Integrated liquid-cooling heat dissipation case

A liquid-cooled heat dissipation, integrated technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problem of low heat exchange efficiency, achieve enhanced heat exchange, reduce weight, and reduce equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

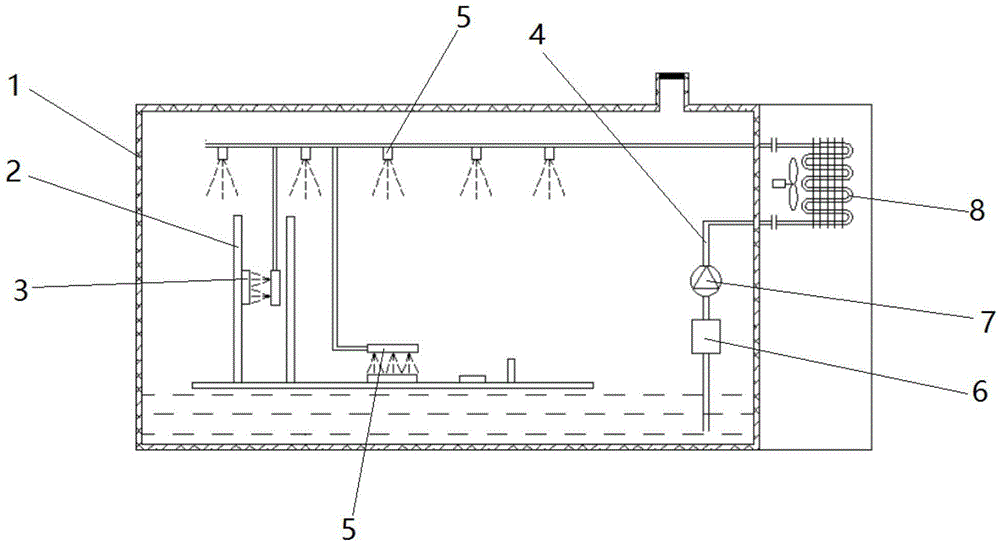

[0032] like figure 1 As shown, the present invention provides an integral liquid-cooled heat dissipation chassis, including a box body 1, a circuit board 2 and a liquid-cooled heat dissipation system, the box body 1 is a closed space composed of multiple wall panels, and the circuit board 2 Placed in the box 1, the circuit board 2 is provided with a plurality of heating devices 3, the bottom of the box 1 forms a liquid storage tank, and the liquid storage tank is used to store cooling liquid, and the cooling liquid is non-conductive liquid.

[0033] The liquid cooling system includes a pipeline 4, a heat exchanger 8, a pump 7, a filter 6 and a spraying mechanism, the heat exchanger 8, the pump 7, and the filter 6 are all arranged on the pipeline 4, and the filter The device 6 can remove impurities in the cooling liquid, the pump 7 pumps the cooling liquid in the liquid storage tank into the pipeline 4, and the heat exchanger 8 is used to cool down the cooling liquid. Both en...

Embodiment 2

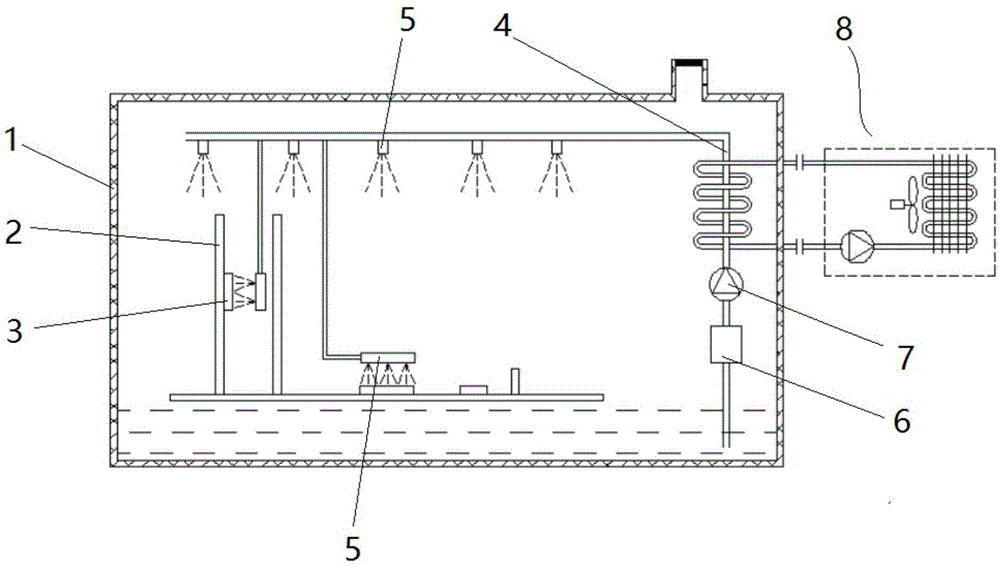

[0038] like figure 2 As shown, the present invention provides an integral liquid-cooled heat dissipation chassis, including a box body 1, a circuit board 2 and a liquid-cooled heat dissipation system, the box body 1 is a closed space composed of multiple wall panels, and the circuit board 2 Placed in the box 1, the circuit board 2 is provided with a plurality of heating devices 3, the bottom of the box 1 forms a liquid storage tank, and the liquid storage tank is used to store cooling liquid, and the cooling liquid is non-conductive liquid.

[0039] The liquid cooling system includes a pipeline 4, a heat exchanger 8, a pump 7, a filter 6 and a spraying mechanism, the heat exchanger 8, the pump 7, and the filter 6 are all arranged on the pipeline 4, and the filter The device 6 can remove impurities in the cooling liquid, the pump 7 pumps the cooling liquid in the liquid storage tank into the pipeline 4, and the heat exchanger 8 is used to cool down the cooling liquid. Both e...

Embodiment 3

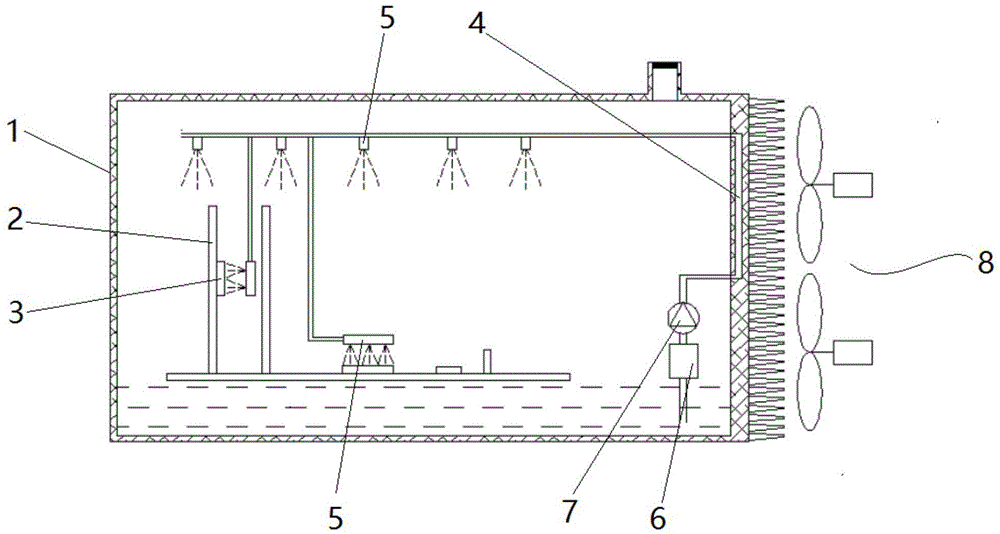

[0044] like image 3 As shown, the present invention provides an integral liquid-cooled heat dissipation chassis, including a box body 1, a circuit board 2 and a liquid-cooled heat dissipation system, the box body 1 is a closed space composed of multiple wall panels, and the circuit board 2 Placed in the box 1, the circuit board 2 is provided with a plurality of heating devices 3, the bottom of the box 1 forms a liquid storage tank, the liquid storage tank is used to store cooling liquid, and the liquid storage tank It is an open-top liquid storage tank, and the cooling liquid is a non-conductive liquid.

[0045] The liquid cooling heat dissipation system includes a pipeline 4, a heat exchanger 8, a pump 7, a filter 6 and a spraying mechanism, the pump 7 and the filter 6 are all arranged on the pipeline 4, and the filter 6 can cool the Impurities in the liquid are removed, the pump 7 pumps the cooling liquid in the liquid storage tank into the pipeline 4, the heat exchanger 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com