Metastable beta type Ti-Nb-Ta-Zr-O alloy and preparation method thereof

A ti-nb-ta-zr-o, alloy technology, applied in the field of medical devices, can solve the problems of low tensile strength, application limitation, low elastic modulus, etc., and achieves low work hardening rate, good processing performance, cold working good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

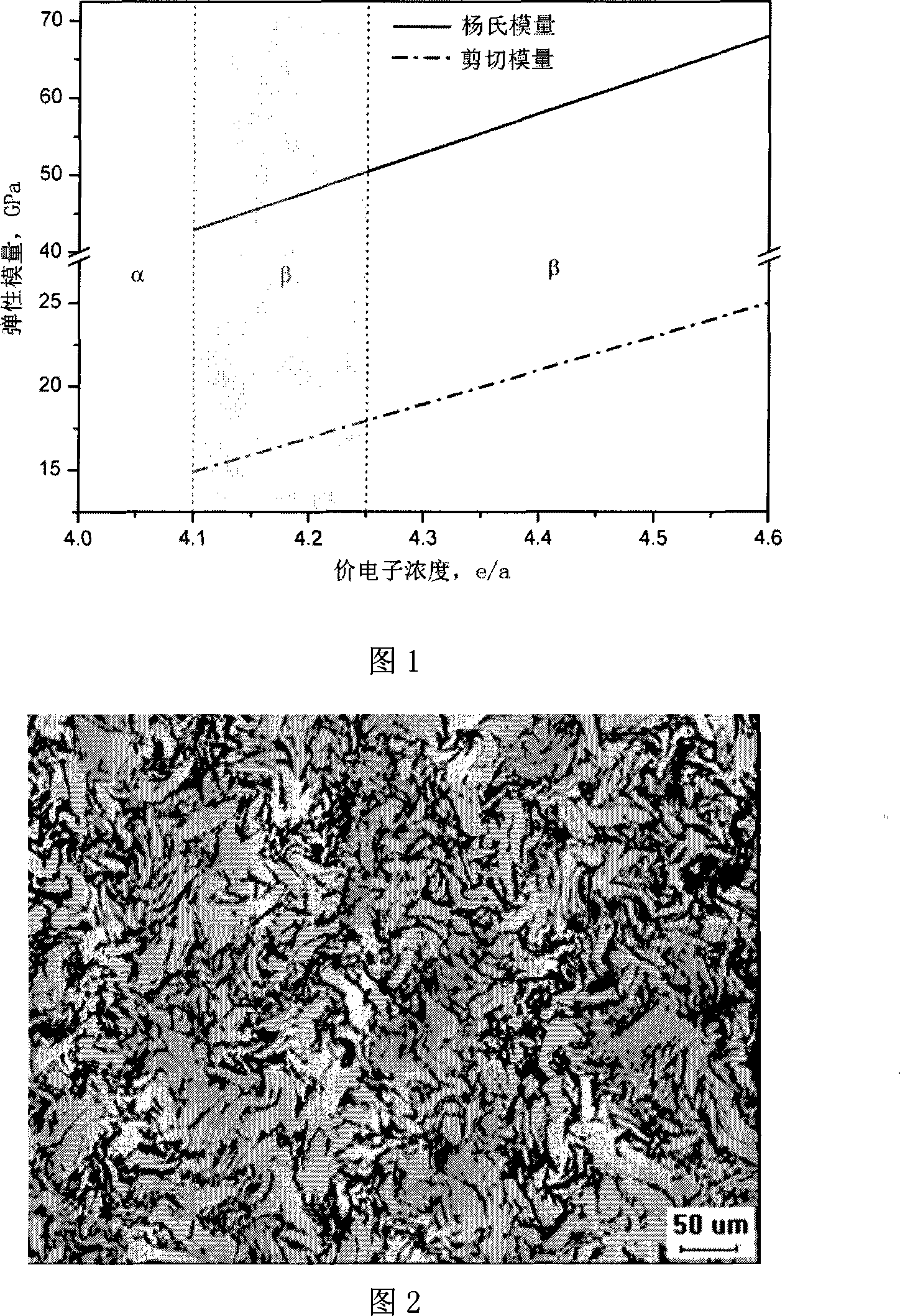

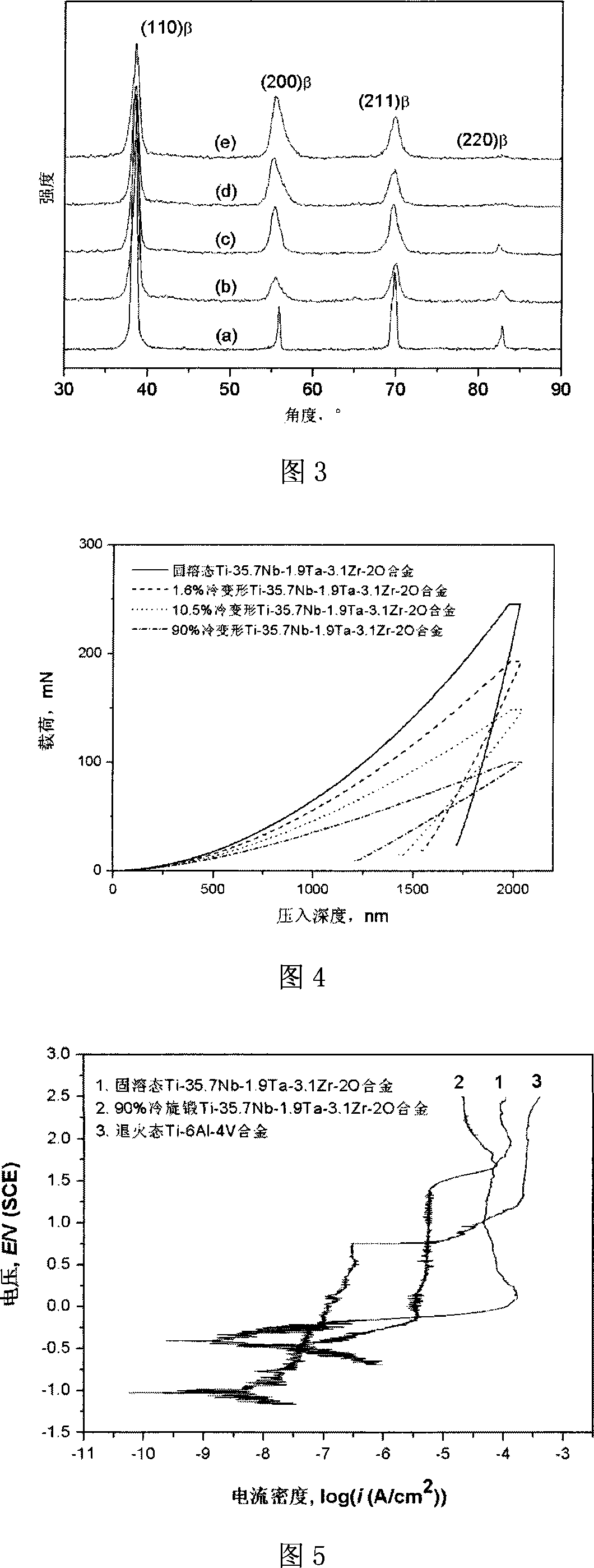

Embodiment 1

[0028] The alloy is prepared from sponge titanium, titanium-niobium master alloy, zirconium block and titanium dioxide. The design masses of each component are: titanium (Ti) 11.5 kg, niobium (Nb) 7.7 kg, zirconium (Zr) White powder (TiO 2 ) 0.8 kg. After the raw materials are pressed into electrodes, they are smelted in a vacuum consumable electric arc furnace; alloy ingots are cast in Hot rolling forming with a deformation amount of 60%, and then After 0.5h vacuum solution treatment, brine cooling, and finally cold rolling at room temperature with a deformation amount of 90% to form a plate to produce the alloy of the present invention. The measured tensile properties at room temperature are: R m =890MPa,R p0.2 =1230Mpa,A e =1.8%, A=13%, E=48Gpa.

Embodiment 2

[0030] The alloy is prepared from sponge titanium, titanium-niobium master alloy, zirconium block and titanium dioxide. The design masses of each component are: titanium (Ti) 11.5 kg, niobium (Nb) 7.7 kg, zirconium (Zr) White powder (TiO 2 )0.2 kg. After the raw materials are pressed into electrodes, they are smelted in a vacuum consumable electric arc furnace; alloy ingots are cast in Hot rolled forming with a deformation of 90%, and then After 1 hour of vacuum solution treatment, water cooling, and finally cold rolling at room temperature with a deformation of 50% into a plate, the alloy of the present invention is produced. The measured tensile properties at room temperature are: R m =830MPa,R p0.2 =1130Mpa,A e =1.9%, A=16%, E=45Gpa.

Embodiment 3

[0032] The alloy is prepared from sponge titanium, titanium-niobium master alloy, tantalum-zirconium master alloy, zirconium block and titanium dioxide. The design masses of each component are: titanium (Ti) 11.5 kg, niobium (Nb) 7.2 kg, tantalum (Ta ) 0.4 kg, zirconium (Zr) 0.6 kg, titanium dioxide (TiO 2 )0.3 kg. After the raw materials are pressed into electrodes, they are smelted in a vacuum consumable electric arc furnace; alloy ingots are cast in hot drawing with a deformation of 75%, and then After 1 hour of vacuum solution treatment, water cooling is carried out, and finally cold drawing with a deformation amount of 70% is carried out at room temperature to produce the alloy of the present invention. The measured tensile properties at room temperature are: R m =850MPa,R p0.2 =1150Mpa,A e =2.2%, A=17%, E=43Gpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com