Biomedical titanium-niobium-based shape memory alloy as well as preparation method, processing method and application method thereof

A biomedical and memory alloy technology, applied in the field of titanium alloys, biomedical materials used in the replacement and repair of human hard tissue, to achieve the effects of alleviating osteoporosis, low cold work hardening rate, and low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

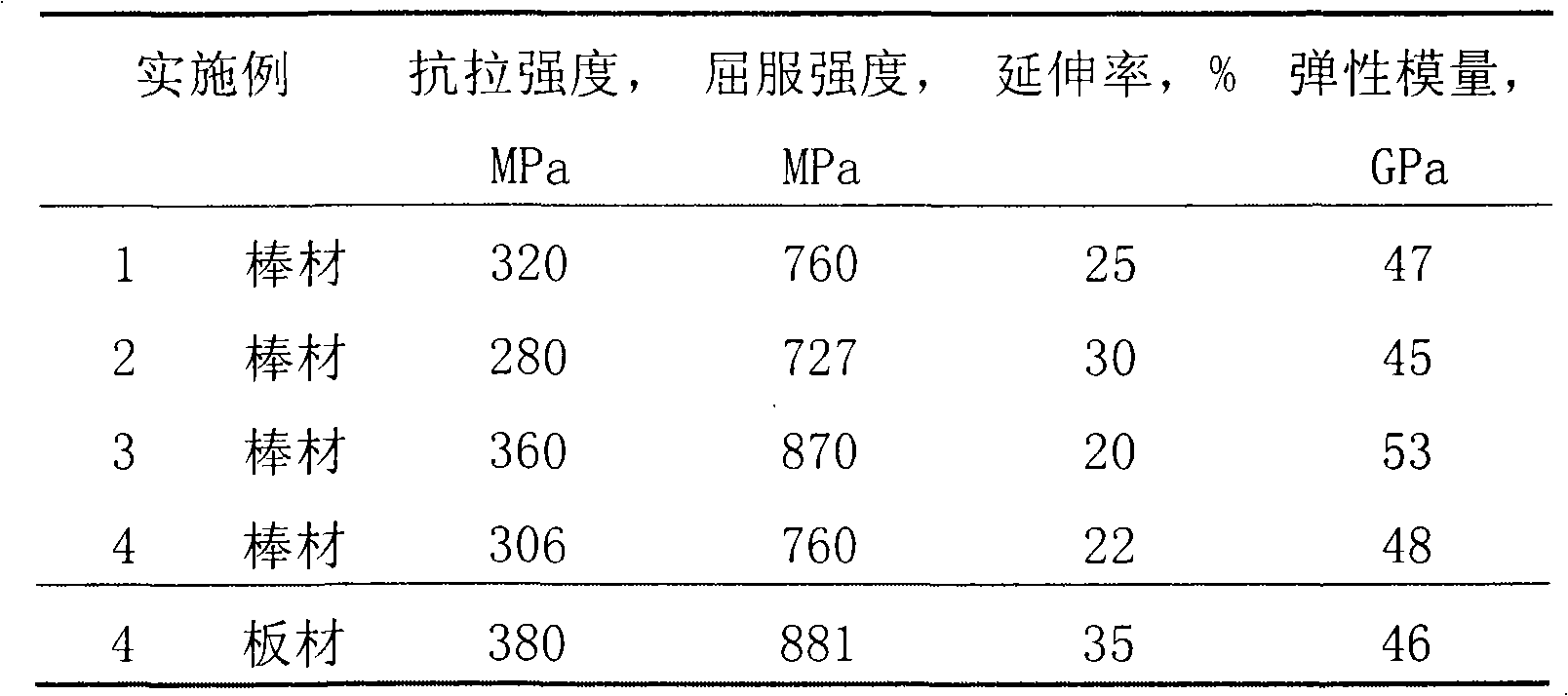

Examples

Embodiment 1

[0032]Using sponge titanium, sponge zirconium, niobium-titanium master alloy, aluminum-titanium master alloy, aluminum-silicon master alloy, titanium-tin master alloy as raw materials, the total weight is 5 kg, and the design quality of each component is: titanium (Ti): Yu Quantity, niobium (Nb): 1.5 kg, aluminum (Al): 0.125 kg, others: zirconium (Zr) + silicon (Si) + tin (Sn): 0.195 kg, of which zirconium (Zr) 0.1525 kg, silicon (Si) 0.025 kg, tin (Sn): 0.0175 kg; carbon (C) in the alloy is 0.05%; hydrogen (H) is 0.005%; oxygen (O) is 0.02%; nitrogen (N) is 0.05%; +Nitrogen (N) is 0.07%. Electrodes of 1 to 3 kg are pressed, smelted into cylindrical ingots through a secondary vacuum consumable electric arc furnace, and the vacuum used for smelting is not greater than 5Pa. The billet is forged at a temperature of 1050 ° C, and after homogenization and heat preservation at 950 ° C for 30 minutes, After being processed into bars by cold swaging, cold rolling, cold drawing, etc.,...

Embodiment 2

[0036] Using sponge titanium, sponge zirconium, niobium-titanium master alloy, aluminum-titanium master alloy, aluminum-silicon master alloy, titanium-tin master alloy as raw materials, the total weight is 5 kg, and the design quality of each component is: titanium (Ti): Yu Quantity, niobium (Nb): 1.75 kg, aluminum (Al): 0.275 kg, others: zirconium (Zr) + silicon (Si) + tin (Sn): 0.145 kg, of which zirconium (Zr) 0.275 kg, silicon (Si) 0.025 kg, tin (Sn): 0.0175 kg; carbon (C) in the alloy is 0.05%; hydrogen (H) is 0.005%; oxygen (O) is 0.03%; nitrogen (N) is 0.03%; +Nitrogen (N) is 0.06%. Electrodes of 1 to 3 kg are pressed, smelted into cylindrical ingots through a secondary vacuum consumable electric arc furnace, and the vacuum used for smelting is not greater than 5Pa. The billet is forged at a temperature of 850 ° C, and after homogenization and heat preservation at 1050 ° C for 60 minutes, Ice water quenching; after the quenching treatment, quench again at 400° C., agin...

Embodiment 3

[0039] Using sponge titanium, sponge zirconium, niobium-titanium master alloy, aluminum-titanium master alloy, aluminum-silicon master alloy, titanium-tin master alloy as raw materials, the total weight is 5 kg, and the design quality of each component is: titanium (Ti): Yu Quantity, niobium (Nb): 1.95 kg, aluminum (Al): 0.015 kg, others: zirconium (Zr) + silicon (Si) + tin (Sn): 0.125 kg, of which zirconium (Zr) 0.275 kg, silicon (Si) 0.275 kg, tin (Sn): 0.275 kg; carbon (C) in the alloy is 0.04%; hydrogen (H) is 0.004%; oxygen (O) is 0.02%; nitrogen (N) is 0.05%; +Nitrogen (N) is 0.07%. Electrodes of 1 to 3 kg are pressed, smelted into cylindrical ingots through a secondary vacuum consumable electric arc furnace, and the vacuum used for smelting is not greater than 5Pa. The billet is forged at a temperature of 950 ° C, and after homogenization and heat preservation at 1000 ° C for 40 minutes, Water quenching; after the quenching treatment, it is aged at 500° C. for 15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com