High-strength hot-rolled steel sheet and manufacturing process therefor

A technology of hot-rolled steel plate and manufacturing method, which is applied in the field of high-strength hot-rolled steel plate and its manufacturing, and can solve the problems of ductility, extension flangeability deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

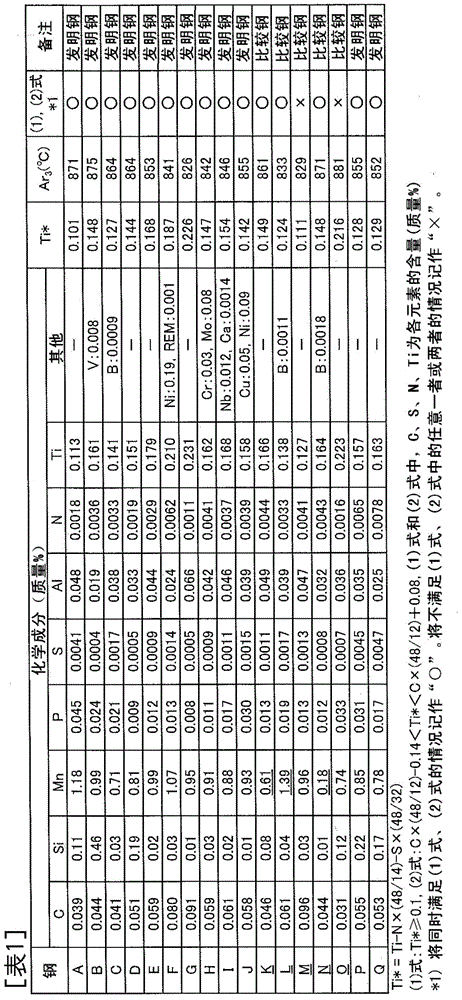

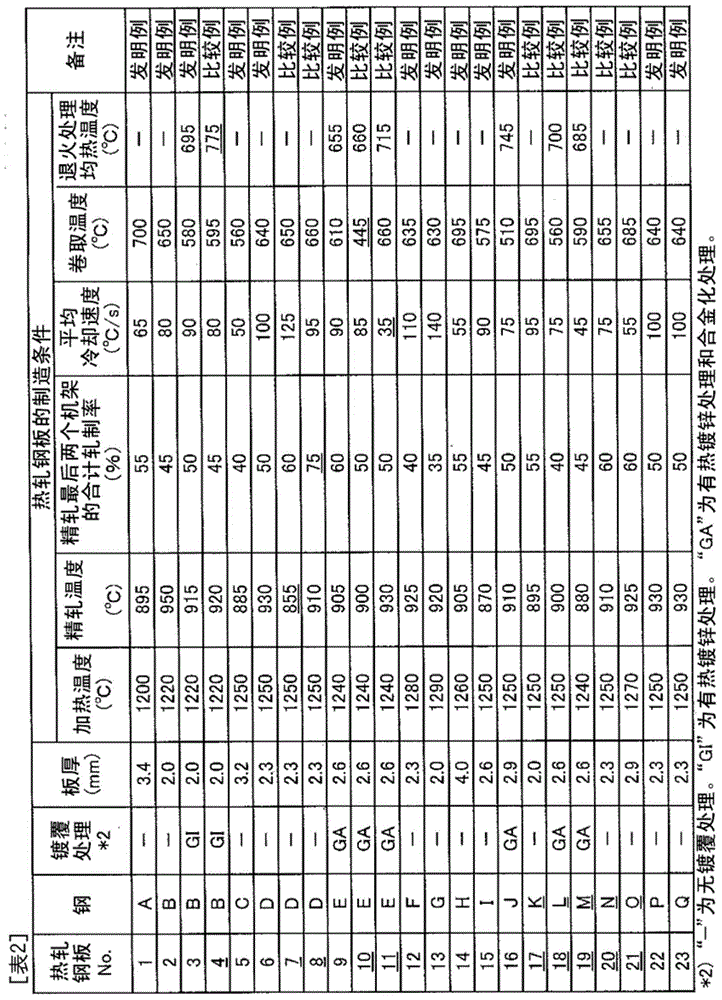

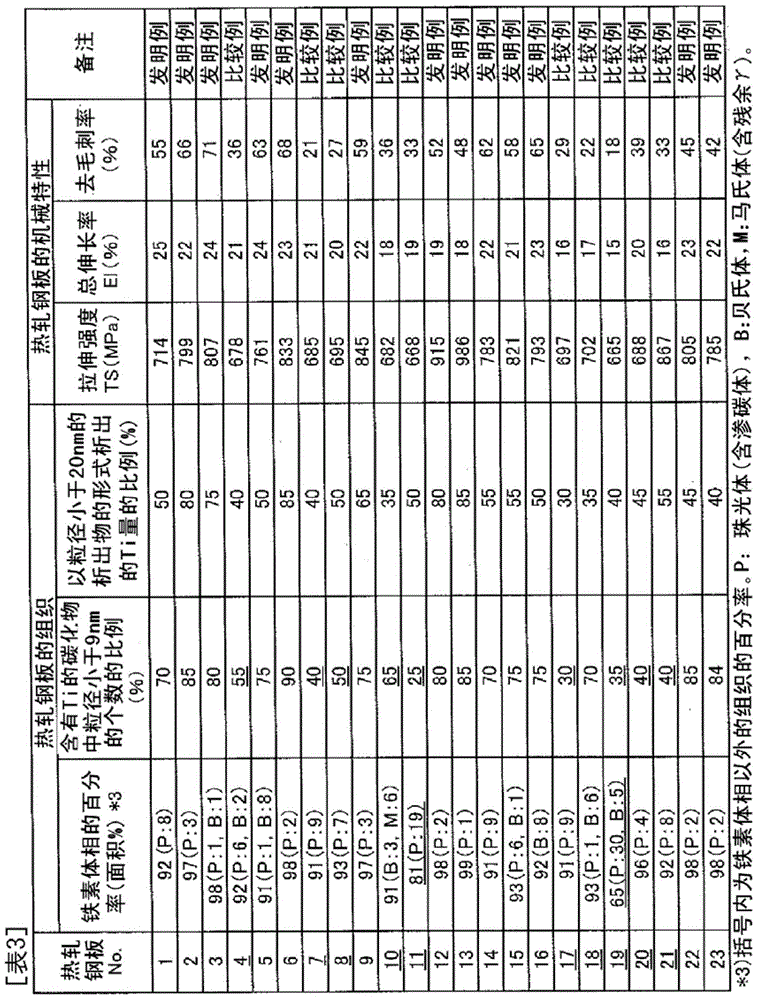

[0130] will have the composition shown in Table 1 and Ar 3 Steel slabs (No.A to Q) at the transformation point were heated to 1200 to 1290°C, and hot rolled steel sheets (No.1 to 23) were produced under the hot rolling conditions shown in Table 2. The plate thickness is 2.0-4.0mm. It should be noted that Ar in Table 1 3 The phase transition point was obtained by the method described above. For some hot-rolled steel sheets (No. 3, 4, 9-11, 16, 18, 19), after pickling, they are passed through the hot-dip galvanizing line, thus, at the soaking temperature shown in Table 2 An annealing treatment is performed, and a hot-dip galvanizing treatment is further performed. It should be noted that the hot-dip galvanizing treatment is the following treatment: the hot-rolled steel sheet after the annealing treatment is immersed in a galvanizing bath (0.1 mass% Al-Zn) at 480° C., and each side is formed on both surfaces of the steel sheet. The amount is 45g / m 2 Hot-dip galvanizing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com