Oxygen top blown converter steel making method

A converter steelmaking and oxygen top blowing technology, applied in the manufacture of converters, etc., can solve the problems of low desulfurization and dephosphorization capacity, long slagging time, and short slagging time, so as to improve metal yield and reduce auxiliary material consumption , the effect of shortening the smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example is used to illustrate the oxygen top-blown converter steelmaking method provided by the present invention.

[0027] Put 150 tons of molten iron into the converter for smelting, wherein the composition and temperature of the molten iron are shown in Table 1 below, then blow oxygen into it and add auxiliary materials, the total of the added auxiliary materials (lime, high magnesium lime and acidic composite slag) The weight and the total amount of oxygen blown are shown in Table 2.

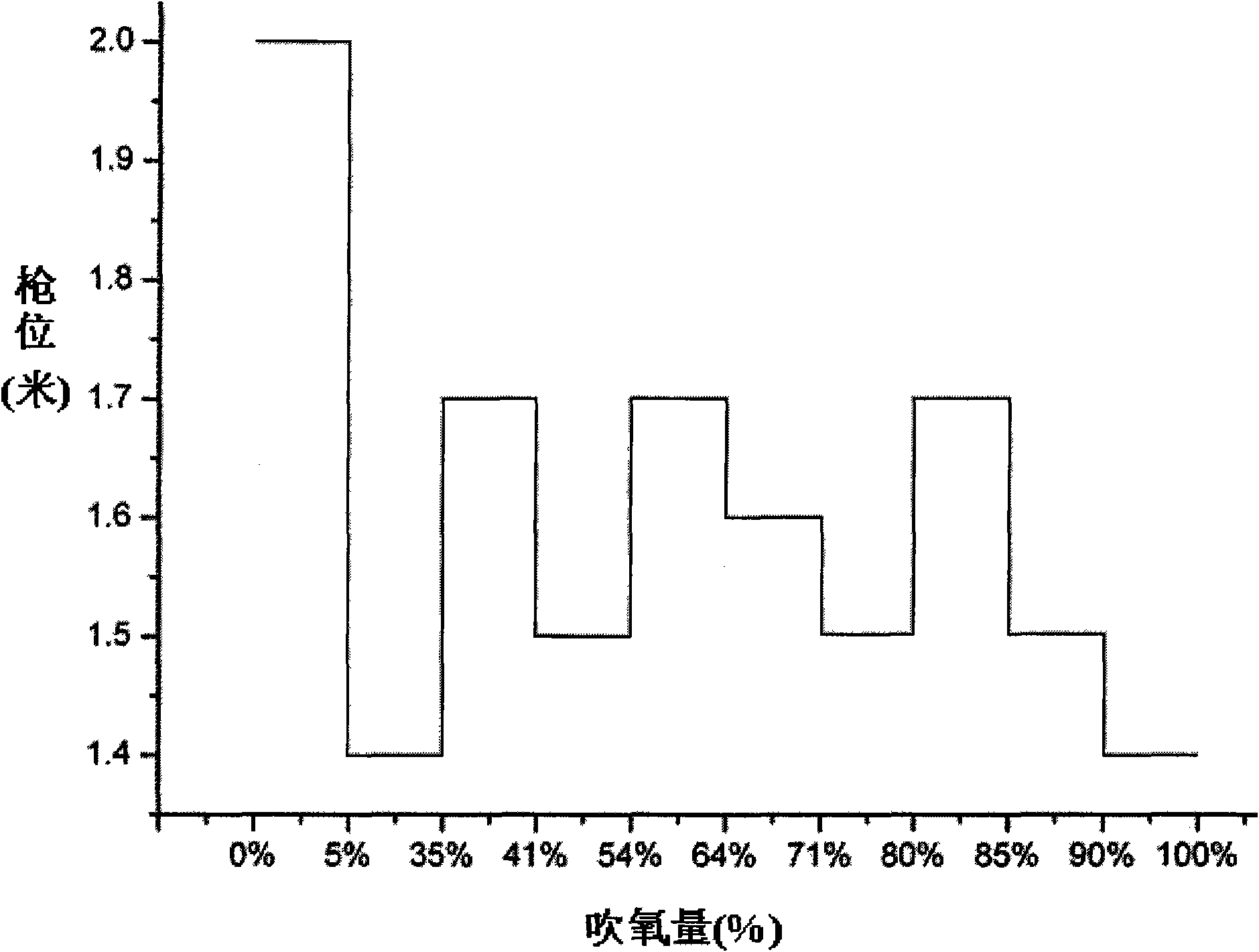

[0028] The corresponding relationship between the addition method of auxiliary materials and the amount of oxygen blowing is: taking the total amount of oxygen blown as a benchmark, when the amount of oxygen blowing is 1%, 60% by weight of lime and 67% by weight of high magnesium lime are added When the amount of oxygen blowing is 4%, 50% by weight of the total amount of composite slag is added; when the amount of oxygen blowing is 35%, 20% by weight of the total amount of lime i...

Embodiment 2

[0040] This example is used to illustrate the oxygen top-blown converter steelmaking method provided by the present invention.

[0041] Put 132 tons of molten iron into the converter for smelting, and then add 6.5 tons of steel scrap, wherein the composition of the molten iron and steel scrap and the furnace temperature of the molten iron are shown in Table 4 below, then blow oxygen into it and add auxiliary materials, the added auxiliary materials ( The total weight of lime, high magnesium lime, composite slag and sludge pellets (produced from finely powdered converter sludge containing 45-50% metallic iron) and the total amount of blown oxygen are shown in Table 5.

[0042] According to the carbon content of the molten iron, the static steelmaking model is used to calculate by computer that it is necessary to add a coolant to cool the steelmaking system by 60°C.

[0043] The corresponding relationship between the way of adding auxiliary materials and the amount of oxygen blo...

Embodiment 3

[0053] This example is used to illustrate the oxygen top-blown converter steelmaking method provided by the present invention.

[0054] Put 137.96 tons of molten iron into the converter for smelting, and then add 9.241 tons of scrap steel, wherein the composition of the molten iron and scrap steel and the furnace temperature of the molten iron are shown in Table 7 below, then blow oxygen into it and add auxiliary materials, the added auxiliary materials ( The total weight of lime, high magnesium lime, composite slag and sludge pellets (produced from finely powdered converter sludge containing 45-50% metallic iron) and the total amount of blown oxygen are shown in Table 8.

[0055] According to the carbon content of the molten iron and the amount of steel scrap added, the static steelmaking model is used to calculate by computer that it is necessary to add a coolant to cool the steelmaking system by 72°C.

[0056]The corresponding relationship between the way of adding auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com