A system and method for coal pyrolysis combined production of activated carbon

A technology of joint production and coal pyrolysis, applied in the field of coal chemical industry, can solve the problems of restricting the development path of coal pyrolysis semi-coke, restricting the rapid development of coal pyrolysis process, and high cost of effective synthesis gas gasification, so as to meet environmental protection and economic efficiency, achieving economies of scale, and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings:

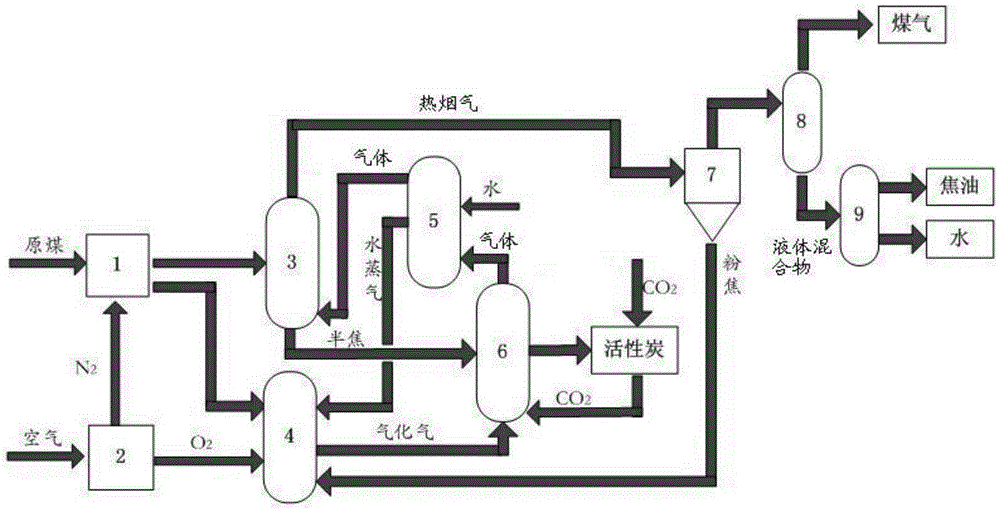

[0027] See figure 1 , A coal pyrolysis combined production system of activated carbon, including coal preparation and gas supply system, activated carbon production system and hot flue gas separation system, the activated carbon production system includes coal pyrolysis unit 3, coal gasification unit 4, pyrolysis semi-coke The carbonization unit 6 and the steam generator 5, the oxygen outlet of the coal preparation and gas supply system are connected to the oxygen inlet of the coal gasification unit 4, and the two coal particle outlets of the coal preparation and gas supply system are respectively connected to the coal pyrolysis unit 3 and coal gasification unit The coal particle inlet of unit 4 is connected; the coal preparation and gas supply system includes a coal preparation device 1 and an air separation device 2. The raw coal inlet of the coal preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com