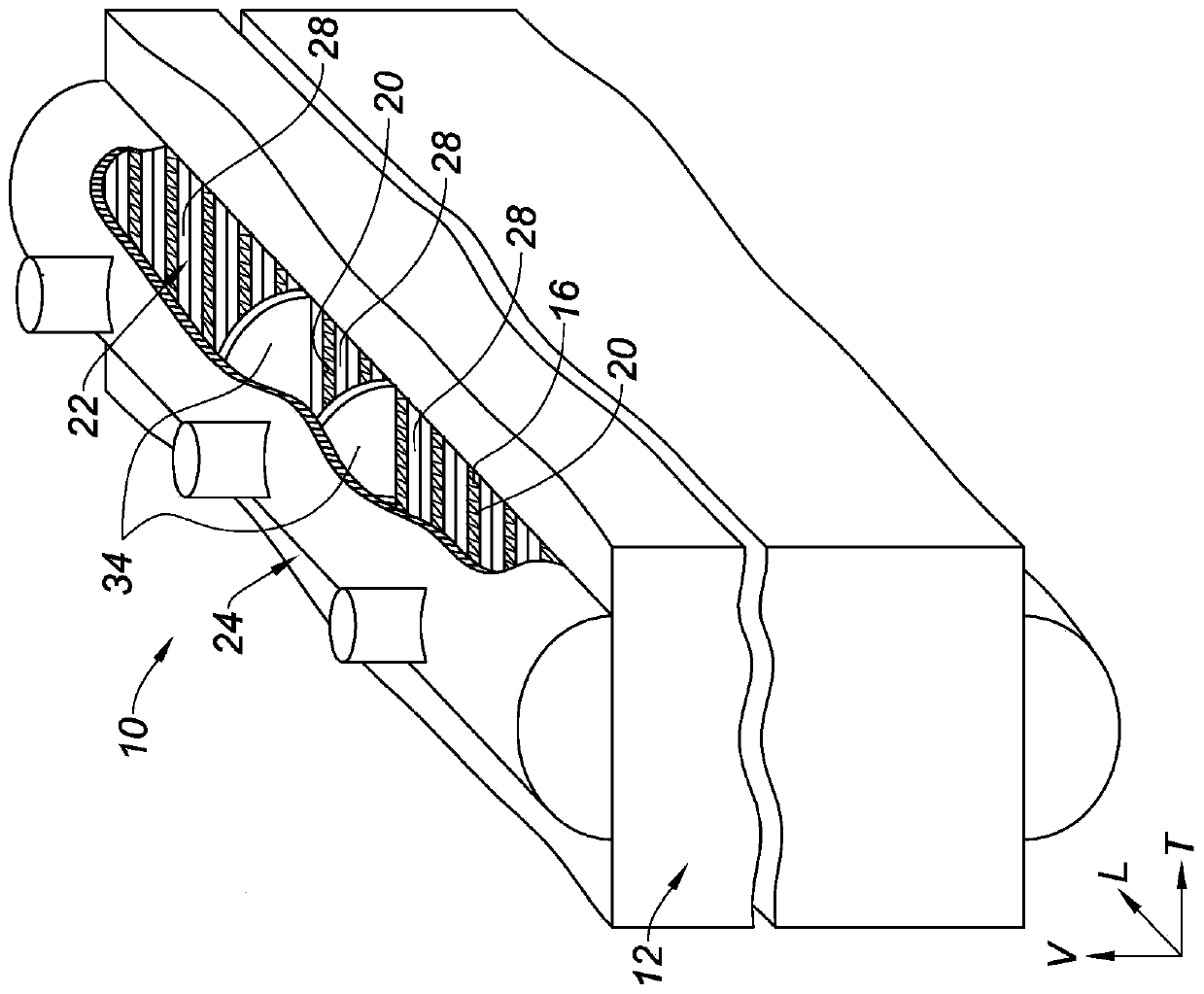

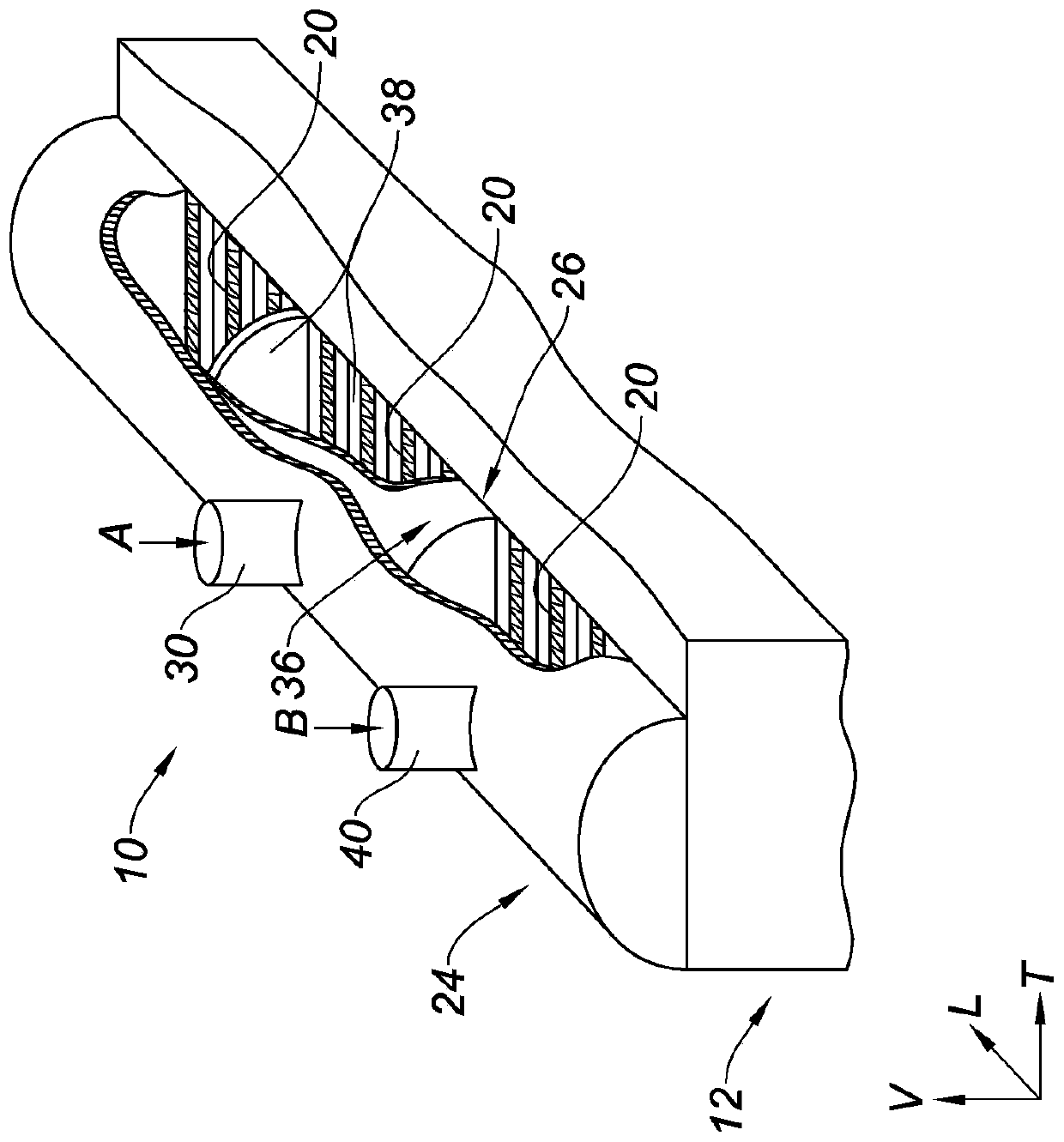

[0051] The description and claims will use, without limitation, the terms longitudinal, vertical and transverse adopted with reference to the trihedral frame of references L, V, T shown in the drawings. The stacking direction L of the sheets is perpendicular to the length in the vertical direction V and the width in the transverse direction T of the partition sheets 15 . The separating web is shown in shortened form; in fact, its length in the vertical direction V is much greater than its width in the transverse direction T.

[0052] For various alternative forms of embodiment, the same reference numerals may be used for elements that are the same or that perform the same function in order to simplify the description.

[0053] figure 1 Shown is a heat exchanger 10 of the brazed plate type, which is particularly intended to equip air separation units.

[0054]The heat exchanger 10 comprises a matrix unit 12 comprising a continuous stack of divider plates 15 and corrugated fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com