Preparation method of IF (Interstitial Free) steel containing phosphorus, silicon and manganese

A technology of molten steel and content, applied in the field of metallurgy, can solve the problems of difficult composition adjustment, long continuous casting pouring cycle, affecting slab quality, etc., and achieve the effects of shortening smelting time, improving production efficiency, and improving slab quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

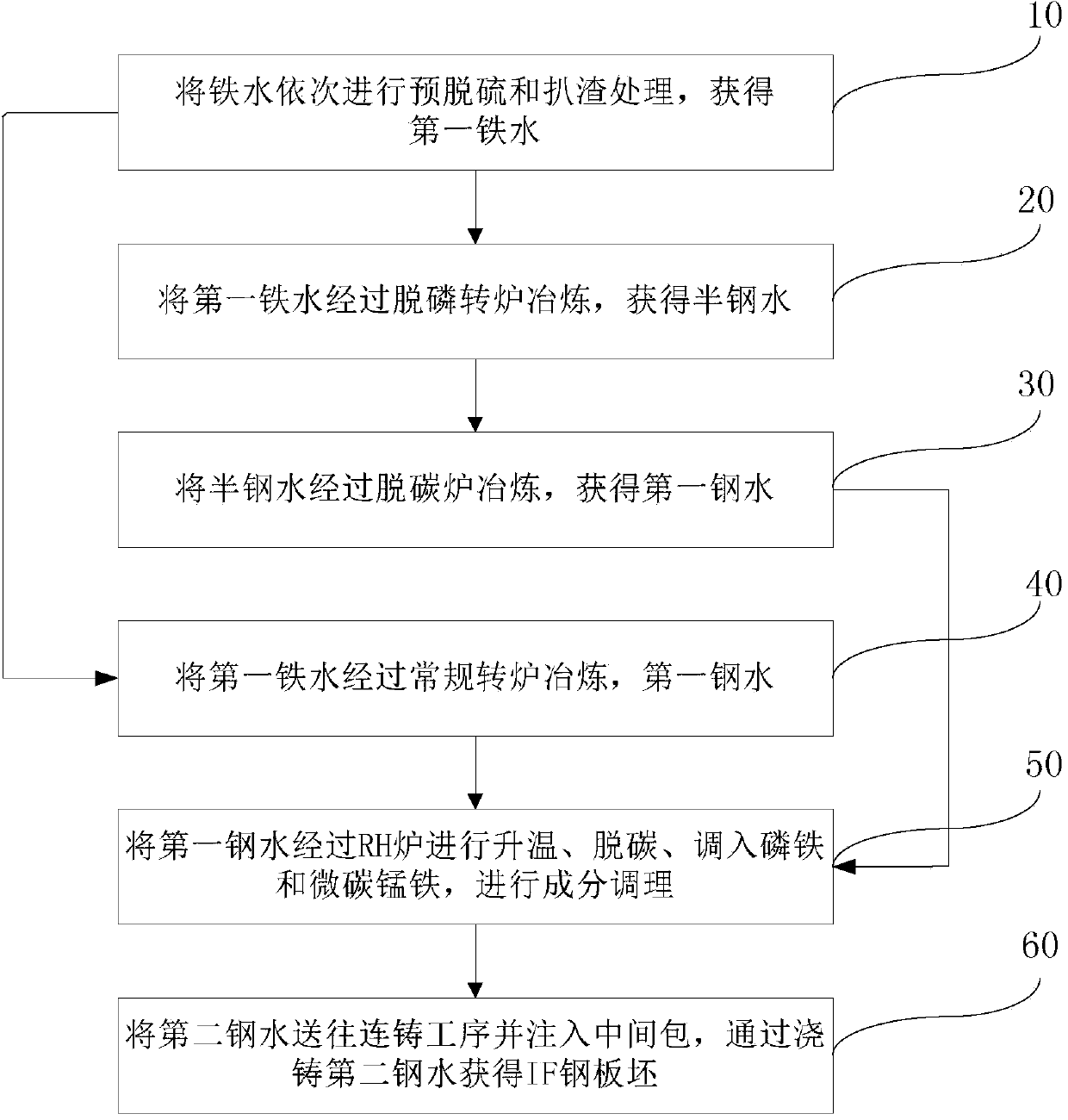

[0017] see figure 1 , the embodiment of the present invention provides a method for preparing IF steel containing phosphorus, silicon and manganese, comprising:

[0018] Step 10, performing pre-desulfurization and slagging treatment on the molten iron in sequence to obtain the first molten iron with a sulfur content≤0.001%. It specifically includes: Step 101, pre-desulfurize the iron ladle containing molten iron at the desulfurization station through KR stirring; molten iron, and prevent the sulfur in the slag from returning to the first molten iron.

[0019] Step 20, smelting the first molten iron through a dephosphorization converter to obtain semi-liquid steel with a C content ≥ 3.0% and a temperature T ≥ 1300°C. It specifically includes: step 201, mixing the first molten iron after pre-desulfurization treatment into the dephosphorization converter, and adding scrap steel accounting for 5% to 15% of the weight of the first molten iron into the dephosphorization converter;...

Embodiment 1

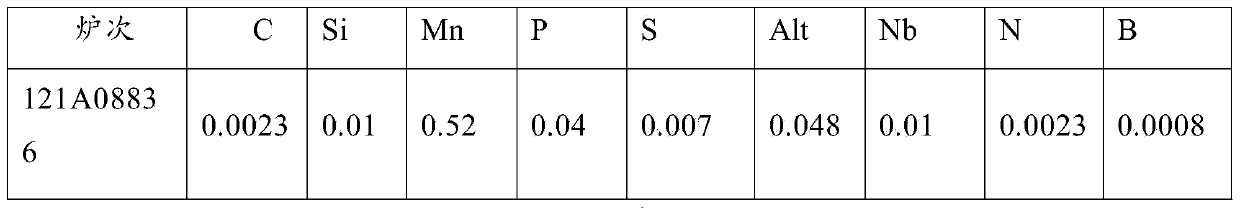

[0027] Bake-hardening steel CR180BH is produced by using the preparation method of phosphorus-containing silicon-manganese-containing IF steel provided in the embodiment of the present invention. The conditions of molten steel entering the RH furnace are C content 0.031%; Si content 0.005%; S content 0.007%; P content 0.031%; Mn content 0.02%; temperature 1625°C; oxygen content 650ppm.

[0028] The temperature and oxygen content are suitable, and no oxygen blowing or scrap addition is required. After treatment for 3 minutes, add ferrophosphorus and ferromanganese according to the target P content of 0.036% and target Mn content of 0.35%. 4 minutes after the alloy was adjusted, samples were taken to analyze the P and Mn content; the P content was 0.037% and the Mn content was 0.31%; RH was treated for 15 minutes, and the oxygen value was 425ppm; Add aluminum grains, and finally transfer 13Kg of boron-iron alloy. 21 minutes when the adjustment is completed.

[0029] After the...

Embodiment 2

[0035] Production of bake-hardening steel CR180BH by using the preparation method of phosphorus-containing, silicon-, and manganese-containing IF steel provided by the embodiment of the present invention: the conditions for entering the molten steel in the RH furnace are: C content 0.028%; Si content 0.004%; S content 0.009%; P content 0.073% ; Mn content 0.02%; temperature 1634 ° C; oxygen content 681ppm.

[0036] The temperature and oxygen content are suitable, and no oxygen blowing or scrap addition is required. After 3 minutes of treatment, ferrophosphorus and ferromanganese were added according to the target P content of 0.081% and target Mn content of 0.35%. 4 minutes after the alloy was adjusted, samples were taken to analyze the P and Mn content; the P content was 0.080% and the Mn content was 0.28%; the RH treatment was 15 minutes, and the oxygen value was 463ppm; Add aluminum particles, and finally transfer 13Kg of ferroboron alloy and 3.0t of ferrosilicon alloy. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com