Steel for high-speed cold working and method for production thereof, and high-speed cold working part and method for production thereof

A manufacturing method and cold working technology, applied in the field of mechanical parts and steel for cold working, can solve the problems of deterioration of metal mold life, easy cracking during processing, inability to ensure the strength of parts, etc., and achieve good cold workability and appropriate chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

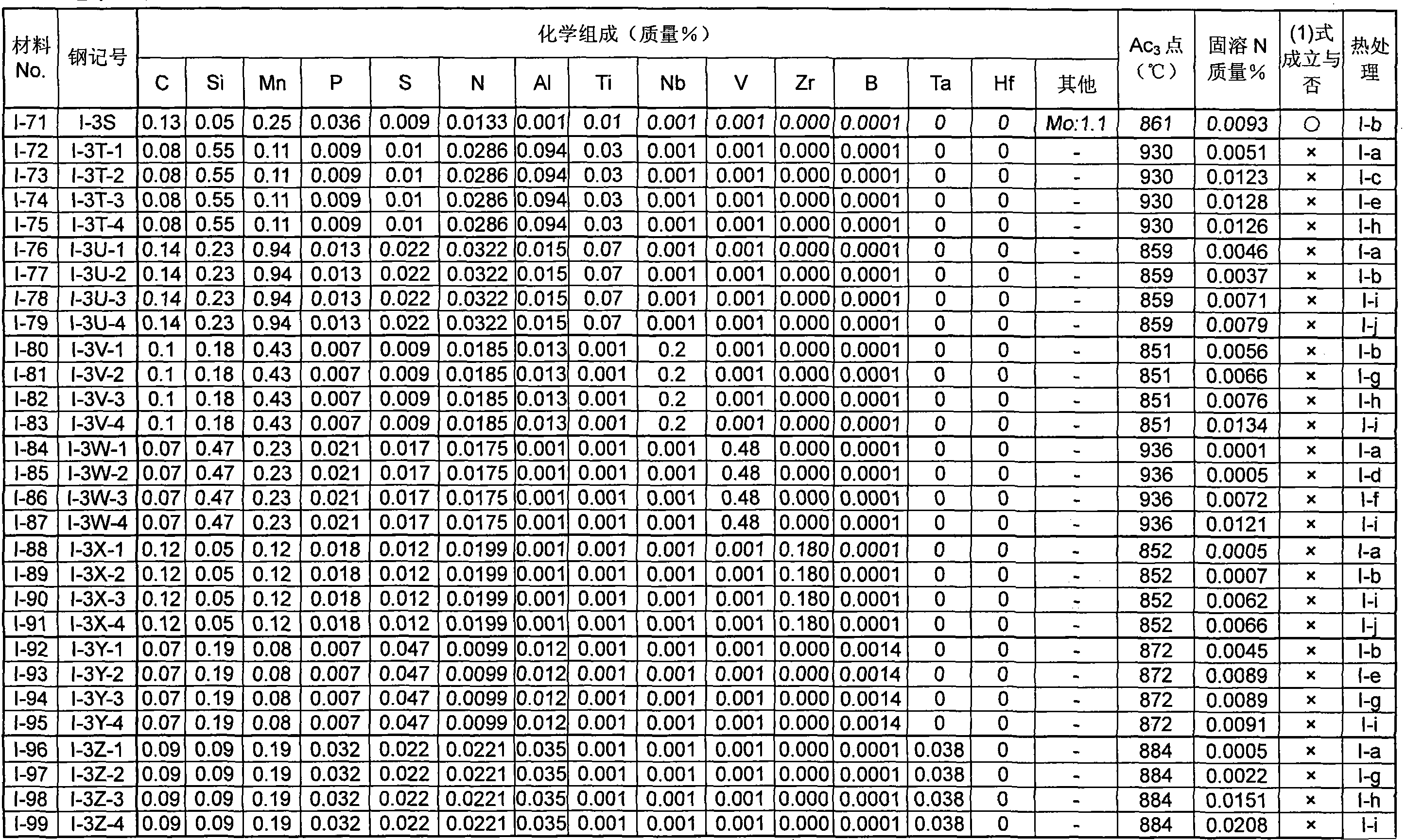

Examples

no. 1 approach

[0116] The steel for high-speed cold working according to the first embodiment of the present invention contains C: 0.03% to 0.15%, Si: 0.005% to 0.6%, Mn: 0.05% to 2%, P: 0.05% or less (excluding 0%), and S: 0.05% or less (excluding 0%) and N: 0.04% or less (excluding 0%), the balance is composed of iron and unavoidable impurities, and the amount of solid solution nitrogen in steel is 0.006% or more.

[0117] (C: 0.03% to 0.15%)

[0118] In the first embodiment of the present invention, in order to realize good machinability and cold workability, the upper limit of the amount of C is set to 0.15%. A more preferable upper limit is 0.12%. In order to secure the strength of the steel, the lower limit of C is 0.03%, preferably 0.04%.

[0119] Explanations other than the amount of C in the first embodiment of the present invention (namely, other basic components and optional components (arbitrary elements), manufacturing method of steel, manufacturing method of parts, balance of...

no. 2 approach

[0121] The steel for high-speed cold working according to the second embodiment of the present invention contains C: 0.15% to 0.6% but not including 0.15%, Si: 0.005% to 0.6%, Mn: 0.05% to 2%, and P: 0.05% or less (excluding 0%), S: 0.05% or less (excluding 0%) and N: 0.04% or less (excluding 0%), the balance is composed of iron and unavoidable impurities, and the content of N as a solid solution state is 0.006% above.

[0122] (C: 0.15% to 0.6% but not including 0.15%)

[0123] In the second embodiment of the present invention, the amount of C is set to exceed 0.15% in order to achieve higher component strength. More preferably, it is 0.16% or more, and it is still more preferable that it is 0.17% or more. On the other hand, when the amount of C is too large, machinability and cold workability deteriorate. Therefore, the upper limit of the amount of C is 0.6%, preferably 0.5%, more preferably 0.4%.

[0124] Explanations other than the amount of C in the second embodiment ...

no. 3 approach

[0126] In the third embodiment of the present invention, it is described about reducing the amount of elements (Al, Ti, Nb, V, Zr, B, Ta, Hf) that reduce solid solution N. Accordingly, a sufficient amount of solid-solution N can be secured, that is, good cold workability can be maintained, and higher component strength can be achieved.

[0127] That is, the steel for high-speed cold working according to the third embodiment of the present invention contains C: 0.03% to 0.6%, Si: 0.005% to 0.6%, Mn: 0.05% to 2%, P: 0.05% or less (excluding 0%), S : 0.05% or less (excluding 0%), N: 0.008 to 0.04%, and the balance is composed of iron and unavoidable impurities. Among the impurities, Al: 0.001% or less (excluding 0%), Ti: 0.002 % or less (excluding 0%), Nb: less than 0.001% (excluding 0%), V: less than 0.001% (excluding 0%), Zr: less than 0.001% (excluding 0%), B: less than 0.0001% (excluding 0%), Ta: 0.0001% or less (excluding 0%), Hf: 0.0001% or less (excluding 0%), and satisfy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com