CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device

A technology of horizontal continuous casting and external field, which is applied in the field of preparation of CuNiSn elastic copper alloy and strip combination external field horizontal continuous casting, and can solve the problems of easy oxidation of alloy elements, scratches on the inner wall of graphite mold, limited dendrite segregation inhibition ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

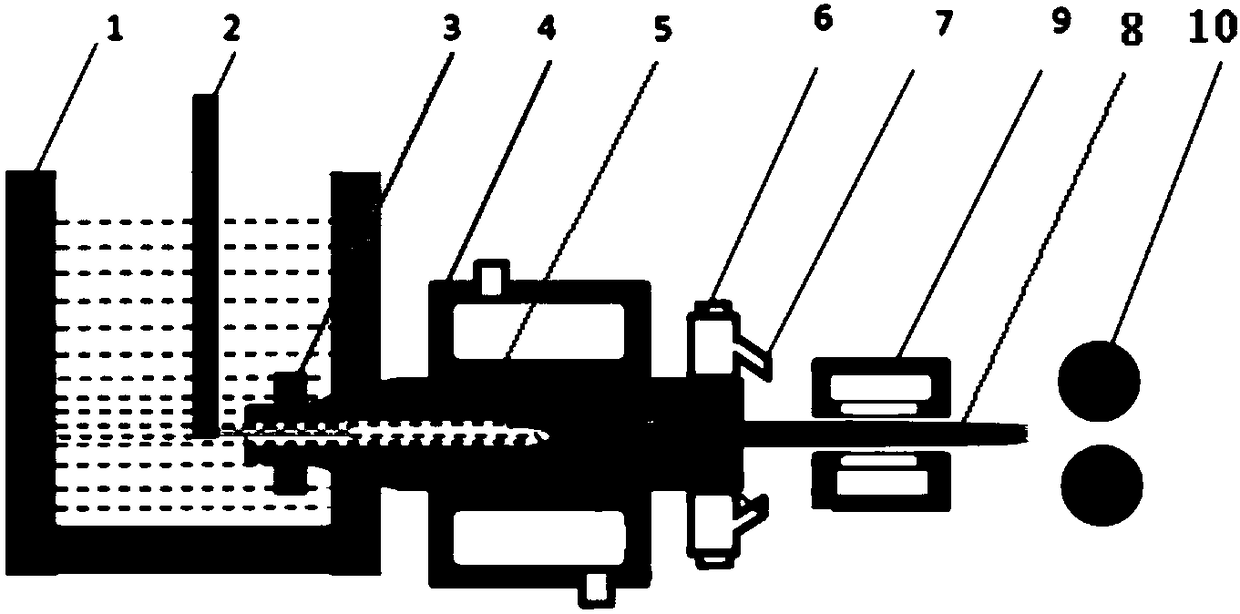

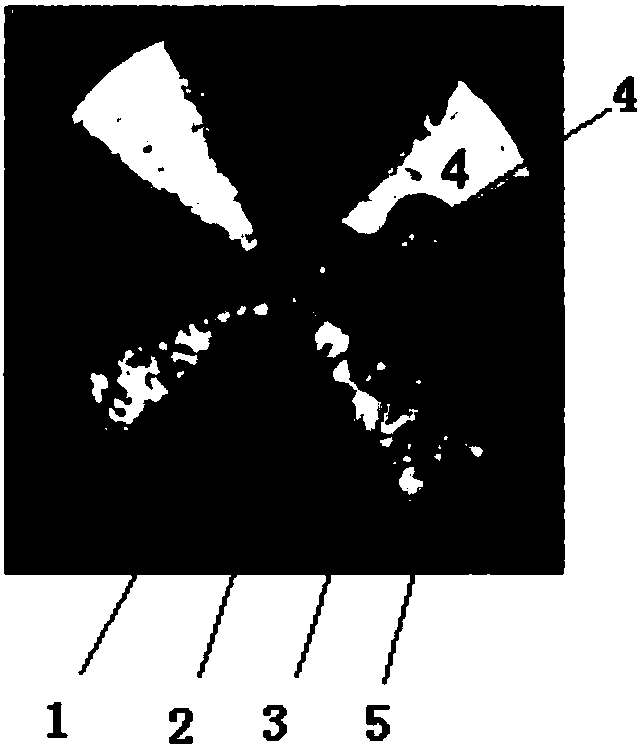

[0054] A CuNiSn-based elastic alloy strip combined external field horizontal continuous casting equipment, the equipment includes a crystallizer 5, a holding furnace 1, a secondary cooling device 9, and a traction device 10, and a primary water cooling jacket 4 is provided outside the crystallizer 5, The inlet end of the crystallizer 5 extends into the chamber of the holding furnace 1, and the outlet end is provided with a protective atmosphere generating device 6; the protective atmosphere generating device 6 is a nitrogen nozzle 7 arranged on the upper and lower surfaces of the outlet of the crystallizer 5, and the airflow direction of the nozzle 7 faces two Secondary cooling device 9, the nitrogen that nozzle 11 ejects forms air curtain at strip blank 8 periphery; Also be provided with ultrasonic generator 2 in holding furnace 1; A boron nitride ceramic casing with high heat resistance and low ultrasonic attenuation is closed; an electromagnetic induction coil 3 is surrounde...

Embodiment 2

[0056] A method for preparing CuNiSn elastic alloy strip combined external field horizontal continuous casting, comprising the following steps:

[0057] Step 1: Alloy Melting

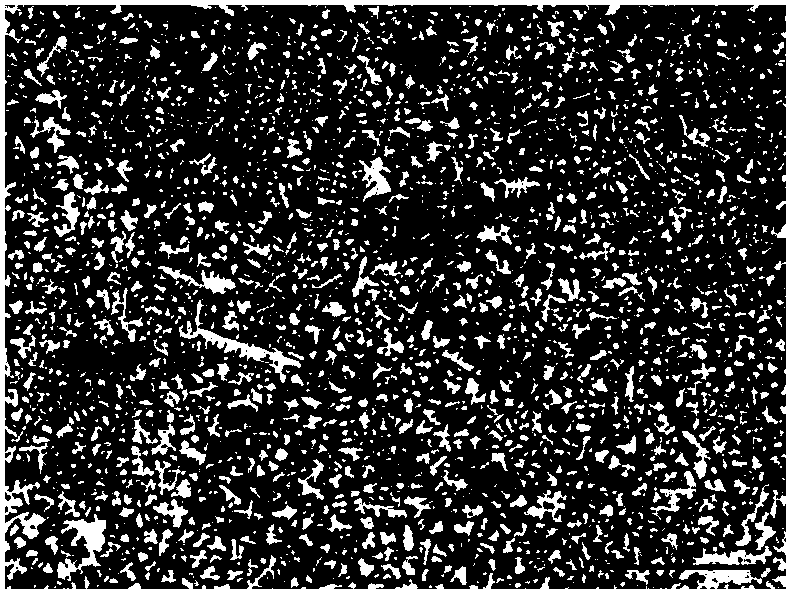

[0058] The alloy composition (mass percentage) is: Ni: 15wt%; Sn: 8.0wt%; Mn: 0.35wt%; Si: 0.2%; B: 0.06%; Sr: 0.10%; The proportion of the designed CuNiSn elastic alloy components is taken. The alloy components are taken, and the electrolytic copper and nickel are heated to 1400°C in a protective atmosphere. After melting, the furnace temperature is lowered to 1270°C. Then, the Sn, copper-magnesium Alloys, copper-manganese master alloy, copper-cerium master alloy, nickel-boron master alloy, copper-strontium master alloy, copper-vanadium master alloy are respectively added to the melt for melting, adding a slagging agent, stirring and removing slag, and then The surface of the melt is covered with charcoal calcined at 700°C, and the melt is transferred to a holding furnace for heat preservation at 1260...

Embodiment 3

[0077] A method for preparing CuNiSn elastic alloy strip combined external field horizontal continuous casting, comprising the following steps:

[0078] Step 1: Alloy Melting

[0079] The alloy composition (mass percentage) is: Ni: 9.0wt%; Sn: 2.0wt%; Mn: 0.3wt%; Si: 0.2%; B: 0.06%; Sr: 0.10%; V: 0.06; the balance is copper; According to the designed ratio of CuNiSn elastic alloy components, the alloy components are taken, and the electrolytic copper and nickel are heated to 1450°C in a protective atmosphere to melt, and then the furnace temperature is lowered to 1260°C. Then, the Sn, copper-magnesium Master alloys, copper-manganese master alloys, copper-cerium master alloys, nickel-boron master alloys, copper-strontium master alloys, and copper-vanadium master alloys are respectively added to the melt for melting, adding a slagging agent, stirring, and removing slag, Cover the surface of the melt with charcoal that has been calcined at 700°C, and transfer the melt to a holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com