High-strength hot-rolled steel sheet having superior punchability and method for producing same

A technology of hot-rolled steel sheets and manufacturing methods, applied in the direction of manufacturing tools, metal rolling, chemical instruments and methods, etc., to achieve the effect of contributing to light weight and improved punching processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

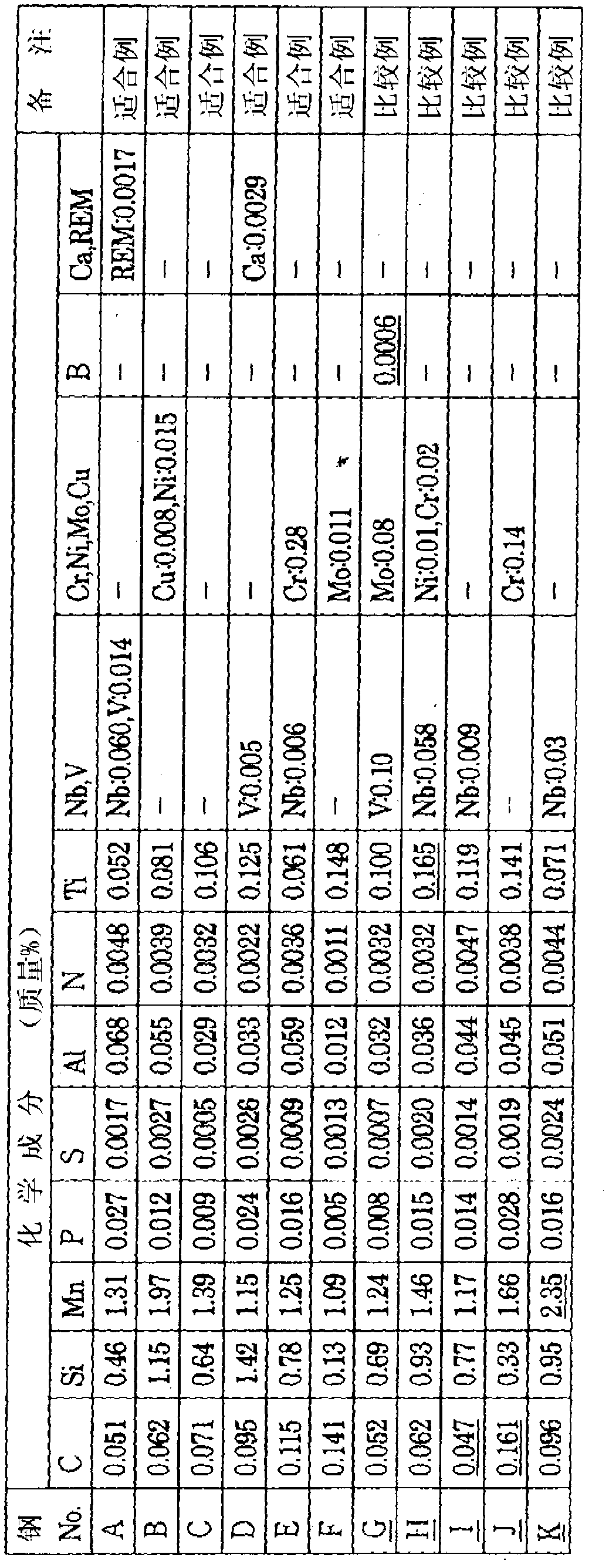

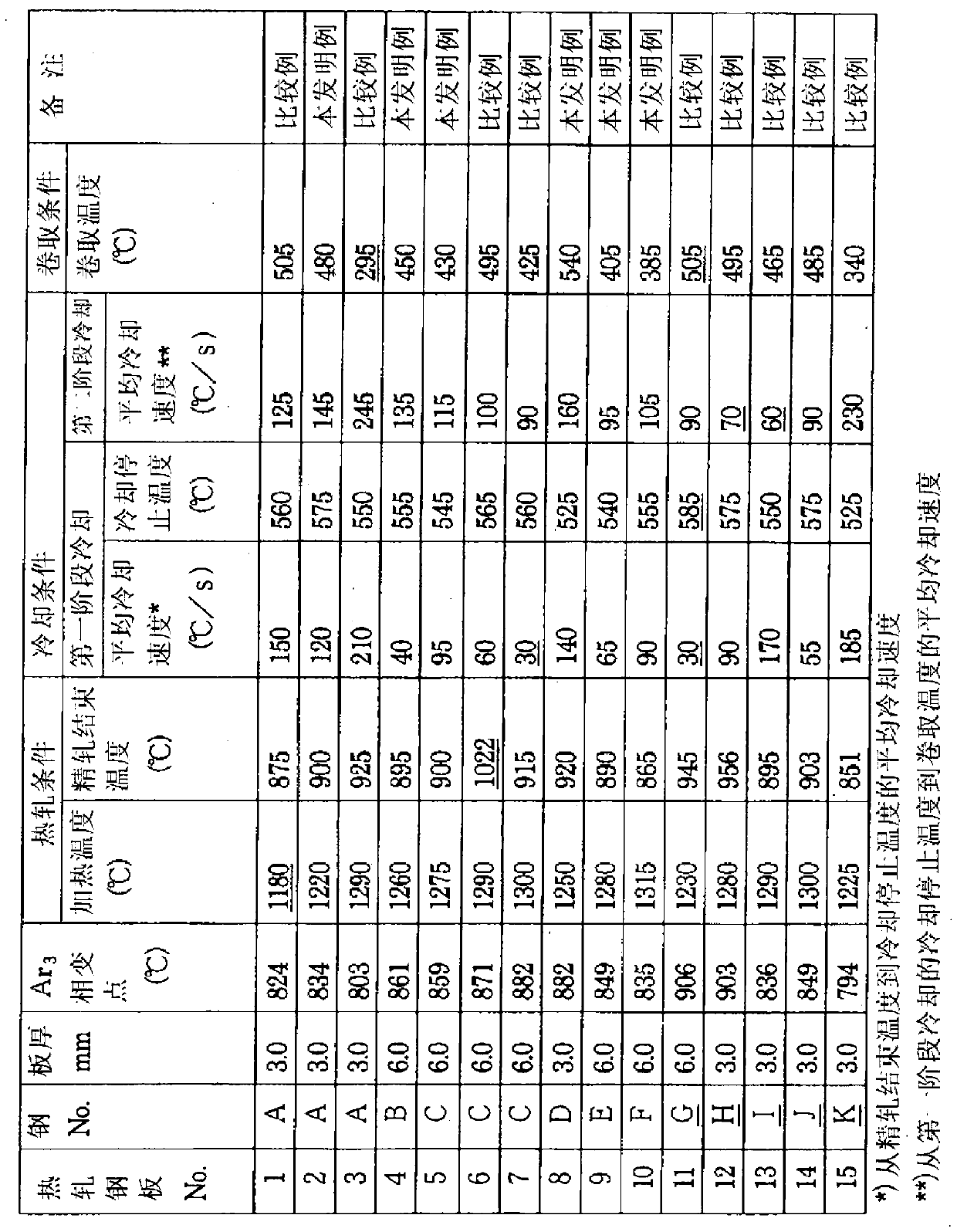

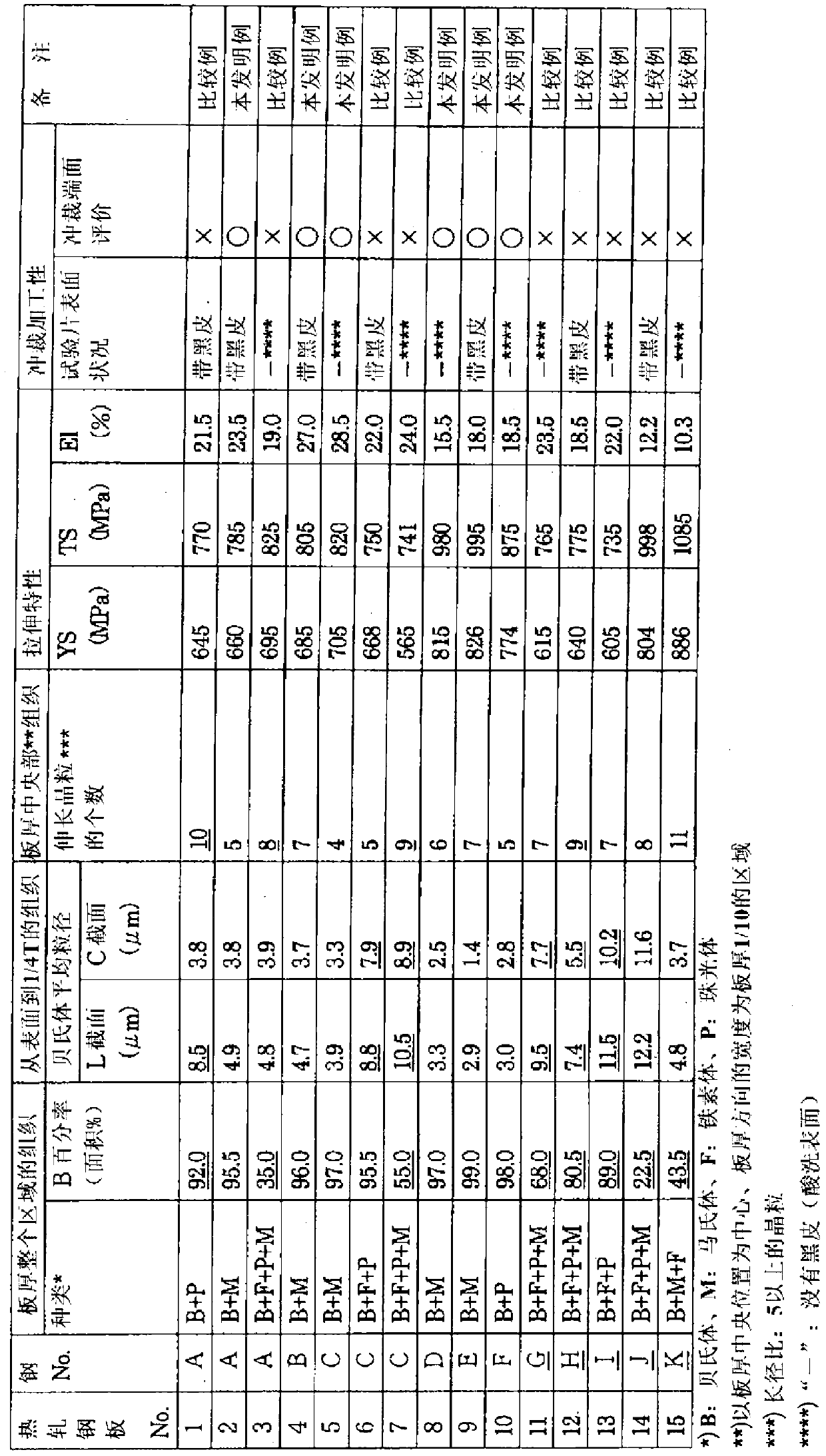

[0083] Molten steel having the composition shown in Table 1 was melted in a converter, and a billet (steel raw material) was produced by continuous casting. These slabs were heated under the conditions shown in Table 2, and subjected to rough rolling and finish rolling under the conditions shown in Table 2. And after finishing rolling, it was cooled under the conditions shown in Table 2, and coiled at the coiling temperature shown in Table 2 to obtain a hot-rolled steel sheet with a thickness shown in Table 2. It should be noted that cooling was started within 2 seconds after finish rolling was completed. Here, the first-stage cooling is represented by an average cooling rate from the finish rolling finish temperature to the cooling stop rate. In addition, the second-stage cooling is represented by the average cooling rate from the cooling stop temperature of the first-stage cooling to the coiling temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com