An outer package for a power storage device and the power storage device

A technology of power storage device and outer packaging, which is applied to battery electrodes, battery boxes/jackets, non-aqueous electrolyte batteries, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

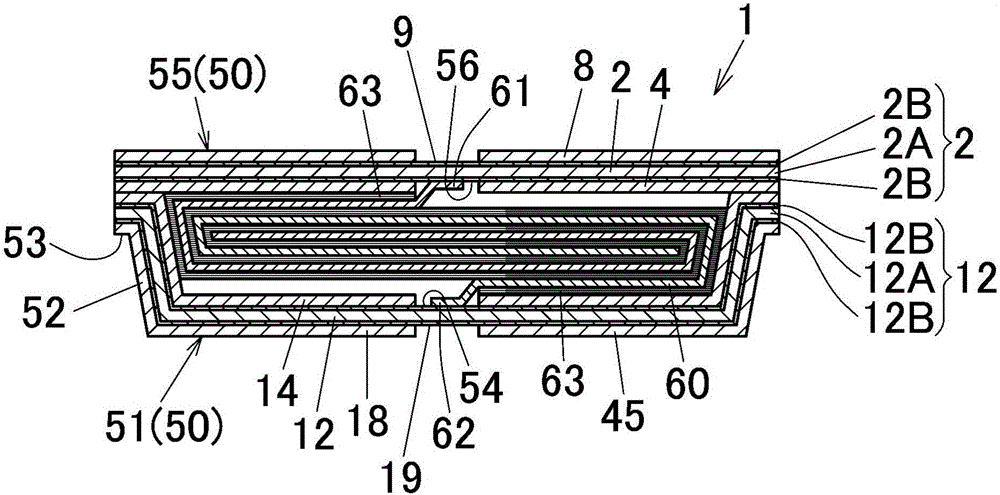

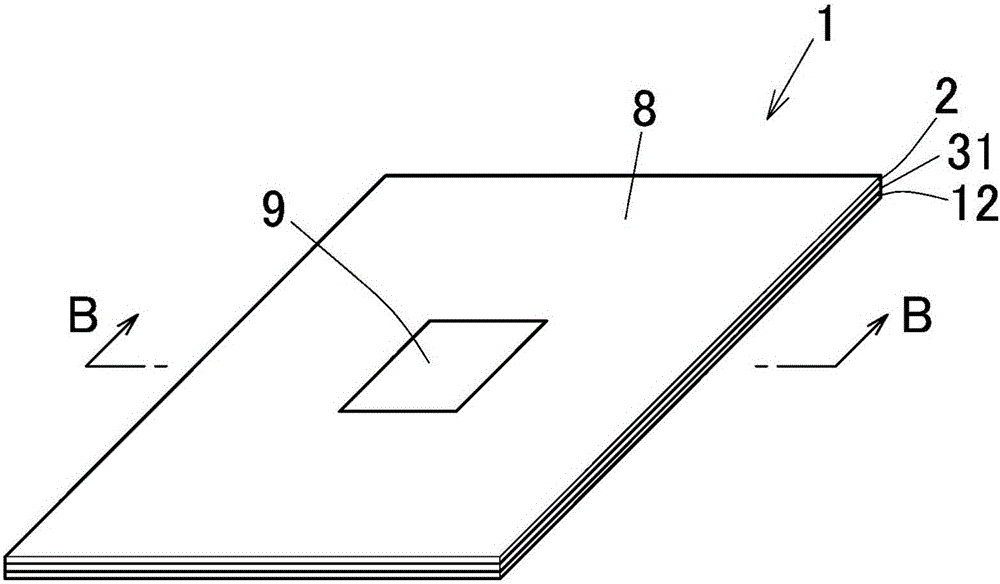

[0151] Coating a chemical conversion treatment solution containing polyacrylic acid, phosphoric acid, and compounds of chromium and fluorine on both sides of a 40 μm-thick nickel-plated (plating thickness: 1 μm) aluminum foil, and drying at 150°C to allow chromium to adhere The amount reaches 3mg / m 2 , thereby obtaining the first metal layer 2 .

[0152] Next, a polyester polyurethane adhesive is applied to one surface of the first metal layer 2 described above. When performing this coating, the central portion of one surface of the first metal layer 2 is used as an adhesive-uncoated region by masking (sticking a masking tape). Thereafter, a biaxially stretched polyamide film (first insulating resin film) 8 having a thickness of 25 μm was pasted on the surface coated with the polyester polyurethane adhesive. Next, an acid-modified polypropylene adhesive is coated on the other surface of the first metal layer 2 . When performing this coating, the central portion of the other...

Embodiment 2

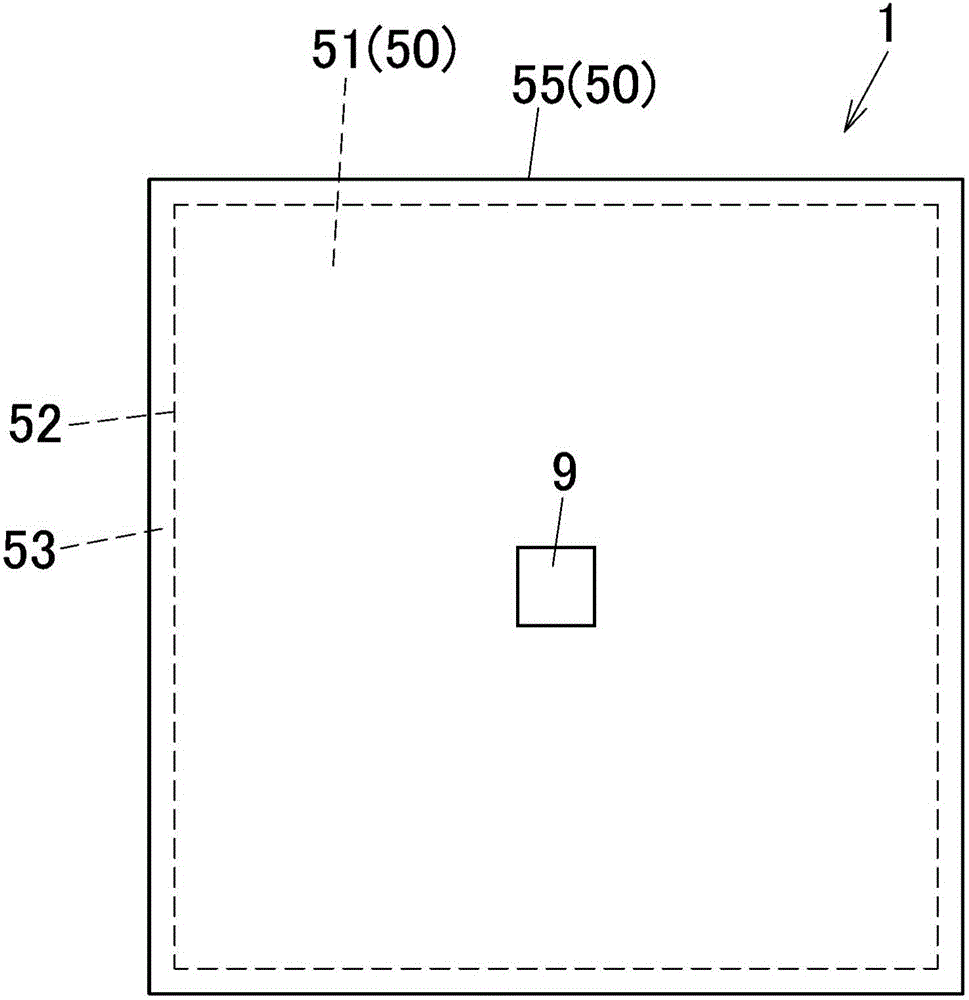

[0155] As the above-mentioned first metal layer 2, except for using a metal layer obtained by subjecting the clad material (aluminum-nickel foil) to the same chemical conversion treatment as in Example 1, an outer package of a flat sheet was obtained in the same manner as in Example 1. Body 50 ( figure 1 cover body 55).

Embodiment 3

[0157] As the above-mentioned first metal layer 2, in addition to using SnO with a thickness of 0.5 μm by coating 2 A flat plate was obtained in the same manner as in Example 1, except that the layer (conductive metal oxide) 2B was laminated on both sides of the aluminum foil (first metal foil) 2A subjected to the same chemical conversion treatment as in Example 1. The outer packaging body 50 of the sheet ( figure 1 cover body 55).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com