Electrically controlled hydrogen-spraying pressure regulating device of fuel cell system

A fuel cell system, fuel cell stack technology, applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve the problems of narrow working range of ejectors, inapplicability to automotive applications, high cost of hydrogen circulation pumps, etc., to achieve operational Effects of increased range, improved utilization, and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

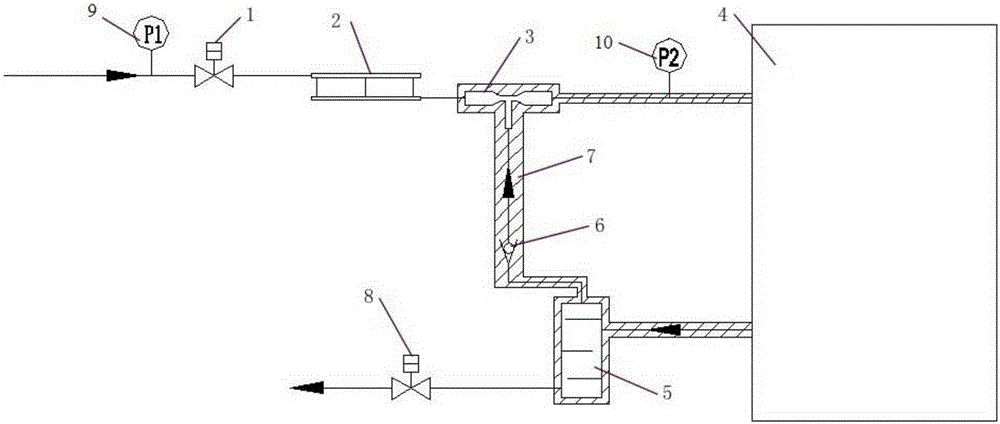

[0030] Such as figure 1 As shown, an electronically controlled hydrogen injection pressure adjustment device for a fuel cell system is used to control the intake air on the hydrogen side of the fuel cell system. The electronically controlled hydrogen injection pressure adjustment device includes:

[0031] Fuel cell stack 4: used for hydrogen fuel cell reaction to generate electricity;

[0032] Hydrogen side intake pressure control component: connected to the hydrogen intake pipe of the fuel cell stack to control the intake pressure of hydrogen and the return flow of hydrogen;

[0033] Drainage assembly: connected to the hydrogen exhaust pipe of the fuel cell stack to discharge the waste water;

[0034] Controller: respectively connected with the hydrogen side intake pressure control component and the hydrogen exhaust component, to control the hydrogen side intake pressure control component and the hydrogen exhaust component, and adjust the hydrogen gas intake side pressure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com