High carbon steel pipe having excellent cold workability, machinability, and quenching properties, and method for manufacturing same

A technology of high-carbon steel pipe and manufacturing method, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reduced productivity and high manufacturing cost, and achieve the effect of excellent high-frequency hardenability and excellent cold workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

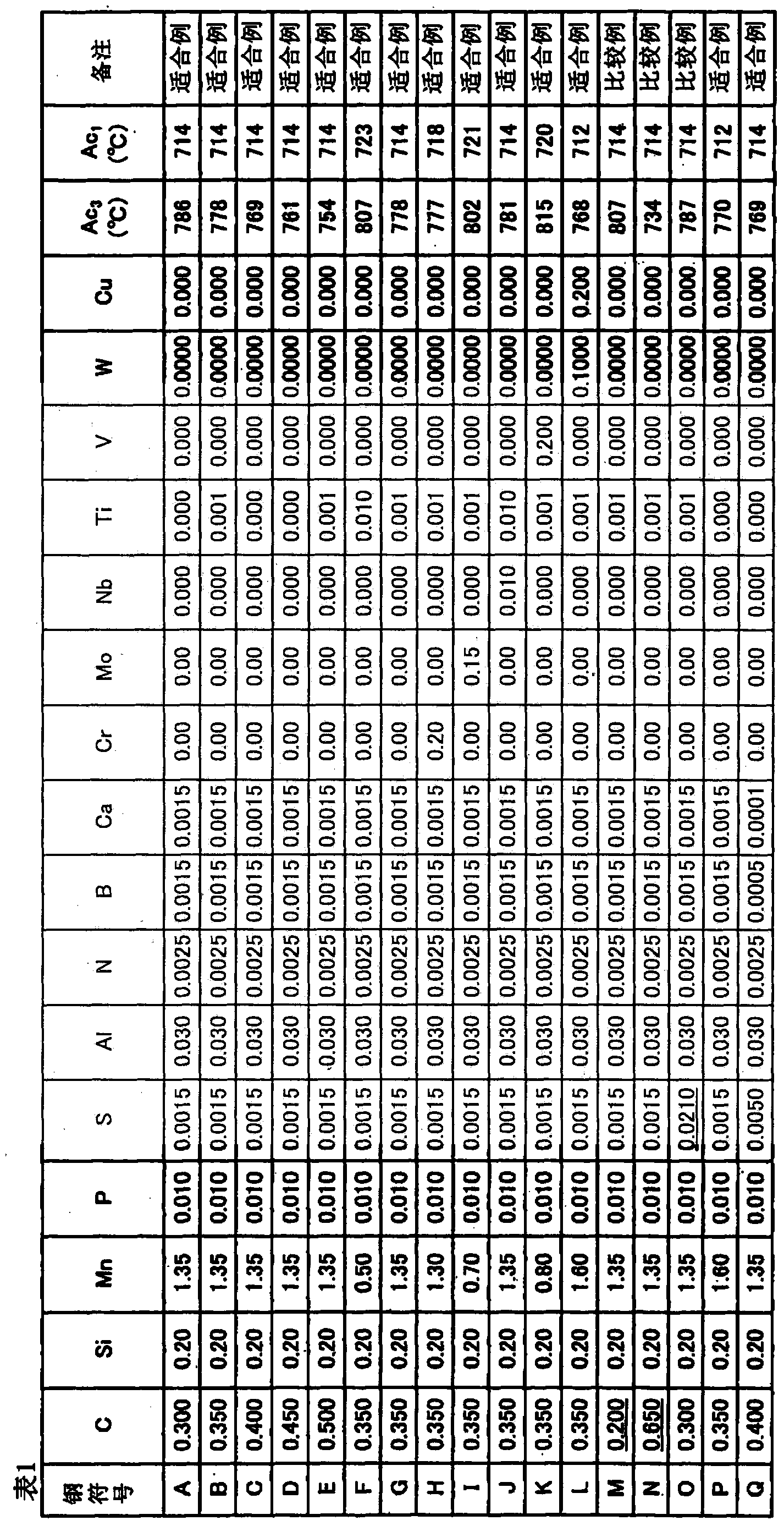

[0087] A hot-rolled steel strip (thickness: 7.0 mm) having the composition shown in Table 1 was continuously roll-formed into a substantially cylindrical open pipe, and resistance welding was performed on the ends of the open pipe. In the pipe-making process, electric resistance welded steel pipes (outer diameter: 89.1mmφ) are produced as raw steel pipes.

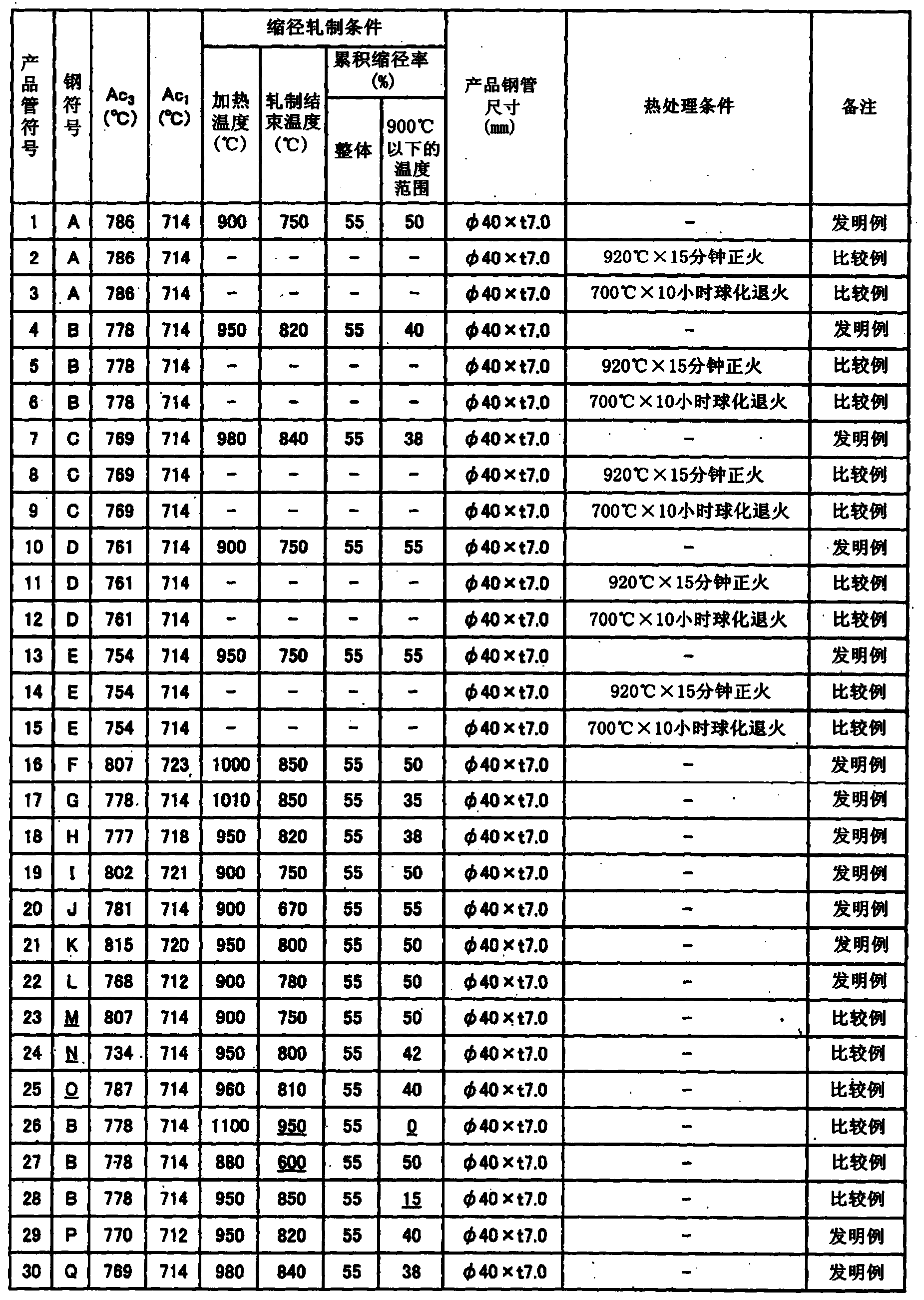

[0088] These raw steel pipes were reduced in diameter under the conditions shown in Table 2 to produce product steel pipes. In addition, the annealing treatment (annealing treatment) of 700 degreeC x 10 hours or the normalizing treatment (normalizing treatment) of 925 degreeC x 15 minutes was given to some steel pipes as a conventional example. In the conventional example, the above-mentioned treatment was performed after processing the steel pipe as a raw material to 40 mmφ.

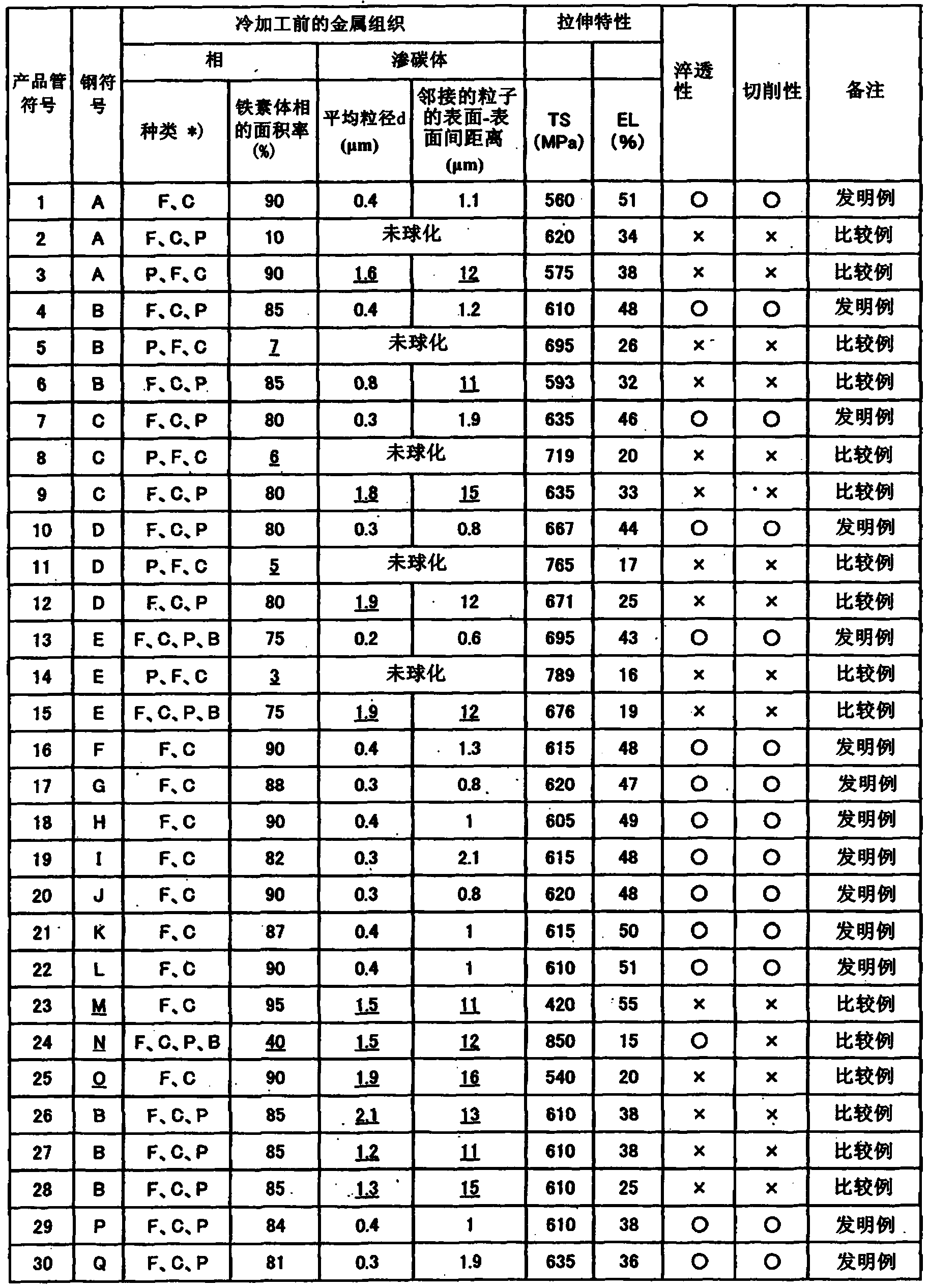

[0089] The obtained steel pipe was subjected to microstructure observation to examine cold workability, hardenability, and machinability. The inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com