High-strength special-purpose cold-rolled non-oriented electrical steel and producing method thereof

A technology of oriented electrical steel and production method, which is applied in the field of production of cold-rolled non-oriented electrical steel products for electromagnetic switches, and can solve problems such as low mechanical life, brittle steel sheets, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

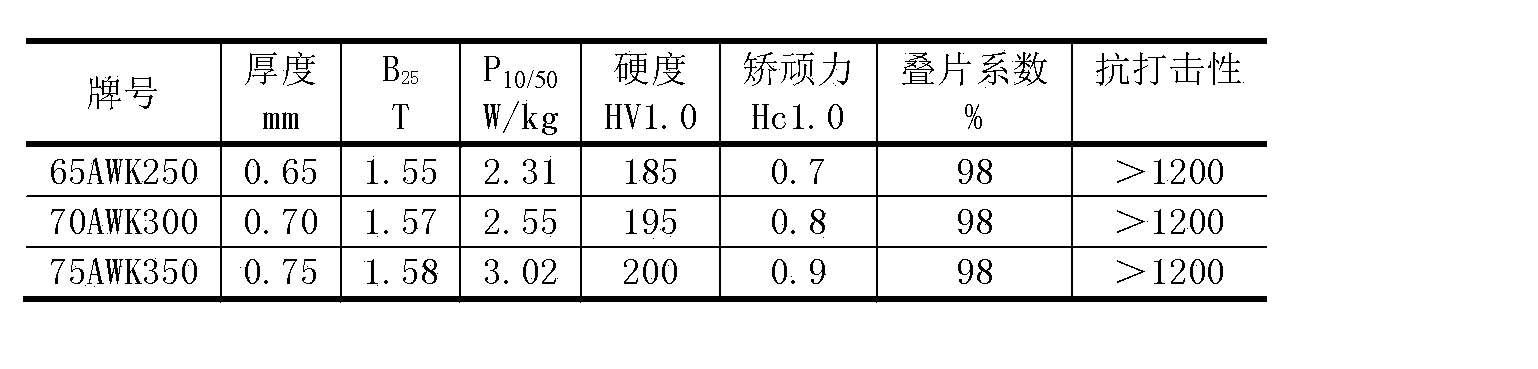

Examples

Embodiment 1

[0016] Example 1: C: 0.0025%, Si: 2.85%, Mn: 0.23%, P: 0.012%, S: 0.001%, Als: 0.55%, N: 0.0021%, Ti: 0.001%, Nb: 0.0015%, V : 0.0013%, the rest is iron and other unavoidable impurity elements.

[0017] The process steps are as follows:

[0018] a) Converter smelting: RH vacuum refining treatment to control the content of each alloy element;

[0019] b) Continuous casting: the molten steel is cast into steel slabs by means of continuous casting, and the specification of the slab is ASP100mm;

[0020] c) Hot rolling: use low temperature heating, billet heating temperature is 1080°C, finish rolling and final rolling coiling adopt high temperature plan, start rolling temperature is 1020°C, finish rolling temperature is 880°C, coiling temperature is 720°C, so that the surface crystallization structure can be increased to 38%, the thickness of the hot-rolled sheet is controlled at 1.2mm, and the hot-rolled coil is pre-cold-rolled;

[0021] d) Normalization: process speed 45m / min...

Embodiment 2

[0024] Embodiment 2: C: 0.0020%, Si: 2.6%, Mn: 0.3%, P: 0.015%, S: 0.0013%, Als: 0.68%, N: 0.0020%, Ti: 0.001%, Nb: 0.0012% , V:0.0016%, the rest is iron and other unavoidable impurity elements.

[0025] The process steps are as follows:

[0026] a) Converter smelting: RH vacuum refining treatment to control the content of each alloy element;

[0027] b) Continuous casting: the molten steel is cast into steel slabs by means of continuous casting, and the specification of the slab is ASP100mm;

[0028] c) Hot rolling: use low temperature heating, billet heating temperature is 1100°C, finish rolling and final rolling coiling adopt high temperature plan, start rolling temperature is 1030°C, finish rolling temperature is 890°C, coiling temperature is 725°C, so that the surface crystallization structure can be increased to 45%, the thickness of the hot-rolled sheet is controlled at 1.7mm, and the hot-rolled coil is pre-cold-rolled;

[0029] d) Normalization: the process speed is...

Embodiment 3

[0032] Embodiment 3: C: 0.0028%, Si: 2.95%, Mn: 0.3%, P: 0.018%, S: 0.0011%, Als: 0.22%, N: 0.0022%, Ti: 0.001%, Nb: 0.0019% , V:0.0014%, the rest is iron and other unavoidable impurity elements.

[0033] The process steps are as follows:

[0034] a) Converter smelting: RH vacuum refining treatment to control the content of each alloy element;

[0035] b) Continuous casting: the molten steel is cast into steel slabs by means of continuous casting, and the specification of the slab is ASP100mm;

[0036] c) Hot rolling: adopt low-temperature heating, billet heating temperature is 1090°C, finish rolling and final rolling coiling adopt high-temperature plan, start rolling temperature is 1035°C, finish rolling temperature is 895°C, coiling temperature is 730°C, so that the surface crystallization structure can be increased to 48%, the thickness of the hot-rolled sheet is controlled at 2.2mm, and the hot-rolled coil is pre-cold-rolled;

[0037] d) Normalization: the process speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com